Abstract

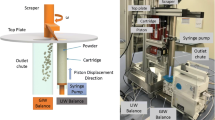

This article presents a case study of a continuous feeding strategy for five pharmaceutical components (active pharmaceutical ingredient (API), Prosolv HD90, crospovidone, magnesium stearate, and colloidal silicon dioxide), for the purpose of developing a direct compression continuous manufacturing system. Feeding options for each of these five powders were examined. Prosolv HD90 and crospovidone easily resulted in optimal feeding conditions, whereas the remaining powders in the formulation presented some challenges. The API displayed flow issues, leading to clogging of the screen with small openings. Magnesium stearate exhibited shear sensitivity; increasing shear of the powder due to hopper agitation resulted in drifting feeding performance. Colloidal silicon dioxide exhibited electrostatic issues that render most tooling options unsuitable for steady operation. All of these difficulties were resolved using the methods described in this article.

Similar content being viewed by others

References

Plumb K. Continuous processing in the pharmaceutical industry: changing the mind set. Chem Eng Res Des. 2005;83(6):730–8.

FDA. Guidance for Industry: PAT—a framework for innovative pharmaceutical development, manufacturing and quality assurance. Food and Drug Administration, 2004.

Wilburn KR. The business case for continuous manufacturing of pharmaceuticals. Thesis, Massachusetts Institute of Technology, 2010.

Leuenberger H. New trends in the production of pharmaceutical granules: batch versus continuous processing. Eur J Pharm Biopharm. 2001;52(3):289–96.

Betz G, Junker-Bürgin P, Leuenberger H. Batch and continuous processing in the production of pharmaceutical granules. Pharm Dev Technol. 2003;8(3):289–97.

Buchholz S. Future manufacturing approaches in the chemical and pharmaceutical industry. Chem Eng Process Process Intensif. 2010;49(10):993–5.

Schaber SD, Gerogiorgis DI, Ramachandran R, Evans JMB, Barton PI, Trout BL. Economic analysis of integrated continuous and batch pharmaceutical manufacturing: a case study. Ind Eng Chem Res. 2011;50(17):10083–92.

Singh R, Boukouvala F, Jayjock E, Ramachandran R, Ierapetritou M, Muzzio F. Flexible multipurpose continuous processing of pharmaceutical tablet manufacturing process. GMP News Eur. Compliance Acad. ECE, 2012.

Singh R, Ierapetritou M, Ramachandran R. An engineering study on the enhanced control and operation of continuous manufacturing of pharmaceutical tablets via roller compaction. Int J Pharm. 2012;438(1–2):307–26.

Singh R, Ierapetritou M, Ramachandran R. System-wide hybrid MPC–PID control of a continuous pharmaceutical tablet manufacturing process via direct compaction. Eur J Pharm Biopharm.

Singh R, Ierapetritou M, Ramachandran R. Hybrid advanced control of flexible multipurpose continuous tablet manufacturing process via direct compaction. In: Computer Aided Chemical Engineering vol. 32, Andrzej Kraslawski and Ilkka Turunen, Ed. Elsevier, 2013;757–762.

Weinekotter R, Reh L. Continuous mixing of fine particles. Part Part Syst Charact. 1995;12(1):46–53.

Danckwerts PV. Continuous flow systems: distribution of residence times. Chem Eng Sci. 1953;2(1):1–13.

Williams JC, Rahman MA. Prediction of the performance of continuous mixers for particulate solids using residence time distributions: part II. Experimental. Powder Technol. 1972;5(5):307–16.

Pernenkil L, Cooney CL. A review on the continuous blending of powders. Chem Eng Sci. 2006;61(2):720–42.

Singh R, Boukouvala F, Jayjock E, Ramachandran R, Ierapetritou M, Muzzio F. Flexible multipurpose continuous processing. Pharm Process. 2012;27(6):22–5.

Dai J, Cui H, Grace JR. Biomass feeding for thermochemical reactors. Prog Energy Combust Sci. 2012;38(5):716–36.

Yang S, Evans JRG. Metering and dispensing of powder; the quest for new solid freeforming techniques. Powder Technol. 2007;178(1):56–72.

Dai J, Grace JR. A model for biomass screw feeding. Powder Technol. 2008;186(1):40–55.

Myhre JB, Ludescher S. Apparatus and method for controlling flow rate in vibratory feeders. 5341307, 1994.

Homer III JC, Walsh JR, Ratcliffe DP. System for checking the calibration of gravimetric feeders and belt scales. 5686653, 1997.

Somsuk N, Wessapan T, Teekasap S. Design and development of a rotary airlock valve for using in continuous pyrolysis process to improve performance. Adv Mater Res. 2011;383–390:7148–54.

K-Tron. K-Tron operating instruction: KSU-II/KCM-KD operation for LWF, WBF, PID, SFM and VOL applications. Pitman, NJ: K-Tron 2006.

Hopkins M. LOSS in weight feeder systems. Meas Control. 2006;39(8):237–40.

Kehlenbeck V, Sommer K. Possibilities to improve the short-term dosing constancy of volumetric feeders. Powder Technol. 2003;138(1):51–6.

Tardos G, Lu Q. Precision dosing of powders by vibratory and screw feeders: an experimental study. Adv Powder Technol. 1996;7(1):51–8.

Engisch WE, Muzzio FJ. Method for characterization of loss-in-weight feeder equipment. Powder Technol. 2012;228:395–403.

Gao Y, Muzzio F, Ierapetritou M. Characterization of feeder effects on continuous solid mixing using fourier series analysis. AICHE J. 2011;57(5):1144–53.

Freeman R, Fu X. Characterisation of powder bulk, dynamic flow and shear properties in relation to die filling. Powder Metall. 2008;51(3):196–201.

Freeman R. Measuring the flow properties of consolidated, conditioned and aerated powders—a comparative study using a powder rheometer and a rotational shear cell. Powder Technol. 2007;174(1–2):25–33.

Vasilenko A, Glasser BJ, Muzzio FJ. Shear and flow behavior of pharmaceutical blends—method comparison study. Powder Technol. 2011;208(3):628–36.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Engisch, W.E., Muzzio, F.J. Loss-in-Weight Feeding Trials Case Study: Pharmaceutical Formulation. J Pharm Innov 10, 56–75 (2015). https://doi.org/10.1007/s12247-014-9206-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-014-9206-1