Abstract

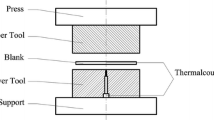

There are two types of hot-stamping processes, direct and indirect, depending on the sequence of the heating, forming, and quenching steps and the method used for each step. In this study, an indirect hot-stamping process consisting of forming at room temperature, heating, and water quenching was applied to develop a coupled torsion beam axle. The analysis results indicated that the application of the heat convection coefficient is critical in the simulations and must take into account the temperature and specific location in the model to ensure the accuracy of the heating and quenching analysis. The heat convection coefficients used in the analysis were directly measured at various positions of the tube (e.g., outside, inside, and bending region) using thermocouples, and the final values were determined through correlation between the actual tests and numerical analysis. The experimental and simulated final deformed shape and temperature distribution were in good agreement.

Similar content being viewed by others

References

Bok, H. H., Lee, M. G., Kim, H. D., Pavlina, E. and Barlat, F. (2011). Prediction of microstructure and mechanical properties in hot stamping process for B-pillar reinforcing part of car body. Int. J. Mechanical Science, 53, 744–754.

Choi, B. L., Choi, D. H., Min, J., Jeon, K., Park, J., Choi, S. and Ko, J. M. (2009). Torsion beam axle system design with a multidisciplinary. Int. J. Automotive Technology 10,1, 49–54.

Geiger, M., Merklein, M. and Hoff, C. (2005). Basic investigations on the hot stamping steel 22MnB5. Adanced Materials Research, 6–8, 795–804.

Karbasian, H. and Tekkaya, A. E. (2010). A review on hot stamping. J. Mater. Process. Technol., 210, 2013–2118.

Kim, H. Y., Park, J. K. and Lee, M. G. (2012). Finite element simulation of hot stamping of tubular beam and its application to die channel design. JIM Materials Trans. 53,5, 838–846.

Lee, M. G., Kim, S. J. and Han, H. N. (2009c). Finite element analyses for the effect of transformation plasticity on springback of hot press forming process. Computational Materials Science, 47, 556–567.

Lee, M. G., Kim, S. J. and Han, H. N. (2010). Simulation of mechanically induced martensitic transformation based on crystal plasticity finite element method: Theory and formulation. Int. J. Plasticity, 26, 688–710.

Lee, M. G., Kim, S. J., Han, H. N. and Jeong, W. C. (2009a). Application of hot press forming process to manufacture an automotive part and its finite element analysis considering phase transformation plasticity. Int. J. Mechanical Science, 51, 888–898.

Lee, M. G., Kim, S. J., Han, H. N. and Jeong, W. C. (2009b). Implicit finite element formulations of plastic deformation during phase transformation of multi-phase steel. Int. J. Plasticity, 25, 1726–1758.

Merklein, M., Lechler, J. and Geiger, M. (2006). Characterisation of the flow properties of the quenchenable ultra high strength steel 22MnB5. Annals of the CIRP, 55, 229–232.

Tekkya, A. E., Karbasian, H., Homberg, W. and Kleiner, M. (2007). Thermo-mechanical coupled simulation of hot stamping components for process design. Production Engineering Research and Development, 1, 85–89.

Turetta, A., Bruschi, S. and Ghiotti, A. (2006). Investigation of 22MnB5 formability in hot stamping operations. J. Mater. Process Technology, 177, 369–400.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, J.K., Kim, Y.S., Seo, O.S. et al. Improved hot-stamping analysis of tubular boron steel with direct measurement of heat convection coefficient. Int.J Automot. Technol. 14, 717–722 (2013). https://doi.org/10.1007/s12239-013-0078-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-013-0078-z