Abstract

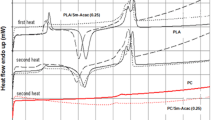

In this study, PLA/PC blends were prepared in order to investigate the effects of the addition of PC loading level into PLA matrix on the mechanical properties of these blends. After that, PLA/PC (70/30), which has the lowest tensile strength value, was selected as a control sample for the compatibilization study. Commercial styrene-acrylic multi-functional-epoxide oligomeric agent (SAmfE), styrene maleic anhydride copolymer (SMA), tetrasilanol phenyl polyhedral oligomeric silsesquioxane (T-POSS) and glycidyl isooctyl-polyhedral oligomeric silsesquioxane (G-POSS) were used as compatibilizers for PLA/PC blends. The variation of mechanical, thermal, structural and morphological properties were examined by conducting tensile tests, dynamic mechanical analyses, differential scanning calorimetry, Fourier Transform IR and scanning electron microscope analyses. Tensile test results showed that the tensile strength and elongation at break values of the PLA/PC blend compatibilized with SAmfE were higher than those of the other blends. DSC analyses revealed that Tg and Tm values of the blends were not significantly affected by compatibilizer but, degree of crystallinity was found to be sensitive to compatibilizer type. DMA results showed that the best mechanical properties were obtained for the PLA/PC/SAmfE blend. When all of the results evaluated, it was found that the SAmfE is the most effective compatibilizer among the using compatibilizer types for PLA/PC blends.

Similar content being viewed by others

References

J. Zhan, L. Song, S. Nie, and Y. Hu, Polym. Degrad. Stabil., 94, 291 (2009).

C. Ke, J. Li, K. Fang, Q. Zhu, J. Zhu, Q. Yan, and Y. Wang, Polym. Degrad. Stabil., 95, 763 (2010).

X. Yuan, D. Wang, L. Chen, X. Wang, and Y. Wang, Polym. Degrad. Stabil., 96, 1669 (2011).

L. Wei, D. Wang, H. Chen, L. Chen, X. Wang, and Y. Wang, Polym. Degrad. Stabil., 96, 1557 (2011).

R. Zhang, X. Xiao, Q. Tai, H. Huang, and Y. Hu, Polym. Eng. Sci., 52, 2620 (2012).

H. Zhu, Q. Zhu, J. Li, K. Tao, L. Xue, and Q. Yan, Polym. Degrad. Stabil., 96, 183 (2011).

L. Song, S. Xuan, X. Wang, and Y. Hu, Thermochim. Acta, 527, 1 (2011).

C. Réti, M. Casetta, S. Duquesne, S. Bourbigot, and R. Delobel, Polym. Adv. Technol., 19, 628 (2008).

M. Kodal, H. Sirin, and G. Ozkoc, Polym. Eng. Sci., 54, 264 (2014).

D.Wang, Y. Song, L. Lin, X. Wang, and Y. Wang, Polymer, 52, 233 (2011).

D. Wang, A. Leuteritz, Y. Wang, U. Wagenknecht, and G. Heinrich, Polym. Degrad. Stabil., 95, 2474 (2010).

N. G. Karsli and A. Aytac, Fiber. Polym., 15, 2607 (2014).

Y. Song, D. Wang, X. Wang, L. Lin, and Y. Wang, Polym. Adv. Technol., 22, 2295 (2011).

Y. Wang and S. Chiao, Soc. Plas. Eng., 10, 1 (2013).

J. Lee, Y. K. Lee, G. D. Choi, S. W. Na, T. S. Park, and W. N. Kim, Polym. Degrad. Stabil., 96, 553 (2011).

Y. Wang, S. M. Chiao, T. F. Hung, and S. Y. Yang, J. Appl. Polym. Sci., 125, 402 (2012).

T. Yu, J. Ren, S. Gu, and M. Yang, Polym. Int., 58, 1058 (2009).

T. Kanzawa and K. Tokumitsu, J. Appl. Polym. Sci., 121, 2908 (2011).

A. M. Harris and E. C. Lee, J. Appl. Polym. Sci., 128, 2136 (2013).

D. Bao, X. Liao, G. He, E. Huang, Q. Yang, and G. Li, J. Cellular Plas., 10, 1 (2014).

D. J. Brunelle, “Encyclopedia of Polymer Science and Technology”, Vol. 7, p.397, John Wiley & Sons, New York, 2000.

B. K. Goriparthi, K. N. S. Suman, and M. R. Nalluri, Polym. Compos., 33, 237 (2012).

V. T. Phuong, M. B. Coltelli, P. Cinelli, M. Cifelli, S. Verstichel, and A. Lazzeri, Polymer, 55, 4498 (2014).

Y. Zhou, L. Luo, W. Liu, G. Zeng, and Y. Chen, Adv. Mater. Sci. Eng., doi: 10.1155/2015/393582 (2015).

R. Al-Itry, K. Lamnawar, and A. Maazouz, Polym. Degrad. Stabil., 97, 1898 (2012).

W. L. Tham, B. T. Poh, Z. A. M. Ishak, and W. S. Chow, J. Appl. Polym. Sci., 133, 42850 (2016).

H. Durgun and G. Bayram, J. Adhes. Sci. Technol., 19, 407 (2005).

S. K. Dogan, S. Gumus, A. Aytac, and G. Ozkoc, Fiber. Polym., 14, 1422 (2013).

Y. Srithep, W. Rungseesantivanon, B. Hararak, and K. Suchiva, J. Polym. Eng., 34, 665 (2014).

Y. M. Corre, J. Duchet, J. Reignier, and A. Maazouz, Rheologica Acta, 50, 613 (2011).

B. Imre, K. Renner, and B. Pukánszky, Express Polym. Lett., 8, 2 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yemisci, F., Aytac, A. Compatibilization of poly(lactic acid)/polycarbonate blends by different coupling agents. Fibers Polym 18, 1445–1451 (2017). https://doi.org/10.1007/s12221-017-6671-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-6671-4