Abstract

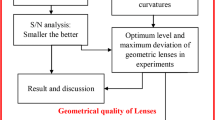

The profile of a bi-aspheric lens is such a way that the thickness narrows down from center to periphery (convex). Injection molding of these profiles has high shrinkage in localized areas, which results in internal voids or sink marks when the part gets cool down to room temperature. This paper deals with the influence of injection molding process parameters such as mold surface temperature, melt temperature, injection time, V/P Switch over by percentage volume filled, packing pressure, and packing duration on the volumetric shrinkage and deflection. The optimal molding parameters for minimum variation in volumetric shrinkage and deflection of bi-aspheric lens have been determined with the application of computer numerical simulation integrated with optimization. The real experimental work carried out with optimal molding parameters and found to have a shallow and steep surface profile accuracy of 0.14 and 1.57 mm, 21.38-45.66 and 12.28-26.90 μm, 41.56-157.33 and 41.56-157.33 nm towards Radii of curvatures (RoC), surface roughness (Ra) and waviness of the surface profiles (profile error Pt), respectively.

Similar content being viewed by others

References

X. Chen and F. Gao, A study of packing profile on injection molded part quality, Material Science and Engineering: A, 358 (2003) 205–213.

T. C. Chang and E. Faison, Shrinkage behaviour and optimization of injection molded parts studied by the Taguchi method, Polym. Eng. Sci., 41 (2001) 703–710.

M. Altan, Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods, Mater Design, 31 (2010) 599–604.

G. H. Hu and Z. S Cui, Effect of packing parameters and gate size on shrinkage of aspheric lens parts, J. Snanghai Jiaotong Univ (Sci), 15 (2010) 84–87.

N. Bhagavatula, D. Michalski, B. Lilly and G. Glozer, Modelling and verification of ejection forces in thermoplastic injection molding, Modelling Simul. Mater. Sci. Eng., 12 (2004) 239 -S254.

R. Thomas and N. McCaffery, The prediction of real product shrinkages, calculated from a simulation of the injection molding process, Annual Technical Conf. (1989) 371–375.

K. M. Tsai, Effect of injection molding process parameters on optical properties of lenses, Appl. Opt., 49 (2010) 6149–6159.

T. S. Kwak, T. Suzuki, W. B. Baeb, Y. Uehara and H. Ohmori, Application of neural network and computer simulation to improve surface profile of injection molding optic lens, J. Mater. Process. Technol., 170 (2005) 24–31.

H. E. Lai and P. J. Wang, Study of process parameters on optical qualities for injection-moulded plastic lenses, Appl. Opt., 47 (2008) 2017–2027.

X. Lu and L. S. Khim, A statistical experimental study of the injection moulding of optical lenses, J. Mater. Process. Technol., 113 (2001) 189–195.

A. M. C. Aghanajafi and A. M. C. Ghazvin, Thermal analysis of HVAC and solar panels using genetic optimization algorithm, J. of Mechanical Science and Technology, 30 (3) (2016) 1405–1412.

J. Beaumont, Shear induces flow imbalance and melt flipper in Autodesk Moldflow injection molding simulation, Autodesk University (2011).

R. Harold, Analysis of variance in experimental design, New York, USA. Springer (1992).

D. C. Montgomery, Design and analysis of experiments, Fifth Ed., New York: Wiley (2001) 65–72.

S. W. Kim and L. S. Turng, Developments of threedimensional computer-aided engineering simulation for injection moulding, Modelling Simul. Mater. Sci. Eng., 12 (2004) 151–173.

G. Taguchi and S. Konishi, Taguchi method, orthogonal arrays and linear graphs: Tools for quality engineering, American Supplier Institute (1987) 35–58.

G. Venkateshwarlu, M. J. Davidson and G. R. N. Tagore, Influence of process parameters on the cup drawing of aluminium 7075 sheet, Int. J. of Engg., Sci and Tech., 2 (11) (2010) 41–49.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

R. Joseph Bensingh is working as a Scientist in ARSTPS, Chennai an R & D wing of CIPET, India. He is pursuing a Ph.D. at Anna University, Chennai. Currently, he is working in design and optimization of plastic products and process development.

Rights and permissions

About this article

Cite this article

Bensingh, R.J., Boopathy, S.R. & Jebaraj, C. Minimization of variation in volumetric shrinkage and deflection on injection molding of Bi-aspheric lens using numerical simulation. J Mech Sci Technol 30, 5143–5152 (2016). https://doi.org/10.1007/s12206-016-1032-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-1032-6