Abstract

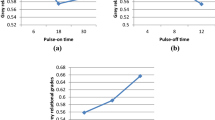

The success of an implant depends upon surface characteristics like roughness, topography, chemistry and hardness. The fabrication of a hard surface in combination with micron-, submicron- and nano-scale surface roughness is a great challenge for biomanufacturing industries. The surface microhardness (MH) needs to be maximized while controlling the Surface roughness (SR). The present research is the first study in which the application of Non-dominated sorting genetic algorithm (NSGA)-II coupled with Taguchi based Response surface methodology (RSM) is used to predict the optimal conditions of Powder mixed electric discharge machining (PMEDM) parameters to fabricate the biocompatible surface on β-phase Ti alloy. Batch vial tests were first carried out in accordance with the L25 orthogonal array. ANOVA analysis gave the significant influencing factors and then mathematical models were developed between input parameters and output responses like SR and MH using Taguchi based RSM technique. These models were then optimized using NSGA-II to obtain a set of Pareto-optimal solutions. From the series of multiple solutions, the best optimal condition to achieve required low SR and high MH was determined, which are 13 A peak current, 5 μs pulse duration, 8% duty cycle (longer pulse-interval) and 8 g/l silicon powder concentration for achieving a required low SR and high MH. The MH considerably increased about 184% compared to the base material, and about 1.02 μm SR can be achieved in combination with micron-, submicron- and nano-scale surface features.

Similar content being viewed by others

References

M. Niinomi, M. Nakai and J. Hieda, Development of new metallic alloys for biomedical applications, Acta Biomater, 8 (2012) 3888–3903.

M. Geetha, A. K. Singh, R. Asokamani and A. K. Gogia, Ti based biomaterials, the ultimate choice for orthopaedic implants-A review, Prog. Mater. Sci., 54 (3) (2009) 397–425.

R. A. Gittens, T. McLachlan, R. Olivares-Navarrete, Y. Cai, S. Berner, R. Tannenbaum, Z. Schwartz, K. H. Sandhage and B. D. Boyana, The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation, Biomaterials, 32 (2011) 3395–3403.

C. Prakash, H. K. Kansal, B. S. Pabla and S. Puri, On the influence of nanoporous layer fabricated by PMEDM on ß-Ti implant: Biological and computational evaluation of bone-implant interface, 5th International Conference of Materials Processing and Characterization, Hyderabad (2016) 1–9.

X. B. Liu, X. J. Meng, H. Q. Liu, G. L. Shi, S. H. Wu, C. F. Sun, M. D. Wang and L. H. Qi, Development and characterization of laser clad high temperature self-lubricating wear resistant composite coatings on Ti-6Al-4V alloy, Mater. Des., 55 (2014) 404–409.

X. Liu, P. K. Chu and C. Ding, Surface modification of titanium, titanium alloys, and related materials for biomedical applications, Mater. Sci. Eng. R., 47 (2004) 49–121.

C. Prakash, H. K. Kansal, B. S. Pabla, S. Puri and A. Aggarwal, Electric discharge machining-a potential choice for surface modification of metallic implants for orthopedics applications: A review, Proc. I. Mech. Engg, Part B: J. Eng. Manuf., 230 (2016) 331–353.

P. W. Peng, K. L. Ou, H. C. Lin, Y. N. Pan and C. H. Wang, Effect of electrical-discharging on formation of nanoporous biocompatible layer on titanium, J. Alloy. Comp., 492 (1-2) (2010) 625–630.

T. S. Yang, M. S. Huang, M. S. Wang, M. H. Lin, M. Y. Tsai and P. Y. Wang, Effect of electrical discharging on formation of nanoporous biocompatible layer on Ti-6Al-4V alloys, Implant Dentistry, 22 (4) (2013) 374–9.

W. F. Lee, T. S. Yang, Y. C. Wu and P. W. Peng, Nanoporous biocompatible layer on Ti-6Al-4V alloys enhanced osteoblast-like cell response, J. Exp. Clin. Med., 5 (3) (2013) 92–96.

T. C. Bin, L. D. Xin, W. Zhan and G. Yang, Electro-spark alloying using graphite electrode on titanium alloy surface for biomedical applications, Appl. Surf. Sci., 257 (15) (2011) 6364–6371.

P. Harcuba, L. Bacakova, J. Strasky, M. Bacakova, K. Novotna and M. Janecek, Surface treatment by electric discharge machining of Ti-6Al-4V alloy for potential application in orthopaedics, J. Mech. Behav. Biomed. Mater., 7 (2012) 96–105.

H. Kumar and J. P. Davim, Role of powder in the machining of Al-10%Sicp metal matrix composites by powder mixed electric discharge machining, J. Compos. Mater., 45 (2) (2010) 133–151.

H. K. Kansal, S. Singh and P. Kumar, Effect of graphite powder mixed EDM on machining rate of AISI D2 die steel, J. Manuf. Process., 9 (1) (2007) 13–22.

B. H. Yan, H. C. Tsai and F. Y. Huang, The effect in EDM of a dielectric of a urea solution in water on modifying the surface of titanium, Int. J. Mach. Tools. Manuf., 45 (2) (2005) 194–200.

M. B. Ndaliman, A. A. Khan and M. Y. Ali, Influence of electrical discharge machining process parameters on surface micro-hardness of titanium alloy, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 227 (2013) 460–464.

Z. M. Zain, M. B. Ndaliman, A. A. Khan and M. Y. Ali, Improving micro-hardness of stainless steel through powder-mixed electrical discharge machining, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. (2014) DOI: 10.1177/0954406214530872.

P. Janmanee and A. Muttamara, Surface modification of tungsten carbide by electrical discharge coating (EDC) using a titanium powder suspension, Appl. Surf. Sci., 258 (19) (2012) 7255–7265.

I. Arun, M. Duraiselvam, V. Senthilkumar, R. Narayanasamy and V. Anandakrishana, Synthesis of electric discharge alloyed nickel-tungsten coating on tool steel and its tribological studies, Mater. Des., 63 (2014) 257–262.

C. Prakash, H. K. Kansal, B. S. Pabla and S. Puri, Proceßsing and characterization of novel biomimetic nanoporous bioceramic surface on ß-Ti Implant by powder mixed electric discharge machining, J. Mater. Eng. Perform., 24 (2015) 3622–3633.

C. Prakash, H. K. Kansal, B. S. Pabla and S. Puri, Potential of powder mixed electric discharge machining to enhance the wear and tribological performance of ß-Ti implant for orthopedic applications, J. Nanoeng Nanomanuf., 5 (4) (2015) 261–269.

C. Prakash, H. K. Kansal, B. S. Pabla and S. Puri, Powder mixed electric discharge machining an innovative surface modification technique to enhance fatigue performance and bioactivity of ß-Ti implant for orthopaedics application, International Conference on Innovative Design and Manufacturing, Auckland (2016) 107.

A. Ikram, N. A. Mufti, M. Q. Saleem and A. R. Khan, Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment, J. of Mech. Sci. and Tech., 27 (7) (2013) 2133–2141.

T. P. Dao and S. C. Huang, Robust design for a flexible bearing with 1-DOF translation using the Taguchi method and the utility concept, J. Mech. Sci. Technol., 29 (8) (2015) 3309–3320.

J. H. Jung and W. T. Kwon, Optimization of EDM process for multiple performance characteristics using Taguchi method and Grey relational analysis, J. Mech. Sci. Technol., 24 (5) (2010) 1083–1090.

M. Santhanakumar, R. Adalarasan and M. Rajmohan, Parameter design for cut surface characteristics in abrasive waterjet cutting of Al/SiC/Al2O3 composite using grey theory based RSM, J. of Mech. Sci. and Tech., 30 (1) (2016) 371–379.

S. Gopalakannan and T. Senthilvelan, Optimization of machining parameters for EDM operations based on central composite design and desirability approach, J. of Mech. Sci. and Tech., 28 (3) (2014) 1045–1053.

Z. Tao, S. Yaoyao, L. Xiaojun and H. Tianran, Optimization of abrasive flow polishing process parameters for static blade ring based on response surface methodology, J. of Mech. Sci. and Tech., 30 (3) (2016) 1085–1093.

R. N. Yadav, V. Yadava and G. K. Singh, Application of non-dominated sorting genetic algorithm for multiobjective optimization of electrical discharge diamond face grinding process, J. of Mech. Sci. and Tech., 28 (6) (2014) 2299–2306.

P. S. Bharti, S. Maheshwari and C. Sharma, Multiobjective optimization of electric-discharge machining process using controlled elitist NSGA-II, J. of Mech. Sci. and Tech., 26 (6) (2012) 1875–1883.

K. Deb, S. Agarwal, A. Pratap and T. Meyarivan, A fast elitist non-dominated sorting genetic algorithm for multiobjective optimization: NSGA-II, IEEE Trans. Evol. Comput., 6 (2) (2000).

A. K. Singh, S. Kumar and V. P. Singh, Effect of the addition of conductive powder in dielectric on the surface properties of superalloy Super Co 605 by EDM process, Int. J. Adv. Manuf. Technol., 77 (1) (2015) 99–106.

C. Prakash, H. K. Kansal, B. S. Pabla and S. Puri, Experimental investigations in powder mixed electrical discharge machining of Ti-35Nb-7Ta-5Zr ß-Ti alloy, Mater. Manuf. Process (2016) DOI: /10.1080/10426914.2016. 1198018.

S. L. Chen, M. H. Lin, G. X. Huang and C. C. Wang, Research of the recast layer on implant surface modified by micro-current electrical discharge machining using deionized water mixed with titanium powder as dielectric solvent, Appl. Surf. Sci., 311 (2014) 47–53.

S. L. Chen, M. H. Lin, C. C. Chen and K. L. Ou, Effect of electro-discharging on formation of biocompatible layer on implant surface, J. Alloys Compd., 456 (1-2) (2008) 413–418.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Hak-Sung Kim

Chander Prakash is an Assistant Professor in the Department of Mechanical Engineering, UIET, Panjab University, He received B. Tech. (2007) and M. Tech. (2010) from Kurukshetra University of Kurukshetra. He is pursuing a Ph.D. from Panjab University, Chandigarh in the area of surface modification of biomedical implants for orthopedics application.

Harmesh Kumar Kansal is a Professor and Head of the Department of Mechanical Engineering, UIET, Panjab University, Chandigarh, India. He received his B.E., M.Tech. and Ph.D. in Mechanical Engineering with distinction. His area of research is non-conventional machining, design of experiment, production engineering, welding and quality control.

Rights and permissions

About this article

Cite this article

Prakash, C., Kansal, H.K., Pabla, B.S. et al. Multi-objective optimization of powder mixed electric discharge machining parameters for fabrication of biocompatible layer on β-Ti alloy using NSGA-II coupled with Taguchi based response surface methodology. J Mech Sci Technol 30, 4195–4204 (2016). https://doi.org/10.1007/s12206-016-0831-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0831-0