Abstract

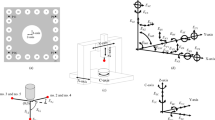

Burr is an undesirable jutting out formed as a result of plastic deformation of a metal during cutting and shearing operations. Burr needs to be minimized by an effective deburring process to improve the efficiency of machining and the quality of product. There is also a growing need for a measurement method or suitable measurement device to inspect burrs, favorably at drilled holes, sizes ranging from micro to macro. In fact, without an appropriate measurement method, it has become more difficult to examine and measure burrs formed on a free surface. In this work, a burr measurement system is developed using a conoscopic holography sensor, which offers certain advantages over interferometry, triangulation, and dynamic focusing, for point-by-point distance mapping. The measurement system is further improved to measure burrs on curved and inclined exit surfaces, whose range exceeds the measurement range of sensors, by using a Z axis adaptation method.

Similar content being viewed by others

References

S. L. Ko and D. A. Dornfeld, A study on burr formation mechanism, J. of Engineering Materials and Technology, 113 (1991) 75–87.

S. K. Min, D. A. Dornfeld and Y. Nakao, Influence of exit surface angle on drilling burr formation, J. Manuf. Sci. E-T Asme., 125 (2003) 637–644.

J. R. Koelsch, Divining edge quality by reading the burrs, Quality Magazine: BNP Media (2001) 24.

H. Schwenke, U. Neuschaefer-Rube, T. Pfeifer and H. Kunzmann, Optical methods for dimensional metrology in production engineering, CIRP Ann-Manuf Techn., 51 (2002) 685–699.

L. Gillespie, Inspecting for burrs, Manufacturing Engineering, 120 (1998) 70–74.

S. L. Ko and S. W. Park, Development of an effective measurement system for burr geometry, Pro. of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 220 (2006) 507–512.

G. Sirat and D. Psaltis, Conoscopic holography, Opt. Lett., 10 (1985) 4–6.

Y. Malet and G. Sirat, Conoscopic holography application: multipurpose rangefinders, Journal of Optics, 29 (1998) 183–187.

M. H. To and S. L. Ko, Application of advanced filtering algorithm for measuring microburr, International e-conference on Computer Science, CRC Press (2007) 251–254.

A. Toropov, An effective visualization and analysis method for edge measurement, Computational Science and Its Applications — ICCSA 2007, Springer (2007) 941–950.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Haedo Jeong

Huu Phuong Hoang received the B.S. degree in Mechatronics from Hochiminh City University of Technology, Viet Nam in 2004. He then received a M.S. and Ph.D. degrees in Mechanical engineering from Konkuk University, Korea in 2009 and 2014, respectively. He is doing research at Konkuk University and his research interest includes measurement system, thin film gravure printing and R2R printed electronics application.

Sung Lim Ko received B.S. and M.S. degrees from Seoul National University in 1980 and 1983, respectively. He then received his Ph.D. degree from University of California, Berkeley in 1989. Since 1993, he has been a faculty member at the Department of Mechanical Design and Production Engineering at Konkuk University in Seoul, Korea. His research interest includes burr technology, precision machining, R2R printed electronics, OLED, organic solar cell, OTFT, gravure printing, slot die coating and imprinting.

Rights and permissions

About this article

Cite this article

Hoang, H.P., To, H.M. & Ko, S.L. Measurement technology using Z axis adaptation for burrs formed on curved surfaces. J Mech Sci Technol 29, 3459–3465 (2015). https://doi.org/10.1007/s12206-015-0744-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0744-3