Abstract

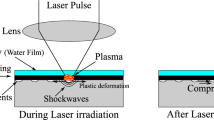

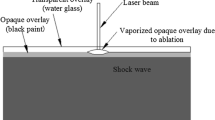

Laser shock peening (LSP) is the newest and most innovative surface treatment technique. LSP residual stress distribution is affected by many parameters. Of them, the parameters are main factors that determine the convergence of finite element analysis (FEA) and characteristic of pressure pulse of laser system. The parameters, related to the convergence of FE simulation, are stability limit time for the stable convergence of results, and solution time for dynamic analysis. The other parameters, related to characteristics of pressure pulse of laser system, are pressure pulse duration time and laser pulse interval time for multiple LSP. In the present work, we have conducted to confirm the influence of time parameters of LSP system on residual stress results using FEA, and we have also predicted optimized range of time parameters.

Similar content being viewed by others

References

K. Ding and L. Ye, Laser shock peening Performance and process simulation, CRC Press (2006) 47–118.

K. Ding and L. Ye, Simulation of multiple laser shock peening of a 35CD4 steel alloy, J.of Materials Processing Technology, 178 (2006) 162–169.

S. Y. Yang, S. D. Choi, J. M. Jun and B. C. Gong, Improving the residual stress characteristics of the metal surface by ND: YAG laser shock peening, J. of the Korean Society of Machine Tool Engineering, 19 (2010) 539–547.

S. Wu, C. Huang, X. Wang and H. Song, A new effective method to estimate the effect of laser shock peening, Int. J. of Impact Engineering, 38 (2011) 322–329.

ABAQUS Version 6. 9, User’s manual, Dassault Systemes (2008).

X. Ling, W. Peng and G. Ma, Influence of laser peening parameters on residual stress field of 304 stainless steel, J. of Pressure Vessel Technology, 130(021120) (2008) 1–8.

C. Yang, D. Hodgson, Q. Liu and L. Ye, Geometrical effects on residual stresses in 7075-T7451 aluminum alloy rods subject to laser shock peening, J. of Materials Processing Technology, 201 (2008) 303–309.

B. W. Bang, S. K. Son, J. M. Kim and C. D. Cho, Residual stress prediction in LSP surface treatment by using FEM, KSME-A, 33(8) (2009) 776–772.

J. H. Kim and Y. J. Kim, Sensitivity analyses of the finite element parameters of laser shock peening for improving fatigue life of metallic components, KSME-A, 34(12) (2010) 1821–1828.

P. Peyre, R. Fabbro and P. Lieurade, Laser shock processing of aluminum alloys. Application to high cycle fatigue behaviour, Materials Science and Engineering, A 210 (1996) 102–113.

P. Ballard, J. Fournier, R. Fabbro and J. Frelat, Residual stresses induced by laser-shocks, J. de Physique IV, 1 (1991) 487–581.

P. Peyre and R. Fabbro, Laser shock processing: a review of the physics and applications, Optical and Quantum Elec tronics, 27 (1995) 1213–1229.

Y. Hu, Z. Yao and J. Hu, 3-D FEM simulation of laser shock processing, Surface & Coating Technology, 201 (2006) 1426–1435.

J. H. Kim, Y. J. Kim and J. S. Kim, Effect of laser shock peening simulation parameters on residual stress of Inconel alloy 600 steel, KSME-A, 36(1) (2012) 43–50.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Kyeongsik Woo

Ju Hee Kim is an asociate professor of the Department of Mechanical Engineering, Korea Military Academy, Seoul, Korea. His main research interests are residual stress analysis for weldment and LSP.

Rights and permissions

About this article

Cite this article

Kim, J.H., Kim, Y.J., Lee, J.W. et al. Study on effect of time parameters of laser shock peening on residual stresses using FE simulation. J Mech Sci Technol 28, 1803–1810 (2014). https://doi.org/10.1007/s12206-014-0327-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0327-8