Abstract

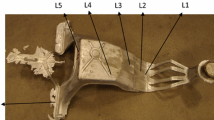

In the gas forming process, the work piece is formed by applying gas pressure. However, the gas pressure and the accompanying gas temperature can result in crack initiation and unstable crack growth. Thus, it is vital to determine the critical values of applied gas pressure and temperature to avoid crack and fracture failure. We studied the mechanism of fracture using an experimental approach and finite element simulations of a perfect aluminum sheet containing no inclusions and voids. The definition of crack was based on ductile damage mechanics. For inspection of initiation of crack and rupture in gas-metal forming, the ABAQUS/EXPLICIT simulation was used. In gas forming, the applied load is the pressure applied rather than the punching force. The results obtained from both the experimental approach and finite element simulations were compared. The effects of various parameters, such as temperature and gas pressure value on crack initiation, were taken into account.

Similar content being viewed by others

References

A. B. Abdullah, S. M Sapuan, Z. Samad, H. M. T. Khaleed and N. A. Aziz, Prediction of geometric defects in the cold embossing of AA6061 aluminum alloy by finite element analysis, Int. J. Sci. Research and Essays, 7(15) (2012) 1630–1638.

J. Lemaitreand and D. Rodrigue, A course on damage mechanics, SpringerVerlag, Berlin (1992).

L. Jean and D. Rodrigue, Engineering damage mechanics, Springer (2005).

J. R. Riceand and D. M. Tracey, On the ductile enlargement of voids in triaxial stress fields, J. Mech. Phys. Solids, 17(3) (1969) 201–217.

J. W. Hancock and A. C. Mackenzie, On the mechanisms of ductile failure in high-strength steels subjected to multiaxial stress-states, J. Mech. Phys. Solids. 24(2-3) (1976) 147–169.

H. Hooputra, H. Gese, H. Delland and H. Werner, A comprehensive failure model for crashworthiness simulation of aluminum extrusions, Int. J. Crashworthiness, 9(5) (2004) 449–463.

S. Ghosh and G. Das, Effect of pre-strain on the indentation fracture toughness of high strength low alloy steel by means of continuum damage mechanics, J. Engine. Fracture Mechanics, 79 (2012) 126–137.

P. Raghavan and S. Ghosh, A continuum damage mechanics model for unidirectional composites undergoing interfacial debonding, J. Mech. Mater, 37(9) (2005) 955–979.

V. Shenoy, I. A. Ashcroft, G. W. Critchlow and A. D. Crocombe, Fracture mechanics and damage mechanics based fatigue lifetime prediction of adhesively bonded joints subjected to variable amplitude fatigue, J. Eng. Fracture Mech., 77(7) (2010) 1073–1090.

A. Keller and K. Hutter, On the thermodynamic consistency of the equivalence principle in continuum damage mechanics, J. Mech. Phys. Solids., 59(5) (2011) 1115–1120.

J. Price, R. N. Ibrahim and D. Ischenko, Inspection of aluminum gas cylinders for cracking in the neck region, Int. J. Pres. Ves. and Piping, 73(1) (1997) 45–51.

M. Singh and T. Markeset, A methodology for risk-based inspection planning of oil and gas pipes based on fuzzy logic framework, J. Engine. Failure Analysis, 16(7) (2009) 2098–2113.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Youngseog Lee

Soheil Gohari received his B.Sc. in Mechanical Engineering (Solids Design) in 2008 and his M.Sc. in Mechanical Engineering in 2011. He is currently a Ph.D. candidate of the College of Engineering and Science at Victoria University, Melbourne, Australia. His main research interests are structural mechanics and materials, advanced composite structures, smart structures design and analysis, fatigue and fracture mechanics, advanced computational mechanics, pressure vessels design and analysis, structural dynamic and vibration, elasticity and plasticity, multi-objective optimizations and numerical simulations.

Zora Vrcelj is currently Senior Lecturer in Structural Engineering at Victoria University, Melbourne. Prior to joining Victoria University in 2012 she was an academic for 10 years within the School of Civil and Environmental Engineering at the University of New South Wales. Her primary research interests are in the area of composite laminated plates, optimization of nano- and micro-members, steel-concrete composite structures, structural stability, biomimetics and innovations in structural engineering education. Since 2010 Dr. Vrcelj has held a Visiting Professor in Civil Engineering position at the University of Novi Sad.

Gholamali Sharifishourabi is a Ph.D. candidate in Mechanical Engineering at Universiti Teknologi Malaysia (UTM). Prior to starting the Ph.D. program, he was a lecturer at Islamic Azad University of Iran. He is currently studying on thermal and mechanical behavior analysis of composite structures and functionally graded materials.

Shokrollah Sharifi Teshnizi is a Ph.D. candidate in Mechanical Engineering at Universiti Teknologi Malaysia (UTM). His academic experience includes teaching finite element analysis in Mechanical Engineering. He also has industrial experience on production manager, CAD/CAM programing and mold designing. His publications are on the area of thermal and mechanical behavior analysis of composite structures and functionally graded materials.

Rouzbeh Abadi is currently a Master student in Structural engineering at Universiti Teknologi Malaysia (UTM). His research area is finite element analysis on concrete and steel structures.

Rights and permissions

About this article

Cite this article

Gohari, S., Sharifi, S., Sharifishourabi, G. et al. Effect of temperature on crack initiation in gas formed structures. J Mech Sci Technol 27, 3745–3754 (2013). https://doi.org/10.1007/s12206-013-0919-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0919-8