Abstract

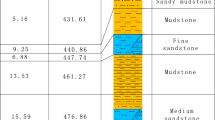

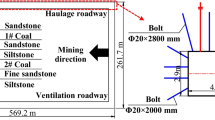

To improve the effectiveness of the directional-predetermined crack blasting in the weak and alternate composite roof, this paper took the coal-containing composite roof of the 12201 working face of Halagou Coal Mine as the engineering background, and based on the technical principles of roof cutting pressure releasing gob-side entry retaining, comprehensive used of theoretical analysis, field experiments and other means, carried out in-depth research on the shaped energy blasting method and parameter design of the coal-containing composite roof. The results show: Through theoretical analysis, in the process of shaped energy blasting, the air column in the hole can reduce the peak blast pressure, which can effectively prevent the weak surrounding rock in the hole from being damaged in the non-cumulative direction and enhance the pre-splitting effect. During detonation at the bottom, the instantaneous pressure in the blast hole is lower than that of detonation at the top, and the action time of blast pressure is longer than detonation at the top. When the buried depth of the explosive (near the blast hole) is less than the critical depth, a “V”-shaped blasting funnel will be formed after the rock blasting, and the critical depth is proportional to the charge. Through field tests on the charge quantity and the length of the sealing mud, when the blast hole depth is 6m, the charge parameters of “3+2+0+1” have a better effect of energy-concentrating blasting, and the crack rate reaches 87%. Besides, field tests have shown that when shaped energy blasting is carried out on soft and hard rock formations, the stemming separation in the shaped energy tube at the interlayer position can ensure the directional pre-cracking effect of hard rock, while effectively avoiding damage to the weak rock formation in the non-cumulative direction.

Similar content being viewed by others

Change history

01 April 2021

An Erratum to this paper has been published: https://doi.org/10.1007/s12205-021-6474-4

References

Guo DY, Lv PF, Pei HB, Shan ZY (2012) Numerical simulation of deep hole energy-accumulating blast fracture gap expansion in coal seam. Journal of China Coal Society 27(2):274–278, DOI: https://doi.org/10.13225/j.cnki.jccs.2012.02.027 (in Chinese)

Guo DY, Zhang C, Zhu TG, Pan JJ (2018a) Effect of charge structure on coal seam deep hole shaped blasting and permeability enhancement. Journal of Engineering Sciences 40(12):1488–1494, DOI: https://doi.org/10.13374/j.issn2095-9389.2018.12.006 (in Chinese)

Guo DY, Zhao JC, Lv PF, Zhai M (2016) Analysis and application of dynamic effect of coal seam deep hole shaped blasting. Journal of Engineering Sciences 38(12):1681–1687, DOI: https://doi.org/10.13374/j.issn2095-9389.2016.12.004 (in Chinese)

Guo DY, Zhao JC, Zhang C, Zhu TG (2018b) Research on the mechanism of controlling pores in deep-hole shaped charge blasting in coal seams. Journal of Rock Mechanics and Engineering 36(4):919–930, DOI: https://doi.org/10.13722/j.cnki.jrme.2017.1038 (in Chinese)

Li YF, Ma SZ (1992) Explosion mechanics. Science Press, Beijing, China (in Chinese)

Liu J, Liu ZG, Gao K, Xue JH, Lou YB (2016) Experimental study on the characteristics of coal seam crack propagation under the blasting load of different charge modes. Journal of Rock Mechanics and Engineering 35(4):735–742, DOI: https://doi.org/10.13722/j.cnki.jrme.2015.0865 (in Chinese)

Paine AS, Please CP (1994) An improved model of fracture propagation by gas during rock blasting-some analytical results. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts 31(6):699–706, DOI: https://doi.org/10.1016/0148-9062(95)96970-m

Rabczuk T, Belytschko T (2004) Cracking particles: A simplified meshfree method for arbitrary evolving cracks. International Journal for Numerical Methods in Engineering 61(13):2316–2343, DOI: https://doi.org/10.1002/nme.1151

Rabczuk T, Belytschko T (2007) A three-dimensional large deformation meshfree method for arbitrary evolving cracks. Computer Methods in Applied Mechanics and Engineering 196(29–30):2777–2799, DOI: https://doi.org/10.1016/j.cma.2006.06.020

Rabczuk T, Zi G, Bordas S, Nguyen-Xuan H (2010) A simple and robust three-dimensional cracking-particle method without enrichment. Computer Methods in Applied Mechanics and Engineering 199(37–40):2437–2455, DOI: https://doi.org/10.1016/j.cma.2010.03.031

Song J, Kim K (1996) Micromechanical modeling of the dynamic fracture process during rock blasting. International Journal of Rock Me-chanics and Mining Sciences & Geomechanics Abstracts 33(4): 387–394

Wu L, Lu WB, Zhong DW, Zhu HB (2010) Blasting mechanism of air space charge in concrete medium. Explosion and Shock 30(01):58–64 (in Chinese)

Yang J, Liu GZ, Lv SR (2004) Study on vibration effects of decked charg in bench blasting. Science and Technology of Energetic Materials 65(2):29–33

Yang RS, Yang GL, Gao X (2017) Theory and practice of directional fracture controlled blasting. Science Press, Beijing, China (in Chinese)

Yang RS, Zhang ZR, Yang LY, Guo XY (2013) Experimental study on the energy-explosion blasting of the seam charge based on hard rock rapid excavation technology. Journal of Rock Mechanics and Engineering 32(2):317–323 (in Chinese)

Zhang RX (2015) Application of air interval blasting technology in Kunyang phosphate mine. PhD Thesis, Kunming University of Science and Technology, Kunming, China (in Chinese)

Zhang JY, Ma QS, Wang QZ (1994) Application of deep-hole bottom air cushion charge structure in open-pit coal mines. China Mining 12:31–33 (in Chinese)

Zhu HB (2006) Blasting mechanism and application of air-spaced charge. PhD Thesis, Wuhan University, Wuhan, China (in Chinese)

Zhu Q, Chen M, Zheng BX, Yan P (2016) Damage distribution characteristics and control technology of air-spaced pre-splitting blasting rock mass. Journal of Rock Mechanics and Engineering 35(S1):2758–2765, DOI: https://doi.org/10.13722/j.cnki.jrme.2014.1465 (in Chinese)

Zhu HB, Lu WB, Wu L (2007) Study on the blasting mechanism of air interval charge. Rock and Soil Mechanics (05):986–990, DOI: https://doi.org/10.16285/j.rsm.2007.05.025 (in Chinese)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51904188,), the Open Fund of State Key Laboratory for GeoMechanics and Deep Underground Engineering (SKLGDUEK1821) and the Zhejiang Collaborative Innovation Center for Prevention and Control of Mountain Geologic Hazards (PCMGH-2016-Z-02). Besides, thanks to all the people who contributed to the research and the manuscript. Finally, I would like to express my heartfelt thanks to the language editors from KSCE Journal of Civil Engineering.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, P., Ye, K., Tao, Z. et al. Experimental Study on Key Parameters of Bidirectional Cumulative Tensile Blasting with Coal-Containing Composite Roof. KSCE J Civ Eng 25, 1718–1731 (2021). https://doi.org/10.1007/s12205-021-1474-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-021-1474-y