Abstract

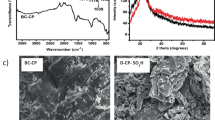

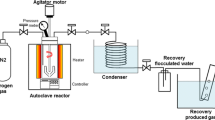

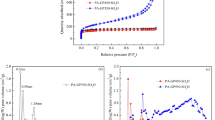

Biochar and ashes derived from coffee husk were used as heterogeneous catalysts in the synthesis of biodiesel through a transesterification reaction. The catalysts were obtained from the carbonization, activation, and combustion of raw coffee husks. Their properties were characterized by solid-state 13C and 31P nuclear magnetic resonance (NMR) spectroscopies and X-ray diffraction, among other techniques. The results evidenced the presence of different inorganic compounds (mostly K- and Ca-containing phases) mixed with the turbostratic structure (in the case of the biochar samples). A biodiesel conversion of 66% (evaluated by 1H NMR analysis of the liquid reaction products) was found for the biochar sample prepared at 700 °C; the activated biochar catalyst prepared at the same temperature showed a higher biodiesel conversion (74%), which can be attributed to its superior specific surface area. The best catalytic efficiency (biodiesel conversion of 93%) was observed for the coffee husk ashes, which is consistent with the higher contents of Ca and K salts in the ashes in comparison with the biochar samples. Reuse tests conducted with the ashes samples showed an efficiency reduction after the second cycle (from around 90% in the first two cycles to 8% in the third cycle), due to the partial removal of active phases (mostly K-containing salts) within the reaction medium. The presented results show that coffee husks are a cheap and environmentally viable source for the production of materials of interest in heterogeneous catalysis, with no need for chemical modification to achieve good efficiency.

Similar content being viewed by others

Data availability

Not applicable.

References

Gouvea BM, Torres C, Franca AS et al (2009) Feasibility of ethanol production from coffee husks. Biotechnol Lett 31:1315–1319. https://doi.org/10.1007/s10529-009-0023-4

Murthy PS, Naidu MM (2012) Sustainable management of coffee industry by-products and value addition—a review. Resour Conserv Recycl 66:45–58. https://doi.org/10.1016/j.resconrec.2012.06.005

de Oliveira F, C, Srinivas K, Helms GL, et al (2018) Characterization of coffee (Coffea arabica) husk lignin and degradation products obtained after oxygen and alkali addition. Bioresour Technol 257:172–180. https://doi.org/10.1016/j.biortech.2018.01.041

International Coffee Organization (2021) Exports of all forms of coffee by exporting countries to all destinations. In: Int. Coffee Organ. https://www.ico.org/prices/m1-exports.pdf. Accessed 1 Feb 2022

Martinez CLM, Saari J, Melo Y et al (2021) Evaluation of thermochemical routes for the valorization of solid coffee residues to produce biofuels: a Brazilian case. Renew Sustain Energy Rev 137:110595. https://doi.org/10.1016/j.rser.2020.110585

de Castro AE, da Silva Martinho F, Barbosa ML, et al (2022) Influence of methyl groups in triphenylmethane dyes on their adsorption on biochars from coffee husks. Water Air Soil Pollut 233. https://doi.org/10.1007/s11270-022-05623-8

Zhou C, Wang Y (2020) Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Sci Technol Adv Mater 21:787–804. https://doi.org/10.1080/14686996.2020.1848213

Cha JS, Park SH, Jung S-C et al (2016) Production and utilization of biochar: a review. J Ind Eng Chem 40:1–15. https://doi.org/10.1016/j.jiec.2016.06.002

Brito GM, Cipriano DF, Schettino MÂ Jr et al (2019) One-step methodology for preparing physically activated biocarbons from agricultural biomass waste. J Environ Chem Eng 7:103113. https://doi.org/10.1016/j.jece.2019.103113

Piccoli V, Gonçalves GDR, Cipriano DF et al (2020) Production of phosphorus-containing activated carbons from coffee husk and application in adsorption processes. Rev Virtual Quim 12:75–88. https://doi.org/10.21577/1984-6835.20200008

Chua SY, Periasamy LA, Goh CMH et al (2020) Biodiesel synthesis using natural solid catalyst derived from biomass waste — a review. J Ind Eng Chem 81:41–60. https://doi.org/10.1016/j.jiec.2019.09.022

Faria DN, Cipriano DF, Schettino MA Jr et al (2020) Study of thermal transformations in Na, Ca-based catalysts supported on activated carbon and their application in the synthesis of biodiesel from soybean oil. J Environ Chem Eng 8:104208. https://doi.org/10.1016/j.jece.2020.104208

Malins K (2018) The potential of K3PO4, K2CO3, Na3PO4 and Na2CO3 as reusable alkaline catalysts for practical application in biodiesel production. Fuel Process Technol 179:302–312. https://doi.org/10.1016/j.fuproc.2018.07.017

Zhao G, Shi J, Liu G et al (2010) Efficient porous carbon-supported MgO catalysts for the transesterification of dimethyl carbonate with diethyl carbonate. J Mol Catal A Chem 327:32–37. https://doi.org/10.1016/j.molcata.2010.05.007

Konwar LJ, Boro J, Deka D (2014) Review on latest developments in biodiesel production using carbon-based catalysts. Renew Sustain Energy Rev 29:546–564. https://doi.org/10.1016/j.rser.2013.09.003

Gohain M, Laskar K, Paul AK et al (2020) Carica papaya stem: a source of versatile heterogeneous catalyst for biodiesel production and C-C bond formation. Renew Energy 147:541–555. https://doi.org/10.1016/j.renene.2019.09.016

Aleman-Ramirez JL, Moreira J, Torres-Arellano S et al (2021) Preparation of a heterogeneous catalyst from moringa leaves as a sustainable precursor for biodiesel production. Fuel 284:118983. https://doi.org/10.1016/j.fuel.2020.118983

Conesa JA, Sánchez NE, Garrido MA, Casas JC (2016) Semivolatile and volatile compound evolution during pyrolysis and combustion of Colombian coffee husk. Energy Fuels 30:7827–7833. https://doi.org/10.1021/acs.energyfuels.6b00791

Saenger M, Hartge EU, Werther J et al (2001) Combustion of coffee husks. Renew. Energy 23:103–121. https://doi.org/10.1016/S0960-1481(00)00106-3

De Oliveira JL, Da Silva JN, Graciosa Pereira E et al (2013) Characterization and mapping of waste from coffee and eucalyptus production in Brazil for thermochemical conversion of energy via gasification. Renew Sustain Energy Rev 21:52–58. https://doi.org/10.1016/j.rser.2012.12.025

Kabayo SM, Kindala JT, Nkanga CI et al (2019) Preparation and characterization of solid acid catalysts derived from coffee husks. Int J Chem Sci 3:5–13

Nguyen HC, Nguyen ML, Su CH et al (2021) Bio-derived catalysts: a current trend of catalysts used in biodiesel production. Catalysts 11:1–28. https://doi.org/10.3390/catal11070812

Chi NTL, Anto S, Ahamed TS et al (2021) A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel 287:119411. https://doi.org/10.1016/j.fuel.2020.119411

Nguyen HC, Nguyen ML, Wang FM et al (2020) Biodiesel production by direct transesterification of wet spent coffee grounds using switchable solvent as a catalyst and solvent. Bioresour Technol 296:122334. https://doi.org/10.1016/j.biortech.2019.122334

Matthies S, Lutterotti L, Wenk HR (1997) Advances in texture analysis from diffraction spectra. J Appl Crystallogr 30:31–42. https://doi.org/10.1107/S0021889896006851

Çaylı G, Küsefoğlu S (2008) Increased yields in biodiesel production from used cooking oils by a two step process: comparison with one step process by using TGA. Fuel Process Technol 89:118–122

Arruda TBMG, Rodrigues FEA, Arruda DTD et al (2016) Chromatography, spectroscopy and thermal analysis of oil and biodiesel of sesame (Sesamum indicum) − an alternative for the Brazilian Northeast. Ind Crops Prod 91:264–271. https://doi.org/10.1016/j.indcrop.2016.07.029

Dantas MB, Conceição MM, Fernandes VJ Jr et al (2007) Thermal and kinetic study of corn biodiesel obtained by the methanol and ethanol routes. J Therm Anal Calorim 87:835–839. https://doi.org/10.1007/s10973-006-7780-2

Almazrouei M, El ST, Janajreh I (2017) Thermogravimetric kinetics and high fidelity analysis of crude glycerol. Energy Procedia 142:1699–1705. https://doi.org/10.1016/j.egypro.2017.12.552

Faria DN, Cipriano DF, Schettino MA Jr et al (2020) Na, Ca-based catalysts supported on activated carbon for synthesis of biodiesel from soybean oil. Mater Chem Phys 249:123173. https://doi.org/10.1016/j.matchemphys.2020.123173

Phuong N Van, Hoang NK, Luan L Van, Tan L V. (2021) Evaluation of NH4+ adsorption capacity in water of coffee husk-derived biochar at different pyrolysis temperatures. Int J Agron 2021 https://doi.org/10.1155/2021/1463814

Kiggundu N, Sittamukyoto J (2019) Pryloysis of coffee husks for biochar production. J Environ Prot (Irvine, Calif) 10:1553–1564. https://doi.org/10.4236/jep.2019.1012092

Haw JF, Maciel GE, Schroeder HA (1984) Carbon-13 nuclear magnetic resonance spectrometric study of wood and wood pulping with cross polarization and magic-angle spinning. Anal Chem 56:1323–1329. https://doi.org/10.1021/ac00272a028

Cipriano DF, Chinelatto LS Jr, Nascimento SA et al (2020) Potential and limitations of 13C CP/MAS NMR spectroscopy to determine the lignin content of lignocellulosic feedstock. Biomass Bioenerg 142:105792. https://doi.org/10.1016/j.biombioe.2020.105792

Rathnayake D, Ehidiamhen PO, Egene CE, et al (2021) Investigation of biomass and agricultural plastic co-pyrolysis: effect on biochar yield and properties. J Anal Appl Pyrolysis 155 https://doi.org/10.1016/j.jaap.2021.105029

Freitas JCC, Emmerich FG, Cernicchiaro GRC et al (2001) Magnetic susceptibility effects on 13C MAS NMR spectra of carbon materials and graphite. Solid State Nucl Magn Reson 20:61–73. https://doi.org/10.1006/snmr.2001.0030

Hunger S, Cho H, Sims JT, Sparks DL (2004) Direct speciation of phosphorus in alum-amended poultry litter: solid-state 31P NMR investigation. Environ Sci Technol 38:674–681. https://doi.org/10.1021/es034755s

Lopes TR, Cipriano DF, Gonçalves GR et al (2017) Multinuclear magnetic resonance study on the occurrence of phosphorus in activated carbons prepared by chemical activation of lignocellulosic residues from the babassu production. J Environ Chem Eng 5:6016–6029. https://doi.org/10.1016/j.jece.2017.11.028

Setter C, Silva FTM, Assis MR et al (2020) Slow pyrolysis of coffee husk briquettes: characterization of the solid and liquid fractions. Fuel 261:116420. https://doi.org/10.1016/j.fuel.2019.116420

Vu NT, Do KU (2021) Insights into adsorption of ammonium by biochar derived from low temperature pyrolysis of coffee husk. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01337-9

Guimarães T, De Oliveira AF, Lopes RP, De Carvalho Teixeira AP (2020) Biochars obtained from arabica coffee husks by a pyrolysis process: characterization and application in Fe(ii) removal in aqueous systems. New J Chem 44:3310–3322. https://doi.org/10.1039/c9nj04144c

Chen G-Y, Shan R, Shi J-F, Yan B-B (2015) Transesterification of palm oil to biodiesel using rice husk ash-based catalysts. Fuel Process Technol 133:8–13. https://doi.org/10.1016/j.fuproc.2015.01.005

Kouzu M, Kasuno T, Tajika M et al (2008) Calcium oxide as a solid base catalyst for transesterification of soybean oil and its application to biodiesel production. Fuel 87:2798–2806. https://doi.org/10.1016/j.fuel.2007.10.019

Di SM, Tesser R, Pengmei L, Santacesaria E (2008) Heterogeneous catalysts for biodiesel production. Energy Fuels 22:207–217. https://doi.org/10.1021/ef700250g

Platonov AY, Evdokimov E, Andrey N, Kurzin AV, Maiyorova HD (2002) Solubility of potassium carbonate and potassium hydrocarbonate in methanol. J Chem Eng Data 47:1175–1176. https://doi.org/10.1021/je020012v

Chouhan APS, Sarma AK (2013) Biodiesel production from Jatropha curcas L. oil using Lemna perpusilla Torrey ash as heterogeneous catalyst. Biomass Bioenerg 55:386–389. https://doi.org/10.1016/j.biombioe.2013.02.009

Mendonça IM, Paes OARL, Maia PJS et al (2019) New heterogeneous catalyst for biodiesel production from waste tucumã peels (Astrocaryum aculeatum Meyer): parameters optimization study. Renew Energy 130:103–110. https://doi.org/10.1016/j.renene.2018.06.059

Vamvuka D, Zografos D (2004) Predicting the behaviour of ash from agricultural wastes during combustion. Fuel 83:2051–2057. https://doi.org/10.1016/j.fuel.2004.04.012

Acknowledgements

The authors are grateful to the Laboratory of Cell Ultrastructure Carlos Alberto Redins (LUCCAR) and the Laboratory for Research and Development of Methodologies for Crude Oil Analysis (LabPetro), Federal University of Espírito Santo (UFES).

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)—Brasil—Finance Code 001. The authors also acknowledge the support from the Brazilian agencies FAPES (grant 280/2021) and CNPq (grant 408001/2016–0).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fernández, J.V., Faria, D.N., Santoro, M.C. et al. Use of Unmodified Coffee Husk Biochar and Ashes as Heterogeneous Catalysts in Biodiesel Synthesis. Bioenerg. Res. 16, 1746–1757 (2023). https://doi.org/10.1007/s12155-022-10516-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10516-z