Abstract

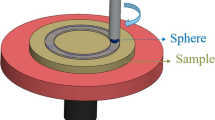

In this study, an investigation was conducted on the effect of cryogenic heat treatment on the wear behavior of AZ91 magnesium alloy using pin-on-disc in a dry and isotonic solution (0.9 wt% NaCl) medium. The wear performance was investigated under loads of 1 N, 3 N, and 5 N. The analysis of the variance method was performed to find the relationship between parameters. The results from the experiment showed that the new microstructure of treated AZ91 was composed of less eutectic phase around β phase and the formation of twin phase was noticed compared to untreated AZ91. The wear analysis demonstrated that in dry and wet medium abrasion and adhesion mechanisms were dominant. Although the untreated sample exhibited better wear resistance in the dry medium, the cryogenically treated sample was better in the wet medium when compared to the wear zone. In addition, the pitting corrosion was observed for all samples in the wet medium; the treated sample had encountered severe pitting compared to the untreated sample. Moreover, the specific wear rate of the treated sample was better than the untreated sample at the wet medium. The coefficient of friction (COF) of the untreated sample was between min. 0.32 and max. 0.54 and higher than the treated sample in the dry medium. However, the COF value of the wet medium was less than a dry medium for all samples and was around 0.24. In general, the treated sample performed better wear resistance in wet medium and was limited at dry medium depending on the applied load.

Similar content being viewed by others

References

Avedesian M M and Baker H 1999 ASM Specialty Handbook: Magnesium and Magnesium Alloys. ASM International. printed in USA: 314

Mert F 2017 Wear behaviour of hot rolled AZ31B magnesium alloy as candidate for biodegradable implant material. T. Nonferr. Metal. Soc. 27(12): 2598–2606

Ilanaganar E and Anbuselvan S 2018 Wear mechanisms of AZ31B magnesium alloy during dry sliding condition. Mater. Today-Proc. 5(1, Part 1): 628-635

Demir A G, Previtali B, Ge Q, Vedani M, Wu W, Migliavacca F, Petrini L, Biffi C A and Bestetti M 2014 Biodegradable magnesium coronary stents: material, design and fabrication. Int. J. Comput. Integ. M. 27(10): 936–945

Ding W 2016 Opportunities and challenges for the biodegradable magnesium alloys as next-generation biomaterials. Regen. Biomater. 3(2): 79–86

Bommala V K, Krishna M G and Rao C T 2019 Magnesium matrix composites for biomedical applications: A review. J. Magnes. Alloy. 7(1): 72–79

Dieringa H and Kainer K U 2007 Magnesium – der Zukunftswerkstoff für die Automobilindustrie? Materialwiss. Werkstofftech. 38(2): 91–96

Mao L and shen L, Chen J, Zhang X, Kwak M, Wu Y, Fan R, Zhang L, Pei J, Yuan G, Song C, Ge J and Ding W, 2017 A promising biodegradable magnesium alloy suitable for clinical vascular stent application. Sci. Rep-UK 7: 46343

Esmaily M, Svensson J E, Fajardo S, Birbilis N, Frankel G S, Virtanen S, Arrabal R, Thomas S and Johansson L G 2017 Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 89: 92–193

García-Rodríguez S, Torres B, Maroto A, López A J, Otero E and Rams J 2017 Dry sliding wear behavior of globular AZ91 magnesium alloy and AZ91/SiCp composites. Wear. 390–391: 1–10

Oteyaka M O, Ghali E and Tremblay R 2012 Corrosion Behaviour of AZ and ZA Magnesium Alloys in Alkaline Chloride Media. Int. J. Corr. 2012: 1–10

Klassen R D, Roberge P R, Lafront A M, Öteyaka M Ö and Ghali E 2003 Magnesium. In: Proceedings of the 6th International Conference Magnesium Alloys and Their Applications. InMagnesium, (Kainer, K. U., Ed.) Wiley‐VCH Verlag GmbH & Co. KGaA: 655-660

Öteyaka M Ö, Lafront A M, Ghali E and Tremblay R 2003 Potentiodynamic Studies of Some AZ and ZA Magnesium Alloys in Different Corrosive Media.InMagnesium: Proceedings of the 6th International Conference Magnesium Alloys and Their Applications: 517-523

Klassen R D, Roberge P, Lafront A M, Öteyaka M and Ghali E 2005 Corrosion behaviour of zinc and aluminum magnesium alloys by scanning reference electrode technique (SRET) and electrochemical noise (EN). Can. Metall. Q. 44: 47–52

Akyüz B 2019 Wear and machinability of AM series magnesium alloys. Mater. Test. 61(1): 49–55

Chelliah N M, Kumar R, Singh H and Surappa M K 2017 Microstructural evolution of die-cast and homogenized AZ91 Mg-alloys during dry sliding condition. J. Magnes. Alloy. 5(1): 35–40

Chelliah N M, Padaikathan P and Kumar R 2019 Evaluation of electrochemical impedance and biocorrosion characteristics of as-cast and T4 heat treated AZ91 Mg-alloys in Ringer’s solution. J. Magnes. Alloy. 7(1): 134–143

Hoche H, Allebrandt D, Scheerer H, Broszeit E and Berger C 2007 Design of wear and corrosion resistant PVD-coatings for magnesium alloys. Materialwiss. Werkstofftech. 38(5): 365–371

Zheng L, Nie H, Liang W, Wang H and Wang Y 2016 Effect of pre-homogenizing treatment on microstructure and mechanical properties of hot-rolled AZ91 magnesium alloys. J. Magnes. Alloy. 4(2): 115–122

Maldar A, Ebrahmi R and Davoodi A 2010 The Effect of Homogenization on Microstructure and Hot Ductility Behaviour of AZ91 Magnesium Alloy. Kovove Mater. 48: 277–287

Zafari A, Ghasemi H M and Mahmudi R 2014 An investigation on the tribological behavior of AZ91 and AZ91+3wt% RE magnesium alloys at elevated temperatures. Mater. Des. (1980-2015). 54:544-552

Meshinchi Asl K, Masoudi A and Khomamizadeh F 2010 The effect of different rare earth elements content on microstructure, mechanical and wear behavior of Mg–Al–Zn alloy. Mater. Sci. Eng., A. 527(7): 2027-2035

Chelliah N M, Singh H and Surappa M K 2016 Correlation between microstructure and wear behavior of AZX915 Mg-alloy reinforced with 12 wt% TiC particles by stir-casting process. J. Magnes. Alloy. 4(4): 306–313

Aatthisugan I, Razal Rose A and Selwyn Jebadurai D 2017 Mechanical and wear behaviour of AZ91D magnesium matrix hybrid composite reinforced with boron carbide and graphite. J. Magnes. Alloy. 5(1): 20–25

Yan H and Wang Z 2016 Effect of heat treatment on wear properties of extruded AZ91 alloy treated with yttrium. J. Rare Earth. 34(3): 308–314

Dieringa H 2017 Influence of Cryogenic Temperatures on the Microstructure and Mechanical Properties of Magnesium Alloys: A Review. Metals. 7(2): 38

Asl K M, Tari A and Khomamizadeh F 2009 Effect of deep cryogenic treatment on microstructure, creep and wear behaviors of AZ91 magnesium alloy. Mater. Sci. Eng. A. 523(1): 27–31

Amini K, Akhbarizadeh A and Javadpour S 2014 Investigating the effect of quench environment and deep cryogenic treatment on the wear behavior of AZ91. Mater. Des. (1980-2015). 54(154-160

Bhavar V, Khot S, Kattire P, Mehata M and Singh R 2015 Effect of Deep Cryogenic Treatment on AISI H-13 Tool Steel. In: 28th ASM Heat Treating Society Conference: 383-389

Wang Y, Liao B, Liu J, Chen S, Feng Y, Zhang Y and Zhang R 2012 Effects of deep cryogenic treatment on the solid-state phase transformation of Cu–Al alloy in cooling process. Phase Transit. 85(7): 650–657

Jiang Y, Chen D, Chen Z and Liu J 2010 Effect of Cryogenic Treatment on the Microstructure and Mechanical Properties of AZ31 Magnesium Alloy. Mater. Manuf. Process. 25(8): 837–841

Liu J, Li G, Chen D and Chen Z 2012 Effect of Cryogenic Treatment on Deformation Behavior of As-cast AZ91 Mg Alloy. Chin. J. Aeronaut. 25(6): 931–936

Gassama B and Öteyaka M Ö 2019 Influence of cryogenic treatment on the corrosion of AZ91 and AM60 magnesium alloys in an isotonic solution. Mater. Test. 61(11): 1039–1044

Mónica P, Bravo P M and Cárdenas D 2017 Deep cryogenic treatment of HPDC AZ91 magnesium alloys prior to aging and its influence on alloy microstructure and mechanical properties. J. Mater. Process. Technol. 239: 297–302

Çakir F H and Çelik O N 2020 Tribological Properties of Cryo-Treated and Aged Ti6Al4V Alloy. Trans. Indian Inst. Met. 73(3): 799–809

Acknowledgement

This study is supported by Eskisehir Osmangazi University, Scientific Research Projects Coordination Unit. Project Number: 2017-1532.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

GASSAMA, B., OZDEN, G. & OTEYAKA, M.O. The effect of deep cryogenic treatment on the wear properties of AZ91 magnesium alloy in dry and in 0.9 wt% NaCl medium. Sādhanā 47, 15 (2022). https://doi.org/10.1007/s12046-021-01794-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01794-y