Abstract

Red and purple grape juices (GJs) have long been consumed worldwide for their unique taste and nutritive value. Moreover, grape is postulated to play an important role in the improvement of cardiovascular risk factors owing to its rich polyphenol content. Little is known regarding GJ’s holistic chemistry and functionality as compared to those of other fruit juices. This review aims to compile the state-of-the art chemistry of colored grape juices and in context to its analysis and nutritional values. Further, a review of potential contaminants to be introduced during manufacturing and other factors that influence juice quality and or health effects are presented to help maximize GJ’s quality. A comparison between analytical methods for juice QC establishment is presented employing hyphenated platforms versus direct spectroscopic techniques. The enrichment of the colored skin with a myriad of phenolics poses it as a functional beverage compared to that of skinless juice.

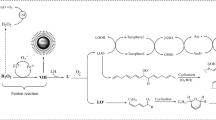

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Grapevines [Vitis spp.] are cultivated worldwide, leading to the development of different species and or varieties (Sargolzaei et al., 2021). There are three widely known Vitis species: Vitaceae V. vinifera: European grapevines, V. labrusca: American grapevines, and V. rotundifolia: Muscadine grapevines (Rehman et al., 2018). V. vinifera, grapevine, represent the most widely planted grape species used for wine, juice, and raisin production (Sargolzaei et al., 2021). Grapevine fruit is a berry which could be red, white, or purple in color. Anthocyanins, a widely distributed pigment class in grapevines, vary as per each variety. Major anthocyanins in grape include derivatives of delphinidin, petunidin, cyanidin, peonidin, and malvidin, all of which are biosynthesized via the flavonoid pathway. Anthocyanins influence grape fruit skin color and the juice and wine color as well as color stability through storage (Ju et al., 2021). The difference in color is attributed to these natural pigments which vary in content according to genetic, environmental, and agronomical factors (Quina & Bastos, 2018). It was recently demonstrated that white grape could have been derived as a mutation of the red one (Ferreira et al., 2019). As a result of having high sugar levels, pectin, various aromatic compounds, and high levels of acids, i.e., tartaric acid mainly, grapes are amenable to many different end uses. The juice of grapes is recognized for a combination of sweetness and acidity taste which makes it appealing to humans (Sanyürek & Çakır, 2018). Grape juice (GJ) could also be further processed, e.g., pasteurized, to attain a long tasting product with improved shelf life. The juice is also widely used as a natural sweetener in several industries aside from being manufactured as juice and exploited to wine production with USA, Brazil, and Spain as the main producing countries (Margraf et al., 2016; VÁZquez-Armenta et al., 2018). Grapes could be also sold as nutraceuticals owing to their antioxidant properties and many other health benefits (Georgiev et al., 2014). The most cultivated V. vinifera comprises up to 5000 true cultivars (cvs.), used in wine, table (fresh fruit), and dried grape manufacturing around the world. Improvements to these cvs. initially relied largely on random selections of natural mutations and or classical breeding to improve agronomic traits and ultimately juice quality.

Grapevines can be differentiated by species type and geographical origins where they are cultivated. For example, in South, North, and Central America, purple grape juices, nectars, and concentrate originate principally from V. labrusca varieties, such as Bordeaux, Concord, and Isabel, whereas in Brazil, the production of grape juices is mainly based on hybrids of V. labrusca grapevines. In Chile, Argentina, and Uruguay, V. vinifera varieties “red and blue grapes” are commonly used to produce grape juices (Lutz et al., 2011). Muscadine (V. rotundifolia) is the main variety used for juice production in European countries, with the most distinguished varieties named Cabernet sauvignon, Merlot, Pinot noir, and Syrah (Chira et al., 2011) used for wine manufacturing owing to their characteristic palatability as per chemical composition.

The taste of grape juice depends on fruit cultivar type as well as processing methods as typical in other juice types (De Vasconcelos Facundo et al., 2010). For example, red juices prepared from V. vinifera grapevines acquire a more acidic taste than V. labrusca, as they generally do not process well (Cosme et al., 2018).

This review focuses on colored grape juices (GJs) “red and purple” owing to their unique chemical composition and health values compared to white juice. This study presents the most updated and comprehensive review of colored GJ including its holistic chemical composition in context to agronomic or cultivar type, analyses, and different processing methods for the first time with future perspectives for improvement.

GJ Chemical Composition

The chemical diversity of grapevines is composed of primary and secondary metabolites. Primary metabolites account for the fruit nutritive value mostly from sugars, whereas secondary metabolites present the health benefits in GJ (Ali et al., 2010).

Grape’s quality relies on both its secondary metabolites as influenced by various environmental factors “climate, temperature, and water,” whereas it has primary metabolites that are crucial for the organoleptic characters and palatability of grapes composed mostly of sugars in ripe berries and its juice (Cosme et al., 2016; Rienth et al., 2021).

Primary Metabolites

The primary metabolites in grape berries are mostly composed of sugars “mainly fructose and glucose” (Muñoz-Robredo et al., 2011) and organic acids “not exceeding more than 1%” (Muñoz-Robredo et al., 2011). Generally, the qualitative and quantitative differences in grapevines’ primary metabolites are based on extrinsic factors including temperature, pH, soil type, and agricultural practices, i.e., fertilizers, etc. (Rienth et al., 2021; Teixeira et al., 2014), as highlighted in the next subsections for each metabolite class.

Sugars

Grape sugars (up to 18.36% weight) as a ripening marker amount for the major component in fresh fruit and juice to account for its sweet taste and energy intake (Jediyi et al., 2019). The profile and level of sugars in grapes and consequently grape juice depend on different factors such as grape maturation stage, region of origin, climate, variety type, agricultural practices, and processing conditions (Muñoz-robredo et al., 2011; Navrátilová et al, 2020).

Major sugars in juice derived from Vitis vines as well as in V. vinifera grapes include glucose and fructose followed by sucrose. Other species than V. vinifera encompasses sucrose up to 10% as in V. rotundifolia and hybrids of V. vinifera × V. labrusca (Cosme et al., 2016). Oligosaccharides detected in GJ include mostly l-kestose followed by raffinose (dos Santos et al., 2019; Cosme et al., 2016).

Organic Acids

Organic acids in grapes are mostly represented by L-tartaric and L-malic acids (90% of total organic acids) in addition to minor levels of succinic, citric, acetic, and lactic acids (Cosme et al., 2016). Organic acids are considered crucial for the preservative effect, acidity, and palatability of grape juice and wine (do Nascimento Silva et al., 2015; Cosme et al., 2016).

Amino Acids

Accumulation of amino acids usually occurs during the last 2 months of grape berry maturation. The major free amino acids in grape berries and juice are proline “up to 2 g/L” and arginine “up to 1.6 g/L” followed by alanine, glutamic and aspartic acids. The variation of amino acid levels depends on grape’s variety as well as other environmental conditions (Cosme et al., 2016; Gutiérrez-Gamboa et al., 2019).

Secondary Metabolites

Volatile Organic Compounds

Volatile organic compounds (VOCs) account for GJ aroma mostly represented by terpenoids, viz., monoterpenes, sesquiterpenes, and carbonyl compounds, to amount for 32.9% of the total volatile composition in fresh GJ. Linalool, citronellol, geraniol, α-ylangene, bicyclogermacrene, β-ciclocitral, β-damascenone, and β-ionone “violet aroma” are common in grape varieties in all their ripening stages, viz., V. vinifera L. grape varieties, Bual, Malvasia, Sercial (white grapevines), and Tinta Negra (red grapevines), whereas other less common volatiles were detected in some ripening stages and in certain varieties (e.g., β-ocimene isomer, β-gurjunene, γ-elemene). Another class of aromatics, i.e., benzaldehyde, phenylacetaldehyde, benzyl alcohol, 2-phenylethanol, and vanillin, were found mainly in berry skin to account for the primary aroma that develops during ripening (Noguerol-Pato et al., 2013). Figure 1 shows the major volatile compounds in different grapes.

Phenolics

Phenolics including flavonoids and non-flavonoids “phenolic acids and stilbenes” (Cosme et al., 2016) are detected in either berry skin or seeds, and to account for the sensory characteristic, color, and astringent characteristic of GJ (Cosme et al., 2016). Flavonoids make up a significant portion of phenolics represented by several subclasses, such as flavones and flavan-3-ol “proanthocyanidins or tannins” (Gouot et al., 2019). The deep color of red and purple GJ is mostly attributed to anthocyanins “specifically in red grapes” and their glycosides (Rienth et al., 2021; Teixeira et al., 2014). The next subsections shall present the different classes of phenolics including flavonoids and non-flavonoids. Figure 1 shows the major phenolics in different grapevines, whereas their distribution is shown in Tables 1 and 2.

Phenolic Acids

In grape pulps and juice, the major phenolic acids either free or conjugated with anthocyanins are hydroxy cinnamic acids. Cinnamates are considered as the third abundant soluble phenolic class after tannins and anthocyanins in GJ exemplified by p-coumaric, ferulic, caffeic, and the ester forms (Król et al., 2014; Weidner et al., 2013). Table 1 shows the major phenolic acids in different grapevines (Ali et al., 2010; Rienth et al., 2021). High phenolic acid levels have been recorded in favor to that of seeds followed by skin and lowest in grapes pulps/juice “2178.8 mg/g, 374.6 mg/g, and 23.8 mg/g gallic acid equivalent, respectively” (Cosme et al., 2016). The inclusion of the skin in different grape products such as GJ could be worthy for its unique chemistry and several human health benefits.

Stilbenes

Grapes represent a rich source of stilbenes either present free, glycosylated, or methylated including cis, trans resveratrol, its glycoside “piceid,” piceatannol, astringin, pallidol, and different isomers of viniferin as shown in Fig. 1. The distribution of different stilbenes in grapevines is summarized in Table 1 (Flamini et al., 2013; Sadovoy et al., 2011; Teixeira et al., 2013). Stilbene accumulation in red grapes was found to be higher than white ones and rationalizing for the famous French paradox in red grapes. Resveratrol, cis and trans are the simplest forms of stilbenes as well as their precursor present potential health benefits “French paradox.”

Flavonoids

Flavonols

Flavonoids comprise a characteristic makeup in grapes mainly in the skin and seeds (Rienth et al., 2021), with flavonols as well as their 3-O-glycosides (Ali et al., 2010) showing differences in red to white grapes. In red grape skin, the main flavonol was quercetin (43.99%), followed by myricetin (36.81%). In contrast, white grape skin was predominated by the flavonol quercetin at (81.35%), followed by kaempferol (16.91%) (Ali et al., 2010). The main flavonols in different grapevines are shown in Fig. 1 and listed in Table 2.

Anthocyanins and Proanthocyanidins “Condensed Tannins”

Both anthocyanins and proanthocyanidins comprise the major phenolics pool in the skin and seeds of grapevines. They are typically responsible for the dark color of red and purple of grapes and their juices (Ćurko et al., 2017). Anthocyanins are biosynthesized mostly in the berry skin from the start of ripening and ought to be more exploited in the future for producing anthocyanin-rich GJs (Rienth et al., 2021).

Proanthocyanidins “flavan-3-ols” reported in grapes were polymers of procyanidins, viz., (+)-catechin, (−)-epicatechin, (−)-epicatechin gallate, (+)-gallocatechin, and (−)-epigallocatechin with variation per grape parts. Figure 1 shows the main proanthocyanidins as well as shown in more details in Table 2 (Cosme et al., 2016; Ćurko et al., 2017; Rienth et al., 2021). Procyanidin dimers and trimers were identified in grape skin and seeds (Ali et al., 2010). It is worth mentioning that the enrichment of red grapes with a blend of procyanidins as catechin and epicatechin polymers poses GJ as a potential functional beverage (Xia et al., 2010).

In V. vinifera cultivar, anthocyanin derivatives, viz., glucosylation at C-3′ of anthocyanins, is known to improve its stability upon processing. The composition of anthocyanin glycosylation derivatives varies among the different grapevine cvs. (Ali et al., 2010; Rienth et al., 2021). In a previous study, authors quantified different anthocyanins in different GJs revealing that cyanidin and malvidin were the major forms, whereas peonidin was the lowest one (Xu et al., 2012). Major anthocyanins are shown in Fig. 1 and Table 2.

Contaminants Detected in GJ

Being generally considered safe and of a high nutritional value, very little evidence questioned their safety and possible contamination problems either from raw grape fruits or during manufacturing processes. This section focuses on different reported contaminants in GJ with emphasis on control methods for the prevention and or detection to ensure best juice quality to consumers. Figure 1 shows the chemical structure of major grapevine contaminants.

Aspergillus and Penicillium Toxins

Ochratoxin A (OTA) is a secondary fungal metabolite produced by filamentous fungal strains, viz., Aspergillus and Penicillium species. OTA possess severe health risks if ingested including nephrotoxicity and hepatotoxicity, and it is a potential carcinogen (Akdeniz et al., 2013; Wei et al., 2018). The European Union set OTA maximum accepted levels in grape products as juice, nectar, and wine not to exceed 2 µg/kg (Commission, 2005). Different analytical procedures have been developed for the detection of these toxins in grapes, wine, juice, and other food products (Wei et al., 2018). Patulin is a toxic metabolite produced by Aspergillus and Penicillium with possible human hazards being carcinogenic and to be monitored in fruit juices including that of grape (Cho et al., 2010; Rahimi & Rezapoor Jeiran, 2015). The identification of patulin during grape juice production is crucial due to the misuse of moldy grapes (Hussain et al., 2020).

Alternaria Toxins

Fruits are usually consumed by humans fresh with no processing steps that allows for molds’ growth leading to its spoilage. Molds such as Alternaria, Botrytis, and various Penicillia types can grow even at refrigeration temperatures. Strains of A. alternata produce toxic metabolites, i.e., alternariol (AOH), alternariol methyl ether (AME) (Asam et al., 2009), and tenuazonic acid (TA) (Walravens et al., 2016).

TA could cause serious problems acting as pro-carcinogen in esophageal mucosa. Consequently, it is crucial to measure the accepted levels of TA toxins in grape-derived products (Prendes et al., 2018). Previously, TA was reported at high levels (139.2–115.5 µg/L) in 42.5% of Iranian grape juice (Safavizadeh et al., 2020).

Other toxins of A. alternata “AOH and AME” have been reported in fresh fruits of red seedless and Concord grapes at different temperatures, which could be limited to red seedless grapes. The production of such toxins occurs post 3 weeks of incubation at 21 °C with levels at 3.3 “AOH” and 1.7 µg/g “AME,” respectively. In Concord variety, the previously mentioned toxins were produced at much lower levels (Tournas & Stack, 2001) as it may be less susceptible to A. alternata infection.

In previous literatures, controlling fungal infection of grapes by Alternaria, Botrytis, Penicillia, and Aspergillus and lowering their mycotoxins have been suggested. Some suggestions were raised for lowering mycotoxin containments. Generally good agricultural practice, efficient aeriation, and continuous visual inspection of damaged berries in grapevines would be effective in preventing spread of mycotoxin-producing yeasts (Paterson et al., 2018). The use of chemical pesticides as cyprodinil and cyprodinil/fludioxonil appeared the most effective in the control of A. carbonarius OTA toxins (Paterson et al., 2018). Natural fungicide and tea tree oil enriched with α-terpineol and terpinen-4-ol would inhibit the fungal growth and OTA production. Biological control by using antagonistic yeasts as Hanseniaspora uvarum (Gómez-Albarrán et al., 2021) and lactic acid bacteria were found effective in controlling the spread of OTA-producing fungi in the vineyards. Yeasts such as Candida friedrichii and C. intermedia inhibit enzymes and expression genes important for OTA biosynthesis (Welke, 2019). Species of Bacillus were found as promising biological tools for controlling OTA-producing fungi as they produce lipopeptides with potential antimicrobial action (Welke, 2019).

Thermal and Non-thermal Processing Technologies in GJ

Thermal Technologies for Preservation of GJ

In GJ production, different techniques are implemented at the industrial level to include mostly either hot or cold pressing. Generally, grapes are first crushed and heated up to 62 °C to ease the extraction of grape content. Pectinases are then added to facilitate juice separation and release of phenolics in the juice. Heated grapes were macerated with continuous stirring for the complete extraction of ingredients “colored anthocyanins and phenolics” (Ayala-Zavala, 2018); the time of maceration depends on grapevine variety, applied temperature, and intensity of required color. The cloudy obtained juice is subjected to clarification from any solid debris then finally thermally pasteurized at 85 °C—“the oldest method used”—and then to be bottled (Cosme et al., 2018). The difference between hot and cold press relies on the maceration temperature “at room temperature in cold press,” time, and the addition of pectolytic enzymes (pectinases). The hot-press method yields juice darker in color and rich in pigments and tannins more than the cold one. Light-colored grapes are thus more adequate for juice extraction by cold press than by hot press, and the temperature never exceeds 62 °C to maintain juice quality and healthy ingredients (Siricururatana, 2011). Figure 2 shows the summary of GJ production and different pasteurization techniques highlighting their advantages and or limitations.

Grapes and GJ are rich in phenolics which is correlated to juice antioxidant effects, in addition to anthocyanins imparting GJ a darker color (Danışman et al., 2015). The stability of these phenolics is affected by thermal processing employed during the production stage. Heat processing is the oldest and most widely used method to prevent against microbial growth and to extend juices’ and beverages’ shelf life. The degradation that occurs during heat treatment upon exposure for long periods of time due to the high reactivity and polymerization of anthocyanins is the main cause for the loss of its characteristic red color and a decrease in health benefits (Danışman et al., 2015).

In red grape cv. Karasakiz (V. vinifera) GJ from Bozcaada, Çanakkale, Turkey, although an increase by 6.9% in the antioxidant activity was observed at 70 °C for over 7 h, a decline by 2.4% and 10.3% was observed at the end of the 7-h heating period at 80 °C and 90 °C, respectively. This decrease was linked to higher loss in anthocyanins (Danışman et al., 2015). Yet in another study, thermal treatment at high temperature but for short periods of time was more efficient in anthocyanin extraction and consequently its color intensity. The study was performed in 2 red wine grape cvs. of V. vinifera from vineyards of Piedmont in Northwest Italy, which are Malvidin Prevalent Variety (MPV, cv Barbera) and Peonidin Prevalent Variety (PPV, cv Nebbiolo). In this study (Lambri et al., 2015), the increasing extraction temperature led to the increased red color due to anthocyanins, though with different patterns in anthocyanins’ profile in examined cvs.

In another attempt, heat processing of grapes “Isabel Precoce” and “BRS Violeta, Brazil” for GJ production for a short period of time yielded enriched juice with bioactive components including phenolics upon comparing different extraction methods to include hot press “heated grapes at 60–65 °C for 30–60 min with addition of pectinases,” cold press “same procedure but with no heat application,” and hot break “applying high temperature 75–85 °C for short time periods 5–10 min.” In the hot break procedure, flavanol yield was the highest (173.4 mg/L), followed by flavonols (34.0) mg/L. In contrast, anthocyanins were found higher in heat processing methods at a yield of 221.7 mg/L compared to cold press at 85.0 mm/L. Phenolic acids were also recorded at higher levels in hot break (67.3 mg/L), than other extraction methods (Silva et al., 2019).

Although heat treatment can negatively affect anthocyanins’ stability in GJ if subjected for long periods of time, it can likewise improve the extraction of bioactives from GJ, i.e., phenolic acids and flavonoids (Silva et al., 2019). Averilla et al. (2019) established a unique method combining enzymatic and heat treatment to increase the recovery of resveratrol and its glucoside by heating grape peel at 95 °C for 10 min, further subjected to a mixture of exo-1,3-β-glucanase and pectinases at 50 °C for 60 min which aided in the release of resveratrol from its glycoside with an overall increase in yield by 50% (Averilla et al., 2019).

Thermal pasteurization is typically used to extend GJs’ microbial stability by killing microbes. Reduction of 7 logarithms of Zygosaccharomyces rouxii which is the most abundant yeast responsible for GJ spoilage was achieved after 90 s at 75 and 80 °C, and 5 s at 85 °C of the pasteurization regimen (Rojo et al., 2019). Nevertheless, such method is unlikely to destroy microbial spores if present in GJ (Farag et al., 2020).

Non-Thermal Technologies for GJ Preservation

Although conventional thermal processing has several benefits, non-thermal processing methods represent novel technologies that have less impact on GJs’ functional and sensory attributes, while ensuring quality and safety. In the next subsections, different approaches for non-thermally GJ processing methods shall be presented to include ultraviolet irradiation, high hydrostatic pressure, and electric pulsed field, which are discussed highlighting their applications, advantages, and or limitations (Putnik et al., 2019).

Ultraviolet Technology

The use of ultraviolet (UV) radiation as a non-thermal technique has been shown to be both effective and simple compared to other methods used for the preservation of fruit juices with minimal costs. Aside from preserving physicochemical parameters, sensory characteristics, and bioactive compounds, the technology can efficiently reduce the number of bacteria in liquid food and drinks without adverse quality defects (Keyser et al., 2008).

UV light wavelengths ranging from 100 to 400 nm for food processing are classified as UV-A (320–400 nm), UV-B (280–320), UV-C (200–280 nm), and UV vacuum (100–200 nm). UV-C light is especially germicidal at 254 nm and thus employed for disinfecting microorganisms in food products. The use of this technology has been frequently applied to liquid food and beverage products after being authorized by the United States Food Drug Administration (US FDA) for food pasteurization (cold pasteurization) (Groenewald et al., 2013). The exact mechanism of UV antimicrobial action is mainly due to that microbial DNA can absorb UV-C which results in the generation of DNA photoproducts that interfere with the two main vital processes for microbial growth, transcription and translation, leading to cell death (Guerrero-Beltran & Barbosa-Canovas, 2011).

In Groenewald et al. (2013), UV-C treatment of acidic pH 2.8 GJ concentrate to inactivate Alicyclobacillus spores was achieved by using the turbulent flow of UV-C radiations at a dose of 367.2 J/L resulting in 4.6 log 10 reduction in spores (Groenewald et al., 2013). In another use of UV-C radiation to inhibit bacterial growth, Moscato and Prosecco white GJ were treated with a UV-C dosage of 1000 J/L found effective in killing different microorganisms, viz., yeast Saccharomyces bayanus with 6–7 log population reduction and Acetobacter, Gluconacetobacter, and Gluconobacter bacterial reduction with no influence on the color or chemical composition of GJ (Lorenzini et al., 2010). Pala and Toklucu (2013) noted that single-pass UV-C treatment with nine lamps of red GJ (12.6 J/mL) resulted in a decreased total aerobic bacterial count by 3.5 log versus 2.8 log reduction in yeast and mold counts (Pala & Toklucu, 2013). This suggests that UV-C is slightly less effective against yeast and fungi in preservation compared to bacteria. Inactivation of the yeast S. cerevisiae VIN13 after applying a pilot-scale UV-C device (1377 J/mL) showed a comparable 3.1 log reduction in blue-red GJ (Pala & Toklucu, 2013). In contrast, post 30 min of treatment with UV-C including a single lamp with 450 kJ /m2 UV-C dose, only a 0.5 log reduction of S. cerevisiae ATCC 10,274 in violet GJ was observed. Such discrepancy could be attributed to differences in juice color, strain of microorganisms, and the type of cultivar to affect the efficacy of UV-C light via absorption (Guerrero‐Beltran et al., 2009).

UV permeation is inversely proportional to the medium absorbance and is therefore influenced by the presence of food UV absorbents that might affect the dose required for microbial inhibition. In fruit juices, for example, various soluble compounds, such as polyphenols, sugars, proteins, and vitamins, may absorb UV-C radiation (Abdul Karim Shah et al., 2016). In addition, insoluble substances like protein, carbohydrates, and large tissue molecules could prohibit or diffuse radiation are also usually one of the hurdles that should be considered (Csapó et al., 2019).

With regard to preserving bioactive compound level, UV-C did not significantly affect total phenolic content or antioxidant effect of Karasakız GJ (Averilla et al., 2019), and in accordance with results in red wine pasteurized using the Sure Pure UV reactor (Milnerton, South Africa) (Lorenzini et al., 2010). A comparison regarding UV light effect against GJ of different colors or origin has yet to be examined to prove such hypothesis and coupled to physicochemical analysis of these juices, and to optimize for UV-C dose used for GJ preservation. However, an exhaustive UV-C dose may cause a photolytic activity of anthocyanins being converted to colorless pigments as reported by Beltran et al. (2009) and to affect GJ organoleptic characters. An increase in residence time of deep violet–colored GJ in the UV-C reactor and a decrease in juice color were observed as colored anthocyanins absorb the UV-C irradiation due to its conjugated structure ultimately leading to fading of GJ color (Guerrero‐Beltran et al., 2009). These findings confirm that UV-C light treatment time and flow rate of the reactor both play a crucial role in determining GJ color changes post treatment and to be considered if applied (Koutchma, 2009).

High Hydrostatic Pressure

One of the powerful non-thermal techniques used for food preservation that operates at room or at mild process temperatures at pressure values between 100 and 1000 MPa is high hydrostatic pressure (HHP) known as high-pressure treatment (HPP). HPP is based on three main operating parameters as related to thermal pasteurization to include temperature (T), pressure (p), and treatment time (t) (Putnik et al., 2019).

Pathogenic and spoilage bacteria, yeasts, and molds are inhibited by HPP, though inactive against spores were found, which is suggestive of other adjuvant treatment for spores’ inactivation or removal if suspected to occur (Farag et al., 2021). However, optimization of HPP parameters (pressure, temperature, time) to ensure its effectiveness should consider juice composition, pH, and the water activity. Rojo et al. (2019) assessed the impact of HHP on concentrated GJ revealing that a 7-log reduction of Zygosaccharomyces rouxii could be achieved using over 500 MPa for 2 min. Asides, increasing the holding time from 3 to 5 min did not improve the juice shelf life or lead to increased log reduction values, whereas 300 MPa showed no inhibition towards Z. rouxii cells. These results are in accordance with that of Chang et al. (2017) reporting that microbial titers (aerobic platform count, coliform, and yeast/mold) were not distinctly lower from those observed in control GJ treated with 300 MPa for 3 min (Chang et al., 2017). However, Rojo et al. (2019) reported that the vegetative cell population of Z. bailii showed a 5-log cycle reduction post 5 min of pressurization at 300 MPa (Rojo et al., 2019). Whether such discrepancy is attributed to either differences in sensitivity among Zygosaccharomyces strains or temperature regimen has yet to be confirmed.

The effect of polyphenol oxidase (PPO) on ascorbic acid–fortified GJ (HHP) phytochemical stability post treatment at 400–550 MPa for 15 min revealed that the total PPO activity showed a threefold increase. Such increase in PPO was concurrent with a decline in anthocyanins and a further antioxidant effect, with a 70 and 46% decline at 400 and 550 MPa, respectively, negatively affecting the juice color and health benefits (Insfran et al., 2007).

Pulsed Electric Field

Pulsed electric field (PEF) is one of the advanced techniques that could be applied for the preservation of GJ quality and safety. Food industry interest in PEF is increasing rapidly as it became more applicable compared to HHP. PEF usage for mechanical and pre-pressure operation introduces promising technology that is able to sustain the nutritional and physicochemical properties of juices within the accepted limits (Putnik et al., 2019).

A physical property called electroporation is caused when a very short (ms or μs) and fast electric pulse (1–80 kV/cm) is applied to a food matrix leading to a local structural disruption of microbial cell (Putnik et al., 2019). Moreover, the anthocyanins level showed an increase in GJ by pre-treatment with PEF by17 and 10% compared to thermal conventional methods and HHP, respectively. Such increase is likely attributed to higher extraction rates of pigments from pulp during treatment (Tiwari et al., 2009).

Microbial cell characteristics need to be considered in PEF treatment, i.e., cell size and cell membrane thickness were found to affect the inhibition capacity of PEF. The larger cells showed higher transmembrane potential and mediated field strength around the cells, attenuating PEF treatment resistance. For example, upon applying 12–24 kV/cm of field strength at a temperature of 30 °C on different microbes, viz., Staphylococcus aureus, Escherichia coli DH5α, and Saccharomyces cerevisiae, treatment time ranged from 30 to 180 μs. The results showed that the least resistant microbes in PEF treatment were S. cerevisiae followed by E. coli DH5α then S. aureus. Such difference in sensitivity was mediated by cell membrane thickness to trigger the electrical field concentrated in the cell membrane and to increase microorganism susceptibility to PEF treatment (Huang et al., 2014).

Asides from microbial characteristics, grape variety used in GJ preparation also presents a variable to be considered when evaluating PEF processing effect and heat treatment. Regarding GJ nutritional value “antioxidant activity and protein content” in Mazuelo grapevines, a 9% reduction, versus 13% in PEF and thermal treatments, respectively, as well protein content showed a lower level in heat treated GJ (18 ± 5 ppm) than that of PEF (29 ± 5 ppm). Although GJ is not an enriched source of protein, still the nitrogen content is crucial in the wine industry for its aroma profiling (Marsellés-Fontanet et al., 2013).

PEF’s effect on purple grape Graciano and red grape Grenache volatile composition showed different effects depending on the fruit variety type. In Graciano, different treatment conditions revealed a decrease in monoterpenoids post treatment. However, in conditions where energy applied was higher (20 µs pulses and frequency 400 Hz), no significant change in terpene level was observed (Garde-Cerdán et al., 2013). In contrast, in Grenache the number of monoterpenoids, at whatever energy input level, showed an increase by 50%. Variation in terpenoid volatiles among the different varieties was correlated with the nature, morphology, and composition of fruit skin or the ease of extraction from Grenache than Graciano grapes. PEF showed improved β-ionone levels. While PEF had a beneficial impact on benzenoid level in Grenache, they were somewhat influenced in Graciano. Hence, the quality of aroma compounds in Grenache was improved by applying PEF treatment, though, in Graciano, no substantial change was observed (Garde-Cerdán et al., 2013).

PEF lowered the levels of C13 norisoprenoids in Graciano by 28%, while no inhibition was observed in Grenache. For ester and benzenoid classes, PEF at low level (10 µs, 300 Hz) influenced their levels by 62% in Graciano, while in Grenache, their levels increased by 32% at higher levels of PEF (20 µs, 400 Hz) (Garde-Cerdán et al., 2013) suggestive of a variety type effect.

Dense Phase or Supercritical Carbon Dioxide

Dense phase CO2 processing (DP-CO2) is a continuous, cheap, accessible, non-thermal processing method for liquid food preservation that employs pressure (< 90 MPa) with carbon dioxide (CO2) used to prevent against food spoilage. In the supercritical state, CO2 has low viscosity (3–7 × 10−5 Pa s) and zero surface tension giving it the advantage to improve the penetration power (Tiwari et al., 2009).

The exact mechanism behind the inhibition power of CO2 is still unknown likely to involve a decline in microbial cell pH, altering cell membrane, cell rending, or loss of pivotal enzymes (Tiwari et al., 2009). A 6-log reduction in yeast population was achieved by applying CO2 at 85 g/kg. Increasing the CO2 ratio to juice concentration, pressure, and temperature led to higher rates of microbial inactivation with no change in sensory characters (Gunes et al., 2005).

Generally, change in GJ color is highly linked with the degradation of anthocyanins and formation of polymeric brown or colorless pigments. A study on Muscadine GJ comparing the effect of dense phase or supercritical carbon dioxide (DPCD) and thermal processing revealed no significant changes in total anthocyanins, whereas 16% loss was observed in thermal treatment. Moreover, anthocyanin stability increased upon storage for 10 weeks at 4 °C due to the elimination of dissolved oxygen, presenting an added value to GJ quality (Tiwari et al., 2009).

Analytical Techniques Used for GJ Quality Control Analysis

Different analytical platforms have been implemented to assess for GJ quality as manifested by its metabolite repertoire including aroma compounds and phenolics, and moreover monitoring the levels of toxins as contaminants from different molds as Aspergillus, Penicillium, and Alternaria. Hereby, a summary of the previous reports on the different analytical techniques implemented for red or purple GJ analyses is presented highlighting their applications, advantages, and/or any limitations. Table 3 shows the different analytical tools, validation parameters, advantages, and limitations used for analysis of grape juice.

Gas Chromatography Mass Spectroscopy Applications

Gas chromatography mass spectrometry (GC–MS) is the standard analytical tool typically used for volatiles profiling in plant samples directly, i.e., terpenoids or post derivatization for small molecular compounds, i.e., sugars, amino acids, and fatty acids (Hegazi et al., 2021a). Such platform has been reported for determining the GJ aroma (Dutra et al., 2018) influence of grape processing on aroma profile or even the freshness level of the prepared juice (Perestrelo et al., 2019) as well as identifying volatile contaminants (Schueuermann et al., 2019), (Dutra et al., 2018; Perestrelo et al., 2019).

The aroma of grape-derived beverages “juice and nectar” depend mostly on its volatile content which varies among different grapevines as discussed earlier (Dutra et al., 2018). Liquid–liquid extraction-gas chromatography-mass spectrometry (LLE-GC–MS) was employed in Brazilian grapevines “V. labrusca and hybrids” for the identification of main aroma compounds, i.e., “anthranilate (MA), 2′-aminoacetophenone (2-AAP) and furaneol.” The results show that in BRS (Cora), MA was detected in nectar samples at higher levels than that of juice (490–7570 and 460 µg/L, respectively). Higher MA levels in nectar samples were due to its use as a natural flavoring agent to enhance aroma, which favors GJ as beverages over nectar. In “Concord” GJ, MA varied per maturation stages and processing conditions from 155 to 6120 µg/L, whereas 2-AAP was absent in all juice and nectar samples. Furaneol was detected in all GJ samples ranging from 150 to 7930 μg/L, and ranging from 450 to 2082 μg/L in nectar. The implemented method was validated by both LOD and LOQ. LOD “limit of detection” is the analyte lowest concentration that can be measured with statistical significance, and LOQ “limit of quantification” is the minimum concentration of the analyte that could be detected quantitatively with the best accuracy and precision (Jannetto, 2017). The LOD (23.94 μg/L) and LOQ were 96.277 μg/L for MA and 2-AAP, respectively (Dutra et al., 2018). A head space solid phase microextraction of red grape fruits “fresh and processed” followed by volatile profiling using GC–MS identified a total of 169 volatiles, with heat-processed fruit juice characterized by the formation of furan compounds (Perestrelo et al., 2019). The detection of these furans could aid in identifying the thermal treatment level in GJ as employed for determining roasting levels in coffee brews (Abdelwareth et al., 2021). A study identified toxic volatile markers of grape berry juice as a marker for infection with fungal pathogens, i.e., Botrytis cinerea, Penicillium expansum, and Aspergillus species “carbonarius and niger” of fungal origin using SPME GC–MS coupled to a chemometric analysis. Different fungal volatiles have been identified as per difference in pathogen type. Identified markers were 1,5-dimethylnaphthalene and unknown sesquiterpenes of infected grapes with B. cinerea, while m-cresol and γ-nonalactone were markers of P. expansum, whereas for Aspergillus species, 2-(4-hexyl-2,5-dioxo-2,5-dihydrofuran-3-yl) acetic acid was the identified marker (Schueuermann et al., 2019).

Another report on SPME coupled to GC–MS was found an effective tool in quantifying geosmin, a volatile fungal toxin of Botrytis cinerea and Penicillium expansum in rotten grapes leading to an earthy smell of GJ, typical of geosmin. The method quantified geosmin with R of 0.995, sensitivity of 0.02 ng/L, LOD and LOQ of 4.7 ng/L and 15.6 ng/L, respectively, RSD of 4.1%, and recovery rate of 115–134% (Morales-Valle et al., 2010).

A new technique was implemented for the fabrication and characterization of new molecularly imprinted solid phase microextraction fibers (MI-SPME) in extracting triazole fungicides from GJ followed by GC–MS analysis. The new (MI-SPME) fiber showed an advantage of renewing its selective binding sites due to thermal degradation of the polymer network. The method showed good precision and accuracy; LOQ was at 100 µg/L which was sufficient for the quantification of triadimenol (100 µg/L), tebuconazole (2000 µg/L), and metconazole (1000 µg/L) in Brazilian GJ samples (de Souza Freitas et al., 2014).

In another study, the use of direct barrier discharge ionization “DBDI” coupled to a new matrix compatible fiber of SPME-GC/MS was found effective for the detection and quantification of pesticides “quinoxyfen, trifloxystrobin, pyraclostrobin, and pyriproxyfen” in a short analysis time. SPME-DBDI-GC/MS was effective in pesticide analysis of such complex matrix of GJ samples due to high levels of sugars and pigments which could implement artifacts in GC results due to thermal degradation. The results revealed pesticide LODs of 3 pg/mL and LOQ ranging from 10 to 100 pg/mL (Mirabelli et al., 2018).

Liquid Chromatography and LC-Mass Spectroscopy

The application of HPLC for primary analysis of metabolites, i.e., sugars and acids, has been reported in different Brazilian “Isabel Precoce, BRS Cora and BRS Violeta” commercial products using validated HPLC coupled to refractive index (RID) and photodiode (PDA) detectors, for detection of sugars and organic acids, respectively which account for the palatability and sensory attributes of GJ. As described by authors, the International Vine and Wine Organization recommends the use of HPLC-RID for the determination of sugar levels in wine and grape musts. The validation of the method was achieved through R2 values of > 0.9982, precision CV% of less than 1.4, recovery of 76–106%, and LOD and LOQ of 0.003–0.44 g/L and 0.008–0.199 g/L, respectively. Results revealed enrichment in sugars “glucose and fructose” detected at 86.61–108.09 and 76.4–92.9 g/L, respectively, with total sugar levels of 163.31–200.97 g/L. Major organic acids in GJ included malic acid (1.56–1.92 g/L) followed by tartaric acid (0.63–5.63 g/L) with a total acid content of 3.60–7.58 g/L. Principal component analysis (PCA) aids in sample classification as per their processing type, posing the validated method as an effective QC tool for grapes and its product analyses (Coelho et al., 2018b). Another study targeted the identification of the different oligosaccharides in different North-eastern Brazil GJs using the validated method on reversed-phase HPLC/RID equipped with an RP C18 column with polar end capping. Oligosaccharides could be utilized as prebiotics to exert a positive effect on human gastrointestinal health. Estimation of different levels of these oligosaccharides in different GJ samples could present an added value aside from being used as beverages. Method validation was achieved through a linearity range of each oligosaccharide, with LOD at 0.047–0.090 g/L and LOQ 0.179–0.214 g/L for nystose and 1-ketose, respectively. Oligosaccharides were detected in GJ samples from both commercial and monovarietal GJ. In commercial samples, 1-ketose levels were 0.445 and 0.098 g/L in Isabel Precoce + BRS Violeta and Isabel Precoce + BRS Cora, respectively. In monovarietal samples, BRS Violeta and BRS Cora, the detected levels were 0.224 and 0.399 g/L, respectively. Raffinose was detected only in monovarietal GJ “BRS Violeta” at 0.196 g/L, whereas nystose was not detected in either commercial or monovarietal GJ (dos Santos Lima et al., 2019).

Phenolics profiling using HPLC–PDA along with mineral analysis, viz., Cu, Mn, and Fe, was reported in organic and conventional monovarietal GJ named Isabel Precoce (V. labrusca) and BRS Violeta (V. labrusca × V. vinifera) Brazil. Conventional GJ samples were enriched in phenolics than organic ones exemplified in anthocyanins ranging from 21 to 469 mg/L. The main anthocyanin was malvidin 3,5-diglucoside detected at 55.5 and 71.4 mg/L, in organic and commercial GJ, respectively. GJ sample preparation by hot digestion with nitric acid and hydrogen peroxide was effective in discoloration to ease mineral detection, with Fe levels found highest in conventional ones (1.65 mg/L). Generally, no significant difference was observed between organic and conventional GJ samples regarding their metal content (Prudencio Dutra et al., 2018).

The RP-HPLC/PDA (C18) core shell column was utilized as an alternative to UHPLC in profiling V. vinifera, V. labrusca, and red hybrid-derived GJ. The selected core shell column improved the selectivity and resolution of the complex matrix of red GJ post SPE fractionation, with lower detection levels of 1.2–27.5 ppb and %RSD of 0.04–0.38. Different protocols have been adopted as per chemical fraction nature. Phloroglucinolysis of condensed tannin fraction, the non-anthocyanin monomeric fraction “hydroxy cinnamic acid, esters, and flavonols,” possessed rapid separation. For anthocyanin analysis, 2 techniques were attempted, namely, pentafluorophenyl (PFP) column or C18 reversed-phase column. The PFP column was found superior in its resolving power for complex anthocyanins (diglucosides) enriched in hybrid cvs. (Manns & Mansfield, 2012).

Anthocyanins in GJ can also be detected using the fluorescence detector as reported in red fruits “red Spanish grapes” (Obón et al., 2011), with the additional advantage of higher sensitivity of fluorescence detection. A study on GJ of São Francisco Valley in Brazil using HPLC/PDA led to the identification of 25 phenolics, with anthocyanins and tannins found predominant in red GJ than in white one. Method validation parameters LOD and LOQ were 0.001–0.19 µg/mL and 0.003–0.37 µg/mL, respectively (Natividade et al., 2013).

A reversed-phase HPLC method coupled to positive ion atmospheric pressure chemical ionization (APCI) was employed for the determination of total resveratrol “free cis and trans” as well as resveratrol from “picied glycoside” after enzymatic hydrolysis in different Concord grape powders, concentrates, extracts, and GJs. The levels of trans, cis, and total resveratrol in grape powder were highest at 1185, 216, and 1401 nmol/g, respectively, while those in GJ were lowest recorded at 1.13, 0.43, and 1.56 nmol/g, respectively, suggestive for the recovery of resveratrol in juice, though they need to be tested in other varieties to be conclusive. Validation of the method was achieved through a regression coefficient (R) of 0.9999, with LOQ of 0.31 pmol and a variant coefficient of 2.6%. Compared to electrospray ionization, APCI has the broadest dynamic range and linearity of response and was thus chosen for stilbene ionization (Wang et al., 2002).

A selective imprinted polymer (MIP-SPE) was reported for contaminant isolation, i.e., OTA (ochratoxin A) in grapevines and juice using HPLC coupled to a fluorescent detector in GJ samples purchased from local markets in Beijing, China. HPLC method validation was achieved through a linearity regression coefficient (R) of 0.9999, detection and quantification limits of 0.025 and 0.08 ng/mL, recovery range of 91.6–101.7%, and inter- and intraday precision of at 1.1% and less than 1.4, respectively (Cao et al., 2013). In another attempt to quantify OTA in red GJ, RP-HPLC coupled to a fluorescent detector was used to quantify OTA using nanosponge “β-cyclodextrin polyurethane polymer” solid phase extraction. However, the method was less sensitive for OTA detection at 0.5–20 ng/mL with an LOD of 0.2 ng/mL compared to Cao et al. (2013) (Appell et al., 2018).

LC–MS is increasingly applied for metabolite profiling in different food matrices (Hegazi et al., 2021a). In grape analysis, the implementation of LC–MS in profiling complex polyphenolic classes (Xu et al., 2011) identified anthocyanins, flavonols, phenolic acids, and proanthocyanidins in GJ and wine. The application of LC–MS for phenolics profiling was further extended using chemometric tools to assess variation in phenolics among 7 grapevine varieties (Crupi et al., 2015). Another application of chemometric tools to correlate grapevine’s antioxidant effect to metabolite profile using HPLC–PDA-MS/MS was reported in 7 table grapevines cvs. from Apulia, Italy, to produce a nutraceutical juice. Results attributed grapevine’s antioxidant activity to anthocyanin enrichment followed by flavonols and falvan-3-ols (Crupi et al., 2015).

Direct Spectroscopic Analysis (FT-IR, 1H-NMR, VIS–NIR-MIR, and Fluorescence)

Compared to hyphenated chromatographic techniques, direct spectroscopic measurement offers a more rapid analysis of GJ and can be more suited for screening of many samples and/or QC by manufacturers but is less powerful in exact metabolite identification (Hegazi et al., 2021b). Fourier transform infrared (FT-IR) spectroscopy coupled to chemometric tools was used for the discrimination of Concord GJ in 100% GJ blends, as well as identification of different GJ varieties, viz., Concord, Red, White, and Niagara GJ varieties, through the differences in IR aromatic bands of phenolics. The benefit of using FT-IR in the analysis of the food complex matrix lies in that the technique is rapid, simple, qualitative, and quantitative, with no sample destruction and use of hazardous solvents (Snyder et al., 2014).

In another study, quercetin was identified as an indicator for the freshness level of GJ using a fluorescent probe graphite carbon nitride (gC3N4) coupled with molecular imprinting for a better sensitivity and selectivity of quercetin with LOD of 2.5 ng/mL, recovery range of 90.7–94.1%, and relative standard deviations of 2.1–5.5%. Quantitative analytical tools (HPLC and LC) used for quercetin analysis coupled to fluorescent detectors have disadvantages such as long analysis time and high solvent consumption. In the work by Xu et al. (2018), the use of fluorescence spectroscopy as a direct tool for the detection of quercetin was reported with no employment of chromatographic techniques with advantages of a short analysis time and better physicochemical and photochemical stabilities. The current limitation of the fluorescence method lies in working in the UV (λexc = 350 nm) which makes the probe prone to interferences by biomatter to display strong background UV absorption and fluorescence (Xu et al., 2018).

The utilization of proton-nuclear magnetic resonance (1H-NMR) coupled to a chemometric tool, i.e., PCA, for the quality control of GJ led to the identification of ethanol in GJ samples as an indication for microorganism fermentation. Commercial GJs purchased from different local markets either with preservatives or sweetened by sucrose or both as well as freshly prepared GJs from producers in Brazil have been assessed. Results revealed a higher ethanol level in GJs with sucrose added with no preservatives, where it could be concluded that sugar aided in the fermentation process, whereas added preservatives even in the presence of sucrose lowered microorganism fermentation. As expected, ethanol levels increased upon storing at warm temperature, especially in added sucrose GJ, whereas GJ samples with no added sucrose showed no ethanol levels during storage in the refrigerator. 1H-NMR coupled to chemometric tool appeared a valuable tool in GJ QC being directly applied to GJ samples with no prior treatments or extensive purification steps (Grandizoli et al., 2014).

A comparison of visible (VIS), near infrared reflectance (NIR), and mid infrared (MIR) spectroscopy coupled to chemometric tools (PCA) was used to differentiate between 2 Australian grape varieties “Chardonnay and Riesling” sourced from different wineries “commercial versus small one.” Differences among samples of GJ could be attributed to different processing techniques of “pressing” mostly attributed to respective bands at 780, 1070, and 1256 cm−1 for water, sugars, and phenolic compounds. The PCA plots of VIS–NIR spectral data were in agreement with that of ATR-MIR showing characteristic bands of water and sugars “fructose and sucrose.” MIR and NIR spectroscopy allowed for the identification of specific groups which were correlated to major chemicals in GJ (Cozzolino et al., 2012).

Front-face fluorescence spectroscopy was reported for the analysis of commercial New Zealand Pinot noir GJ samples of closely related vineyards and different grapevine clones enriched in polyphenolics and aromatic amino acids. Fingerprinting of samples was recorded via 3-dimensional excitation and emission matrices (EEM) over multiple excitation and emission wavelengths. Parallel factor analysis (PARAFAC) is a multiway data analysis methodology that was applied to identify deconvulated sample components and classify the dataset. The score plot showed differences among samples of different vineyard and clones as per their chemical fluorophores. The excitation/ emission maxima at 278/360 nm were assigned to tryptophan and hydroxy benzoic acid derivatives for vineyard discrimination, whereas 260/390 nm contributed to caffeic acid for clonal differentiation posing such tool as a sensitive technique for the analysis of fluorescent compounds in GJ (Schueuermann et al., 2018).

ICP-MS Mineral Analysis

Comparison of elemental composition in GJ derived from 19 organic and 17 ordinary grape sources from local markets in Brazil was reported using inductively coupled plasma mass-spectrometry (ICP-MS). Higher levels of Ba (5263 ng/g, 1818 ng/g), Ce (2311 ng/g, 1561 ng/g), and La (2080 ng/g, 1204 ng/g) were detected in organic samples rather than ordinary GJ samples, respectively, while Na (223.77 µg/g, 24.03 µg/g) and V (31.64 ng/g, 9.58 ng/g) were higher in ordinary GJ than organic ones, respectively. Employment of multivariate data analysis aided in confirming the authenticity of organic GJ from non-organic ones as per their micro and macro-elemental composition (Borges et al., 2016a).

Another study confirmed the higher sodium levels in non-organic GJ using the same platform for the determination of elemental levels in both 19 organic and 18 non-organic GJ samples from different locations in Brazil. Forty-four elements were quantified with mean values of K and Sn levels found higher in organic GJ (15,195 ng/g, 45.8 ng/g) than non-organic samples (6571 ng/g, 18 ng/g), while Na levels in non-organic GJ was higher (231 ng/g) versus organic ones (24 ng/g) likely attributed to the use of high Na preservatives in non-organic GJ (Maione et al., 2016).

Conclusions and Future Directions

This comprehensive review capitalizes on GJ with emphasis on its holistic chemical composition and sensory characters. The chemical profiling of grape fruit and GJ is presented in context to their primary and secondary metabolites.

Stilbenes were abundant mostly in the skin of grapes and suggestive for the value of skin inclusion during GJ preparation considering its health benefits. Recovery of resveratrol in juice was found low compared to its richness in wine though more evidence is needed by comparing wine to juice from different cvs. or origin. Application of hurdle technology seems to be opportunistic with regard to improving recovery of bioactive compounds during juice preparation, i.e., enzymatic and heat treatment to increase the recovery of resveratrol. Exploitation of non-thermal methods in juice preparation is at the economical level, while ensuring quality and safety shall aid to produce GJ with improved quality. The focus on fruit cv. more enriched in anthocyanins inside the pulp rather than the peel may provide high juice quality. In GJ, antioxidant activity was found to be more related to anthocyanins at higher levels compared to other flavonoid subclasses.

Phenolic markers to distinguish dark skin grapes “red and purple” from white grapes abundant in the former skin and seeds typically include anthocyanins and proanthocyanidins. Proanthocyanidins varied within grape parts, being dominant in the seeds and the skin, and less abundant in while pulps and juice. Compared to these healthy phytochemicals, hazardous chemicals in GJ derived from infection by “Aspergillus, Penicillium, and Alternaria species” include toxic metabolites such as ochratoxin A to be monitored in GJ.

To insure GJ quality with least hazards from microbial infection, different processing techniques are implemented typically involving heat. Although thermal techniques are the oldest method that effectively lower the level of microbial growth, its main drawback lies in loss of anthocyanins in GJ, a marker for its color and health benefits. Non-thermal techniques were thus increasingly implemented including UV-C irradiation being effective for preservation of GJ as well as sustaining its quality. High hydrostatic pressure (HHP) has an advantage of application of high pressure at mild temperature, though it is not effective against spore control if present in GJ accidentally. An advanced preservation process superior to thermal and HHP is pulsed electric field (PEF) with an advantage of the use of mechanical and pre-pressure techniques while maintaining the bioactive components and nutritional value. Another cheap non-thermal method for GJ preservation is dense phase CO2 (DP-CO2), with its microbial inhibition power found likewise not to affect GJ anthocyanin stability.

The review also highlights the different analytical techniques used for analysis and quality control assessment of GJ, highlighting the advantages and limitations of each technique. Different analytical platforms have been reported for GJ analysis as per the nature of metabolites in addition to implementation of new techniques. GC–MS is suited for analysis of volatile components, with coupling of SPME to GC–MS increasing its sensitivity in volatile collection and detection. The use of omics technology has gained attention for the discrimination of GJ as per their varieties, authenticity, and quality levels, which was implemented for the detection and classification of volatile mycotoxins in GJ as contaminant. Detection of pesticide contaminants in GJ was reported using a novel matrix of SPME fiber coupled to direct barrier discharge ionization (DBDI)-GC/MS suited for the analysis of complex GJ samples enriched with sugars and pigments.

Compared to GC–MS, implementation of HPLC methods is extensively reported in GJ targeting its phytonutrient components, i.e., polyphenolics. Utilization of MS detectors coupled to UV is effective in polyphenolic characterization, with further chemometric analysis to allow for their level’s discrimination among grape varieties or GJ. Anthocyanins as well as thiol compounds could be detected through normal and reversed-phase HPLC, respectively coupled to fluorescent detector in red grapes due its higher sensitivity. RP-HPLC/APCI has been utilized in the determination of resveratrol in GJ with APCI presenting the broadest dynamic range compared to other ionization methods, and to be considered if stilbenes are the main target for detection in GJ.

To improve the detection limit of contaminants from microbial infection, i.e., OTA in GJ, several attempts were reported including MI-SPE-HPLC coupled to fluorescent detector and or better extraction via the β-cyclodextrin polyurethane polymer in red table GJ. Another indirect tool for microbial infection based on its fermentation product appeared through 1H-NMR used for the detection of ethanol.

ICP-MS showed potential in the authentication of organic GJ from conventional ones based on sodium level. Implementation of FT-IR spectroscopy in the differentiation of GJ varieties is of potential based on IR aromatic bands, and whether direct UV fingerprint is superior has yet to be examined in GJ. The use of visible, near, and mid IR spectroscopy was effective in the differentiation of GJ from Australian varieties depending on their characteristic bands of water, sugars, and phenolics. Moreover, the inclusion of bioassays that can determine enzyme activities or biological effects in GJ in parallel to chemical analysis should be now pursued. To conclude, GJ authentication as a potential functional beverage should be subjected to different quality control measures to insure its health benefits and safety.

Data Availability

Not data available for this review article.

References

Abdelwareth, A., Zayed, A., & Farag, M. A. (2021). Chemometrics-based aroma profiling for revealing origin, roasting indices, and brewing method in coffee seeds and its commercial blends in the Middle East. Food Chemistry, 349, 129162.

Abdul Karim Shah, N. N., Shamsudin, R., Abdul Rahman, R., & Adzahan, N. M. (2016). Fruit juice production using ultraviolet pasteurization: A review. Beverages, 2(3), 22.

Akdeniz, A. S., Ozden, S., & Alpertunga, B. (2013). Ochratoxin A in dried grapes and grape-derived products in Turkey. Food Additives & Contaminants: Part b, 6(4), 265–269.

Ali, K., Maltese, F., Choi, Y. H., & Verpoorte, R. (2010). Metabolic constituents of grapevine and grape-derived products. Phytochemistry Reviews, 9(3), 357–378.

Appell, M., Evans, K. O., Jackson, M. A., & Compton, D. L. (2018). Determination of ochratoxin A in grape juice and wine using nanosponge solid phase extraction clean-up and liquid chromatography with fluorescence detection. Journal of Liquid Chromatography Related Technologies, 41(15–16), 949–954.

Asam, S., Konitzer, K., Schieberle, P., & Rychlik, M. (2009). Stable isotope dilution assays of alternariol and alternariol monomethyl ether in beverages. Journal of Agricultural and Food Chemistry, 57(12), 5152–5160.

Averilla, J. N., Oh, J., Wu, Z., Liu, K. H., Jang, C. H., Kim, H. J., Kim, J. S., & Kim, J. S. (2019). Improved extraction of resveratrol and antioxidants from grape peel using heat and enzymatic treatments. Journal of the Science of Food Agriculture, 99(8), 4043–4053.

Ayala-Zavala, J. (2018). Winery and grape juice extraction by-products. In: Plant food by-products. 157–181. Apple Academic Press.

Borges, E. M., Volmer, D. A., Brandelero, E., Gelinski, J. M. L. N., Gallimberti, M., & Barbosa, F. (2016a). Monitoring the authenticity of organic grape juice via chemometric analysis of elemental data. Food Analytical Methods, 9(2), 362–369.

Borges, E. M., Volmer, D. A., Brandelero, E., Lafayette Neves Gelinski, J. M., Gallimberti, M., & Barbosa, F., Jr. (2016b). Monitoring the authenticity of organic grape juice via chemometric analysis of elemental data. Food Analytical Methods, 9(2), 362–369.

Cao, J., Zhou, S., Kong, W., Yang, M., Wan, L., & Yang, S. (2013). Molecularly imprinted polymer‐based solid phase clean‐up for analysis of ochratoxin A in beer, red wine, and grape juice. Journal of Separation Science. 36(7), 1291–1297.

Chang, Y. H., Wu, S. J., Chen, B. Y., Huang, H. W., & Wang, C. Y. (2017). Effect of high-pressure processing and thermal pasteurization on overall quality parameters of white grape juice. Journal of the Science of Food Agriculture, 97(10), 3166–3172.

Chen, Y., Wang, Z., Zhang, H., Liu, Y., Zhang, S., Meng, Q., & Liu, W. (2018). Isolation of high purity anthocyanin monomers from red cabbage with recycling preparative liquid chromatography and their photostability. Molecules, 23(5), 991.

Chira, K., Lorrain, B., Ky, I., & Teissedre, P.-L. (2011). Tannin composition of cabernet-sauvignon and merlot grapes from the bordeaux area for different vintages (2006 to 2009) and comparison to tannin profile of five 2009 vintage mediterranean grapes varieties. Molecules, 16(2), 1519–1532.

Cho, M. S., Kim, K., Seo, E., Kassim, N., Mtenga, A. B., Shim, W.-B., Lee, S.-H., & Chung, D.-H. (2010). Occurrence of patulin in various fruit juices from South Korea: An exposure assessment. Food Science Biotechnology, 19(1), 1–5.

Coelho, E. M., da Silva Padilha, C. V., Miskinis, G. A., Barroso de So, A. G., Pereira, G. E., de Azevedo, L. C., & Lima, Md. S. (2018a). Simultaneous analysis of sugars and organic acids in wine and grape juices by HPLC: Method validation and characterization of products from northeast Brazil. Journal of Food Composition and Analysis, 66, 160–167.

Coelho, E. M., da Silva Padilha, C. V., Miskinis, G. A., de Sá, A. G. B., Pereira, G. E., de Azevêdo, L. C., & dos Santos, L. M. (2018b). Simultaneous analysis of sugars and organic acids in wine and grape juices by HPLC: Method validation and characterization of products from northeast Brazil. Journal of Food Composition Analysis, 66, 160–167.

Commission, E. (2005). Commission regulation (EC) no 123/2005 of 26 January 2005 amending regulation (EC) no 466/2001 as regards ochratoxin A. Official Journal of the European Union, 25, 3–5.

Cosme, F., Gonçalves, B., Inês, A., Jordão, A. M., & Vilela, A. (2016). Grape and wine metabolites: Biotechnological approaches to improve wine quality. Grape Wine Biotechnology, 187–214.

Cosme, F., Pinto, T., & Vilela, A. (2018). Phenolic compounds and antioxidant activity in grape juices: A chemical and sensory view. Beverages, 4(1), 22.

Cozzolino, D., Cynkar, W., Shah, N., & Smith, P. (2012). Varietal differentiation of grape juice based on the analysis of near- and mid-infrared spectral data. Food Analytical Methods, 5(3), 381–387.

Crupi, P., Bergamini, C., Perniola, R., Dipalmo, T., Clodoveo, M. L., & Antonacci, D. (2015). A chemometric approach to identify the grape cultivar employed to produce nutraceutical fruit juice. European Food Research Technology, 241(4), 487–496.

Csapó, J., Prokisch, J., Albert, C., & Sipos, P. (2019). Effect of UV light on food quality and safety. Acta Univ Sapientiae, 12, 21–41.

Ćurko, N., Tomašević, M., Cvjetko Bubalo, M., Gracin, L., Radojčić Redovniković, I., Kovačević Ganić, K., & biotechnology,. (2017). Extraction of proanthocyanidins and anthocyanins from grape skin by using ionic liquids. Food Technology, 55(3), 429–437.

Danışman, G., Arslan, E., & Toklucu, A. K. (2015). Kinetic analysis of anthocyanin degradation and polymeric colour formation in grape juice during heating. Czech Journal of Food Sciences, 33(2), 103–108.

de Souza Freitas, L. A., Vieira, A. C., Mendonca, F. R., & JA & Figueiredo EC,. (2014). Molecularly imprinted fibers with renewable surface for solid-phase microextraction of triazoles from grape juice samples followed by gas chromatography mass spectrometry analysis. The Analyst, 139(3), 626–632.

De Vasconcelos Facundo, H. V., De Souza Neto, M. A., Maia, G. A., Narain, N., & Dos Santos, G. D. (2010). Changes in flavor quality of pineapple juice during processing. Journal of Food Processing Preservation, 34(3), 508–519.

do Nascimento Silva FL, Schmidt EM, Messias CL, Eberlin MN & Sawaya ACHF,. (2015). Quantitation of organic acids in wine and grapes by direct infusion electrospray ionization mass spectrometry. Analytical Methods, 7(1), 53–62.

dos Santos, L. M., Nunes, P. C., & de Araújo Silva BdL, da Silva Padilha CV, do Bonfim THF, Stamford TLM, da Silva Vasconcelos MA & de Souza Aquino J,. (2019). Determining 1-kestose, nystose and raffinose oligosaccharides in grape juices and wines using HPLC: Method validation and characterization of products from Northeast Brazil. Journal of Food Science Technology, 56(10), 4575–4584.

Dutra, Md. C. P., de Souza, J. F., Viana, A. C., de Oliveira, D., Pereira, G. E., & dos Santos, L. M. (2018). Rapid determination of the aromatic compounds methyl-anthranilate, 2′-aminoacetophenone and furaneol by GC-MS: Method validation and characterization of grape derivatives. Food Research International, 107, 613–618.

Farag, M. A., Mesak, M. A., Saied, D. B., & Ezzelarab, N. M. (2021). Trends in food science & technology uncovering the dormant food hazards, a review of foodborne microbial spores' detection and inactivation methods with emphasis on their application in the food industry. Trends in Food Science & Technology.

Farag, M. A., Mesak, M. A., Saied, D. B., & Ezzelarab, N. M. (2021). Uncovering the dormant food hazards, a review of foodborne microbial spores’ detection and inactivation methods with emphasis on their application in the food industry. Trends in Food Science & Technology, 107, 252–267.

Ferreira, V., Matus, J. T., Pinto-Carnide, O., Carrasco, D., Arroyo-García, R., & Castro, I. (2019). Genetic analysis of a white-to-red berry skin color reversion and its transcriptomic and metabolic consequences in grapevine (Vitis vinifera cv.‘Moscatel Galego’). BMC Genomics. 20(1), 1–17.

Flamini, R., Mattivi, F., De Rosso, M., Arapitsas, P., & Bavaresco, L. (2013). Advanced knowledge of three important classes of grape phenolics: Anthocyanins, stilbenes and flavonols. International Journal of Molecular Sciences, 14(10), 19651–19669.

Garde-Cerdán, T., González-Arenzana, L., López, N., López, R., Santamaría, P., & López-Alfaro, I. (2013). Effect of different pulsed electric field treatments on the volatile composition of Graciano, Tempranillo and Grenache grape varieties. Innovative Food Science Emerging Technologies, 20, 91–99.

Genova, G., Iacopini, P., Baldi, M., Ranieri, A., Storchi, P., & Sebastiani, L. (2012). Temperature and storage effects on antioxidant activity of juice from red and white grapes. International Journal of Food Science Technology, 47(1), 13–23.

Georgiev, V., Ananga, A., & Tsolova, V. (2014). Recent advances and uses of grape flavonoids as nutraceuticals. Nutrients, 6(1), 391–415.

Gómez-Albarrán, C., Melguizo, C., Patiño, B., Vázquez, C., & Gil-Serna, J. (2021). Diversity of mycobiota in Spanish grape berries and selection of Hanseniaspora uvarum U1 to prevent mycotoxin contamination. Toxins, 13(9), 649.

Gouot, J. C., Smith, J. P., Holzapfel, B. P., & Barril, C. (2019). Grape berry flavonoid responses to high bunch temperatures post véraison: Effect of intensity and duration of exposure. Molecules, 24(23), 4341.

Grandizoli, C. W. P. D. S., Campos, F. R., Simonelli, F., & Barison, A. (2014). Grape juice quality control by means of 1H-NMR spectroscopy and chemometric analysis. Quimica Nova, 37(7), 1227–1232.

Granato, D., Margraf, T., Brotzakis, I., Capuano, E., & van Ruth, S. M. (2015). Characterization of conventional, biodynamic, and organic purple grape juices by chemical markers, antioxidant capacity, and instrumental taste profile. Journal of Food Science, 80(1), C55–C65.

Groenewald, W., Gouws, P., Cilliers, F., & Witthuhn, R. (2013). The use of ultraviolet radiation as a nonthermal treatment for the inactivation of alicyclobacillus acidoterrestris spores in water, wash water from a fruit processing plant and grape juice concentrate. Journal for New Generation Sciences, 11(2), 19–32.

Guerrero-Beltran, J. A., & Barbosa-Canovas, G. V. (2011). Ultraviolet-C light processing of liquid food products. Nonthermal Processing Technologies for Food, 262–270.

Guerrero-Beltran, J., Welti-Chanes, J., & Barbosa-Canovas, G. V. (2009). Ultraviolet-C light processing of grape, cranberry and grapefruit juices to inactivate Saccharomyces cerevisiae. Journal of Food Process Engineering, 32(6), 916–932.

Gunes, G., Blum, L. K., & Hotchkiss, J. H. (2005). Inactivation of yeasts in grape juice using a continuous dense phase carbon dioxide processing system. Journal of the Science of Food Agriculture, 85(14), 2362–2368.

Gutiérrez-Gamboa, G., Garde-Cerdán, T., Moreno-Simunovic, Y., & Pérez-Álvarez, E. P. (2019). Amino acid composition of grape juice and wine: principal factors that determine its content and contribution to the human diet. In: Nutrients in Beverages. 369–391. Elsevier.

Hegazi, N. M., El-Shamy, S., Fahmy, H., & Farag, M. A. (2021a). Pomegranate juice as a super-food: A comprehensive review of its extraction, analysis, and quality assessment approaches. Journal of Food Composition Analysis, 97,.

Hegazi, N. M., Khattab, A. R., Frolov, A., Wessjohann, L. A., & Farag, M. A. (2021b). Authentication of saffron spice accessions from its common substitutes via a multiplex approach of UV/VIS fingerprints and UPLC/MS using molecular networking and chemometrics. Food Chemistry, 130739.

Huang, K., Jiang, T., Wang, W., Gai, L., & Wang, J. (2014). A comparison of pulsed electric field resistance for three microorganisms with different biological factors in grape juice via numerical simulation. Food Science Biotechnology, 7(7), 1981–1995.

Hussain, S., Asi, M. R., Iqbal, M., Akhtar, M., Imran, M., & Ariño, A. (2020). Surveillance of patulin in apple, grapes, juices and value-added products for sale in Pakistan. Foods, 9(12), 1744.

Insfran, D. P., Martinez, D. F., Talcott, S., & Brenes, C. (2007). Stability of copigmented anthocyanins and ascorbic acid in muscadine grape juice processed by high hydrostatic pressure. Journal of Food Science, 72(4), S247–S253.

Jannetto, P. (2017). Therapeutic drug monitoring using mass spectrometry. Mass Spectrometry for the Clinical Laboratory, 165–179.

Jediyi, H., Naamani, K., Elkoch, A. A., & Lemjiber, N. (2019). Changes in grapes composition during ripening of five Vitis vinifera L varieties as related to Tephritidae and Drosophilidae infestations. Physiology Molecular Biology of Plants, 25(6), 1407–1418.

Ju, Y., Yang, L., Yue, X., Li, Y., He, R., Deng, S., Yang, X., & Fang, Y. (2021). Anthocyanin profiles and color properties of red wines made from Vitis davidii and Vitis vinifera grapes. Food Science and Human Wellness, 10(3), 335–344.

Keyser, M., Műller, I. A., Cilliers, F. P., Nel, W., & Gouws, P. A. (2008). Ultraviolet radiation as a non-thermal treatment for the inactivation of microorganisms in fruit juice. Innovative Food Science & Emerging Technologies, 9(3), 348–354.

Koutchma, T. (2009). Advances in ultraviolet light technology for non-thermal processing of liquid foods. Food Bioprocess Technology, 2(2), 138–155.

Król, A., Amarowicz, R., & Weidner, S. (2014). Changes in the composition of phenolic compounds and antioxidant properties of grapevine roots and leaves (Vitis vinifera L.) under continuous of long-term drought stress. Acta Physiologiae Plantarum. 36(6), 1491–1499.

Lambri, M., Torchio, F., Colangelo, D., Segade, S. R., Giacosa, S., De Faveri, D. M., Gerbi, V., & Rolle, L. (2015). Influence of different berry thermal treatment conditions, grape anthocyanin profile, and skin hardness on the extraction of anthocyanin compounds in the colored grape juice production. Food Research International, 77, 584–590.

Lorenzini, M., Fracchetti, F., Bolla, V., Stefanelli, E., Rossi, F., & Torriani, S. (2010). Ultraviolet light (UV-C) irradiation as an alternative technology for the control of microorganisms in grape juice and wine. In 33rd World congress of vine and wine, 8th general assembly of the OIV, p 1240.

Lutz, M., Jorquera, K., Cancino, B., Ruby, R., & Henriquez, C. (2011). Phenolics and antioxidant capacity of table grape (Vitis vinifera L.) cultivars grown in Chile. Journal of food science, 76(7), C1088-C1093.

Maione, C., de Paula, E. S., Gallimberti, M., Batista, B. L., Campiglia, A. D., Barbosa, F., Jr., & Barbosa, R. M. (2016). Comparative study of data mining techniques for the authentication of organic grape juice based on ICP-MS analysis. Expert Systems with Applications, 49, 60–73.

Manns, D. C., & Mansfield, A. K. (2012). A core-shell column approach to a comprehensive high-performance liquid chromatography phenolic analysis of Vitis vinifera L. and interspecific hybrid grape juices, wines, and other matrices following either solid phase extraction or direct injection. Journal of Chromatography a, 1251, 111–121.

Margraf, T., Santos, É. N. T., de Andrade, E. F., van Ruth, S. M., & Granato, D. (2016). Effects of geographical origin, variety and farming system on the chemical markers and in vitro antioxidant capacity of Brazilian purple grape juices. Food Research International, 82, 145–155.

Marsellés-Fontanet, Á. R., Puig-Pujol, A., Olmos, P., Mínguez-Sanz, S., & Martín-Belloso, O. (2013). A comparison of the effects of pulsed electric field and thermal treatments on grape juice. Food Bioprocess Technology, 6(4), 978–987.

Mirabelli, M. F., Gionfriddo, E., Pawliszyn, J., & Zenobi, R. (2018). A quantitative approach for pesticide analysis in grape juice by direct interfacing of a matrix compatible SPME phase to dielectric barrier discharge ionization-mass spectrometry. The Analyst, 143(4), 891–899.

Morales-Valle, H., Silva, L. C., Oliveira, J. M., Venancio, A., & Lima, N. (2010). Microextraction and gas chromatography/mass spectrometry for improved analysis of geosmin and other fungal "off’ volatiles in grape juice. Journal of Microbiological Methods, 83(1), 48–52.

Muñoz-Robredo, P., Robledo, P., Manríquez, D., Molina, R., & Defilippi, B. G. (2011). Characterization of sugars and organic acids in commercial varieties of table grapes. Chilean Journal of Agricultural Research, 71(3), 452.

Natividade, M. M. P., Corrêa, L. C., de Souza, S. V. C., Pereira, G. E., & de Oliveira Lima, L. C. (2013). Simultaneous analysis of 25 phenolic compounds in grape juice for HPLC: Method validation and characterization of São Francisco Valley samples. Microchemical Journal, 110, 665–674.

Navrátilová, M., Beranová, M., Severová, L., Šrédl, K., Svoboda, R., & Abrhám, J. (2020). The impact of climate change on the sugar content of grapes and the sustainability of their production in the Czech Republic. Sustainability, 13(1), 222.

Noguerol-Pato, R., González-Álvarez, M., González-Barreiro, C., Cancho-Grande, B., & Simal-Gándara, J. (2013). Evolution of the aromatic profile in Garnacha Tintorera grapes during raisining and comparison with that of the naturally sweet wine obtained. Food Chemistry, 139(1–4), 1052–1061.

Obón, J., Díaz-García, M., & Castellar, M. (2011). Red fruit juice quality and authenticity control by HPLC. Journal of Food Composition Analysis, 24(6), 760–771.

Pala, Ç. U., & Toklucu, A. K. (2013). Effects of UV-C light processing on some quality characteristics of grape juices. Food Bioprocess Technology, 6(3), 719–725.

Paterson, R. R. M., Venâncio, A., Lima, N., Guilloux-Bénatier, M., & Rousseaux, S. (2018). Predominant mycotoxins, mycotoxigenic fungi and climate change related to wine. Food Research International, 103, 478–491.

Perestrelo, R., Silva, C., Silva, P., Medina, S., & Câmara, J. S. (2019). Differentiation of fresh and processed fruit juices using volatile composition. Molecules, 24(5), 974.

Prendes, L. P., Fontana, A. R., Merín, M. G., & D´ Amario Fernández A, Bottini R, Ramirez ML, Morata de Ambrosini VI & nutrition,. (2018). Natural occurrence and production of tenuazonic acid in wine grapes in Argentina. Food Science, 6(3), 523–531.

Prudencio Dutra, Md. C., Rodrigues, L. L., de Oliveira, D., Pereira, G. E., & Lima, Md. S. (2018). Integrated analyses of phenolic compounds and minerals of Brazilian organic and conventional grape juices and wines: Validation of a method for determination of Cu. Fe and Mn. Food Chemistry, 269, 157–165.