Abstract

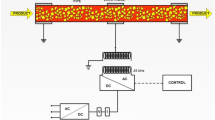

The cost of high pressure processing (HPP) and the environmental impact of pulsed electric fields (PEF), HPP and thermal pasteurization of orange juice were estimated in the US. The cost analysis was based on commercial processing conditions that were validated for a 2-month shelf-life of orange juice under refrigeration conditions. Total electricity consumption was estimated to be 38,100 and 1,000,000 k Wh/year for thermal and HPP processing, respectively. Total pasteurization cost of HPP was estimated to be 10.7 ¢/l for processing 16,500,000 l/year (3,000 l/h). Of this, capital costs accounted for 59 % (6.3 ¢/l), labor costs accounted for 37 % (4.0 ¢/l) and utility charges, mainly electricity, accounted for 4 % (0.4 ¢/l). The total HPP cost was 7-folds higher than that of conventional thermal processing (1.5 ¢/l). The equivalent CO2 emission was 90,000 kg for thermal processing and 700,000 and 773,000 kg for PEF and HPP, respectively. This corresponds to an increase between 7- and 8-folds in comparison to the thermal processing. Increasing the production output by 2- to 6-folds reduced the total production costs of nonthermal processing by 50–75 %. A deeper knowledge of the processing costs and environmental impact of nonthermal technologies will afford companies a better understanding of the benefits and limitations of these novel systems.

Similar content being viewed by others

References

AACE (1990). Conducting technical and economic evaluations in the process and utility industries (pp. 15–26). Morgantown, WV: Association for the Advancement of Cost Engineering.

Babcock & Wilcox Company. (2005). Steam: its generation and use. 41st edition. New York, USA.

Bauman, H. C. (1964). Fundamentals of cost engineering in the chemical industry (pp. 171–180). London: Reinhold Pub. Corp.

Buzrul, S., Alpas, H., Largeteau, A., & Demazeau, G. (2008). Inactivation of Escherichia coli and Listeria innocua in kiwifruit and pineapple juices by high hydrostatic pressure. International Journal of Food Microbiology, 124, 275–278.

Clark, J. P. (2013). Processing and engineering highlights. Food Technology, 67(6), 117–120.

Dalsgaard, H., & Abbotts, A. W. (2003). Improving energy efficiency. In B. Mattson & U. Sonesson (Eds.), Environmentally-friendly food processing (pp. 116–129). Cambridge: Woodhead Publishing Limited.

Deru, M., and Torcellini, P. (2007). Energy and emission factors for energy use in buildings. US Department of Energy, National Renewable Energy Laboratory Technical Report, NREL/TP-550–38617. Colorado, USA.

Garcia-Graells, C., Hauben, K. J. A., & Michiels, C. W. (1998). High-pressure inactivation and sublethal injury of pressure-resistant Escherichia coli mutants in fruit juices. Applied and Environmental Microbiology, 64, 1566–1568.

Gaudreau, M., Hawkey, T., Petry, J., & Kempkes, M. (2005). Solid-state power systems for pulsed electric field (PEF) processing. Pulsed Power Conference, IEEE, 13–17 June 2005 (pp. 1278–1281). CA: Monterey.

Huang, K., & Wang, J. (2009). Designs of pulsed electric fields treatment chambers for liquid foods pasteurization process: a review. Journal of Food Engineering, 95, 227–239.

Jelen, F. C., & Black J. (1983). Cost and optimization engineering. McGraw-Hill Book Company, New York, USA.

Jin, T., & Zhang, Q. H. (2002). Cost evaluation of a commercial scale PEF system. IFT Annual Meeting, technical program 91E-21. CA: Anaheim.

Kempkes, M. A. (2011). Pulsed electric field (PEF) systems for commercial food and juice processing. In C. J. Doona, K. Kustin, & F. E. Feeherry (Eds.), Case studies in novel food processing technologies (pp. 73–102). Cambridge: Woodhead Publishing.

Kozempel, M., McAloon, A., & Yee, W. (1998). The cost of pasteurizing apple cider. Food Technology, 52, 50–52.

Ludikhuyze, L., Van Loey, A., Indrawati, Hendrickx, M. (2002). High pressure processing of fruit and vegetables. In: Fruit and vegetable processing, Ed. Jongen, W.M.F., Woodhead Publishing, pp. 349–362. Cambridge, UK.

Mattson, B., & Sonesson, U. (2003). Introduction. In B. Mattson & U. Sonesson (Eds.), Environmentally-friendly food processing (pp. 1–2). Cambridge: Woodhead Publishing Limited.

Min, S., Jin, Z. T., Min, S. K., Yeom, H., & Zhang, Q. H. (2003a). Commercial-scale pulsed electric field processing of orange juice. Journal of Food Science, 68, 1265–1271.

Min, S., Jin, Z. T., & Zhang, Q. H. (2003b). Commercial scale pulsed electric field processing of tomato juice. Journal of Agricultural and Food Chemistry, 51, 3338–3344.

Mujica-Paz, H., Valdez-Fragoso, A., Tonello, C., Welti-Chanes, J., & Torres, J. A. (2011). High pressure processing technologies for the pasteurization and sterilization of foods. Food and Bioprocess Technology, 4, 969–985.

Pereira, R. N., & Vicente, A. A. (2010). Environmental impact of novel thermal and non-thermal technologies in food processing. Food Research International, 43, 1936–1943.

Rendueles, E., Omer, M. K., Alvseike, O., Alonso-Calleja, C., Capita, R., & Prieto, M. (2011). Microbiological food safety assessment of high hydrostatic pressure processing: a review. LWT--Food Science and Technology, 44, 1251–1260.

Saiz, A. H., Mingo, S. T., Balda, F. P., & Tonello, C. (2008). Advances in design for successful commercial high pressure food processing. Food Australia, 60, 154–156.

Sampedro, F., McAloon, A., Yee, W., Fan, X., Zhang, H. Q., & Geveke, D. J. (2013). Cost analysis of commercial pasteurization of orange juice by pulsed electric fields. Innovative Food Science and Emerging Technologies, 17, 72–78.

Thakur, B. R., & Nelson, P. E. (1998). High-pressure processing and preservation of food. Food Reviews International, 14, 427–447.

Toepfl, S., Mathys, A., Heinz, V., & Knorr, D. (2006). Review: potential of high hydrostatic pressure and pulsed electric fields for energy efficient and environmentally friendly food processing. Food Reviews International, 22, 405–423.

Tonello, C. (2011). Case studies on high-pressure processing of foods, In: Nonthermal processing technologies for food, Ed. Zhang, QH, Barbosa-Cánovas, GV, Balasubramiam, VM, Dunne, CP, Farkas, DF, Yuan, JTC, Wiley-Blackwell, pp. 37–50. New Jersey, USA.

Web of Knowledge, Web of Science Database. (2012). Consulted on 11/14/2012 with keywords of high pressure (NOT liquid chromatography), pulsed electric fields, irradiation, ultrasounds, from 2002–2012 and from articles, book chapters and reviews.

Acknowledgments

The authors are grateful to the Fundación Española para la Ciencia y la Tecnología (FECYT) from Ministerio de Innovación y Ciencia from Spain for providing the postdoctoral grant to Dr. Fernando Sampedro. The authors acknowledge Drs. Tony Jin and Brendan Niemira for their helpful reviews of the final draft. The authors also acknowledge Mr. Joseph Sites for providing technical assistance with the HPP unit and Mr. Michael Kempkes of Diversified Technologies, Inc. (Bedford, MA), Ms. Carole Tonello of Hiperbaric S.A. (Burgos, Spain) and Mr. Nick de Pinto of Avure Technologies (Franklin, TN) for their valuable data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sampedro, F., McAloon, A., Yee, W. et al. Cost Analysis and Environmental Impact of Pulsed Electric Fields and High Pressure Processing in Comparison with Thermal Pasteurization. Food Bioprocess Technol 7, 1928–1937 (2014). https://doi.org/10.1007/s11947-014-1298-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1298-6