Abstract

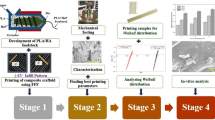

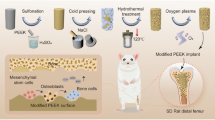

Poly-ether-ether-ketone (PEEK) has evolved to be the preferred biomaterial for orthopedic implants; however, its bioinert nature significantly limits its osseointegration property. Porous PEEK implants can effectively promote osseointegration, yet pores also decrease the scaffold’s load-bearing capacity. Hence, it is critical to developing an optimum pore-sized scaffold with favorable mechanical properties. In this study, we used 3D printing to develop PEEK scaffolds with precise pores ranging from 100 µm to 600 µm. We first experimentally determined the scaffolds’ compressive properties and then used finite element analysis (FEA) to investigate the scaffolds’ stress distribution and failure modes. Results indicate that 3D-printed PEEK with 300-µm pore size exhibits the highest yield compressive strength, and increasing the pore size beyond that would decrease the specimen’s yield strength. Furthermore, FEA denoted that the stress distribution is the maximum in the scaffold core along the longitudinal axis under compressive load and less on the scaffold’s outer shell. Finally, buckling simulation results confirmed that the specimens fail according to the second buckling mode with two curvatures, similar to the real-time experimental results. Our studies suggest that 3D-printed PEEK specimens with 300-µm pore sizes exhibit the best compressive yield strength suitable for orthopedic applications.

Similar content being viewed by others

References

J.B. Rose, Discovery and development of the “Victrex” Polyaryletherketone PEEK, in High performance polymers: their origin and development (Springer, Berlin, 1986), pp. 187–193.

R.B. Rigby, Polyetheretherketone, in Engineering thermoplastics (CRC Press, Cambrigde, 2020), pp. 299–314.

S.M. Kurtz and J.N. Devine, Biomaterials 28, 4845 (2007).

A. Bhattacharjee, A. Gupta, M. Verma, P.A. Murugan, P. Sengupta, S. Matheshwaran, I. Manna, and K. Balani, Ceram. Int. 45, 12225 (2019).

A. Bhattacharjee, R. Hassan, A. Gupta, M. Verma, P.A. Murugan, P. Sengupta, M. Saravanan, I. Manna, and K. Balani, J. Am. Ceram. Soc. 103, 4090 (2020).

J.-H. Chen, C. Liu, L. You, and C.A. Simmons, J. Biomech. 43, 108 (2010).

M. Niinomi, Mater. Sci. Eng., A 243, 231 (1998).

Y. Noyama, T. Miura, T. Ishimoto, T. Itaya, M. Niinomi, and T. Nakano, Mater. Trans. 53, 565 (2012).

W.T. Lee, J.Y. Koak, Y.J. Lim, S.K. Kim, H.B. Kwon, and M.J. Kim, J Biomed Mater Res Part B Appl Biomater 100, 1044 (2012).

C.S. Li, C. Vannabouathong, S. Sprague, M. Bhandari, Clinical Medicine Insights: Arthritis and Musculoskeletal Disorders 8 (2015) CMAMD-S20354.

A. Alnazzawi, J Int Soc Prevent Commun Dentistry 8, 93 (2018).

B. Di Maggio, P. Sessa, P. Mantelli, P. Maniscalco, F. Rivera, G.M. Calori, L. Bisogno, G. Scaravilli, and M. Caforio, Injury 48, S34 (2017).

P. Sikder, J.A. Ferreira, E.A. Fakhrabadi, K.Z. Kantorski, M.W. Liberatore, M.C. Bottino, and S.B. Bhaduri, Dent. Mater. 36, 865 (2020).

S. Najeeb, Z. Khurshid, J.P. Matinlinna, F. Siddiqui, M.Z. Nassani, and K. Baroudi, Int J Dent 2015, 1–7 (2015).

F. Rahmitasari, Y. Ishida, K. Kurahashi, T. Matsuda, M. Watanabe, and T. Ichikawa, Dent J 5, 35 (2017).

Y. Ren, P. Sikder, B. Lin, and S.B. Bhaduri, Mater. Sci. Eng., C 85, 107 (2018).

P. Sikder, C.R. Grice, B. Lin, V.K. Goel, and S.B. Bhaduri, ACS Biomater. Sci. Eng. 4, 2767 (2018).

J.H. Lee, H.L. Jang, K.M. Lee, H.-R. Baek, K. Jin, K.S. Hong, J.H. Noh, and H.-K. Lee, Acta Biomater. 9, 6177 (2013).

S. Stübinger, A. Drechsler, A. Bürki, K. Klein, P. Kronen, and B. von Rechenberg, J Biomed Mater Res Part B: Appl Biomater 104, 1182 (2016).

W. Wang, C.J. Luo, J. Huang, and M. Edirisinghe, J. R. Soc. Interf 16, 20180955 (2019).

H. Zhou, V.K. Goel, and S.B. Bhaduri, Mater. Lett. 125, 96 (2014).

K. Gan, H. Liu, L. Jiang, X. Liu, X. Song, D. Niu, T. Chen, and C. Liu, Dent. Mater. 32, e263 (2016).

D. Briem, S. Strametz, K. Schröoder, N.M. Meenen, W. Lehmann, W. Linhart, A. Ohl, and J.M. Rueger, J. Mater. Sci. - Mater. Med. 16, 671 (2005).

A. Xu, X. Liu, X. Gao, F. Deng, Y. Deng, and S. Wei, Mater. Sci. Eng., C 48, 592 (2015).

X. Wu, X. Liu, J. Wei, J. Ma, F. Deng, and S. Wei, Int. J. Nanomed. 7, 1215 (2012).

R.S. Brum, P.R. Monich, F. Berti, M.C. Fredel, L.M. Porto, C.A.M. Benfatti, and J.C.M. Souza, Mater. Chem. Phys. 223, 542 (2019).

M. Fedel, T.T. Wong, G. Speranza, B. Lohberger, M. Nogler, and F. Awaja, Surf. Coat. Technol. 374, 95 (2019).

R.A. Surmenev, Surf. Coat. Tech. 206, 2035 (2012).

M.S.A. Bakar, M.H.W. Cheng, S.M. Tang, S.C. Yu, K. Liao, C.T. Tan, K.A. Khor, and P. Cheang, Biomaterials 24, 2245 (2003).

N. Abbasi, S. Hamlet, R.M. Love, and N.-T. Nguyen, J Sci: Adv Mater Devic 5, 1 (2020).

V. Karageorgiou and D. Kaplan, Biomaterials 26, 5474 (2005).

K. Elhattab, S.B. Bhaduri, J.G. Lawrence, and P. Sikder, ACS Appl. Bio Mater. 4, 3276 (2021).

X.P. Tan, Y.J. Tan, C.S.L. Chow, S.B. Tor, and W.Y. Yeong, Mater. Sci. Eng., C 76, 1328 (2017).

K. Elhattab, P. Sikder, J.M. Walker, M.C. Bottino, and S.B. Bhaduri, Mater. Lett. 263, 127227 (2020).

Y. Su, J. He, N. Jiang, H. Zhang, L. Wang, X. Liu, D. Li, and Z. Yin, Mater. Des. 191, 108671 (2020).

H. Spece, T. Yu, A.W. Law, M. Marcolongo, and S.M. Kurtz, J. Mech. Behav. Biomed. Mater. 109, 103850 (2020).

X. Feng, L. Ma, H. Liang, X. Liu, J. Lei, W. Li, K. Wang, Y. Song, B. Wang, and G. Li, ACS Omega 5, 26655 (2020).

Z. Liu, M. Zhang, Z. Wang, Y. Wang, W. Dong, W. Ma, S. Zhao, and D. Sun, Compos. B Eng. 230, 109512 (2022).

S.H. Oh, I.K. Park, J.M. Kim, and J.H. Lee, Biomaterials 28, 1664 (2007).

S. Ishihara, A.J. McEvily, T. Goshima, K. Kanekasu, and T. Nara, J. Mater. Sci. - Mater. Med. 11, 661 (2000).

M. Vaezi and S. Yang, Virtual and Physical Prototyping 10, 123 (2015).

A. Standard, ASTM International, West Conchohocken (2008).

I. Maskery, N.T. Aboulkhair, A.O. Aremu, C.J. Tuck, and I.A. Ashcroft, Addit. Manuf. 16, 24 (2017).

B. Xu, K.-W. Lee, W. Li, M.J. Yaszemski, L. Lu, Y. Yang, and S. Wang, Mater. Des. 211, 110150 (2021).

C. Yang, X. Tian, D. Li, Y. Cao, F. Zhao, and C. Shi, J. Mater. Process. Technol. 248, 1 (2017).

M.C. Sobieraj and C.M. Rimnac, Fracture fatigue and notch behavior of PEEK, in PEEK biomaterials handbook (Elsevier, Armsterdam, 2019).

E.F. Morgan, G.U. Unnikrisnan, and A.I. Hussein, Annu. Rev. Biomed. Eng. 20, 119 (2018).

W. Wu, P. Geng, G. Li, D. Zhao, H. Zhang, and J. Zhao, Materials 8, 5834 (2015).

P. Geng, J. Zhao, W. Wu, W. Ye, Y. Wang, S. Wang, and S. Zhang, J. Manuf. Process. 37, 266 (2019).

P. Wang, B. Zou, H. Xiao, S. Ding, and C. Huang, J. Mater. Process. Technol. 271, 62 (2019).

F.J.Q. Gonzalez and N. Nuno, Biomater Biomech Bioeng 3, 1 (2016).

G. Campoli, M.S. Borleffs, S.A. Yavari, R. Wauthle, H. Weinans, and A.A. Zadpoor, Mater. Des. 49, 957 (2013).

N. Soro, L. Brassart, Y. Chen, M. Veidt, H. Attar, and M.S. Dargusch, Mater. Sci. Eng., A 725, 43 (2018).

H. Shen and L.C. Brinson, Int. J. Solids Struct. 44, 320 (2007).

A. Maiti, W. Small, J.P. Lewicki, T.H. Weisgraber, E.B. Duoss, S.C. Chinn, M.A. Pearson, C.M. Spadaccini, R.S. Maxwell, and T.S. Wilson, Sci. Rep. 6, 1 (2016).

Q. Li, W. Zhao, Y. Li, W. Yang, and G. Wang, Polymers 11, 656 (2019).

Acknowledgements

P. Sikder acknowledges his start-up Grant No. STARTUP06 at Cleveland State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gummadi, S.K., Saini, A., Owusu-Danquah, J.S. et al. Mechanical Properties of 3D-Printed Porous Poly-ether-ether-ketone (PEEK) Orthopedic Scaffolds. JOM 74, 3379–3391 (2022). https://doi.org/10.1007/s11837-022-05361-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05361-6