Abstract

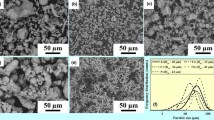

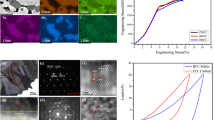

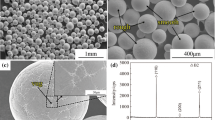

W6Mo5Cr4V2Co5Nb (825 K) alloy was prepared by a two-step sintering process from overspray 825 K alloy powder. The overspray powder characteristics and the microstructure and mechanical properties of the as-sintered 825 K alloy were investigated. Results showed that two types of carbides formed a network structure in the overspray powder, which had spherical or quasispherical shape: one was MC carbide that was rich in vanadium (V), and the other was M2C carbide enriched with vanadium (V) and tungsten (W). The sintered 825 K alloy contained M6C and MC carbides, of which M6C was rich in tungsten (W) and molybdenum (Mo), and both of these two carbides were uniformly distributed in the alloy matrix. The alloy had relative density of 98.43%, hardness of HRC 51.8, and superior bending strength of 2042 MPa. These mechanical properties can meet the requirements of most engineering applications.

Similar content being viewed by others

References

Y.H. Moon, J.W. Kim, and D.W. Lee, J. Mater. Process. Technol. 153, 654 (2004).

L. Westin and H. Wisell, Scand. J. Metall. 25, 41 (1996).

P. Hellman, Scand. J. Metall. 27, 44 (1998).

L. Lu, L.G. Hou, H. Cui, J.F. Huang, Y.A. Zhang, and J.S. Zhang, J. Iron. Steel Res. Int. 23, 501 (2016).

L. Lu, L.G. Hou, J.X. Zhang, H.B. Wang, H. Cui, J.F. Huang, Y.A. Zhang, and J.S. Zhang, Mater. Charact. 117, 1 (2016).

H.B. Wang, L.G. Hou, J.X. Zhang, L. Lu, H. Cui, and J.S. Zhang, Mater. Charact. 106, 245 (2015).

M. Saravanan, B. Sivaiah, A.K. Srivastava, and A. Dhar, Mater. Des. 60, 21 (2014).

R.A. Mesquita and C.A. Barbosa, Mater. Sci. Eng., A 383, 87 (2004).

Q.Y. Chu, P. Wang, G.K. He, M.D. Li, H.J. Zhu, R. Liu, and F.B. Pei, Chem. Eng. J. 325, 169 (2017).

G.Q. Zhang, H. Yuan, D.L. Jiao, Z. Li, Y. Zhang, and Z.W. Liu, Mater. Sci. Eng., A 558, 566 (2012).

N. Raghukiran and R. Kumar, J. Mater. Process. Technol. 213, 401 (2013).

A. Schulz, V. Uhlenwinkel, C. Escher, R. Kohlmann, A. Kulmburg, M.C. Montero, R. Rabitsch, W. Schützenhöferf, D. Stocchi, and D. Viale, Mater. Sci. Eng., A 477, 69 (2008).

Y. Yang and S.P. Hannula, Mater. Sci. Eng., A 477, 63 (2008).

V.C. Srivastava, P. Ghosal, and S.N. Ojha, Mater. Lett. 56, 797 (2002).

V.C. Srivastava, R.K. Mandal, S.N. Ojha, and K. Venkateswarlu, Mater. Sci. Eng., A 471, 38 (2007).

C.R.M. Afonso, C. Bolfarini, W.J. Botta Filho, and C.S. Kiminami, Mater. Sci. Eng., A 449, 884 (2007).

X.F. Zhou, F. Fang, J.Q. Jiang, W.L. Zhu, and H.X. Xu, Mater. Sci. Technol. 1499, 28 (2012).

R.M. German, Metall. Mater. Trans. A 28, 1553 (1997).

Q.X. Liu, D.P. Lu, L. Lu, Q. Hu, Q.F. Fu, and Z. Zhou, J. Iron. Steel Res. Int. 22, 245 (2015).

Acknowledgements

This research is sponsored by the National High Technology Research and Development Program of China (863 Program) under Grant No. 2012AA03A509 and the National Natural Science Foundation of China (No. 51204015).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Pi, Z., Lu, X., Yang, F. et al. Particle Characteristics and Densification of W6Mo5Cr4V2Co5Nb Overspray Powder. JOM 70, 2224–2229 (2018). https://doi.org/10.1007/s11837-018-2926-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2926-9