Abstract

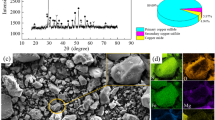

Due to stringent environmental requirements and the complex occurrence of valuable metals, traditional pyrometallurgical methods are unsuitable for treating low-grade nickel-copper matte. A clean and sustainable two-stage sulfating roasting and water-leaching process was used to simultaneously extract valuable metals from low-grade nickel-copper matte. Ammonium and sodium sulfate were used as sulfating agents. The first roasting temperature, mass ratio of ammonium sulfate to matte, roasting time, dosage of sodium sulfate, second roasting temperature and leaching temperature were studied. Under optimal conditions, 98.89% of Ni, 97.48% of Cu and 95.82% of Co, but only 1.34% of Fe, were extracted. X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to reveal the sulfating mechanism during the roasting process.

Similar content being viewed by others

References

A.E. Warner, C. Diaz, A. Dalvi, P. Mackey, A. Tarasov, and R. Jones, JOM-US 59, 58 (2007).

K.-H. Park, D. Mohapatra, B.R. Reddy, and C.W. Nam, Hydrometallurgy 86, 164 (2007).

J. Provis, J. Van Deventer, J. Rademan, and L. Lorenzen, Hydrometallurgy 70, 83 (2003).

R. Van Schalkwyk, J. Eksteen, J. Petersen, E. Thyse, and G. Akdogan, Miner. Eng. 24, 524 (2011).

K.H. Park, D. Mohapatra, and B.R. Reddy, Sep. Purif. Technol. 51, 332 (2006).

Y. Fu, B.-c. Li, C.-i. Fan, X.-j. Zhai, X.-j. Zhang, and D.-h. Li, Trans. Nonferr. Metal. Soc. 20, s71–s76 (2010).

K.H. Park, D. Mohapatra, K. Hong-In, and G. Xueyi, Sep. Purif. Technol. 56, 303 (2007).

R. Berezowsky, M. Collins, D. Kerfoot, and N. Torres, JOM-US 43, 9 (1991).

I.K. Thege, Thermochim. Acta 60, 149 (1983).

R.V. Siriwardane, J.A. Poston Jr., E.P. Fisher, M.-S. Shen, and A.L. Miltz, Appl. Surf. Sci. 152, 219 (1999).

H. Tagawa, Thermochim. Acta 80, 23 (1984).

M. Jiang, T. Sun, Z. Liu, J. Kou, N. Liu, and S. Zhang, Inter. J. Miner. Process. 123, 32 (2013).

J.E. Hoffmann, JOM-US 41, 33 (1989).

P. Distin, JOM-US 30, 30 (1978).

M. Liu, Z. You, Z. Peng, X. Li, and G. Li, JOM-US 68, 567 (2016).

Q. Li, J.-j. Hu, Y.-b. Yang, B. Xu, T. Jiang, Mechanism of Na2SO4 on Refractory Gold Concentrate at Roasting Pretreatment. In Drying, Roasting, and Calcining of Minerals. Springer; 2015: 59.

K. Luthra, Metall. Mater. Trans. A 13, 1647 (1982).

C. Smeaton (Electronic Theses and Dissertations, 2012), p. 450.

A.J. Monhemius, G. Thorsen, in Proc. Int. Solvent Extr. Conf. ISEC’80, Liege, Belgium, 1980, Vol. 3, paper 80-91.

R. Zboril, M. Mashlan, D. Krausova, The Mechanism of β-Fe2O3 Formation by Solid-State Reaction between NaCl and Fe2(SO4)3, in Mössbauer Spectroscopy in Materials Science (Springer, 1999), p. 49.

G. Kolta and M. Askar, Thermochim. Acta 11, 65 (1975).

D. Lindberg, R. Backman, and P. Chartrand, J. Chem. Thermodyn. 38, 1568 (2006).

D. Yu, T.A. Utigard, and M. Barati, Metall. Mater. Trans. B 45, 662 (2014).

K. Jacob and G. Iyengar, Metall. Trans. B 17, 323 (1986).

Acknowledgements

This research was jointly supported by the National Basic Research Program of China (Grant 2014CB643405), National Natural Science Foundation of China (Grant 51204036), Program for Top Young Talents of Higher Education Institutions of Hebei Province (Grant BJ201604), Fundamental Research Funds for the Central Universities (Grant N152304010) and Hebei Province Natural Science Fund (Grant E2017501073).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cui, F., Mu, W., Wang, S. et al. A Sustainable and Selective Roasting and Water-Leaching Process to Simultaneously Extract Valuable Metals from Low-Grade Ni-Cu Matte. JOM 70, 1977–1984 (2018). https://doi.org/10.1007/s11837-018-2798-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2798-z