Abstract

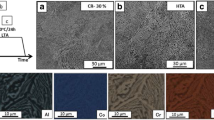

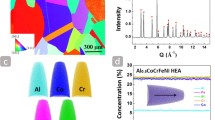

Compression behavior of the Al0.5CoCrCuFeNi high-entropy alloy (HEA) was studied at different temperatures from 673 K to 873 K at a low strain rate of 5 × 10−5/s to investigate the temperature effect on the mechanical properties and serration behavior. The face-centered-cubic (fcc) structure is confirmed at the lower temperature of 673 K and 773 K, and a structure of mixed fcc and body-centered cubic (bcc) is identified at a higher temperature of 873 K after compression tests using high-energy synchrotron x-ray diffraction. By comparing the stress–strain curves at different temperatures, two opposite directions of serrations types were found, named upward serrations appearing at 673 K and 773 K and downward serrations at 873 K, which may be due to dynamic strain aging.

Similar content being viewed by others

Reference

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

J.-W. Yeh, S.-Y. Chang, Y.-D. Hong, S.-K. Chen, and S.-J. Lin, Mater. Chem. Phys. 103, 41 (2007).

M. Gao and D. Alman, Entropy 15, 4504 (2013).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater Sci. 61, 1 (2014).

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J. Weber, J.C. Neuefeind, Z. Tang, and P.K. Liaw, Nat. Commun. 6, 5964 (2015).

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Acta Mater. 81, 428 (2014).

K.M. Youssef, A.J. Zaddach, C. Niu, D.L. Irving, and C.C. Koch, Mater. Res. Lett. 3, 95 (2014).

A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, and W. Zhang, JOM 66, 1984 (2014).

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, and P.K. Liaw, Acta Mater. 60, 5723 (2012).

Z.N. An, H.L. Jia, Y.Y. Wu, P.D. Rack, A.D. Patchen, Y.Z. Liu, Y. Ren, N. Li, and P.K. Liaw, Mater. Res. Lett. 1 (2015).

C.P. Lee, Y.Y. Chen, C.Y. Hsu, J.W. Yeh, and H.C. Shih, J. Electrochem. Soc. 154, C424 (2007).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, Science 345, 1153 (2014).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2012).

C.-J. Tong, M.-R. Chen, S.-K. Chen, J.-W. Yeh, T.-T. Shun, S.-J. Lin, and S.-Y. Chang, Metall. Mater. Trans. A 36A, 1263 (2005).

J. Antonaglia, X. Xie, Z. Tang, C.W. Tsai, J.W. Qiao, Y. Zhang, M.O. Laktionova, E.D. Tabachnikova, J.W. Yeh, O.N. Senkov, M.C. Gao, J.T. Uhl, P.K. Liaw, and K.A. Dahmen, JOM 66, 2002 (2014).

T. Takasugi, H. Honjo, Y. Kaneno, and H. Inoue, Acta Mater. 50, 847–855 (2002).

X.J. Yu and K.S. Kumar, Int. J. Refract. Met. Hard Mater. 41, 329 (2013).

J. Antonaglia, X. Xie, G. Schwarz, M. Wraith, J. Qiao, Y. Zhang, P.K. Liaw, J.T. Uhl, and K.A. Dahmen, Sci. Rep. 4, 4382 (2014).

J.W. Qiao, F.Q. Yang, G.Y. Wang, P.K. Liaw, and Y. Zhang, Scripta Mater. 63, 1081 (2010).

J.W. Qiao, Y. Zhang, and P.K. Liaw, Intermetallics 18, 2057 (2010).

J.W. Qiao, H.L. Jia, Y. Zhang, P.K. Liaw, and L.F. Li, Mater. Chem. Phys. 136, 75 (2012).

Y. Cao, X. Xie, J. Antonaglia, B. Winiarski, G. Wang, Y.C. Shin, P.J. Withers, K.A. Dahmen, and P.K. Liaw, Sci. Rep. 5, 10789 (2015).

H.L. Jia, L.L. Zheng, W.D. Li, N. Li, J.W. Qiao, G.Y. Wang, Y. Ren, P.K. Liaw, and Y. Gao, Metall. Mater. Trans. A 46, 2431 (2015).

T. Burgess, K.J. Laws, and M. Ferry, Acta Mater. 56, 4829 (2008).

I.S. Kim and M.C. Chaturvedi, Mater. Sci. Eng. 37, 165 (1979).

S.A. Nalawade, M. Sundararaman, R. Kishore, and J.G. Shah, Scripta Mater. 59, 991 (2008).

L.J. Meng, J. Sun, H. Xing, and G.W. Pang, J. Nucl. Mater. 394, 34 (2009).

S.Y. Chen, X. Yang, K. Dahmen, P.K. Liaw, and Y. Zhang, Entropy 16, 870 (2014).

M.C. Cai, L.S. Niu, T. Yu, H.J. Shi, and X.F. Ma, Mater. Sci. Eng. A 527, 5175 (2010).

V. Shankar, M. Valsan, K. Bhanu Sankara Rao, and S.L. Mannan, Metall. Mater. Trans. A 35A, 3129 (2004).

D. Thevenet, M. Mliha-Touati, and A. Zeghloul, Mater. Sci. Eng. A A266, 175 (1999).

P.G. McCormick, Philos. Mag. 23, 949 (1971).

C.-J. Tong, Y.-L. Chen, S.-K. Chen, J.-W. Yeh, T.-T. Shun, C.-H. Tsau, S.-J. Lin, and S.-Y. Chang, Metall. Mater. Trans. A 236A, 881 (2005).

C.-W. Tsai, Y.-L. Chen, M.-H. Tsai, J.-W. Yeh, T.-T. Shun, and S.-K. Chen, J. Alloys Compd. 486, 427 (2009).

K. Prasad and V.K. Varma, Mater. Sci. Eng. A 486, 158 (2008).

S. Fu, T. Cheng, Q. Zhang, Q. Hu, and P. Cao, Acta Mater. 60, 6650 (2012).

K. Zhang and Z. Fu, Intermetallics 28, 34 (2012).

A.V.D. Beukel and U.F. Kocks, Acta Metall. 30, 1027 (1982).

L.P. Kubin and Y. Estrin, Phys. Stat. Sol. 172, 173 (1992).

P.G. McCormick, Acta Metall. 20, 351 (1972).

P. Rodriguez, Bull. Mater. Sci. 6, 653 (1984).

Acknowledgements

The National Science Foundation (DMR-0909037, CMMI-0900291 and CMMI-1100080), the Department of Energy Office of Nuclear Energy’s Nuclear Energy University Programs (NEUP, Grant 00119262), and the DOE Office of Fossil Energy, NETL (DE-FE0008855, DE-FE-0024054, and DE-FE-0011194), with Drs. C.V. Cooper, A. Ardell, Z.M. Taleff, R.O. Jenseng Jr., L. Tian, V. Cedro, R. Dumt, S. Lesica, S. Markovich, and J. Mullen as program managers, provided additional funding, particularly for K.A.D. at University of Illinois at Urbana Champaign and S.C., X.X., and P.K.L. at The University of Tennessee. X.X. and P.K.L. very much appreciates the support from the U.S. Army Office Project (W911NF-13-1-0438) with the program managers, Drs. S.N. Mathaudhu and D.M. Stepp. J.W.Q. would like to acknowledge the financial support of the Youth Natural Science Foundation of Shanxi Province, China (No. 2015021005). The current research used resources of the Advanced Photon Source, a U.S. Department of Energy Office of Science User Facility operated for the DOE Office of Science by the Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Y.Z. appreciates the financial support of the National High Technology Research and Development Program of China (No. 2009AA03Z113) and the National Science Foundation of China (Nos. 51471025 and 51210105006), 111 Project (B07003), and the Program for Changjiang Scholars and the Innovative Research Team of the University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S., Xie, X., Chen, B. et al. Effects of Temperature on Serrated Flows of Al0.5CoCrCuFeNi High-Entropy Alloy. JOM 67, 2314–2320 (2015). https://doi.org/10.1007/s11837-015-1580-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1580-8