Abstract

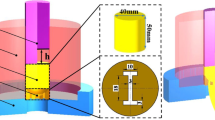

The hot rolling experiment of AZ31 magnesium alloy was carried out by laying anoverlay mold at the initial temperature of 400 °C. According to the Mizushima automatic plan view pattern control system (MAS) rolling theory and the cross rolling process, different reductions in the middle and edges of the magnesium alloy were realized, and the influence of the regional controlled reduction rolling on the edge cracks and microstructure gradient of the magnesium alloy were analyzed. It is shown that this rolling approach has reduced the maximum edge crack depth of the rolled piece by 56.85%, and there is a weakening tendency in the base surface texture of the strip edge, the base surface texture density drops from 23.97 to 17.48 after ordinary flat rolling. It exhibits basal texture gradients from the edge to the middle of the sheet along the RD direction, which reflected the uneven deformation of the sheets. It is suitable for the processing of metal molds that require large edge reductions such as mobile phone shells, and provided a theoretical basis for the variable thickness rolling of the magnesium alloy strip.

摘要

在400 °C初始温度下, 将AZ31镁合金置于衬板模具上进行热轧实验. 根据MAS轧制理论和交 叉轧制工艺, 实现镁合金边部和中部区域的不同压下量轧制, 分析分区域控制压下率轧制对镁合金边 裂和组织梯度的影响. 结果表明, 这种轧制方法使轧件的最大边缘裂纹深度减小了56.85%, 并且板带 边部的基面织构呈现弱化的趋势, 其基面织构强度从普通平轧时的23.97 下降到17.48. 沿RD方向从 板带边部到中部呈现出一定的组织梯度, 反映了轧板的不均匀变形. 这种轧制方法适用于如手机壳等 需要进行边部大压下量的金属模具的加工过程, 并为镁合金板带的变厚度轧制过程提供了理论依据.

Similar content being viewed by others

References

CHU Chen-liang, WU Xiao-quan, QIU Shui-cai, et al. Microstructure and Gd-rich phase evolution of as-cast AZ31-xGd magnesium alloys during semi-solid isothermal heat treatment [J]. Journal of Central South University, 2021, 28(1): 1–15. DOI:https://doi.org/10.1007/s11771-020-4504-x.

XU Tian-cai, YANG Yan, PENG Xiao-dong, et al. Overview of advancement and development trend on magnesium alloy [J]. Journal of Magnesium and Alloys, 2019, 7(3): 536–544. DOI:https://doi.org/10.1016/j.jma.2019.08.001.

LIU Hong-guang, CAO Fu-yong, SONG Guang-ling, et al. Review of the atmospheric corrosion of magnesium alloys [J]. Journal of Materials Science & Technology, 2019, 35(9): 2003–2016. DOI:https://doi.org/10.1016/j.jmst.2019.05.001.

HAN Ting-zhuang, HUANG Guang-sheng, WANG Li-fei, et al. Evolution of microstructure and formability of AZ31 Mg alloy sheets processed by continuous bending with various accumulated strains [J]. Rare Metal Materials and Engineering, 2020(1): 21–26. (in Chinese)

JIA Wei-tao, LE Qi-chi. Heat-transfer analysis of AZ31B Mg alloys during single-pass flat rolling: Experimental verification and mathematical modeling [J]. Materials & Design, 2017, 121: 288–309. DOI: https://doi.org/10.1016/j.matdes.2017.02.079.

DING Yun-peng, LE Qi-chi, ZHANG Zhi-qiang, et al. Effect of vertical rolling at various temperatures on subsequent multi-pass severe rolling of AZ31B alloy sheet [J]. Journal of Materials Processing Technology, 2013, 213(12): 2101–2108. DOI:https://doi.org/10.1016/j.jmatprotec.2013.06.005.

WEI Jian-chun, HUANG Qing-xue, HUANG Zhi-quan, et al. Variable gauge rolling impact on the edge damage of AZ31 magnesium alloy sheets [J]. Rare Metal Materials and Engineering, 2018, 47(2): 652–656. (in Chinese)

ZHANG Hua, HUANG Guang-sheng, ROVEN H J, et al. Influence of different rolling routes on the microstructure evolution and properties of AZ31 magnesium alloy sheets [J]. Materials & Design, 2013, 50: 667–673. DOI: https://doi.org/10.1016/j.matdes.2013.03.053.

LIU Di, LIU Zu-yan, WANG Er-de. Effect of rolling reduction on microstructure, texture, mechanical properties and mechanical anisotropy of AZ31 magnesium alloys [J]. Materials Science and Engineering A, 2014, 612: 208–213. DOI:https://doi.org/10.1016/j.msea.2014.06.034.

ZHI Chen-chen, MA Li-feng, HUANG Qing-xue, et al. Improvement of magnesium alloy edge cracks by multi-cross rolling [J]. Journal of Materials Processing Technology, 2018, 255: 333–339. DOI:https://doi.org/10.1016/j.jmatprotec.2017.12.022.

GUO Fei, ZHANG Ding-fei, YANG Xu-sheng, et al. Effect of rolling speed on microstructure and mechanical properties of AZ31 Mg alloys rolled with a wide thickness reduction range [J]. Materials Science and Engineering A, 2014, 619: 66–72. DOI:https://doi.org/10.1016/j.msea.2014.09.024.

GUO Fei, ZHANG Ding-fei, YANG Xu-sheng, et al. Influence of rolling speed on microstructure and mechanical properties of AZ31 Mg alloy rolled by large strain hot rolling [J]. Materials Science and Engineering A, 2014, 607: 383–389. DOI:https://doi.org/10.1016/j.msea.2014.04.024.

JIA Wei-tao, LE Qi-chi, TANG Yan, et al. Role of prevertical compression in deformation behavior of Mg alloy AZ31B during super-high reduction hot rolling process [J]. Journal of Materials Science & Technology, 2018, 34(11): 2069–2083. DOI:https://doi.org/10.1016/j.jmst.2018.04.005.

HUANG Zhi-quan, HUANG Qing-xue, WEI Jian-chun, et al. Inhibitory effects of prefabricated crown on edge crack of rolled AZ31 magnesium alloy plate [J]. Journal of Materials Processing Technology, 2017, 246: 85–92. DOI: https://doi.org/10.1016/j.jmatprotec.2017.01.034.

XIE Zhen-dong, GUAN Yan-jin, YU Xiao-hui, et al. Effects of ultrasonic vibration on performance and microstructure of AZ31 magnesium alloy under tensile deformation [J]. Journal of Central South University, 2018, 25(7): 1545–1559. DOI:https://doi.org/10.1007/s11771-018-3847-z.

ZHANG Ding-fei, DAI Qing-wei, FANG Lin, et al. Prediction of edge cracks and plastic-damage analysis of Mg alloy sheet in rolling [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 1112–1117. DOI: https://doi.org/10.1016/S1003-6326(11)60829-7.

DING Yun-peng, LE Qi-chi, ZHANG Zhi-qiang, et al. Effect of rolling speed on microstructure and mechanical properties of as-cast AZ31B alloy under different reduction schedules [J]. Journal of Materials Processing Technology, 2016, 233: 161–173. DOI:https://doi.org/10.1016/j.jmatprotec.2016.02.023.

WANG Hui-yuan, FENG Ting-ting, ZHANG Lei, et al. Achieving a weak basal texture in a Mg-6Al-3Sn alloy by wave-shaped Die rolling [J]. Materials & Design, 2015, 88: 157–161. DOI:https://doi.org/10.1016/j.matdes.2015.08.154.

SUN Zheng, WU Yang, XIN Yun-chang, et al. Varying the strong basal texture in a Mg-3Al-1Zn plate by a new wave-shaped interface rolling [J]. Materials Letters, 2018, 213: 151–153. DOI:https://doi.org/10.1016/j.matlet.2017.11.032.

WANG Jin-hui, JIN Pei-peng, LI Xiao-qiang, et al. Effect of rolling with different amounts of deformation on microstructure and mechanical properties of the Mg-1Al-4Y alloy [J]. Materials Characterization, 2020, 161: 110149. DOI:https://doi.org/10.1016/j.matchar.2020.110149.

NUGMANOV D, KNEZEVIC M, ZECEVIC M, et al. Origin of plastic anisotropy in (ultra)-fine-grained Mg-Zn-Zr alloy processed by isothermal multi-step forging and rolling: Experiments and modeling [J]. Materials Science and Engineering A, 2018, 713: 81–93. DOI: https://doi.org/10.1016/j.msea.2017.12.045.

JI Ya-feng, DUAN Jin-rui, LI Hua-ying, et al. Improvement of edge crack damage of magnesium alloy by optimizing the edge curve during cross variable thickness rolling [J]. The International Journal of Advanced Manufacturing Technology, 2021, 112(7, 8): 1993–2002. DOI: https://doi.org/10.1007/s00170-020-06517-x.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Project(52005358) supported by the National Natural Science Foundation of China; Projects(201901D111243, 201901D111241) supported by the Natural Science Foundation of Shanxi Province, China; Project(2019-KF-25-05) supported by the Natural Science Foundation of Liaoning Province, China

Contributors

The overarching research goals were developed by JI Ya-feng and DUAN Jin-rui. JI Ya-feng and DUAN Jin-rui conducted the physics experiment. DUAN Jin-rui and YUAN Hao established the numerical model. DUAN Jin-rui analyzed the research results. The initial draft of the manuscript was written by DUAN Jin-rui. JI Ya-feng, LI Hua-ying, SUN Jie and MA Li-feng reviewed and edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ji, Yf., Duan, Jr., Yuan, H. et al. Effect of variable thickness cross rolling on edge crack and microstructure gradient of AZ31 magnesium alloy. J. Cent. South Univ. 29, 1124–1132 (2022). https://doi.org/10.1007/s11771-022-4973-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4973-1