Abstract

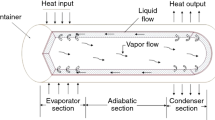

Nanotechnology is widely used in heat transfer devices to improve thermal performance. Nanofluids can be applied in heat pipes to decrease thermal resistance and achieve a higher heat transfer capability. In the present article, a comprehensive literature review is performed on the nanofluids’ applications in heat pipes. Based on reviewed studies, nanofluids have a high capacity to boost the thermal behavior of various types of heat pipes such as conventional heat pipes, pulsating heat pipes, and thermosyphons. Besides, it is observed that there must be a selected amount of concentration for the high-performance utilization of nanoparticles; high concentration of nanoparticles causes a higher thermal resistance which is mainly attributed to increment in the dynamic viscosity and the higher possibility of particles’ agglomeration. Enhancement in heat transfer performance is the result of increasing in nucleation sites and the intrinsically greater nanofluids’ thermal conductivity.

摘要

纳米技术被广泛应用于传热装置中, 以提高热性能. 纳米流体应用于热管中, 可降低热管的热 阻, 提高热管的传热能力. 文中, 对纳米在流体热管中的应用进行了全面的综述. 阐述了纳米流体对 传统热管、脉动热管、热虹膜等各种类型热管的热性能的影响. 此外, 发现了纳米颗粒的高效利用必 须有一定的浓度; 因动力黏度的增加导致颗粒团聚的可能性越高, 高浓度的纳米颗粒会产生较高的热 阻. 热传递性能的增强是晶核位置的增多和纳米流体本身具有的更大热导率的结果.

Similar content being viewed by others

References

MOHAMMADI A, AHMADI M H, BIDI M, JODA F, VALERO A, USON S. Exergy analysis of a combined cooling, heating and power system integrated with wind turbine and compressed air energy storage system [J]. Energy Convers Manag, 2017, 131: 69–78. DOI: https://doi.org/10.1016/j.enconman.2016.11.003.

AHMADI M H, AHMADI M A, ABOUKAZEMPOUR E, GROSU L, POURFAYAZ F, BIDI M. Exergetic sustainability evaluation and optimization of an irreversible Brayton cycle performance [J]. Front Energy, 2017: 1–12. DOI: https://doi.org/10.1007/s11708-017-0445-y.

AHMADI M H, AFSHAR M A, NASERI A, BIDI M, HADIYANTO H. Modeling and PSO optimization of Humidifier-Dehumidifier desalination [J]. Int J Renew Energy Dev, 2017, 7: 59–64. DOI: https://doi.org/10.14710/ijred.7.1.59-64.

AHMADI M H, AHMADI M A. Thermodynamic analysis and optimization of an irreversible Ericsson cryogenic refrigerator cycle [J]. Energy Convers Manag, 2015, 89: 147–155. DOI:https://doi.org/10.1016/j.enconman.2014.09.064.

SADATSAKKAK S A, AHMADI M H, AHMADI M A. Thermodynamic and thermo-economic analysis and optimization of an irreversible regenerative closed Brayton cycle [J]. Energy Convers Manag, 2015, 94: 124–129. DOI: https://doi.org/10.1016/j.enconman.2015.01.040.

ASHOURI M, ASTARAEI F R, GHASEMPOUR R, AHMADI M H, FEIDT M. Optimum insulation thickness determination of a building wall using exergetic life cycle assessment [J]. Appl Therm Eng, 2016, 106: 307–315. DOI: https://doi.org/10.1016/j.applthermaleng.2016.05.190.

NOROOZIAN A, MOHAMMADI A, BIDI M, AHMADI M H. Energy, exergy and economic analyses of a novel system to recover waste heat and water in steam power plants [J]. Energy Convers Manag, 2017, 144: 351–360. DOI: https://doi.org/10.1016/j.enconman.2017.04.067.

NASERI A, BIDI M, AHMADI M H. Thermodynamic and exergy analysis of a hydrogen and permeate water production process by a solar-driven transcritical CO2 power cycle with liquefied natural gas heat sink [J]. Renew Energy, 2017, 113: 1215–1228. DOI: https://doi.org/10.1016/j.renene.2017.06.082.

MIRZAEI M, AHMADI M H, MOBIN M, NAZARI M A, ALAYI R. Energy, exergy and economics analysis of an ORC working with several fluids and utilizes smelting furnace gases as heat source [J]. Therm Sci Eng Prog, 2017, 5: 230–237. DOI: https://doi.org/10.1016/j.tsep.2017.11.011.

AHMADI M H, AHMADI M A, POURFAYAZ F, BIDI M. Thermodynamic analysis and optimization for an irreversible heat pump working on reversed Brayton cycle [J]. Energy Convers Manag, 2016, 110: 260–267. DOI: https://doi.org/10.1016/j.enconman.2015.12.028.

SADATSAKKAK S A, AHMADI M H, AHMADI M A. Optimization performance and thermodynamic analysis of an irreversible nano scale Brayton cycle operating with Maxwell–Boltzmann gas [J]. Energy Convers Manag, 2015, 101: 592–605. DOI: https://doi.org/10.1016/j.enconman.2015.06.004.

SIAVASHI M, JAMALI M. Erratum to: Optimal selection of annulus radius ratio to enhance heat transfer with minimum entropy generation in developing laminar forced convection of water-Al2O3 nanofluid flow [J]. Journal of Central South University, 2017, 24(10): 2486. DOI: https://doi.org/10.1007/s11771-017-3660-0.

YU Xiao-hui, ZHANG Yu-feng, ZHANG Yan, HE Zhong-lu, DONG Sheng-ming, MA Xue-lian, YAO Sheng. Intelligent prediction on performance of high-temperature heat pump systems using different refrigerants [J]. Journal of Central South University, 2018, 25(11): 2754–2765. DOI: https://doi.org/10.1007/s11771-018-3951-0.

NAREI H, GHASEMPOUR R, NOOROLLAHI Y. The effect of employing nanofluid on reducing the bore length of a vertical ground-source heat pump [J]. Energy Convers Manag, 2016, 123: 581–591. DOI: https://doi.org/10.1016/j.enconman.2016.06.079.

ARAMESH M, POURFAYAZ F, KASAEIAN A. Numerical investigation of the nanofluid effects on the heat extraction process of solar ponds in the transient step [J]. Sol Energy, 2017, 157: 869–879. DOI: https://doi.org/10.1016/j.solener.2017.09.011.

PISE G A, SALVE S S, PISE A T, PISE A A. Investigation of solar heat pipe collector using nanofluid and surfactant [J]. Energy Procedia, 2016, 90: 481–491. DOI: https://doi.org/10.1016/j.egypro.2016.11.215.

AKBARIANRAD N, MOHAMMADIAN F, ALHUYI NAZARI M, RAHBANI NOBAR B. Applications of nanotechnology in endodontic: A review [J]. Nanomedicine J, 2018, 5(3): 121–126. DOI: https://doi.org/10.22038/nmj.2018.005.0001.

MOHAMADIAN F, EFTEKHAR L, HAGHIGHI BARDINEH Y. Applying GMDH artificial neural network to predict dynamic viscosity of an antimicrobial nanofluid [J]. Mashhad Univ Med Sci, 2018, 5(4): 217–221. DOI: https://doi.org/10.22038/nmj.2018.05.00005.

ALRASHED A A, KARIMIPOUR A, BAGHERZADEH S A, SAFAEI M R, AFRAND M. Electro-and thermophysical properties of water-based nanofluids containing copper ferrite nanoparticles coated with silica: Experimental data, modeling through enhanced ANN and curve fitting [J]. Int J Heat Mass Transf, 2018, 127: 925–935. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.123.

HAGHIGHI BARDINEH Y, MOHAMADIAN F, AHMADI M H, AKBARIANRAD N. Medical and dental applications of renewable energy systems [J]. Int J Low-Carbon Technol, 2018: 1–7. DOI: https://doi.org/10.1093/ijlct/cty040.

ARANI A A A, AKBARI O A, SAFAEI M R, MARZBAN A, ALRASHED A A A A, AHMADI G R, NGUYZN T K. Heat transfer improvement of water/single-wall carbon nanotubes (SWCNT) nanofluid in a novel design of a truncated double-layered microchannel heat sink [J]. Int J Heat Mass Transf, 2017, 113: 780–795. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.089.

MAHIAN O, KIANIFAR A, KALOGIROU S A, POP I, WONGWISES S. A review of the applications of nanofluids in solar energy [J]. Int J Heat Mass Transf, 2013, 57(2): 582–594. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.10.037.

MAHIAN O, KIANIFAR A, SAHIN A Z, WONGWISES S. Heat transfer, pressure drop, and entropy generation in a solar collector using SiO2/water nanofluids: Effects of nanoparticle size and pH [J]. J Heat Transfer, 2015, 137: 061011. DOI: https://doi.org/10.1115/1.4029870.

TAWFIK M M. Experimental studies of nanofluid thermal conductivity enhancement and applications: A review [J]. Renew Sustain Energy Rev, 2017, 75: 1239–1253. DOI: https://doi.org/10.1016/j.rser.2016.11.111.

PONMANI S, WILLIAM J K M, SAMUEL R, NAGARAJAN R, SANGWAI J S. Formation and characterization of thermal and electrical properties of CuO and ZnO nanofluids in xanthan gum [J]. Colloids Surfaces A: Physicochem Eng Asp, 2014, 443: 37–43. DOI: https://doi.org/10.1016/j.colsurfa.2013.10.048.

CUI W, SHEN Z, YANG J, WU S. Molecular dynamics simulation on flow behaviors of nanofluids confined in nanochannel [J]. Case Stud Therm Eng, 2015, 5: 114–121. DOI: https://doi.org/10.1016/j.csite.2015.03.007.

ALAWI O A, SIDIK N A C, XIAN H W, KEAN T H, KAZI S N. Thermal conductivity and viscosity models of metallic oxides nanofluids [J]. Int J Heat Mass Transf, 2018, 116: 1314–1325. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.133.

HOSSEINI S M, SAFAEI M R, GOODARZI M, ALRASHED A A A A, NGUYEN T K. New temperature, interfacial shell dependent dimensionless model for thermal conductivity of nanofluids [J]. Int J Heat Mass Transf, 2017, 114: 207–210. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.061.

YIAMSAWAS T, DALKILIC A S, MAHIAN O, WONGWISES S. Measurement and correlation of the viscosity of water-based Al2O3 and TiO2 nanofluids in high temperatures and comparisons with literature reports [J]. Journal of Dispersion Science and Technology, 2013, 34: 1697–1703. DOI: https://doi.org/10.1080/01932691.2013.764483.

AHMADI M H, MIRLOHI A, NAZARI M A, GHASEMPOUR R. A review of thermal conductivity of various nanofluids [J]. J Mol Liq, 2018, 265: 181–188. DOI: https://doi.org/10.1016/j.molliq.2018.05.124.

AHMADI M H, AHMADI M A, NAZARI M A, MAHIAN O, GHASEMPOUR R. A proposed model to predict thermal conductivity ratio of Al2O3/EG nanofluid by applying least squares support vector machine (LSSVM) and genetic algorithm as a connectionist approach [J]. J Therm Anal Calorim, 2018, 135: 271–281. DOI: https://doi.org/10.1007/s10973-018-7035-z.

RASHIDI S, ESKANDARIAN M, MAHIAN O, PONCET S. Combination of nanofluid and inserts for heat transfer enhancement [J]. J Therm Anal Calorim, 2018, 135: 437–460. DOI: https://doi.org/10.1007/s10973-018-7070-9.

RASHIDI S, MAHIAN O, LANGURI E M. Applications of nano fluids in condensing and evaporating systems [J]. J Therm Anal Calorim, 2017, 131: 2027–2039. DOI: https://doi.org/10.1007/s10973-017-6773-7.

MAHIAN O, LOLSL L, AMANI M. Recent advances in modeling and simulation of nanofluid flows-Part I: Fundamentals and theory [J]. Phys Rep, 2018, 700: 1–48. DOI: https://doi.org/10.1016/j.physrep.2018.11.004.

MAHIAN O, LOLSL L, AMANI M. Recent advances in modeling and simulation of nanofluid flows—Part II: Applications [J]. Phys Rep, 2018, 791: 1–59. DOI: https://doi.org/10.1016/j.physrep.2018.11.003.

ALIZADEH H, GHASEMPOUR R, SHAFII M B, AHMADI M H, YAN W M, NAZARI M A. Numerical simulation of PV cooling by using single turn pulsating heat pipe [J]. Int J Heat Mass Transf, 2018, 127: 203–208. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.108.

NAZARI M A, GHASEMPOUR R, SHAFII M B, AHMADI M H. Experimental investigation of triton X-100 solution on pulsating heat pipe thermal performance [J]. J Thermophys Heat Transf, 2018, 32: 806–812: 1–7. DOI: https://doi.org/10.2514/1.T5295.

ASME. Heat pipe technology history [EB/OL]. [2019-02-05] https://doi.org/www.amsenergy.com/heat-pipe-technology-history/.

FAEGH M, SHAFII M B. Experimental investigation of a solar still equipped with an external heat storage system using phase change materials and heat pipes [J]. Desalination, 2017, 409: 128–135. DOI: https://doi.org/10.1016/j.desal.2017.01.023.

QU J, WU H, WANG Q. Experimental investigation of silicon-based micro-pulsating heat pipe for cooling electronics [J]. Nanoscale Microscale Thermophys Eng, 2012, 16(1): 37–49. DOI: https://doi.org/10.1080/15567265.2011.645999.

ARAB M, SOLTANIEH M, SHAFII M B. Experimental investigation of extra-long pulsating heat pipe application in solar water heaters [J]. Exp Therm Fluid Sci, 2012, 42: 6–15. DOI: https://doi.org/10.1016/j.expthermflusci.2012.03.006.

SHIRZADI N, ROSHANDEL R, SHAFII M B. Integration of miniature heat pipes into a proton exchange membrane fuel cell for cooling applications [J]. Heat Transf Eng, 2017, 38(18): 1595–1605. DOI: https://doi.org/10.1080/01457632.2016.1262722.

JAHANGIRI MAMOURI S, GHOLAMI DERAMI H, GHIASI M, SHAFII M B, SHIEE Z. Experimental investigation of the effect of using thermosyphon heat pipes and vacuum glass on the performance of solar still [J]. Energy, 2014, 75: 501–507. DOI: https://doi.org/10.1016/j.energy.2014.08.005.

JAFARI MOSLEH H, JAHANGIRI MAMOURI S, SHAFII M B, HAKIM SIMA A. A new desalination system using a combination of heat pipe, evacuated tube and parabolic trough collector [J]. Energy Convers Manag, 2015, 99: 141–150. DOI: https://doi.org/10.1016/j.enconman.2015.04.028.

MOHAMMADI M, MOHAMMADI M, GHAHREMANI A R, SHAFII M B, MOHAMMADI N. Experimental investigation of thermal resistance of a ferrofluidic closed-loop pulsating heat pipe [J]. Heat Transf Eng, 2014, 35(1): 25–33. DOI: https://doi.org/10.1080/01457632.2013.810086.

TASLIMIFAR M, MOHAMMADI M, AFSHIN H, SAIDI M H, SHAFII M B. Overall thermal performance of ferrofluidic open loop pulsating heat pipes: An experimental approach [J]. Int J Therm Sci, 2013, 65: 234–241. DOI: https://doi.org/10.1016/j.ijthermalsci.2012.10.016.

FAGHRI A. Heat pipe science and technology [M]. Taylor & Francis, 1995.

POPLASKI L M, BENN S P, FAGHRI A. Thermal performance of heat pipes using nanofluids [J]. Int J Heat Mass Transf, 2017, 107(7, 8): 358–371. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.111.

WUSIMAN K E B J, CHUNG H S, NINE M J, HANDRY A, EOM Y S, KIM J H, JEONG H M. Heat transfer characteristics of nanofluid through circular tube [J]. Journal of Central South University, 2013, 20(1): 142–148. DOI: https://doi.org/10.1007/s11771-013-1469-z.

TANG Y, CHEN Q, HUAN GUAN W, TAO LI Z, HAI YU B, YUAN W. Thermal analysis of an LED module with a novelly assembled heat pipe heat sink [J]. Journal of Central South University, 2017, 24(4): 921–928. DOI: https://doi.org/10.1007/s11771-017-3494-9.

MA H, LIANG S. Heat transport capability in pulsating heat pipes [C]// 8th AIAA/ASME Joint Thermophysics and Heat Transfer Conference. 2002. DOI: https://doi.org/10.2514/6.2002-2765.

NIKOLAYEV V S. Effect of tube heat conduction on the single branch pulsating heat pipe start-up [J]. Int J Heat Mass Transf, 2016, 95: 477–487. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2015.12.016.

ALAGAPPAN N, KARUNAKARAN N. Thermal characteristics of a circular finned thermosyphon using different working fluids [J]. Appl Mech Mater, 2014, 575: 322–328. DOI: https://doi.org/10.13140/RG.2.1.2780.5609.

YANG X F, LIU Z H. Flow boiling heat transfer in the evaporator of a loop thermosyphon operating with CuO based aqueous nanofluid [J]. Int J Heat Mass Transf, 2012, 55(25, 26): 7375–7384. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.07.026.

KHALILI M, SHAFII M B. Experimental and numerical investigation of the thermal performance of a novel sintered-wick heat pipe [J]. Appl Therm Eng, 2016, 94: 59–75. DOI: https://doi.org/10.1016/j.applthermaleng.2015.10.120.

ABOUTALEBI M, NIKRAVAN MOGHADDAM A M, MOHAMMADI N, SHAFII M B. Experimental investigation on performance of a rotating closed loop pulsating heat pipe [J]. Int Commun Heat Mass Transf, 2013, 45: 137–145. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2013.04.008.

KHALILI M, SHAFII M B. Investigaing thermal performance of a partly sintered-wick heat pipe filled with different working fluids [J]. Sci Iran, 2016, 23(6): 2616–2625. DOI: https://doi.org/10.24200/sci.2016.3971.

REAY D, KEW P. Heat pipes: Theory, design and applications [M]. Elsevier, 2013.

SEDIGHI E, AMARLOO A, SHAFII B. Numerical and experimental investigation of flat-plate pulsating heat pipes with extra branches in the evaporator section [J]. Int J Heat Mass Transf, 2018, 126: 431–441. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.047.

SEDIGHI E, AMARLOO A, SHAFII M B. Experimental investigation of the thermal characteristics of single-turn pulsating heat pipes with an extra branch [J]. Int J Therm Sci, 2018, 134: 258–268. DOI: https://doi.org/10.1016/j.ijthermalsci.2018.08.024.

YANG K S, CHENG Y C, JENG M S, CHIEN K H, SHYU J C. An experimental investigation of micro pulsating heat pipes [J]. Micromachines, 2014, 5(2): 385–395. DOI: https://doi.org/10.1109/NEMS.2013.6559862.

SHAFII M B, ARABNEJAD S, SABOOHI Y, JAMSHIDI H. Experimental investigation of pulsating heat pipes and a proposed correlation [J]. Heat Transf Eng, 2010, 31(10): 854–861. DOI: https://doi.org/10.1080/01457630903547636.

WU Q, XU R, ZHANG H, LI Y. Heat transfer of closed flat-plat loop pulsating heat pipe in start-up stage [C]// ICMREE2011-Proc. 2011 Int Conf Mater Renew Energy Environ. 2011, 1: 864–868. DOI: https://doi.org/10.1109/ICMREE.2011.5930941.

HAN X, WANG X, ZHENG H, XU X, CHEN G. Review of the development of pulsating heat pipe for heat dissipation [J]. Renew Sustain Energy Rev, 2016, 59: 692–709.

GOSHAYESHI H R, GOODARZI M, SAFAEI M R, DAHARI M. Experimental study on the effect of inclination angle on heat transfer enhancement of a ferrofluid in a closed loop oscillating heat pipe under magnetic field [J]. Exp Therm Fluid Sci, 2016, 74: 265–270. DOI: https://doi.org/10.1016/j.expthermflusci.2016.01.003.

NAZARI M A, AHMADI M H, GHASEMPOUR R. A review on pulsating heat pipes: From solar to cryogenic applications [J]. Applied Energy, 2018, 222: 475–484. DOI: https://doi.org/10.1016/j.apenergy.2018.04.020.

ALHUYI NAZARI M, AHMADI M H, GHASEMPOUR R, SHAFII M B. How to improve the thermal performance of pulsating heat pipes: A review on working fluid [J]. Renew Sustain Energy Rev, 2018, 91: 630–638. DOI: https://doi.org/10.1016/j.rser.2018.04.042.

SARAFRAZ M M, HORMOZI F, PEYGHAMBARZADEH S M. Thermal performance and efficiency of a thermosyphon heat pipe working with a biologically ecofriendly nanofluid [J]. Int Commun Heat Mass Transf, 2014, 57: 297–303. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2014.08.020.

TECCHIO C, OLIVEIRA J L G, PAIVA K V, MANTELLI M B H, GANDOLFI R, RIBEIRO L G S. Thermal performance of thermosyphons in series connected by thermal plugs [J]. Exp Therm Fluid Sci, 2017, 88: 409–422. DOI: https://doi.org/10.1016/j.expthermflusci.2017.06.021.

LV F Y, ZHANG P, OREJON D, ASKOUNIS A, SHEN B. Heat transfer performance of a lubricant-infused thermosyphon at various filling ratios [J]. Int J Heat Mass Transf, 2017, 115: 725–736. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2017.07.062.

GEDIK E. Experimental investigation of the thermal performance of a two-phase closed thermosyphon at different operating conditions [J]. Energy Build, 2016, 127: 1096–1107. DOI: https://doi.org/10.1016/j.enbuild.2016.06.066.

RAMEZANIZADEH M, ALHUYI NAZARI M, AHMADI M H, AÇIKKALP E. Application of nanofluids in thermosyphons: A review [J]. J Mol Liq, 2018, 272: 395–402. DOI: https://doi.org/10.1016/j.molliq.2018.09.101.

RAMEZANIZADEH M, ALHUYI NAZARI M, AHMADI M H, CHAU K. Experimental and numerical analysis of a nanofluidic thermosyphon heat exchanger [J]. Eng Appl Comput Fluid Mech, 2019, 13(1): 40–47. DOI: https://doi.org/10.1080/19942060.2018.1518272.

SURESHKUMAR R, MOHIDEEN S T, NETHAJI N. Heat transfer characteristics of nanofluids in heat pipes: A review [J]. Renew Sustain Energy Rev, 2013, 20: 397–410. DOI: https://doi.org/10.1016/j.rser.2012.11.044.

SCHREIBER M, WITS W W, TE RIELE G J. Numerical and experimental investigation of a counter-current two-phase thermosyphon with cascading pools [J]. Appl Therm Eng, 2016, 99: 133–146. DOI: https://doi.org/10.1016/j.applthermaleng.2015.12.095.

DAIMARU T, YOSHIDA S, NAGAI H. Study on thermal cycle in oscillating heat pipes by numerical analysis [J]. Appl Therm Eng, 2017, 113: 1219–1227. DOI: https://doi.org/10.1016/j.applthermaleng.2016.11.114.

SHEWALE S P, SAHU S K, CHOUGULE S S, PISE A T. A review of heat pipe with nanofluid for electronic cooling [C]// Int Conf Adv Eng Technol. 2014, ICAET. DOI: https://doi.org/10.1109/ICAET.2014.7105296.

LATAOUI Z, JEMNI A. Experimental investigation of a stainless steel two-phase closed thermosyphon [J]. Appl Therm Eng, 2017, 121: 721–727. DOI: https://doi.org/10.1016/j.applthermaleng.2017.04.135.

ARABNEJAD S, RASOULIAN R, SHAFII M B, SABOOHI Y. Numerical investigation of the performance of a U-shaped pulsating heat pipe [J]. Heat Transf Eng, 2010, 31(14): 1155–1164. DOI: https://doi.org/10.1080/01457631003689278.

EBRAHIMI M, SHAFII M B, BIJARCHI M A. Experimental investigation of the thermal management of flat-plate closed-loop pulsating heat pipes with interconnecting channels [J]. Appl Therm Eng, 2015, 90: 838–847. DOI: https://doi.org/10.1016/j.applthermaleng.2015.07.040.

SHAFII M B, FAGHRI A, ZHANG Y. Analysis of heat transfer in unlooped and looped pulsating heat pipes [J]. Int J Numer Methods Heat Fluid Flow, 2002, 12(5): 585–609. DOI: https://doi.org/10.1108/09615530210434304.

HOLLEY B, FAGHRI A. Analysis of pulsating heat pipe with capillary wick and varying channel diameter [J]. Int J Heat Mass Transf, 2005, 48(13): 2635–2651. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2005.01.013.

XU D, LI L, LIU H. Experimental investigation on the thermal performance of helium based cryogenic pulsating heat pipe [J]. Exp Therm Fluid Sci, 2016, 70: 61–68. DOI: https://doi.org/10.1016/j.expthermflusci.2015.08.024.

JIAO A J, MA H B, CRITSER J K. Experimental investigation of cryogenic oscillating heat pipes [J]. Int J Heat Mass Transf, 2009, 52(15, 16): 3504–3509. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2009.03.013.

LIU Y, GUO K. A novel cryogenic power cycle for LNG cold energy recovery [J]. Energy, 2011, 36(5): 2828–2833. DOI: https://doi.org/10.1016/j.energy.2011.02.024.

CAO Y, FAGHRI A. Closed-form analytical solutions of high-temperature heat pipe startup and frozen startup limitation [J]. J Heat Transfer, 1992, 114(4): 1028. DOI: https://doi.org/10.1115/1.2911873.

AHMADI M H, NAZARI M A, GHASEMPOUR R, MADAH H, SHAFII M B, AHMADI M A. Thermal conductivity ratio prediction of Al2O3/water nanofluid by applying connectionist methods [J]. Colloids Surfaces A: Physicochem Eng Asp, 2018, 541: 154–164. DOI: https://doi.org/10.1016/j.colsurfa.2018.01.030.

MAJID S, MOHAMMAD J. Optimal selection of annulus radius ratio to enhance heat transfer with minimum entropy generation in developing laminar forced convection of water-Al2O3 nanofluid flow [J]. Journal of Central South University, 2017, 24(8): 1850–1865. DOI: https://doi.org/10.1007/s11771-017-3593-7.

MAHMUDUL HAQUE A K M, KWON S, KIM J. An experimental study on thermal characteristics of nanofluid with graphene and multi-wall carbon nanotubes [J]. Journal of Central South University, 2015, 22(8): 3202–3210. DOI: https://doi.org/10.1007/s11771-015-2857-3.

AZARI A. Thermal conductivity modeling of water containing metal oxide nanoparticles [J]. Journal of Central South University, 2015, 22(3): 1141–1145. DOI: https://doi.org/10.1007/s11771-015-2626-3.

CHOI S U S, ZHANG Z G, YU W, LOCKWOOD F E, GRULKE E. Anomalous thermal conductivity enhancement in nanotube suspension [J]. Appl Phys Lett, 2001, 79: 2252–2254. DOI: https://doi.org/10.1063/1.1408272.

JIANG W, DING G, PENG H, GAO Y, WANG K. Experimental and model research on nanorefrigerant thermal conductivity [J]. HVAC&R Res, 2009, 15(3): 651–669. DOI: https://doi.org/10.1080/10789669.2009.10390855.

PRYAZHNIKOV M I, MINAKOV A V, RUDYAK V Y, GUZEI D V. Thermal conductivity measurements of nanofluids [J]. Int J Heat Mass Transf, 2017, 104: 1275–1282. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.080.

HONG T K, YANG H S, CHOI C J. Study of the enhanced thermal conductivity of Fe nanofluids [J]. J Appl Phys, 2005, 97(6): 064311. DOI: https://doi.org/10.1063/1.1861145.

ZHU D, LI X, WANG N, WANG X, GAO J, LI H. Dispersion behavior and thermal conductivity characteristics of Al2O3–H2O nanofluids [J]. Curr Appl Phys, 2009, 9(1): 131–139. DOI: https://doi.org/10.1016/j.cap.2007.12.008.

ALAWI O A, SIDIK N A C, MOHAMMED H A, SYAHRULLAIL S. Fluid flow and heat transfer characteristics of nanofluids in heat pipes: A review [J]. Int Commun Heat Mass Transf, 2014, 56: 50–62. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2014.04.014.

GUPTA N K, TIWARI A K, GHOSH S K. Heat transfer mechanisms in heat pipes using nanofluids—A review [J]. Exp Therm Fluid Sci, 2018, 90: 84–100. DOI: https://doi.org/10.1016/j.expthermflusci.2017.08.013.

POPLASKI L M, BENN S P, FAGHRI A. Thermal performance of heat pipes using nanofluids [J]. Int J Heat Mass Transf, 2017, 107: 358–371. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.111.

GHANBARPOUR M, KHODABANDEH R. Entropy generation analysis of cylindrical heat pipe using nanofluid [J]. Thermochim Acta, 2015, 610: 37–46. DOI: https://doi.org/10.1016/j.tca.2015.04.028.

GUNNASEGARAN P, ABDULLAH M Z, SHUAIB N H. Influence of nanofluid on heat transfer in a loop heat pipe [J]. Int Commun Heat Mass Transf, 2013, 47: 82–91. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2013.07.003.

MASHAEI P R, SHAHRYARI M, FAZELI H, HOSSEINALIPOUR S M. Numerical simulation of nanofluid application in a horizontal mesh heat pipe with multiple heat sources: A smart fluid for high efficiency thermal system [J]. Appl Therm Eng, 2016, 100: 1016–1030. DOI: https://doi.org/10.1016/j.applthermaleng.2016.02.111.

NAPHON P, ASSADAMONGKOL P, BORIRAK T. Experimental investigation of titanium nanofluids on the heat pipe thermal efficiency [J]. Int Commun Heat Mass Transf, 2008, 35(10): 1316–1319. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2008.07.010.

CHEN Y J, WANG P Y, LIU Z H, LI Y Y. Heat transfer characteristics of a new type of copper wire-bonded flat heat pipe using nanofluids [J]. Int J Heat Mass Transf, 2013, 67: 548–559. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2013.08.060.

KANG S W, WEI W C, TSAI S H, HUANG C C. Experimental investigation of nanofluids on sintered heat pipe thermal performance [J]. Appl Therm Eng, 2009, 29(5, 6): 973–979. DOI: https://doi.org/10.1016/j.applthermaleng.2008.05.010.

KAVUSI H, TOGHRAIE D. A comprehensive study of the performance of a heat pipe by using of various nanofluids [J]. Adv Powder Technol, 2017, 28(11): 3074–3084. DOI: https://doi.org/10.1016/j.apt.2017.09.022.

VIJAYAKUMAR M, NAVANEETHAKRISHNAN P, KUMARESAN G. Thermal characteristics studies on sintered wick heat pipe using CuO and Al2O3 nanofluids [J]. Exp Therm Fluid Sci, 2016, 79: 25–35. DOI: https://doi.org/10.1016/j.expthermflusci.2016.06.021.

WAN Z, DENG J, LI B, XU Y, WANG X, TANG Y. Thermal performance of a miniature loop heat pipe using water–copper nanofluid [J]. Appl Therm Eng, 2015, 78: 712–719. DOI: https://doi.org/10.1016/j.applthermaleng.2014.11.010.

GUNNASEGARAN P, ABDULLAH M Z, YUSOFF M Z, KANNA R. Heat transfer in a loop heat pipe using diamond-H2O nanofluid [J]. Heat Transf Eng, 2017, 39: 117–131: 1–15. DOI: https://doi.org/10.1080/01457632.2017.1363616.

GHANBARPOUR M, NIKKAM N, KHODABANDEH R, TOPRAK M S. Improvement of heat transfer characteristics of cylindrical heat pipe by using SiC nanofluids [J]. Appl Therm Eng, 2015, 90: 127–135. DOI: https://doi.org/10.1016/j.applthermaleng.2015.07.004

SENTHIL R, RATCHAGARAJA D, SILAMBARASAN R, MANIKANDAN R. Contemplation of thermal characteristics by filling ratio of Al2O3 nanofluid in wire mesh heat pipe [J]. Alexandria Eng J, 2016, 55(2): 1063–1068. DOI: https://doi.org/10.1016/j.aej.2016.03.011.

ALY W I A, ELBALSHOUNY M A, ABD EL- HAMEED H M, FATOUH M. Thermal performance evaluation of a helically-micro-grooved heat pipe working with water and aqueous Al2O3 nanofluid at different inclination angle and filling ratio [J]. Appl Therm Eng, 2017, 110: 1294–1304. DOI: https://doi.org/10.1016/j.applthermaleng.2016.08.130.

MOUSA M G. Effect of nanofluid concentration on the performance of circular heat pipe [J]. Ain Shams Eng J, 2011, 2(1): 63–69. DOI: https://doi.org/10.1016/j.asej.2011.03.003.

GHANBARPOUR M, NIKKAM N, KHODABANDEH R, TOPRAK M S, MUHAMMED M. Thermal performance of screen mesh heat pipe with Al2O3 nanofluid [J]. Exp Therm Fluid Sci, 2015, 66: 213–220. DOI: https://doi.org/10.1016/j.expthermflusci.2015.03.024.

HUNG Y H, TENG T P, LIN B G. Evaluation of the thermal performance of a heat pipe using alumina nanofluids [J]. Exp Therm Fluid Sci, 2013, 44: 504–511. DOI: https://doi.org/10.1016/j.expthermflusci.2012.08.012.

TENG T P, HSU H G, MO H E, CHEN C C. Thermal efficiency of heat pipe with alumina nanofluid [J]. J Alloys Compd, 2010, 504: S380–S384. DOI: https://doi.org/10.1016/j.jallcom.2010.02.046.

PANDIARAJ P, GNANAVELBABU A, SARAVANAN P. Experimental and statistical analysis of MgO nanofluids for thermal enhancement in a novel flat plate heat pipes [J]. Int J Nanosci, 2018, 17(1, 2): 1760018. DOI: https://doi.org/10.1142/S0219581X17600183.

MASHAEI P R, SHAHRYARI M. Effect of nanofluid on thermal performance of heat pipe with two evaporators; application to satellite equipment cooling [J]. Acta Astronaut, 2015, 111: 345–355. DOI: https://doi.org/10.1016/j.actaastro.2015.02.003.

MOHANRAJ C, DINESHKUMAR R, MURUGAN G. Experimental studies on effect of heat transfer with CuO-H2O nanofluid on flat plate heat pipe [J]. Mater Today Proc, 2017, 4(2): 3852–3860. DOI: https://doi.org/10.1016/j.matpr.2017.02.283.

VENKATACHALAPATHY S, KUMARESAN G, SURESH S. Performance analysis of cylindrical heat pipe using nanofluids–An experimental study [J]. Int J Multiph Flow, 2015, 72: 188–197. DOI: https://doi.org/10.1016/j.ijmultiphaseflow.2015.02.006.

WANG G S, SONG B, LIU Z H. Operation characteristics of cylindrical miniature grooved heat pipe using aqueous CuO nanofluids [J]. Exp Therm Fluid Sci, 2010, 34(8): 1415–1421. DOI: https://doi.org/10.1016/j.expthermflusci.2010.07.004.

HAJIAN R, LAYEGHI M, ABBASPOUR SANI K. Experimental study of nanofluid effects on the thermal performance with response time of heat pipe [J]. Energy Convers Manag, 2012, 56: 63–68. DOI: https://doi.org/10.1016/j.enconman.2011.11.010.

GHANBARPOUR M, NIKKAM N, KHODABANDEH R, TOPRAK M S. Thermal performance of inclined screen mesh heat pipes using silver nanofluids [J]. Int Commun Heat Mass Transf, 2015, 67: 14–20. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2015.06.009.

SALEH R, PUTRA N, PRAKOSO S P, SEPTIADI W N. Experimental investigation of thermal conductivity and heat pipe thermal performance of ZnO nanofluids [J]. Int J Therm Sci, 2013, 63: 125–132. DOI: https://doi.org/10.1016/j.ijthermalsci.2012.07.011.

ARYA A, SARAFRAZ M M, SHAHMIRI S, MADANI S A H, NIKKHAH V, NAKHJAVANI S M. Thermal performance analysis of a flat heat pipe working with carbon nanotube-water nanofluid for cooling of a high heat flux heater [J]. Heat Mass Transf, 2017, 54: 985–997. DOI: https://doi.org/10.1007/s00231-017-2201-6.

SADEGHINEZHAD E, AZIZIAN R, AKHIANI A R, TAHAN LATIBARI S, MEHRALI M. Effect of nitrogen-doped graphene nanofluid on the thermal performance of the grooved copper heat pipe [J]. Energy Convers Manag, 2016, 118: 459–473. DOI: https://doi.org/10.1016/j.enconman.2016.04.028.

THARAYIL T, ASIRVATHAM L G, DAU M J, WONGWISES S. Entropy generation analysis of a miniature loop heat pipe with graphene–water nanofluid: Thermodynamics model and experimental study [J]. Int J Heat Mass Transf, 2017, 106: 407–421. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2016.08.035.

THARAYIL T, ASIRVATHAM L G, RAVINDRAN V, WONGWISES S. Thermal performance of miniature loop heat pipe with graphene–water nanofluid [J]. Int J Heat Mass Transf, 2016, 93: 957–968. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2015.11.011

PARK S S, KIM N J. A study on the characteristics of carbon nanofluid for heat transfer enhancement of heat pipe [J]. Renew Energy, 2014, 65: 123–129. DOI: https://doi.org/10.1016/j.renene.2013.07.040.

SADEGHINEZHAD E, MEHRALI M, ROSEN M A. Experimental investigation of the effect of graphene nanofluids on heat pipe thermal performance [J]. Appl Therm Eng, 2016, 100: 775–787. DOI: https://doi.org/10.1016/j.applthermaleng.2016.02.071.

KIM H J, LEE S H, BIN KIM S, JANG S P. The effect of nanoparticle shape on the thermal resistance of a flat-plate heat pipe using acetone-based Al2O3 nanofluids [J]. Int J Heat Mass Transf, 2016, 92: 572–577. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2015.09.013.

TSAI C Y, CHIEN H T, DING P P, CHAN B, LUH T Y, CHEN P H. Effect of structural character of gold nanoparticles in nanofluid on heat pipe thermal performance [J]. Mater Lett, 2004, 58(9): 1461–1465. DOI: https://doi.org/10.1016/j.matlet.2003.10.009.

BRAHIM T, JEMNI A. Numerical case study of packed sphere wicked heat pipe using Al2O3 and CuO based water nanofluid [J]. Case Stud Therm Eng, 2016, 8: 311–321. DOI: https://doi.org/10.1016/j.csite.2016.09.002.

KUMARESAN G, VENKATACHALAPATHY S, ASIRVATHAM L G. Experimental investigation on enhancement in thermal characteristics of sintered wick heat pipe using CuO nanofluids [J]. Int J Heat Mass Transf, 2014, 72: 507–516. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2014.01.029.

VIJAYAKUMAR M, NAVANEETHAKRISHNAN P, KUMARESAN G, KAMATCHI R. A study on heat transfer characteristics of inclined copper sintered wick heat pipe using surfactant free CuO and Al2O3 nanofluids [J]. J Taiwan Inst Chem Eng, 2017, 81: 190–198. DOI: https://doi.org/10.1016/j.jtice.2017.10.032.

HASSAN M I, ALZAROONI I A, SHATILLA Y. The effect of water-based nanofluid incorporating Al2O3 nanoparticles on heat pipe performance [J]. Energy Procedia, 2015, 75: 3201–3206. DOI: https://doi.org/10.1016/j.egypro.2015.07.674.

WANG W, DUAN G, LI J, ZHAO W, LI C, LIU Z. The preparation and thermal performance research of spherical Ag-H2O nanofluids & applied in heat pipe [J]. Appl Therm Eng, 2017, 116: 811–822. DOI: https://doi.org/10.1016/j.applthermaleng.2017.02.018.

KIM K M, BANG I C. Effects of graphene oxide nanofluids on heat pipe performance and capillary limits [J]. Int J Therm Sci, 2016, 100: 346–356. DOI: https://doi.org/10.1016/j.ijthermalsci.2015.10.015.

KESHAVARZ MORAVEJI M, RAZVARZ S. Experimental investigation of aluminum oxide nanofluid on heat pipe thermal performance [J]. Int Commun Heat Mass Transf, 2012, 39(9) 1444–1448. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2012.07.024.

GOSHAYESHI H R, SAFAEI M R, GOODARZI M, DAHARI M. Particle size and type effects on heat transfer enhancement of Ferro-nanofluids in a pulsating heat pipe [J]. Powder Technol, 2016, 301: 1218–1226. DOI: https://doi.org/10.1016/j.powtec.2016.08.007.

BECK M P, YUAN Y, WARRIER P, TEJA A S. The effect of particle size on the thermal conductivity of alumina nanofluids [J]. J Nanoparticle Res, 2009, 11(5): 1129–1136. DOI: https://doi.org/10.1007/s11051-008-9500-2.

HASSAN H, HARMAND S. Study of the parameters and characteristics of flat heat pipe with nanofluids subjected to periodic heat load on its performance [J]. Int J Therm Sci, 2015, 97: 126–142. DOI: https://doi.org/10.1016/j.ijthermalsci.2015.06.009.

MONIRIMANESH N, NOWEE S M, KHAYYAMI S, ABRISHAMCHI I. Performance enhancement of an experimental air conditioning system by using TiO2/ methanol nanofluid in heat pipe heat exchangers [J]. Heat Mass Transf, 2016, 52(5): 1025–1035. DOI: https://doi.org/10.1007/s00231-015-1615-2.

NEGM M N A, ABDEL- REHIM A A, ATTIA A A A. Investigating the effect of Al2O3/water nanofluid on the efficiency of a thermosyphon flat-plate solar collector [M]// Volume 8: Heat Transfer and Thermal Engineering. 2016: V008T10A097. DOI: https://doi.org/10.1115/IMECE2016-66039.

BUSCHMANN M H. Nanofluids in thermosyphons and heat pipes: Overview of recent experiments and modelling approaches [J]. Int J Therm Sci, 2013, 72: 1–17. DOI: https://doi.org/10.1016/j.ijthermalsci.2013.04.024.

ALAGAPPAN N, KARUNAKARAN N. Performance investigation of 405 stainless steel thermosyphon using cerium (IV) oxide nano fluid [J]. International Journal of Engineering, 2017, 30(4) 575–581. DOI: https://doi.org/www.civilica.com/Paper-JR_IJE-JR_IJE-30-5_004=Performance-Investigation-of-405-Stainless-Steel-Thermosyphon-using-Cerium-IV-Oxide-Nano-Fluid.html.

PARAMATTHANUWAT T, BOOTHAISONG S, RITTIDECH S, BOODDACHAN K. Heat transfer characteristics of a two-phase closed thermosyphon using de ionized water mixed with silver nano [J]. Heat Mass Transf, 2010, 46(3): 281–285. DOI: https://doi.org/10.1007/s00231-009-0565-y.

SARAFRAZ M M, HORMOZI F, PEYGHAMBARZADEH S M. Role of nanofluid fouling on thermal performance of a thermosyphon: Are nanofluids reliable working fluid? [J]. Appl Therm Eng, 2015, 82: 212–224. DOI: https://doi.org/10.1016/j.applthermaleng.2015.02.070.

HUMINIC G, HUMINIC A. Heat transfer characteristics of a two-phase closed thermosyphons using nanofluids [J]. Exp Therm Fluid Sci, 2011, 35(3): 550–557. DOI: https://doi.org/10.1016/j.expthermflusci.2010.12.009.

HUMINIC G, HUMINIC A. Numerical study on heat transfer characteristics of thermosyphon heat pipes using nanofluids [J]. Energy Convers Manag, 2013, 76: 393–399. DOI: https://doi.org/10.1016/j.enconman.2013.07.026.

ABDOLLAHI A, KARIMI DARVANJOOGHI M H, KARIMIPOUR A, SAFAEI M R. Experimental study to obtain the viscosity of CuO-loaded nanofluid: Effects of nanoparticles’ mass fraction, temperature and basefluid’s types to develop a correlation [J]. Meccanica, 2018, 53(15): 3739–3757. DOI: https://doi.org/10.1007/s11012-018-0916-1.

KISEEV V, AMINEV D, SAZHI O. Two-phase nanofluid-based thermal management systems for LED cooling [J]. IOP Conf Ser Mater Sci Eng, 2017, 192(1): 012020. DOI: https://doi.org/10.1088/1757-899X/192/1/012020.

BUSCHMANN M H, FRANZKE U. Improvement of thermosyphon performance by employing nanofluid [J]. Int J Refrig, 2014, 40: 416–428. DOI: https://doi.org/10.1016/j.ijrefrig.2013.11.022.

GRAB T, GROSS U, FRANZKE U, BUSCHMANN M H. Operation performance of thermosyphons employing titania and gold nanofluids [J]. Int J Therm Sci, 2014, 86: 352–364. DOI: https://doi.org/10.1016/j.ijthermalsci.2014.06.019.

HERIS S Z, MOHAMMADPUR F, SHAKOURI A. Effect of electric field on thermal performance of thermosyphon heat pipes using nanofluids [J]. Mater Res Bull, 2014, 53: 21–27. DOI: https://doi.org/10.1016/j.materresbull.2014.01.030.

KAMYAR A, ONG K S, SAIDUR R. Effects of nanofluids on heat transfer characteristics of a two-phase closed thermosyphon [J]. Int J Heat Mass Transf, 2013, 65: 610–618. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2013.06.046.

HOSEINZADEH S, SAHEBI S A R, GHASEMIASL R, MAJIDIAN A R. Experimental analysis to improving thermosyphon (TPCT) thermal efficiency using nanoparticles/based fluids (water) [J]. Eur Phys J Plus, 2017, 132(5): 197. DOI: https://doi.org/10.1140/epjp/i2017-11455-3.

SÖZEN A, MENLIK T, GÜRÜM, IRMAK A F, KILIÇ F, AKTAŞ M. Utilization of fly ash nanofluids in two-phase closed thermosyphon for enhancing heat transfer [J]. Exp Heat Transf, 2016, 29(3): 337–354. DOI: https://doi.org/10.1080/08916152.2014.976724.

HERIS S Z, MOHAMMADPUR F, MAHIAN O, SAHIN A Z. Experimental study of two phase closed thermosyphon using Cuo/water nanofluid in the presence of electric field [J]. Exp Heat Transf, 2015, 28(4): 328–343. DOI: https://doi.org/10.1080/08916152.2014.883448.

SALEHI H, ZEINALI HERIS S, SHARIFI F, RAZBANI M A. Effects of a nanofluid and magnetic field on the thermal efficiency of a two-phase closed thermosyphon [J]. Heat Transf Res, 2013, 42(7): 630–650. DOI: https://doi.org/10.1002/htj.21043.

KHEDKAR R S, SONAWANE S S, WASEWAR K L. Influence of CuO nanoparticles in enhancing the thermal conductivity of water and monoethylene glycol based nanofluids [J]. Int Commun Heat Mass Transf, 2012, 39(5): 665–669. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2012.03.012.

PAL B, PAL B. Influence of CuO nanostructures on the thermal conductivity of di water and ethylene glycol based nanofluids [J]. Part Sci Technol, 2015, 33(3): 224–228. DOI: https://doi.org/10.1080/02726351.2014.953647.

BARBÉS B, PÁRAMO R, BLANCO E, CASANOVA C. Thermal conductivity and specific heat capacity measurements of CuO nanofluids [J]. J Therm Anal Calorim, 2014, 115(2): 1883–1891. DOI: https://doi.org/10.1007/s10973-013-3518-0.

LIU Z H, YANG X F, GUO G L. Effect of nanoparticles in nanofluid on thermal performance in a miniature thermosyphon [J]. J Appl Phys, 2007, 102(1): 013526. DOI: https://doi.org/10.1063/1.2748348.

YANG X, LIU Z. boiling heat transfer in the evaporator of a loop thermosyphon operating with CuO based aqueous nanofluid [J]. Int J Heat Mass Transf, 2012, 55(25, 26): 7375–7384. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.07.026.

ASMAIE L, HAGHSHENASFARD M, MEHRABANI- ZEINABAD A, NASR ESFAHANY M. Thermal performance analysis of nanofluids in a thermosyphon heat pipe using CFD modeling [J]. Heat Mass Transf, 2013, 49(5): 667–678. DOI: https://doi.org/10.1007/s00231-013-1110-6.

SARAFRAZ M M, HORMOZI F. Experimental study on the thermal performance and efficiency of a copper made thermosyphon heat pipe charged with alumina–glycol based nanofluids [J]. Powder Technol, 2014, 266: 378–387. DOI: https://doi.org/10.1016/j.powtec.2014.06.053.

CHOUGULE S S, PRADESH M. Thermal performance of two phase thermosyphon flat-plate solar collectors using nanofluid [J]. J Sol Energy Eng, 2013, 136: 1–5. DOI: https://doi.org/10.1115/1.4025591.

ZEINALI HERIS S, FALLAHI M, SHANBEDI M, AMIRI A. Heat transfer performance of two-phase closed thermosyphon with oxidized CNT/water nanofluids [J]. Heat Mass Transf, 2016, 52(1): 85–93. DOI: https://doi.org/10.1007/s00231-015-1548-9.

AMIRI A, SADRI R, SHANBEDI M, AHMADI G, CHEW B T, KAZI S. Performance dependence of thermosyphon on the functionalization approaches: An experimental study on thermo-physical properties of graphene nanoplatelet- based water nanofluids [J]. Energy Convers Manag, 2015, 92: 322–330. DOI: https://doi.org/10.1016/j.enconman.2014.12.051.

ASIRVATHAM L G, WONGWISES S, BABU J. Heat transfer performance of a glass thermosyphon using graphene–acetone nanofluid [J]. J Heat Transfer, 2015, 137(11): 111502. DOI: https://doi.org/10.1115/1.4030479.

SHANBEDI M, HERIS S Z, BANIADAM M, AMIRI A, MAGHREBI M. Investigation of heat-transfer characterization of EDA-MWCNT/DI-water nanofluid in a two-phase closed thermosyphon [J]. Ind Eng Chem Res, 2012, 51(3): 1423–1428. DOI: https://doi.org/10.1021/ie202110g.

SHANBEDI M, HERIS S Z, AMIRI A, BANIADAM M. Improvement in heat transfer of a two-phased closed thermosyphon using silver-decorated MWCNT/water [J]. J Dispers Sci Technol, 2013: 130905033551000. DOI: https://doi.org/10.1080/01932691.2013.833101.

KHANDEKAR S, JOSHI Y M, MEHTA B. Thermal performance of closed two-phase thermosyphon using nanofluids [J]. Int J Therm Sci, 2008, 47(6): 659–667. DOI: https://doi.org/10.1016/j.ijthermalsci.2007.06.005.

CHEN Y J, WANG P Y, LIU Z H. Application of water-based SiO2 functionalized nanofluid in a loop thermosyphon [J]. Int J Heat Mass Transf, 2013, 56: 59–68. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.09.048.

PARK Y, TANSHEN M R, NINE M J, CHUNG H, JEONG H. Characterizing pressure fluctuation into single-loop oscillating heat pipe [J]. Journal of Central South University, 2012, 19(9): 2578–2583. DOI: https://doi.org/10.1007/s11771-012-1313-x.

XU R J, ZHANG X H, WANG R X, XU S H, WANG H S. Experimental investigation of a solar collector integrated with a pulsating heat pipe and a compound parabolic concentrator [J]. Energy Convers Manag, 2017, 148: 68–77. DOI: https://doi.org/10.1016/j.enconman.2017.04.045.

KARGAR SHARIF ABAD H, GHIASI M, JAHANGIRI MAMOURI S, SHAFII M B. A novel integrated solar desalination system with a pulsating heat pipe [J]. Desalination, 2013, 311: 206–210. DOI: https://doi.org/10.1016/j.desal.2012.10.029.

JALILIAN M, KARGARSHARIFABAD H, ABBASI GODARZI A, GHOFRANI A, SHAFII M. B. Simulation and optimization of pulsating heat pipe flat-plate solar collectors using neural networks and genetic algorithm: A semi-experimental investigation [J]. Clean Technol Environ Policy, 2016, 18(7): 2251–2264. DOI: https://doi.org/10.1007/s10098-016-1143-x.

NAZARI M A, AHMADI M H, GHASEMPOUR R. A review on pulsating heat pipes: From solar to cryogenic applications [J]. Appl Energy, 2018, 222: 475–484. DOI: https://doi.org/10.1016/j.apenergy.2018.04.020.

CUI X, ZHU Y, LI Z, SHUN S. Combination study of operation characteristics and heat transfer mechanism for pulsating heat pipe [J]. Appl Therm Eng, 2014, 65(1, 2):. 394–402. DOI: https://doi.org/10.1016/j.applthermaleng.2014.01.030.

VENKATA SURESH J, BHRAMARA P. CFD analysis of multi turn pulsating heat pipe [J]. Mater Today Proc, 2017, 4(2): 2701–2710. DOI: https://doi.org/10.1016/j.matpr.2017.02.146.

XUE Z H, QU W. Experimental and theoretical research on a ammonia pulsating heat pipe: New full visualization of flow pattern and operating mechanism study [J]. Int J Heat Mass Transf, 2017, 106: 149–166. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.042.

KHEDKAR S G, PACHGHARE P R, MAHALLE A M. Effect of working fluid on thermal performance of closed loop pulsating heat pipe: A review [J]. National Conference on Innovative Paradigms in Engineering & Technolog, 2012, 2(3): 41–48. DOI: https://doi.org/www.researchgate.net/publication/254861913_Effect_of_Working_Fluid_on_Thermal_Performance_of_Closed_Loop_Pulsating_Heat_Pipe_A_Review.

ZHANG X M. Experimental study of a pulsating heat pipe using Fc-72, Ethanol, and water as working fluids [J]. Exp Heat Transf, 2004, 17(1): 47–67. DOI: https://doi.org/10.1080/08916150490246546.

MA H B, WILSON C, YU Q, PARK K, CHOI U S, TIRUMALA M. An experimental investigation of heat transport capability in a nanofluid oscillating heat pipe [J]. J Heat Transfer, 2006, 128(11): 1213–1216. DOI: https://doi.org/10.1115/1.2352789.

WILSON C A. Experimental investigation of nanofluid oscillating heat pipes [C]// University of Missouri–Columbia, 2006. DOI: https://doi.org/mospace.umsystem.edu/xmlui/bitstream/handle/10355/4553/research.pdf?sequence=3&origin=publication_detail.

JIA H, JIA L, TAN Z. An experimental investigation on heat transfer performance of nanofluid pulsating heat pipe [J]. J Therm Sci, 2013, 22(5): 484–490. DOI: https://doi.org/10.1007/s11630-013-0652-8.

RUDRESHA S, KUMAR V. CFD analysis and experimental investigation on thermal performance of closed loop pulsating heat pipe using different nanofluids experiments apparatus and procedure [J]. Int J Adv Res, 2014, 2(8): 753–760. DOI: https://doi.org/www.journalijar.com/article/2552/cfd-analysis-and-experimental-investigation-on-thermal-performance-of-closed-loop-pulsating-heat-pipe-using-different-nanofluids/.

WANG S, LIN Z, ZHANG W, CHEN J. Experimental study on pulsating heat pipe with functional thermal fluids [J]. Int J Heat Mass Transf, 2009, 52(21, 22): 5276–5279. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2009.04.033.

SHANBEDI M, ZEINALI HERIS S, BANIADAM M, AMIRI A. The effect of multi-walled carbon nanotube/water nanofluid on thermal performance of a two-phase closed thermosyphon [J]. Exp Heat Transf, 2013, 26(1): 26–40. DOI: https://doi.org/10.1080/08916152.2011.631078.

HUMINIC G, HUMINIC A, FLEACA C, DUMITRACHE F, MORJAN I. Thermo-physical properties of water based SiC nanofluids for heat transfer applications [J]. Int Commun Heat Mass Transf, 2017, 84: 94–101. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2017.04.006.

MOHAMMADI M, TASLIMIFAR M, HAGHAYEGH S, HSNNANI S K, SHAFII M B, SAIDI M H. Open-loop pulsating heat pipes charged with magnetic nanofluids: Powerful candidates for future electronic coolers [J]. Nanoscale Microscale Thermophys Eng, 2014, 18(1): 18–38. DOI: https://doi.org/10.1080/15567265.2013.787570.

GOSHAYESHI H R, GOODARZI M, DAHARI M. Effect of magnetic field on the heat transfer rate of kerosene/Fe2O3 nanofluid in a copper oscillating heat pipe [J]. Exp Therm Fluid Sci, 2015, 68: 663–668. DOI: https://doi.org/10.1016/j.expthermflusci.2015.07.014.

WANNAPAKHE S, RITTIDECH S, BUBPHACHOT B, WATANABE O. Heat transfer rate of a closed-loop oscillating heat pipe with check valves using silver nanofluid as working fluid [J]. J Mech Sci Technol, 2009, 23(6): 1576–1582. DOI: https://doi.org/10.1007/s12206-009-0424-2.

GONZALEZ M, KIM Y J. Experimental study of a pulsating heat pipe using nanofluid as a working fluid [C]// In Fourteenth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). 2014: 541–546. DOI: https://doi.org/10.1109/ITHERM.2014.6892328.

LIN Y H, KANG S W, CHEN H L. Effect of silver nano-fluid on pulsating heat pipe thermal performance [J]. Appl Therm Eng, 2008, 28(11, 12): 1312–1317. DOI: https://doi.org/10.1016/j.applthermaleng.2007.10.019.

PARK K, MA H. Nanofluid effect on the heat transport capability in a well-balanced oscillating heat pipe [J]. J Thermophys Heat Transf, 2007, 21(2): 443–445. DOI: https://doi.org/10.2514/1.22409.

KARTHIKEYAN V K, RAMACHANDRAN K, PILLAI B C, BRUSLY SOLOMON A. Effect of nanofluids on thermal performance of closed loop pulsating heat pipe [J]. Exp Therm Fluid Sci, 2014, 54: 171–178. DOI: https://doi.org/10.1016/j.expthermflusci.2014.02.007.

TANSHEN M R, LEE S, KIM J, KANG D, NOH J, CHUNG H S, JEONG H M, HUH S. Pressure distribution inside oscillating heat pipe charged with aqueous Al2O3 nanoparticles, MWCNTs and their hybrid [J]. Journal of Central South University, 2014, 21(6): 2341–2348. DOI: https://doi.org/10.1007/s11771-014-2186-y.

TANSHEN M R, MUNKHBAYAR B, NINE M J, CHUNG H, JEONG H. Effect of functionalized MWCNTs/water nanofluids on thermal resistance and pressure fluctuation characteristics in oscillating heat pipe [J]. Int Commun Heat Mass Transf, 2013, 48: 93–98. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2013.08.011.

JI Y, WILSON C, CHEN H, MA H. Particle shape effect on heat transfer performance in an oscillating heat pipe [J]. Nanoscale Res Lett, 2011, 6(1): 296. DOI: https://doi.org/10.1186/1556-276X-6-296.

ESFAHANI M R, LANGURI E M, NUNNA M R. Effect of particle size and viscosity on thermal conductivity enhancement of graphene oxide nanofluid [J]. Int Commun Heat Mass Transf, 2016, 76: 308–315. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2016.06.006.

HOSSEIN KARIMI DARVANJOOGHI M, NASR ESFAHANY M. Experimental investigation of the effect of nanoparticle size on thermal conductivity of in-situ prepared silica–ethanol nanofluid [J]. Int Commun Heat Mass Transf, 2016, 77: 148–154. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2016.08.001.

LEE S, CHOI S U S, LI S, EASTMAN J A. Measuring thermal conductivity of fluids containing oxide nanoparticles [J]. J Heat Transfer, 1999, 121(2): 280. DOI: https://doi.org/10.1115/1.2825978.

CHOPKAR M, SUDARSHAN S, DAS P K, MANNA I. Effect of particle size on thermal conductivity of nanofluid [J]. Metall Mater Trans A, 2008, 39(7): 1535–1542. DOI: https://doi.org/10.1007/s11661-007-9444-7.

JI Y, MA H, SU F, WANG G. Particle size effect on heat transfer performance in an oscillating heat pipe [J]. Exp Therm Fluid Sci, 2011, 35(4): 724–727. DOI: https://doi.org/10.1016/j.expthermflusci.2011.01.007.

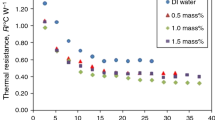

NAZARI M A, GHASEMPOUR R, AHMADI M H, HEYDARIAN G, SHAFII M B. Experimental investigation of graphene oxide nanofluid on heat transfer enhancement of pulsating heat pipe [J]. Int Commun Heat Mass Transf, 2018, 91: 90–94. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2017.12.006.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Nazari, M.A., Ahmadi, M.H., Sadeghzadeh, M. et al. A review on application of nanofluid in various types of heat pipes. J. Cent. South Univ. 26, 1021–1041 (2019). https://doi.org/10.1007/s11771-019-4068-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4068-9