Abstract

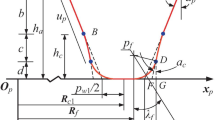

In order to effectively improve meshing performance of spiral bevel and hypoid gears generated by the duplex helical method, the effects of straight lined and circular cutting edges profile on meshing and contact of spiral bevel and hypoid gears were investigated analytically. Firstly, a mathematical model of spiral bevel and hypoid gears with circular blade profile was established according to the cutting characteristics of the duplex helical method. Based on a hypoid gear drive, the tooth bearings and the functions of transmission errors of four design cases were analyzed respectively by the use of the tooth contact analysis (TCA), and the contact stresses of the four design cases were analyzed and compared using simulation software. Finally, the curvature radius of the circular profile blade was optimized. The results show that the contact stresses are availably reduced, and the areas of edge contact and severe contact stresses can be avoided by selecting appropriate circular blade profile. In addition, the convex and concave sides are separately modified by the use of different curvature radii of inside and outside blades, which can increase the flexibility of the duplex helical method.

Similar content being viewed by others

References

XIE Shuang-xi. A genuine face milling cutter geometric model for spiral bevel and hypoid gears [J]. International Journal of Advanced Manufacturing Technology, 2013, 67: 2619–2626.

ARTONI A, BRACCI A, GABICCINI M, GUIGGIANI M. Optimization of the loaded contact pattern in hypoid gears by automatic topography modification [J]. ASME Journal of Mechanical Design, 2009, 131: 011008.

STADTFELD H J. Guidelines for modern bevel gear grinding [J]. Gear Technology, 2008: 42–53.

ZENG Tao. Design and manufacture of spiral bevel and hypoid gears [J]. Harbin: Harbin Institute of Technology Press, 1989: 209–218. (in Chinese)

LELKES M, MÁRIALIGETI J, PLAY D. Numerical determination of cutting parameters for the control of klingelnberg spiral bevel gear geometry [J]. ASME Journal of Mechanical Design, 2002, 124: 761–771.

NIE Shao-wu, DENG Xiao-zhong, LI Tian-xing, ZHANG Hua, DENG Jing. Tooth meshing contact analysis for bevel gears by face hobbing method based on arc blade profile [J]. Journal of Aerospace Power, 2012, 27(6): 1424–1431. (in Chinese)

NIE Shao-wu, DENG Xiao-zhong, SU Jan-xin, GAO Zhen-shan, ZHANG Hua. Flank modification simulation and high-order transmission error design for epicycloid bevel gears [J]. Journal of Machine Design, 2013, 30(5): 32–37. (in Chinese)

KAWASAKI K. Effect of cutting edge profile on meshing and contact of spiral bevel gears in cyclo-palloid system [J]. Mechanics Based Design of Structures and Machines, 2005, 33: 343–357.

SHIH Y P. A lengthwise modification for face-Hobbed straight bevel gears [C]// Proceedings of the ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. New York: American Society of Mechanical Engineers, 2013: 1–7.

SIMON V. Design of face-hobbed spiral bevel gears with reduced maximum tooth contact pressure and transmission errors [J]. Chinese Journal of Aeronautics, 2013, 26(3): 777–790. (in Chinese)

SIMON V V. Influence of tooth modifications on load distribution in face-hobbed spiral bevel gears [C]// Proceedings of the ASME 2011 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference. New York: American Society of Mechanical Engineers, 2011: 1–13.

SIMON V V. Influence of tooth modifications on tooth contact in face-hobbed spiral bevel gears [J]. Mechanism and Machine Theory, 2011, 46: 1980–1998.

HUSTON R L, COY J J. Surface geometry of circular cut spiral bevel gears [J]. ASME Journal of Mechanical Design, 1982, 104: 743–748.

LITVIN F L, FUENTES A. Gear geometry and applied theory (second edition) [J]. New York: Cambridge University Press, 2004: 627–678.

LITVIN F L, FUENTES A, HAYASAKA K. Design, manufacture, stress analysis, and experimental tests of low-noise high endurance spiral bevel gears [J]. Mechanism and Machine Theory, 2006, 41: 83–118.

FUENTES A, GONZALEZ-PEREZ I, LITVIN F L, HAYASAKA K, YUKISHIMA K. Design, manufacture, and evaluation of prototypes of low-Noise high-endurance spiral bevel gear drives [C]// Proceedings of IDETC/CIE 2005 ASME 2005 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference. New York: American Society of Mechanical Engineers, 2005: DETC2005-84013.

LITVIN F L, WANG A G, HANDSCHUH R F. Computerized generation and simulation of meshing and contact of spiral bevel gears with improved geometry [J]. Computer Methods in Applied Mechanics and Engineering, 1998, 158: 35–64.

SIMON V. Head-cutter for optimal tooth modifications in spiral bevel gears [J]. Mechanism and Machine Theory, 2009, 44: 1420–1435.

SIMON V. Optimal modifications of gear tooth surfaces [J]. Gear Technology, 2011: 62–72.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2011CB706800-G) supported by the National Basic Research Program of China; Project(51375159) supported by the National Natural Science Foundation of China; Project(20120162110004) supported by the Postdoctoral Science Foundation of China; Project(2015JJ5020) supported by the Science Foundation of Hunan Province, China

Rights and permissions

About this article

Cite this article

Zhang, Y., Yan, Hz., Zeng, T. et al. Tooth surface geometry optimization of spiral bevel and hypoid gears generated by duplex helical method with circular profile blade. J. Cent. South Univ. 23, 544–554 (2016). https://doi.org/10.1007/s11771-016-3101-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3101-5