Abstract

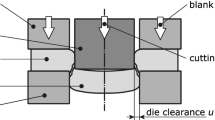

In order to cope with the difficulties of shearing operations of press hardened steels, this work attempted to optimize these processes. Herefore, it is necessary to reduce the press forces and stresses in tools, while still obtaining adequate sheared edge quality levels. To reach this goal, different punch chamfer angles (0°, 2°, 7° and 20°) and relative cutting clearances (5, 10 and 15 % of the sheet thickness) were tested in a cutting tool, which was adapted in a way that different active elements could be mounted. The tool was equipped with a measurement system, which allowed the determination of the process forces in three dimensions at each punch stroke. Basis was an AlSi coated 22MnB5 sheet with a thickness of 1.5 mm. In addition a finite element model was developed to predict the stress distribution in tools and the sheared edge qualities. According to the experimental results the application of a 20° chamfer angle succeeded to reduce the forces and stresses of tools, but the sheared parts had a poor quality. In contrast, the 7° chamfer angle gave lowest tool stresses and sufficient part qualities, but the forces were very high. The simulation results agreed with the experimental data, except for the prediction of the rollover zone. These deviations were attributed among others to the presence of the AlSi coating, which was not considered.

Similar content being viewed by others

References

Goede M (2009) SuperLIGHT-car project—an integrated research approach for lightweight car body innovations. In: Proceedings of the international conference on innovative developments for lightweight vehicle structures, Germany, pp 25–38

Banik J, Lenze FJ, Sikora S, Laurenz R (2011) Tailored properties—a pivotal question for hot forming. In: Proceedings of the 3rd international conference on hot sheet metal forming of high-performance steel, Germany, pp 13–20

Mackensen A, Golle M, Golle R, Hoffmann H (2010) Experimental investigation of the cutting force reduction during the blanking operation of AHSS sheet materials. CIRP Ann Manuf Technol 59:283–286

Fritz M (2011) Process optimization of laser cutting and in the heating process. In: Proceedings of the 3rd international conference on hot sheet metal forming of high-performance steel, Germany, pp 239–246

Picas I, Hernández R, Casellas D, Valls I (2010) Strategies to increase the tool performance in punching operations of UHSS. In: Proceedings of the 50th IDDRG conference, Austria, pp 325–334

Picas I, Muñoz R, Lara A, Hernández R, Casellas D (2011) Effect of the cutting process in the mechanical and fatigue properties of press hardened 22MnB5 steel. In: Proceedings of the 3rd international conference on hot sheet metal forming of high-performance steel, Germany, pp 85–92

Hambli R, Reszka M (2002) Fracture criteria identification using an inverse technique method and blanking experiment. Int J Mech Sci 44:1349–1361

So H, Faßmann D, Hoffmann H, Golle M, Schaper M (2012) An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J Mater Process Technol 212:437–449

Abaqus (2010) Abaqus 6.10 online documentation. Dassault Systèmes

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24:1071–1096

Beese A, Luo M, Li Y, Bai Y, Wierzbicki T (2010) Partially coupled anisotropic fracture model for sheets. Eng Fract Mech 77:1128–1152

Bai Y, Wierzbicki T (2010) Application of extended Mohr–Coulomb criterion to ductile fracture. Int J Fract 161:1–20

Acknowledgments

The research leading to these results has received funding from the European Union’s Seventh Framework Programme (FP7/2007–2013) under grant agreement n° CP-FP 228841-2 (TailorTool).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nothhaft, K., Suh, J., Golle, M. et al. Shear cutting of press hardened steel: influence of punch chamfer on process forces, tool stresses and sheared edge qualities. Prod. Eng. Res. Devel. 6, 413–420 (2012). https://doi.org/10.1007/s11740-012-0404-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0404-8