Abstract

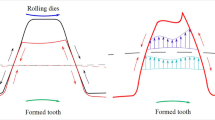

The complex shape of gears is very attractive to the near-net-shape PM technology. The strength of conventional PM parts is reduced by the residual porosity due to the power law relationship between the density and the mechanical properties. The maximum stresses in gears are found in the tooth root and the flank near or directly at the surface, so that by a local densification of the near surface layer the maximum load carrying capacity of the complete gear can be increased. This surface densification can be achieved by a rolling process. Due to the own elastic-plastic behavior of PM materials and due to the continuous change of the contact conditions during rolling, the process is too complex to be described analytically. To gain a better understanding of the process, the numerical simulation is a capable method. In this paper an FEA model is prepared and verified based on an experimental investigation. Additionally, case studies were carried out in order to analyze the relationship between the process parameters and the densification result.

Similar content being viewed by others

References

Beiss P (2003) Iron and steel: manufacturing route, chap 5, structural mass production. In: Landolt-Börnstein—Group VIII Advanced Materials and Technologies, pp 5–20

Hanejko F, Rawlings A, Narasimhan KSV (2005) Surface densified P/M steel—comparison with wrought steel grades. Euro PM2005, Prague, pp 509–511

Petersen J (2004) Wälzfestigkeitsuntersuchung von Sinterstählen und Neuentwicklung eines Wälzfestigkeitsprüfstands. Dissertation RWTH, Aachen University

Kotthoff G (2003) Neue Verfahren zur Tragfähigkeitssteigerung von gesinterten Zahnrädern. Dissertation RWTH, Aachen University

Nigarura S, Trasorras JRL (2001) Rolling contact fatigue properties of DensiFormed™ sintered alloys advances in powder metallurgy and particulate materials. MPIF/APMI, Princeton, pp 155–168

Lipp K, Sonsino CM (2000) Hochfeste Sinterstähle—Einsatz hochfester umweltfreundlicher Sinterstähle für hochbelastbare Bauteile. Forschungskuratorium für Maschinenbau (FKM), Frankfurt/Main

Nigarura S, Blanchard P, Trasorras JRL (2001) Processing effects on rolling contact fatigue properties of sintered and DensiForme™ ferrous alloy. MPIF/APMI, Princeton, pp 16–35

Lawcock R, Buckley-Golder K, Sarafinchan D (1999) Testing of high endurance PM steels, for automotive transmission gearing components. In: Society of Automotive Engineers Paper 1999-01-0293

Jones PK, Buckley-Golder K, Lawcock R, Shivanath R (1997) Densification strategies for high endurance P/M components. Int J Powder Metallurgy 33(3):37–44

Strehl R (1997) Tragfähigkeit von Zahnrädern aus hochfesten Sinterstählen. Dissertation RWTH, Aachen University

Chidester AJ, Green WB, Corbo K (1993) High-Hardness, High-Density Powder Metal Bearing Applications. ASTM, Philadelphia

Cadle TM, Landgraf CJ, Brewin P, Nurthen P (1991) Rolling contact of P/M steel—effects of sintering temperature and material density advances in powder metallurgy and particulate materials. MPIF/APMI, Princeton, pp 175–182

Trasorras JRL, Nigarura S, Sigl LS (2006) DensiForm® technology for wrought-steel-like performance of powder metal components. In: Society of Automotive Engineers Paper 2006-01-0398

Forden L, Bengtsson S, Bergström M (2005) Comparison of high performance PM gears manufactured by conventional and warm compaction and surface densification. Powder Metallurgy 48(1):10–12

Sandner C, Ratzi R, Lorenz B, Tobie T (2002) Sintered gears—achievable load-carrying capacities by conventional and new production methods. In: International conference on gears, Munich, pp 295–310

Höganäs AB (1998) Eisen- und Stahlpulver für Sinterformteile. Firmenschrift der Höganäs AB, Höganäs

Trasorras JRL, Riley ET (2006) US007025929B2: Method and apparatus for densifying powder metal gears

Woolf RM (2005) US006899846B2: Method of producing surface densified metal articles

Woolf R (2003) US006517772B1: Apparatus and method for forming powder metal gears

Woolf RM, Trasorras JRL (2000) US006151941A: Apparatus and method for roll forming gears

Shivanath R, Peter J (1998) US005729822A: Gear

Cole CJ, Shivanath R, Jones P (1998) US005711187A: Gear wheels rolled from powder metal blanks and method of manufacture

Hertz H (1895) Über die Berührung elastischer Körper, Leipzig

Altena H, Danninger H (2005) Wärmebehandlung von Sinterstahl-Präzisionsteilen, Part 2: Prozess und Anlagentechnik. BHM Berg- und Hüttenmännische Monatshefte 150(5):170–175

Danninger H, Altena H (2005) Wärmebehandlung von Sinterstahl-Präzisionsteilen, Part 1: Basic considerations. BHM Berg- und Hüttenmännische Monatshefte 150(3):77–81

Bassan D, Asit A, Pidria MF, Zingale P (2005) PM surface densification technology: a numerical-experimental methodology for rolling tool design. Euro PM2005, Prague, pp 217–224

Bassan D (2004) Asti M, Pidria M, Zingale, P.: A new simulation methodology for PM surface densification process. Euro PM2004, Vienna

Engström A (2003) FEM simulations of gear surface densification. Mini Thesis, Swedish Institute for Metals Research

Kuhn HA, Downey CL (1971) Deformation characteristics and plasticity theory of sintered powder materials. Int J Powder Metallurgy 7(1):15–25

Weichert D (1999) Mechanik II für Ingenieure : Festigkeitslehre. RWTH, Aachen University, Aachen

Doraivelu SM, Gegel HL, Gunasekera JS, Malas JC, Morgan JT (1984) A new yield function for compressible P/M materials. Int J Mech Sci 26:527

Shima S, Oyane M (1976) Plasticity theory for porous materials. Int J Mech Sci 18:285

Kauffmann P (2005) Numerische Simulation des Oberflächenverdichtens von gesinterten Zahnrädern durch Querwalzen. Mini Thesis, Laboratory of Machine Tools and Production Engineering, RWTH, Aachen University

Gurson AL (1975) Plastic flow and fracture behavior of ductile materials incorporating void nucleation, growth and interaction. Dissertation, Brown University

Ponte Castañeda P, Zaidman M (1994) Constitutive models for porous materials with evolving microstructure. J Mech Phys Solids 42:1459–1497

Gologanu M, Leblond JB (1993) Approximate models for ductile metals containing non-spherical voids - case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41:1723–1754

Author information

Authors and Affiliations

Corresponding author

Additional information

The investigations described in this present paper were sponsored by the WZL Gear Research-Circle.

Rights and permissions

About this article

Cite this article

Klocke, F., Schröder, T. & Kauffmann, P. Fundamental study of surface densification of PM gears by rolling using FE analysis. Prod. Eng. Res. Devel. 1, 113–120 (2007). https://doi.org/10.1007/s11740-007-0006-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0006-z