Abstract

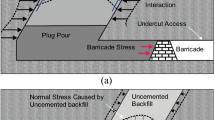

The curing temperature-dependent cement hydration causes the nonlinear evolution of fracture behavior and properties of fiber-reinforced cemented paste backfill (CPB) and thus influences the stability of mine backfill materials in deep mines. Therefore, the coupled effect of curing temperature (20, 35, and 45 °C) and cement hydration at different curing times (3, 7, and 28 d) on the mode-I and mode-II fracture behavior and properties of fiber-reinforced CPB is investigated. A comprehensive experimental testing program consisting of semicircular bend tests, direct shear tests, measurement of volumetric water content and matric suction, TG/DTG tests, and SEM observation is carried out. The results show that the coupled thermochemical effect results in strongly nonlinear development of pre- and post-peak behavior of fiber-reinforced CPB. Moreover, the results discover a positive linear correlation between fracture toughness and shear strength parameters and also reveal the vital role played by matric suction in the formation of fracture toughness. Furthermore, predictive functions are developed to estimate the coupled thermochemical effect on the development of KIc and KIIc. Therefore, the findings and the developed mathematical tools have the potential to promote the successful application of fiber-reinforced CPB technology in deep underground mines.

Similar content being viewed by others

References

Yılmaz T, Ercikdi B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test. Nondestructive Testing and Evaluation, 2016, 31(3): 247–266

Sari M, Yilmaz E, Kasap T, Guner N U. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Construction & Building Materials, 2022, 328: 127109

Ercikdi B, Külekci G, Yılmaz T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings. Construction & Building Materials, 2015, 93: 573–583

Libos I L S, Cui L. Time- and temperature-dependence of compressive and tensile behaviors of polypropylene fiber-reinforced cemented paste backfill. Frontiers of Structural and Civil Engineering, 2021, 15(4): 1025–1037

Yılmaz T, Ercikdi B. Effect of construction and demolition waste on the long-term geo-environmental behaviour of cemented paste backfill. International Journal of Environmental Science and Technology, 2022, 19(5): 3701–3714

Cavusoglu I, Yilmaz E, Yilmaz A O. Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technology, 2021, 384: 17–28

Qi C, Guo L, Wu Y, Zhang Q, Chen Q. Stability evaluation of layered backfill considering filling interval, backfill strength and creep behavior. Minerals (Basel), 2022, 12(2): 1–16

Zhang H, Cao S, Yilmaz E. Influence of 3D-printed polymer structures on dynamic splitting and crack propagation behavior of cementitious tailings backfill. Construction & Building Materials, 2022, 343: 128137

Li J, Cao S, Yilmaz E, Liu Y. Compressive fatigue behavior and failure evolution of additive fiber-reinforced cemented tailings composites. International Journal of Minerals Metallurgy and Materials, 2022, 29(2): 345–355

Xue G, Yilmaz E, Song W, Cao S. Mechanical, flexural and microstructural properties of cement-tailings matrix composites: Effects of fiber type and dosage. Composites. Part B, Engineering, 2019, 172: 131–142

Yi X W, Ma G W, Fourie A. Centrifuge model studies on the stability of fibre-reinforced cemented paste backfill stopes. Geotextiles and Geomembranes, 2018, 46(4): 396–401

Zhao Z, Cao S, Yilmaz E. Effect of layer thickness on flexural property and microstructure of 3D printed rhomboid polymer reinforced cemented tailings composites. International Journal of Minerals Metallurgy and Materials, 2023, 30: 236–249

Chakilam S, Cui L. Effect of polypropylene fiber content and fiber length on the saturated hydraulic conductivity of hydrating cemented paste backfill. Construction & Building Materials, 2020, 262: 120854

Cao S, Yilmaz E, Yin Z, Xue G, Song W, Sun L. CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cement and Concrete Composites, 2021, 116: 103865

Wang A, Cao S, Yilmaz E. Effect of height to diameter ratio on dynamic characteristics of cemented tailings backfills with fiber reinforcement through impact loading. Construction & Building Materials, 2022, 322: 126448

Chen X, Shi X, Zhang S, Chen H, Zhou J, Yu Z, Huang P. Fiber-reinforced cemented paste backfill: The effect of fiber on strength properties and estimation of strength using nonlinear models. Materials (Basel), 2020, 13(3): 1–20

Wang Y, Yu Z, Wang H. Experimental investigation on some performance of rubber fiber modified cemented paste backfill. Construction & Building Materials, 2021, 271: 121586

Yi X, Ma G, Fourie A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotextiles and Geomembranes, 2015, 43(3): 207–215

Wang C, Ren Z, Huo Z, Zheng Y, Tian X, Zhang K, Zhao G. Properties and hydration characteristics of mine cemented paste backfill material containing secondary smelting water-granulated nickel slag. Alexandria Engineering Journal, 2021, 60(6): 4961–4971

Torabi A R, Pirhadi E. Extension of the virtual isotropic material concept to mixed mode I/II loading for predicting the last-ply-failure of U-notched glass/epoxy laminated composite specimens. Composites. Part B, Engineering, 2019, 176: 107287

Torabi A R, Majidi H R, Cicero S, Ibáñez-Gutiérrez F T, Fuentes J D. Experimental verification of the Fictitious Material Concept for tensile fracture in short glass fibre reinforced polyamide 6 notched specimens with variable moisture. Engineering Fracture Mechanics, 2019, 212: 95–105

Ajayi O, Le Pen L, Zervos A, Powrie W. A behavioural framework for fibre-reinforced gravel. Geotechnique, 2017, 67(1): 56–68

Jahanbakhsh P, Saberi K F, Soltaninejad M, Hashemi S H. Laboratory investigation of modified roller compacted concrete pavement (RCCP) containing macro synthetic fibers. International Journal of Pavement Research and Technology, 2022, 1–15

Wang W, Kang H, Li N, Guo J, Girma D Y, Liu Y. Experimental investigations on the mechanical and microscopic behavior of cement-treated clay modified by nano-MgO and fibers. International Journal of Geomechanics, 2022, 22(6): 04022059

Dong Q, Liang B, Jia L, Jiang L. Effect of sulfide on the long-term strength of lead-Zinc tailings cemented paste backfill. Construction & Building Materials, 2019, 200: 436–446

Libos I L S, Cui L. Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Engineering Fracture Mechanics, 2020, 235: 107174

Liu J, Li Y, Qiao L. Analytical solutions of stress intensity factors for a centrally cracked brazilian disc considering tangential friction effects. Rock Mechanics and Rock Engineering, 2022, 55(4): 2459–2470

Xu W, Cao P. Fracture behaviour of cemented tailing backfill with pre-existing crack and thermal treatment under three-point bending loading: Experimental studies and particle flow code simulation. Engineering Fracture Mechanics, 2018, 195: 129–141

Wang X, Yu J, Li Q, Yu Y, Lv H. Study on the crack evolution process and stress redistribution near crack tip in soil. International Journal of Geomechanics, 2022, 22(1): 04021255

Liu J, Zhao L, Chang F, Chi L. Mechanical properties and microstructure of multilayer graphene oxide cement mortar. Frontiers of Structural and Civil Engineering, 2021, 15(4): 1058–1070

Raffaldi M J, Seymour J B, Richardson J, Zahl E, Board M. Cemented paste backfill geomechanics at a narrow-vein underhand cut-and-fill mine. Rock Mechanics and Rock Engineering, 2019, 52(12): 4925–4940

Fang K, Fall M. Effects of curing temperature on shear behaviour of cemented paste backfill-rock interface. International Journal of Rock Mechanics and Mining Sciences, 2018, 112: 184–192

Fang K, Ren L, Jiang H. Development of Mode I and Mode II fracture toughness of cemented paste backfill: Experimental results of the effect of mix proportion, temperature and chemistry of the pore water. Engineering Fracture Mechanics, 2021, 258: 108096

Yilmaz E, Fall M. Paste Tailings Management. Cham: Springer International, 2017

Fang K, Fall M. Chemically induced changes in the shear behaviour of interface between rock and tailings backfill undergoing cementation. Rock Mechanics and Rock Engineering, 2019, 52(9): 3047–3062

Libos I L S, Cui L, Liu X. Effect of curing temperature on time-dependent shear behavior and properties of polypropylene fiber-reinforced cemented paste backfill. Construction & Building Materials, 2021, 311: 125302

Koohestani B, Belem T, Koubaa A, Bussière B. Experimental investigation into the compressive strength development of cemented paste backfill containing nano-silica. Cement and Concrete Composites, 2016, 72: 180–189

Ayatollahi M R, Aliha M R M. Fracture parameters for a cracked semi-circular specimen. International Journal of Rock Mechanics and Mining Sciences, 2004, 41: 20–25

Lim I L, Johnston I W, Choi S K. Stress intensity factors for semicircular specimens under three-point bending. Engineering Fracture Mechanics, 1993, 44(3): 363–382

Matsuda S. Theoretical approach to determine dynamic fatigue strength characteristics of ceramics under variable loading rates on the basis of SCG concept. International Journal of Fracture, 2019, 215(1–2): 175–182

Torabi A R, Jabbari M, Akbardoost J. Scaling effects on notch fracture toughness of graphite specimens under mode I loading. Engineering Fracture Mechanics, 2020, 235: 107153

Huang S, Yan E, Fang K, Li X. Effects of binder type and dosage on the mode I fracture toughness of cemented paste backfill-related structures. Construction & Building Materials, 2021, 270: 121854

Feng G, Kang Y, Wang X. Fracture failure of granite after varied durations of thermal treatment: An experimental study. Royal Society Open Science, 2019, 6(7): 190144

Ayatollahi M R, Aliha M R M. Wide range data for crack tip parameters in two disc-type specimens under mixed mode loading. Computational Materials Science, 2007, 38(4): 660–670

Torabi A R, Jabbari M, Akbardoost J. Mixed mode notch fracture toughness assessment of quasi-brittle polymeric specimens at different scales. Theoretical and Applied Fracture Mechanics, 2020, 109: 102682

Torabi A R, Pirhadi E. Translaminar notch fracture toughness expressions for composite laminates. Theoretical and Applied Fracture Mechanics, 2022, 119: 103332

Fang K, Cui L. Experimental investigation of fiber content and length on curing time-dependent mode-I fracture behavior and properties of cemented paste backfill and implication to engineering design. Fatigue & Fracture of Engineering Materials & Structures, 2022, 45(11): 3302–3318

Torabi A R, Rahimi A S, Ayatollahi M R. Tensile fracture analysis of a ductile polymeric material weakened by U-notches. Polymer Testing, 2017, 64: 117–126

Torabi A R, Rahimi A S, Ayatollahi M R. Fracture study of a ductile polymer-based nanocomposite weakened by blunt V-notches under mode I loading: Application of the Equivalent Material Concept. Theoretical and Applied Fracture Mechanics, 2018, 94: 26–33

Torabi A R, Rahimi A S, Ayatollahi M R. Elastic-plastic fracture assessment of CNT-reinforced epoxy/nanocomposite specimens weakened by U-shaped notches under mixed mode loading. Composites. Part B, Engineering, 2019, 176: 107114

Torabi A R, Rahimi A S, Ayatollahi M R. Mixed mode I/II fracture prediction of blunt V-notched nanocomposite specimens with nonlinear behavior by means of the Equivalent Material Concept. Composites. Part B, Engineering, 2018, 154: 363–373

Rahimi A S, Ayatollahi M R, Torabi A R. Ductile failure analysis of blunt V-notched epoxy resin plates subjected to combined tension-shear loading. Polymer Testing, 2018, 70: 57–66

Aliha M R M, Saghafi H. The effects of thickness and Poisson’s ratio on 3D mixed-mode fracture. Engineering Fracture Mechanics, 2013, 98: 15–28

Yuan X, Tian Y, Liu Q, Liu S, Dou Q, Aliha M R M. KIc and KIIc measurement for hot mix asphalt mixtures at low temperature: Experimental and theoretical study using the semicircular bend specimen with different thicknesses. Fatigue & Fracture of Engineering Materials & Structures, 2021, 44(3): 832–846

Vizini V O S, Futai M M. Mode II fracture toughness determination of rock and concrete via Modified Direct Shear Test. Engineering Fracture Mechanics, 2021, 257: 108007

Holthusen D, Batistão A C, Reichert J M. Amplitude sweep tests to comprehensively characterize soil micromechanics: Brittle and elastic interparticle bonds and their interference with major soil aggregation factors organic matter and water content. Rheologica Acta, 2020, 59(8): 545–563

Barani O R, Khoei A R, Mofid M. Modeling of cohesive crack growth in partially saturated porous media: A study on the permeability of cohesive fracture. International Journal of Fracture, 2011, 167(1): 15–31

Shen Z, Jiang M, Thornton C. Shear strength of unsaturated granular soils: Three-dimensional discrete element analyses. Granular Matter, 2016, 18(3): 1–13

Rahimi-Aghdam S, Bažant Z P, Abdolhosseini Qomi M J. Cement hydration from hours to centuries controlled by diffusion through barrier shells of CSH. Journal of the Mechanics and Physics of Solids, 2017, 99: 211–224

Dong P, Allahverdi A, Andrei C M, Bassim N D. Liquid cell transmission electron microscopy reveals C-S-H growth mechanism during Portland cement hydration. Materialia, 2022, 22: 101387

Jiang H, Fall M, Li Y, Han J. An experimental study on compressive behaviour of cemented rockfill. Construction & Building Materials, 2019, 213: 10–19

Yilmaz E, Belem T, Bussière B, Mbonimpa M, Benzaazoua M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents. Construction & Building Materials, 2015, 75: 99–111

Pane I, Hansen W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cement and Concrete Research, 2005, 35(6): 1155–1164

Ahmadinezhad A, Jafarzadeh F, Sadeghi H. Combination of water head control and axis translation techniques in new unsaturated cyclic simple shear tests. Soil Dynamics and Earthquake Engineering, 2019, 126: 105818

Lu S, Lu Y, Peng W, Ju Z, Ren T. A generalized relationship between thermal conductivity and matric suction of soils. Geoderma, 2019, 337: 491–497

Cui L, Fall M. An evolutive elasto-plastic model for cemented paste backfill. Computers and Geotechnics, 2016, 71: 19–29

Cui L, Fall M. A coupled thermo-hydro-mechanical-chemical model for underground cemented tailings backfill. Tunnelling and Underground Space Technology, 2015, 50: 396–414

Fang K, Fall M. Shear behaviour of rock-tailings backfill interface: Effect of cementation, rock type, and rock surface roughness. Geotechnical and Geological Engineering, 2021, 39(3): 1753–1770

Cui L, Fall M. Mechanical and thermal properties of cemented tailings materials at early ages: Influence of initial temperature, curing stress and drainage conditions. Construction & Building Materials, 2016, 125: 553–563

Acknowledgements

This research is funded by the Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, K., Cui, L. Experimental investigation of evolutive mode-I and mode-II fracture behavior of fiber-reinforced cemented paste backfill: Effect of curing temperature and curing time. Front. Struct. Civ. Eng. 17, 256–270 (2023). https://doi.org/10.1007/s11709-022-0924-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0924-z