Abstract

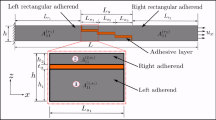

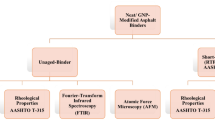

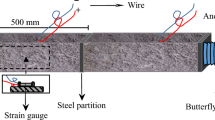

The thermodynamic property of asphalt binder is changed by the addition of crumb rubber, which in turn influences the self-healing property as well as the cohesion and adhesion within the asphalt-aggregate system. This study investigated the self-healing and interface properties of crumb rubber modified asphalt (CRMA) using thermodynamic parameters based on the molecular simulation approach. The molecular models of CRMA were built with representative structures of the virgin asphalt and the crumb rubber. The aggregate was represented by SiO2 and Al2O3 crystals. The self-healing capability was evaluated with the thermodynamic parameter wetting time, work of cohesion and diffusivity. The interface properties were evaluated by characterizing the adhesion capability, the debonding potential and the moisture susceptibility of the asphalt-aggregate interface. The self-healing capability of CRMA is found to decrease as the rubber content increases. The asphalt-Al2O3 interface with higher rubber content has stronger adhesion and moisture stability. But the influence of crumb rubber on the interfacial properties of asphalt-SiO2 interface has no statistical significance. Comparing with the interfacial properties of the asphalt-SiO2 interface, the asphalt-Al2O3 interface is found to have a stronger adhesion but a worse moisture susceptibility for its enormous thermodynamic potential for water to displace the asphalt binder.

Similar content being viewed by others

References

Zhang J, Cui S, Cai J, Pei J, Jia Y. Life-cycle reliability evaluation of semi-rigid materials based on modulus degradation model. KSCE Journal of Civil Engineering, 2018, 22(6): 2043–2054

Nejad F M, Aghajani P, Modarres A, Firoozifar H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Construction & Building Materials, 2012, 26(1): 481–189

Li R, Dai Y, Wang P, Sun C, Zhang J, Pei J. Evaluation of Nano-ZnO dispersed state in bitumen with digital imaging processing techniques. Journal of Testing and Evaluation, 2017, 46(3): 20160401

Yildirim Y. Polymer modified asphalt binders. Construction & Building Materials, 2007, 21(1): 66–72

Lo Presti D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Construction & Building Materials, 2013, 49: 863–881

Xiao F, Yao S, Wang J, Wei J, Amirkhanian S. Physical and chemical properties of plasma treated crumb rubbers and high temperature characteristics of their rubberised asphalt binders. Road Materials and Pavement Design, 2018 (in press)

Li R, Yu Y, Zhou B, Guo Q, Li M, Pei J. Harvesting energy from pavement based on piezoelectric effects: Fabrication and electric properties of piezoelectric vibrator. Journal of Renewable and Sustainable Energy, 2018, 10(5): 054701

Abdelrahman M, Carpenter S. Mechanism of interaction of asphalt cement with crumb rubber modifier. Transportation Research Record: Journal of the Transportation Research Board, 1999, 1661(1): 106–113

Shu X, Huang B. Recycling of waste tire rubber in asphalt and Portland cement concrete: An overview. Construction & Building Materials, 2014, 67: 217–224

Zanzotto L, Kennepohl G. Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transportation Research Record: Journal of the Transportation Research Board, 1996, 1530(1): 51–58

Mull M, Stuart K, Yehia A. Fracture resistance characterization of chemically modified crumb rubber asphalt pavement. Journal of Materials Science, 2002, 37(3): 557–566

Yu H, Leng Z, Zhou Z, Shih K, Xiao F, Gao Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. Journal of Cleaner Production, 2017, 141: 336–345

Li R, Wang C, Wang P, Pei J. Preparation of a novel flow improver and its viscosity-reducing effect on bitumen. Fuel, 2016, 181: 935–941

Wang S, Yuan C, Jiaxi D. Crumb tire rubber and polyethylene mutually stabilized in asphalt by screw extrusion. Journal of Applied Polymer Science, 2014, 131(23): 81–86

Sultana S, Bhasin A. Effect of chemical composition on rheology and mechanical properties of asphalt binder. Construction & Building Materials, 2014, 72: 293–300

Bhasin A, Little D N, Vasconcelos K L, Masad E. Surface free energy to identify moisture sensitivity of materials for asphalt mixes. Transportation Research Record: Journal of the Transportation Research Board, 2007, 2001(1): 37–45

Alvarez A E, Ovalles E, Epps Martin A. Comparison of asphalt rubber-aggregate and polymer modified asphalt-aggregate systems in terms of surface free energy and energy indices. Construction & Building Materials, 2012, 35: 385–392

Tan Y, Guo M. Using surface free energy method to study the cohesion and adhesion of asphalt mastic. Construction & Building Materials, 2013, 47: 254–260

Bhasin A, Howson J, Masad E, Little D, Lytton R. Effect of modification processes on bond energy of asphalt binders. Transportation Research Record: Journal of the Transportation Research Board, 2007, 1998(1): 29–37

Cheng D, Little D, Lytton R, Holste J. Surface energy measurement of asphalt and its application to predicting fatigue and healing in asphalt mixtures. Transportation Research Record: Journal of the Transportation Research Board, 2002, 1810(1): 44–53

Sun D, Sun G, Zhu X, Guarin A, Li B, Dai Z, Ling J. A comprehensive review on self-healing of asphalt materials: Mechanism, model, characterization and enhancement. Advances in Colloid and Interface Science, 2018, 256: 65–93

Bhasin A, Bommavaram D, Greenfiled M. Intrinsic healing in asphalt binders—Measurement and impact of molecular morphology. In: The 6th International Conference on Maintenance and Rehabilitation of Pavements and Technological Control. Torino: Turin Polytechnic, 2009

Zhang J, Fan Z, Hu D, Hu Z, Pei J, Kong W. Evaluation of asphaltaggregate interaction based on the rheological properties. International Journal of Pavement Engineering, 2018, 19(7): 586–592

Bhasin A, Little D N, Bommavaram R, Vasconcelos K. A framework to quantify the effect of healing in bituminous materials using material properties. Road Materials and Pavement Design, 2008, 9(sup1): 219–242

Kanitpong K, Bahia H. Relating adhesion and cohesion of asphalts to the effect of moisture on laboratory performance of asphalt mixtures. Transportation Research Record: Journal of the Transportation Research Board, 2005, 1901(1): 33–43

Kök B V, Çolak H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Construction & Building Materials, 2011, 25(8): 3204–3212

Qu X, Liu Q, Guo M, Wang D, Oeser M. Study on the effect of aging on physical properties of asphalt binder from a microscale perspective. Construction & Building Materials, 2018, 187: 718–729

Li R, Guo Q, Du H, Pei J. Mechanical property and analysis of asphalt components based on molecular dynamics simulation. Journal of Chemistry, 2017, 2017: 1531632

Chen Z, Pei J, Li R, Xiao F. Performance characteristics of asphalt materials based on molecular dynamics simulation—A review. Construction & Building Materials, 2018, 189: 695–710

Zhang L, Greenfield M L. Analyzing properties of model asphalts using molecular simulation. Energy & Fuels, 2007, 21(3): 1712–1716

Bhasin A, Bommavaram R, Greenfield M L, Little D N. Use of molecular dynamics to investigate self-healing mechanisms in asphalt binders. Journal of Materials in Civil Engineering, 2011, 23(4): 485–492

Xu G, Wang H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel, 2017, 188: 1–10

Guo M, Tan Y, Wei J. Using molecular dynamics simulation to study concentration distribution of asphalt binder on aggregate surface. Journal of Materials in Civil Engineering, 2018, 30(5): 04018075

Wang P, Zhai F, Dong Z, Wang L, Liao J, Li G. Micromorphology of asphalt modified by polymer and carbon nanotubes through molecular dynamics simulation and experiments: Role of strengthened interfacial interactions. Energy & Fuels, 2018, 32(2): 1179–1187

Ding Y, Huang B, Shu X, Zhang Y, Woods M E. Use of molecular dynamics to investigate diffusion between virgin and aged asphalt binders. Fuel, 2016, 174: 267–273

Li R, Du H, Fan Z, Pei J. Molecular dynamics simulation to investigate the interaction of asphaltene and oxide in aggregate. Advances in Materials Science and Engineering. 2016, 2016: 3817123

Sun H. COMPASS: An ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. Journal of Physical Chemistry B, 1998, 102(38): 7338–7364

van Duin A C, Dasgupta S, Lorant F, Goddard W A. ReaxFF: A reactive force field for hydrocarbons. Journal of Physical Chemistry A, 2001, 105(41): 9396–9409

Pan T, Lu Y, Lloyd S. Quantum-chemistry study of asphalt oxidative aging: An XPS-aided analysis. Industrial & Engineering Chemistry Research, 2012, 51(23): 7957–7966

Kmiecik S, Gront D, Kolinski M, Wieteska L, Dawid A E, Kolinski A. Coarse-grained protein models and their applications. Chemical Reviews, 2016, 116(14): 7898–7936

Marrink S J, Risselada H J, Yefimov S, Tieleman D P, De Vries A H. The MARTINI force field: Coarse grained model for biomolecular simulations. Journal of Physical Chemistry B, 2007, 111(27): 7812–7824

Arash B, Park H S, Rabczuk T. Mechanical properties of carbon nanotube reinforced polymer nanocomposites: A coarse-grained model. Composites. Part B, Engineering, 2015, 80: 92–100

Materials Studio. Version 8.0. San Diego, CA: Biovia Inc., 2014

Artok L, Su Y, Hirose Y, Hosokawa M, Murata S, Nomura M. Structure and reactivity of petroleum-derived asphaltene. Energy & Fuels, 1999, 13(2): 287–296

Yao H, Dai Q, You Z. Molecular dynamics simulation of physicochemical properties of the asphalt model. Fuel, 2016, 164: 83–93

Siddique R, Naik T R. Properties of concrete containing scrap-tire rubber—An overview. Waste Management, 2004, 24(6): 563–569

Tanaka Y. Structural characterization of natural polyisoprenes: Solve the mystery of natural rubber based on structural study. Rubber Chemistry and Technology, 2001, 74(3): 355–375

Sun D, Lin T, Zhu X, Tian Y, Liu F. Indices for self-healing performance assessments based on molecular dynamics simulation of asphalt binders. Computational Materials Science, 2016, 114: 86–93

Read J, Whiteoak D. The Shell Bitumen Handbook. Thomas Telford, 2003

Li D D, Greenfield M L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel, 2014, 115: 347–356

Argyris D, Cole D R, Striolo A. Dynamic behavior of interfacial water at the silica surface. Journal of Physical Chemistry C, 2009, 113(45): 19591–19600

Wool R, O’connor K. A theory crack healing in polymers. Journal of Applied Physics, 1981, 52(10): 5953–5963

Schapery R. Nonlinear fracture analysis of viscoelastic composite materials based on a generalized J integral theory. In: Kawata K, Akasak T, eds. Japan-U.S. Conference on Composite materials: Mechanics, mechanical properties and fabrication. Tokyo: Japan Society for Composite Materials Tokyo, 1982: 171–180

Gao Y, Zhang Y, Gu F, Xu T, Wang H. Impact of minerals and water on bitumen-mineral adhesion and debonding behaviours using molecular dynamics simulations. Construction & Building Materials, 2018, 171: 214–222

Frenkel D, Smit B. Understanding Molecular Simulation: From Algorithms to Applications. Academic Press: New York, 2002

Lv Q, Huang W, Xiao F. Laboratory evaluation of self-healing properties of various modified asphalt. Construction & Building Materials, 2017, 136: 192–201

Acknowledgements

This study was supported by the Special Fund for Basic Scientific Research of Central College of Chang’an University (Nos. 300102218405, 300102218413, and 310821153502), and the Department of Science & Technology of Shaanxi Province (Nos. 2016ZDJC-24 and 2017KCT-13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, D., Pei, J., Li, R. et al. Using thermodynamic parameters to study self-healing and interface properties of crumb rubber modified asphalt based on molecular dynamics simulation. Front. Struct. Civ. Eng. 14, 109–122 (2020). https://doi.org/10.1007/s11709-019-0579-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-019-0579-6