Abstract

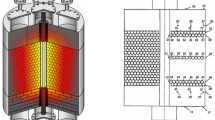

In a severe accident of a nuclear power reactor, coolant channel blockage by solidified molten core debris may significantly influence the core degradations that follow. The moving particle semi-implicit (MPS) method is one of the Lagrangian-based particle methods for analyzing incompressible flows. In the study described in this paper, a novel solidification model for analyzing melt flowing channel blockage with the MPS method has been developed, which is suitable to attain a sufficient numerical accuracy with a reasonable calculation cost. The prompt velocity diffusion by viscosity is prioritized over the prompt velocity correction by the pressure term (for assuring incompressibility) within each time step over the “mushy zone” (between the solidus and liquidus temperature) for accurate modeling of solidification before fixing the coordinates of the completely solidified particles. To sustain the numerical accuracy and stability, the corrective matrix and particle shifting techniques have been applied to correct the discretization errors from irregular particle arrangements and to recover the regular particle arrangements, respectively. To validate the newly developed algorithm, 2-D benchmark analyses are conducted for steady-state freezing of the water in a laminar flow between two parallel plates. Furthermore, 3-D channel blockage analyses of a boiling water reactor (BWR) fuel support piece have been performed. The results show that a partial channel blockage develops from the vicinity of the speed limiter, which does not fully develop into a complete channel blockage, but still diverts the incoming melt flow that follows to the orifice region.

Similar content being viewed by others

Abbreviations

- α :

-

Threshold parameter

- C :

-

Corrective matrix

- C p :

-

Specific heat capacity

- CR :

-

Parameter of Ramacciotti model

- d :

-

Dimension number

- f :

-

Force

- g :

-

Gravity

- H :

-

Half of the flow channel width

- h :

-

Enthalpy

- k :

-

Thermal conductivity

- l 0 :

-

Particle size

- L :

-

Row vector

- n 0 :

-

Initial particle number density

- P :

-

Pressure

- Q :

-

Heat source

- Re :

-

Reynolds number

- r e :

-

Effective interaction radius

- r :

-

Position vector

- t :

-

Time

- T :

-

Temperature

- T 0 :

-

Inflow temperature

- T W :

-

Wall temperature

- u :

-

Velocity vector

- ū mo :

-

Inflow rate

- w(r):

-

Weight function

- x,y :

-

Position

- γ :

-

Solid fraction

- θ W :

-

Dimensionless wall temperature

- λ :

-

Correction factor

- μ :

-

Dynamic viscosity

- ν :

-

Kinematic viscosity

- ρ :

-

Density

- ϕ :

-

A scalar quantity

- i,j :

-

Particle identification number

- l:

-

Liquidus

- s:

-

Solidus

References

Yu Y, Yang Y. URANS simulation of the turbulent flow in tight lattice bundle. Frontiers in Energy, 2011, 5(4): 404–411

Tolman E L, Kuan P, Broughton J M. TMI-2 accident scenario update. Nuclear Engineering and Design, 1988, 108(1–2): 45–54

Gauntt R O, Humphries L L. Final results of the XR2-1 BWR metallic melt relocation experiment. Office of Scientific and Technical Information (OSTI), 1997

Tokyo Electric Power Company. Evaluation of the situation of cores and containment vessels of Fukushima Daiichi Nuclear Power Station Units-1 to 3 and examination into unsolved issues in the accident progression progress. Tokyo Electric Power Company, Report No. 4, 2015

Sandia National Laboratories. MELCOR Computer Code Manuals Vol. 2: Reference Manual Version 2.2.9541 2017. SAND2017-0876 O, 2017

Organisation for Economic Co-operation and Development, Nuclear Energy Agency. Benchmark Study of the Accident at the Fukushima Daiichi Nuclear Power Plant (BSAF Project) Phase 1 Summary Report. NEA/CSNI/R18, 2015

Luxat D. Modular Accident Analysis Program (MAAP)-MELCOR Crosswalk Phase 1 Study. Technical Update, 2014

Koshizuka S, Oka Y. Moving-particle semi-implicit method for fragmentation of incompressible fluid. Nuclear Science and Engineering, 1996, 123(3): 421–434

Chen R, Oka Y. Numerical analysis of freezing controlled penetration behavior of the molten core debris in an instrument tube with MPS. Annals of Nuclear Energy, 2014, 71: 322–332

Goto Y, Yamaji A. Analysis of eutectic and metallic melt flow and blockage in BWR control rod guide tube by MPS method. In: Proceedings of TopSafe 2017, Vienna, Austria, 2017

Takahashi N, Duan G, Furuya M, et al. Analysis of hemispherical vessel ablation failure involving natural convection by MPS method with corrective matrix. International Journal of Advanced Nuclear Reactor Design and Technology, 2019, 1: 19–29

Yamaji A, Li X. Development of MPS method for analyzing melt spreading behavior and MCCI in severe accidents. Journal of Physics: Conference Series, 2016, 739(1): 012002 (in Chinese)

Duan G, Yamaji A, Koshizuka S. A novel multiphase MPS algorithm for modeling crust formation by highly viscous fluid for simulating corium spreading. Nuclear Engineering and Design, 2019, 343: 218–231

Xu R, Stansby P, Laurence D. Accuracy and stability in incompressible SPH (ISPH) based on the projection method and a new approach. Journal of Computational Physics, 2009, 228(18): 6703–6725

Khayyer A, Gotoh H, Shimizu Y. Comparative study on accuracy and conservation properties of two particle regularization schemes and proposal of an optimized particle shifting scheme in ISPH context. Journal of Computational Physics, 2017, 332: 236–256

Duan G, Koshizuka S, Yamaji A, et al. An accurate and stable multiphase moving particle semi-implicit method based on a corrective matrix for all particle interaction models. International Journal for Numerical Methods in Engineering, 2018, 115(10): 1287–1314

Kikuchi Y, Shigemasa Y, Oe A, et al. Steady-state freezing of liquids in laminar flow between two parallel plates. Journal of Nuclear Science and Technology, 1986, 23(11): 979–991

Vacondio R, Altomare C, De Leffe M, et al. Grand challenges for smoothed particle hydrodynamics numerical schemes. Computational Particle Mechanics, 2021, 8: 575–588

Jeong S M, Nam J W, Hwang S C, et al. Numerical prediction of oil amount leaked from a damaged tank using two-dimensional moving particle simulation method. Ocean Engineering, 2013, 69: 70–78

Sun P N, Colagrossi A, Le Touzé D, et al. Extension of the δ-Plus-SPH model for simulating Vortex-Induced-Vibration problems. Journal of Fluids and Structures, 2019, 90: 19–42

Koshizuka S, Shibata K. MPS-SW-MAIN-Ver.2.0. P 8827-1. 2006

Spindler B, Veteau J M. Simulation of spreading with solidification: assessment synthesis of THEMA code. Rapport CEA-R-6053, 2004

Alsmeyer H, Cron T, Foit J J, et al. Test report of the Melt Spreasding Tests ECOKATS-V1 and ECOKATS-1. 2004

Ramacciotti M, Journeau C, Sudreau F, et al. Viscosity models for corium melts. Nuclear Engineering and Design, 2001, 204(1–3): 377–389

Duan G, Chen B. Large Eddy Simulation by particle method coupled with Sub-Particle-Scale model and application to mixing layer flow. Applied Mathematical Modelling, 2015, 39(10–11): 3135–3149

Kirillov P L, Terentieva M I, Deniskina N B. Thermophysical Properties of Materials for Nuclear Engineering. 2nd ed. Moscow: IzdAT Publishing House, 2007

Acknowledgements

This work was supported by the Nuclear Energy Science & Technology and Human Resource Development Project (through concentrating wisdom), the Advanced Theoretical and Experimental Physics, Waseda University, and the TCU priority promotion research supported by Tokyo City University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kawakami, R., Li, X., Duan, G. et al. Improvement of solidification model and analysis of 3D channel blockage with MPS method. Front. Energy 15, 946–958 (2021). https://doi.org/10.1007/s11708-021-0754-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-021-0754-z