Abstract

In order to increase efficiency and achieve a further CO2-reduction, the next generation of power plant turbines will have steam turbine inlet temperatures that are considerably higher than the current ones. The high pressure steam turbine inlet temperature is expected to be increased up to approximately 700°C with a live steam pressure of 30 MPa. The elevated steam parameters in the high and intermediate pressure turbines can be encountered with Ni-base alloys, but this is a costly alternative associated with many manufacturing difficulties. Collaborative research centre 561 “Thermally Highly Loaded, Porous and Cooled Multi-Layer Systems for Combined Cycle Power Plants” at RWTH Aachen University proposes cooling the highly loaded turbines instead, as this would necessitate the application of far less Ni-base alloys.

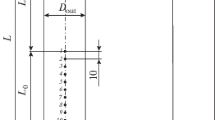

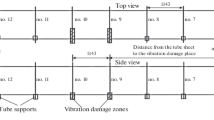

To protect the thermally highly loaded components, a sandwich material consisting of two thin face sheets and a core made from a woven wire mesh is used to cover the walls of the steam turbine casing. The cooling steam is led through the woven wire mesh between the two face sheets to achieve a cooling effect. The wire mesh provides the grid-sheet with structural rigidity under varying operating conditions.

In the present work, the cooling performance of the gridsheets will be investigated applying the conjugate heat transfer method to ultra-supercritical live and cooling steam conditions for a section of the cooling structure. The behaviour of the flow and the heat transfer in the grid-sheet will be analyzed in detail using a parameter variation. The numerical results should give a first prediction of the cooling performance under future operating conditions.

Similar content being viewed by others

References

Bohn D. Advanced steam and gas turbine technologies for future power plant generation. Invited Lecture to the A.S.I./SKODA Conference on Steam Turbines and Other Turbomachinery, Plzen, Czech Republic, 2007

Luby P. Supercritical systems: the market for supercritical steam turbines has undergone dramatic changes in the last ten years. But the future outlook appears positive and the indications are that further growth lies ahead. Modern Power Systems, 2003, 27–32

Retzlaff K M, Ruegger W A. Steam turbines for ultrasuper-critical power plants. GER-3945A (first presented at PowerGen Europe’96), 1996

Obara I, Tanaka Y, Magoshi R, et al. Design of 600°C class 1000MW steam turbine. JSME International Journal, Series B, 1998, 41(3): 734–739

Dilthey U, Ohse P, Piontek D. Welding of hollow structures made of high-temperature materials. Schweißen und Schneiden, 2004, 56(1): 11–15

Dilthey U, El-Magd E, Brandenburg A, et al. Lasergeschweißte Hohlraumstrukturen aus dem martensitischen Werkstoff P92 als neuartiges Kühlkonzept für hochbelastete Teile der Dampfturbine. Proceedings of the 28th Vortragsveranstaltung der Forschungsvereinigung Warmfeste Stähle (FVW), Düsseldorf, 2005

Kopp R, Franzke M, Hohmeier P, et al. Bending of sandwich structures with usable cavities for active cooling applications in steam turbines. Annals of the German Academic Society for Production Engineering, 2005, 12(1): 71–76

El-Magd E, Stuhrmann J, Gebhard J. Low cycle fatigue behaviour of sandwich structures of P92 and Nicrofer 6025HT. Proceedings of the 8th Liege Conference on Materials for Advanced Power Engineering, Part II, Liege, Belgium, 2006, 1147–1156

Kopp R, Wiedner C, El-Magd E, et al. Comparison between visioplasticity measurements and finite element computations for tensile tests on cold rolled perforated ferritic chromium steel P92. Comp Mat Sci, 2004, 31(3,4): 439–447

Bohn D, Ren J, Kusterer K. Cooling performance of the steam-cooled blade in a steam turbine cascade. ASME Turbo Expo, Paper No. GT2005-68148, Reno, Nevada, USA, 2005

Bohn D, Kusterer K, Wolff A, et al. Experimental and numerical investigations of a steam-cooled vane. ASME Turbo Expo, Paper No. GT2002-30210, Amsterdam, The Netherlands, 2002

Eberle A, Schmatz M A, Bissinger N. Generalized flux vectors for hypersonic shock-capturing. AIAA-Paper 90-0390, 1990

Anderson W K, Thomas J L, van Leer B. A comparison of finite volume flux vector splitting for the euler equations. AIAA-Paper 85-0122, 1985

Schmatz MA. Three-dimensional viscous flow simulations using an implicit relaxation scheme. Notes on Numerical Fluid-Mechanics (NNFM), 1988, 22: 226–242

Baldwin B S, Lomax H. Thin layer approximation and algebraic model for separated turbulent flows. AIAA-Paper 78-257, 1978

Bohn D, Bonhoff B, Schönenborn H, et al. Validation of a numerical model for the coupled simulation of fluid flow and diabatic walls with application to film-cooled turbine blades. VDI-Berichte, 1995, 1186: 259–272

Bohn D, Schönenborn H, Bonhoff B, et al. Prediction of the filmcooling effectiveness in gas turbine blades using a numerical model for the coupled simulation of fluid flow and diabatic walls. ISABE95-7105, 1995

Wagner W, Cooper J R, Dittmann A, et al. The IAPWS-1997 Industrial Formulation for the Thermodynamic Properties of Water and Steam. Berlin: Springer, 1998

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bohn, D., Krewinkel, R. & Tian, S. Cooling performance of grid-sheets for highly loaded ultra-supercritical steam turbines. Front. Energy Power Eng. China 3, 313–320 (2009). https://doi.org/10.1007/s11708-009-0036-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-009-0036-7