Abstract

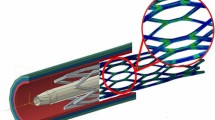

A stent is a medical device designed to serve as a temporary or permanent internal scaffold to maintain or increase the lumen of a body conduit. The researchers and engineers diverted to investigate biodegradable materials due to the limitation of metallic materials in stent application such as stent restenosis which requires prolonged anti platelet therapy, often result in smaller lumen after implantation and obstruct re-stenting treatments. Biomedical implants with temporary function for the vascular intervention are extensively studied in recent years. The rationale for biodegradable stent is to provide the support for the vessel in predicted period of time and then degrading into biocompatible constituent. The degradation of stent makes the re-stenting possible after several months and also ameliorates the vessel wall quality. The present article focuses on the biodegradable materials for the cardiovascular stent. The objective of this review is to describe the possible biodegradable materials for stent and their properties such as design criteria, degradation behavior, drawbacks and advantages with their recent clinical and preclinical trials.

Similar content being viewed by others

References

Arjomand H, Turi Z G, Mc Cormick D, et al. Percutaneous coronary intervention: historical perspectives, current status, and future directions. American Heart Journal, 2003, 146(5): 787–796

Mueller R L, Sanborn T A. The history of interventional cardiology: cardiac catheterization, angioplasty, and related interventions. American Heart Journal, 1995, 129(1): 146–172

Boucher R A, Myler R K, Clark D A, et al. Coronary angiography and angioplasty. Catheterization and Cardiovascular Diagnosis, 1988, 14(4): 269–285

de la Cruz K I, Tsai P I, Cohn W E, et al. Revascularization treatment recommendations based on atherosclerotic disease distribution: coronary artery bypass grafting versus stenting. Current Atherosclerosis Reports, 2008, 10(5): 434–437

Mani G, Feldman M D, Patel D, et al. Coronary stents: a materials perspective. Biomaterials, 2007, 28(9): 1689–1710

Waksman R. Biodegradable stents: they do their job and disappear. The Journal of Invasive Cardiology, 2006, 18(2): 70–74

Bertrand O F, Sipehia R, Mongrain R, et al. Biocompatibility aspects of new stent technology. Journal of the American College of Cardiology, 1998, 32(3): 562–571

Roubin G S, Cannon A D, Agrawal S K, et al. Intracoronary stenting for acute and threatened closure complicating percutaneous transluminal coronary angioplasty. Circulation, 1992, 85 (3): 916–927

Regar E, Sianos G, Serruys P W. Stent development and local drug delivery. British Medical Bulletin, 2001, 59(5): 227–248

Ashby D T, Dangas G, Mehran R, et al. Coronary artery stenting. Catheterization and Cardiovascular Interventions, 2002, 56(1): 83–102

Holzapfel G A, Sommer G, Gasser C T, et al. Determination of layer-specific mechanical properties of human coronary arteries with nonatherosclerotic intimal thickening and related constitutive modeling. American Journal of Physiology- Heart and Circulatory Physiology, 2005, 289(5): H2048–H2058

Frohlich J, Dobiasova M, Lear S, et al. The role of risk factors in the development of atherosclerosis. Critical Reviews in Clinical Laboratory Sciences, 2001, 38(5): 401–440

Robaina S, Jayachandran B, He Y, et al. Platelet adhesion to simulated stented surfaces. Journal of Endovascular Therapy, 2003, 10(5): 978–986

Rogers C, Edelman E R. Endovascular stent design dictates experimental restenosis and thrombosis. Circulation, 1995, 91 (12): 2995–3001

Farb A, Weber D K, Kolodgie F D, et al. Morphological predictors of restenosis after coronary stenting in humans. Circulation, 2002, 105(25): 2974–2980

Wentzel J J, Gijsen F J, Stergiopulos N, et al. Shear stress, vascular remodeling and neointimal formation. Journal of Biomechanics, 2003, 36(5): 681–688

Wentzel J J, Krams R, Schuurbiers J C, et al. Relationship between neointimal thickness and shear stress after Wallstent implantation in human coronary arteries. Circulation, 2001, 103 (13): 1740–1745

Berry J L, Manoach E, Mekkaoui C, et al. Hemodynamics and wall mechanics of a compliance matching stent: in vitro and in vivo analysis. Journal of Vascular & Interventional Radiology, 2002, 13(1): 97–105

Glagov S, Zarins C K, Masawa N, et al. Mechanical functional role of non-atherosclerotic intimal thickening. Frontiers of Medical and Biological Engineering, 1993, 5(1): 37–43

Babapulle M N, Eisenberg M J. Coated stents for the prevention of restenosis: Part II. Circulation, 2002, 106(22): 2859–2866

Rebelo N, Perry M. Finite element analysis for the design of Nitinol medical devices. Minimally Invasive Therapy & Allied Technologies, 2009, 9(2): 75–80

Kastrati A, Dirschinger J, Boekstegers P, et al. Influence of stent design on 1-year outcome after coronary stent placement: a randomized comparison of five stent types in 1,147 unselected patients. Catheterization and Cardiovascular Interventions, 2000, 50(3): 290–297

Griffiths H, Peeters P, Verbist J, et al. Future devices: bioabsorbable stents. The British Journal of Cardiology, 2004, 11: AIC 80–AIC 84

Tominaga R, Kambic H E, Emoto H, et al. Effects of design geometry of intravascular endoprostheses on stenosis rate in normal rabbits. American Heart Journal, 1992, 123(1): 21–28

Gurbel P A, Callahan K P, Malinin A I, et al. Could stent design affect platelet activation? Results of the Platelet Activation in STenting (PAST) study. The Journal of Invasive Cardiology, 2002, 14(10): 584–589

Leimgruber P P, Roubin G S, Anderson H V, et al. Influence of intimal dissection on restenosis after successful coronary angioplasty. Circulation, 1985, 72(3): 530–535

Fischman D L, Leon M B, Baim D S, et al. A randomized comparison of coronary-stent placement and balloon angioplasty in the treatment of coronary artery disease. New England Journal of Medicine, 1994, 331(8): 496–501

Nuutinen J P, Clerc C, Reinikainen R, et al. Mechanical properties and in vitro degradation of bioabsorbable selfexpanding braided stents. Journal of Biomaterials Science: Polymer Edition, 2003, 14(3): 255–266

Morton A C, Crossman D, Gunn J. The influence of physical stent parameters upon restenosis. Pathologie Biologie, 2004, 52 (4): 196–205

Lau K W, Johan A, Sigwart U, et al. A stent is not just a stent: Stent construction and design do matter in its clinical performance. Singapore Medical Journal, 2004, 45(7): 305–311

Rogers C D. Optimal stent design for drug delivery. Reviews in Cardiovascular Medicine, 2004, 5(Suppl 2): S9–S15

Bennett M R, O’Sullivan M. Mechanisms of angioplasty and stent restenosis: implications for design of rational therapy. Pharmacology & Therapeutics, 2001, 91(2): 149–166

Tabata Y. Biomaterial technology for tissue engineering applications. Journal of the Royal Society Interface, 2009, 6(Suppl 3): S311–S324

Ramcharitar S, Serruys P W. Fully biodegradable coronary stents: progress to date. American Journal of Cardiovascular Drugs, 2008, 8(5): 305–314

Ormiston J A, Serruys P W, Regar E, et al. A bioabsorbable everolimus-eluting coronary stent system for patients with single de-novo coronary artery lesions (ABSORB): a prospective openlabel trial. Lancet, 2008, 371(9616): 899–907

Seiler H G, Sigel H, Sigel A. Handbook on toxicity of inorganic compounds. Analytica Chimica Acta, 1987, 237: 511

Garg S, Serruys P. Biodegradable stents and non-biodegradable stents. Minerva Cardioangiologica, 2009, 57(5): 537–565

Bourantas C V, Onuma Y, Farooq V, et al. Bioresorbable scaffolds: current knowledge, potentialities and limitations experienced during their first clinical applications. International Journal of Cardiology, 2013, 167(1): 11–21

Heublein B, Rohde R, Kaese V, et al. Biocorrosion of magnesium alloys: a new principle in cardiovascular implant technology? Heart, 2003, 89(6): 651–656

Wiebe J, Nef H M, Hamm C W. Current status of bioresorbable scaffolds in the treatment of coronary artery disease. Journal of the American College of Cardiology, 2014, 64(23): 2541–2551

Iqbal J, Onuma Y, Ormiston J, et al. Bioresorbable scaffolds: rationale, current status, challenges, and future. European Heart Journal, 2014, 35(12): 765–776

Wang Y, Zhang X. Vascular restoration therapy and bioresorbable vascular scaffold. Regenerative Biomaterials, 2014, 1(1): 49–55

Waksman R, Pakala R, Kuchulakanti P K, et al. Safety and efficacy of bioabsorbable magnesium alloy stents in porcine coronary arteries. Catheterization and Cardiovascular Interventions, 2006, 68(4): 607–617, discussion 618–619

Ako J, Bonneau H N, Honda Y, et al. Design criteria for the ideal drug-eluting stent. The American Journal of Cardiology, 2007, 100(8B): 3M–9M

Kitabata H, Waksman R, Warnack B. Bioresorbable metal scaffold for cardiovascular application: current knowledge and future perspectives. Cardiovascular Revascularization Medicine, 2014, 15(2): 109–116

Di Mario C, Griffiths H, Goktekin O, et al. Drug-eluting bioabsorbable magnesium stent. Journal of Interventional Cardiology, 2004, 17(6): 391–395

Ruiz-García J, Refoyo E, Cuesta-López E, et al. Comparative results between metal stent and bioresorbable scaffold at two years postimplantation. Revista Espanola de Cardiologia (English Edition), 2014, 67(1): 66–68

Echeverri D, Cabrales J R. Terapia de restauración vascular con plataformas biorreabsorbibles. La cuarta revolución. Revista Colombiana de Cardiología, 2014, 21(4): 231–240

Puppi D, Chiellini F, Piras A M, et al. Polymeric materials for bone and cartilage repair. Progress in Polymer Science, 2010, 35 (4): 403–440

Williams D F. Biodegradation of surgical polymers. Journal of Materials Science, 1982, 17(5): 1233–1246

Helmus M N, Gibbons D F, Cebon D. Biocompatibility: meeting a key functional requirement of next-generation medical devices. Toxicologic Pathology, 2008, 36(1): 70–80

Chen G, Ushida T, Tateishi T. Scaffold design for tissue engineering. Macromolecular Bioscience, 2002, 2(2): 67–77

Freier T. Biopolyesters in tissue engineering applications. Advances in Polymer Science, 2006, 203(1): 1–61

Sokolsky-Papkov M, Langer R, Domb A J. Synthesis of aliphatic polyesters by polycondensation using inorganic acid as catalyst. Polymers for Advanced Technologies, 2011, 22(5): 502–511

Tamai H, Igaki K, Kyo E, et al. Initial and 6-month results of biodegradable poly-l-lactic acid coronary stents in humans. Circulation, 2000, 102(4): 399–404

Ceonzo K, Gaynor A, Shaffer L, et al. Polyglycolic acid-induced inflammation: role of hydrolysis and resulting complement activation. Tissue Engineering, 2006, 12(2): 301–308

Brown D A, Lee EW, Loh C T, et al. A new wave in treatment of vascular occlusive disease: biodegradable stents–clinical experience and scientific principles. Journal of Vascular and Interventional Radiology, 2009, 20(3): 315–324

Martin O, Averous L. Poly (lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer, 2001, 42(14): 6209–6219

Sabir M I, Xu X, Li L. A review on biodegradable polymeric materials for bone tissue engineering applications. Journal of Materials Science, 2009, 44(21): 5713–5724

Pamula E, Menaszek E. In vitro and in vivo degradation of poly (L-lactide-co-glycolide) films and scaffolds. Journal of Materials Science: Materials in Medicine, 2008, 19(5): 2063–2070

Leenslag JW, Pennings A J, Bos R R, et al. Resorbable materials of poly(L-lactide): VII. In vivo and in vitro degradation. Biomaterials, 1987, 8(4): 311–314

Grabow N, Schlun M, Sternberg K, et al. Mechanical properties of laser cut poly(L-lactide) micro-specimens: implications for stent design, manufacture, and sterilization. Journal of Biomechanical Engineering, 2005, 127(1): 25–31

Stack R S, Califf R M, Phillips H R, et al. Interventional cardiac catheterization at Duke Medical Center. American Journal of Cardiology, 1988, 62(10 Pt 2): 3F–24F

Venkatraman S, Boey F, Lao L L. Implanted cardiovascular polymers: Natural, synthetic and bio-inspired. Progress in Polymer Science, 2008, 33(9): 853–874

Piao L, Deng M, Chen X, et al. Ring-opening polymerization of e-caprolactone and L-lactide using organic amino calcium catalyst. Polymer, 2003, 44(8): 2331–2336

Bourantas C V, Zhang Y, Farooq V, et al. Bioresorbable scaffolds: current evidence and ongoing clinical trials. Current Cardiology Reports, 2012, 14(5): 626–634

Lepu Medical. NeoVas biodegradable scaffold ongoing clinical trials overview.[EB/OL], 2015, http://finance.qq.com/a/ 20151127/030523.htm

MicroPort®. Firesorb bioresorbable rapamycin target eluting coronary scaffold system completes first successful implantation in the first FIM clinical trial.[EB/OL], 2015, http://www. microportmedical.com/en/media.php?curr_page = news_details& id = 339

Engelberg I, Kohn J. Physico-mechanical properties of degradable polymers used in medical applications: a comparative study. Biomaterials, 1991, 12(3): 292–304

Pitt C G, Gu Z W. Modification of the rates of chain cleavage of poly(e-caprolactone) and related polyesters in the solid state. Journal of Controlled Release, 1987, 4(4): 283–292

Heller J. Development of poly(ortho esters): a historical overview. Biomaterials, 1990, 11(9): 659–665

van der Giessen W J, Lincoff A M, Schwartz R S, et al. Marked inflammatory sequelae to implantation of biodegradable and nonbiodegradable polymers in porcine coronary arteries. Circulation, 1996, 94(7): 1690–1697

Gao R, Shi R, Qiao S, et al. A novel polymeric local heparin delivery stent: Initial experimental study. Journal of the American College of Cardiology, 1996, 27(2): 85–86

Susawa T, Shiraki K, Shimizu Y. Biodegradable intracoronary stents in adult dogs. Journal of the American College of Cardiology, 1993, 21: 483A

Tsuji T, Tamai H, Igaki K, et al. Biodegradable stents as a platform to drug loading. International Journal of Cardiovascular Interventions, 2003, 5(1): 13–16

Zidar J, Lincoff A, Stack R. Biodegradable stents. Textbook of Interventional Cardiology, 1994, 2: 787–802

Ye Y W, Landau C, Meidell R S, et al. Improved bioresorbable microporous intravascular stents for gene therapy. ASAIO Journal, 1996, 42(5): M823–M827

Heller J, Barr J, Ng S Y, et al. Poly(ortho esters)–their development and some recent applications. European Journal of Pharmaceutics and Biopharmaceutics, 2000, 50(1): 121–128

Capancioni S, Schwach-Abdellaoui K, Kloeti W, et al. In vitro monitoring of poly (ortho ester) degradation by electron paramagnetic resonance imaging. Macromolecules, 2003, 36 (16): 6135–6141

Göpferich A. Mechanisms of polymer degradation and erosion. Biomaterials, 1996, 17(2): 103–114

Hofmann D, Entrialgo-Castaño M, Kratz K, et al. Knowledgebased approach towards hydrolytic degradation of polymerbased biomaterials. Advanced Materials, 2009, 21(32–33): 3237–3245

Heller J. Poly (ortho esters). Berlin Heidelberg: Springer, 1993, 41–92

Heller J, Penhale DW, Fritzinger B K, et al. Controlled release of contraceptive steroids from biodegradable poly (ortho esters). Contraceptive Delivery Systems, 1983, 4(1): 43–53

Shih C, Higuchi T, Himmelstein K J. Drug delivery from catalysed erodible polymeric matrices of poly(ortho ester)s. Biomaterials, 1984, 5(4): 237–240

Baei M S, Najafpour G D, Younesi H, et al. Poly(3- hydroxybutyrate) synthesis by cupriavidus necator DSMZ 545 utilizing various carbon sources. World Applied Sciences Journal, 2009, (2): 157–161

Holland S J, Jolly A M, Yasin M, et al. Polymers for biodegradable medical devices: II. Hydroxybutyrate–hydroxyvalerate copolymers: hydrolytic degradation studies. Biomaterials, 1987, 8(4): 289–295

Wang H T, Palmer H, Linhardt R J, et al. Degradation of poly (ester) microspheres. Biomaterials, 1990, 11(9): 679–685

Zhao K, Deng Y, Chen G Q. Effects of surface morphology on the biocompatibility of polyhydroxyalkanoates. Biochemical Engineering Journal, 2003, 16(2): 115–123

Gogolewski S, Jovanovic M, Perren S M, et al. Tissue response and in vivo degradation of selected polyhydroxyacids: polylactides (PLA), poly(3-hydroxybutyrate) (PHB), and poly(3-hydroxybutyrate- co-3-hydroxyvalerate) (PHB/VA). Journal of Biomedical Materials Research, 1993, 27(9): 1135–1148

Unverdorben M, Spielberger A, Schywalsky M, et al. A polyhydroxybutyrate biodegradable stent: preliminary experience in the rabbit. Cardiovascular and Interventional Radiology, 2002, 25(2): 127–132

Domb A J, Amselem S, Shah J, et al. Polyanhydrides: Synthesis and characterization. Berlin Heidelberg: Springer, 1993, 93–141

Lucas N, Bienaime C, Belloy C, et al. Polymer biodegradation: mechanisms and estimation techniques. Chemosphere, 2008, 73 (4): 429–442

Davies M C, Shakesheff K M, Shard A G, et al. Surface analysis of biodegradable polymer blends of poly(sebacic anhydride) and poly(DL-lactic acid). Macromolecules, 1996, 29(6): 2205–2212

Uhrich K E, Gupta A, Thomas T T, et al. Synthesis and characterization of degradable poly(anhydride-co-imides). Macromolecules, 1995, 28(7): 2184–2193

Chasin M, Domb A, Ron E, et al. Polyanhydrides as drug delivery systems. In: Chasin M, Langer R, eds. Biodegradable Polymers as Drug Delivery Systems. New York: Marcel Dekker, 1990, 45: 43–70

Laurencin C, Domb A, Morris C, et al. Poly(anhydride) administration in high doses in vivo: studies of biocompatibility and toxicology. Journal of Biomedical Materials Research, 1990, 24(11): 1463–1481

Jabara R. Poly-anhydride based on salicylic acid and adipic acid anhydride. Barcelona, Spain: EuroPCR, 2009

Wang S, Lu L, Yaszemski M J. Bone-tissue-engineering material poly(propylene fumarate): correlation between molecular weight, chain dimensions, and physical properties. Biomacromolecules, 2006, 7(6): 1976–1982

Shung A K, Timmer M D, Jo S, et al. Kinetics of poly(propylene fumarate) synthesis by step polymerization of diethyl fumarate and propylene glycol using zinc chloride as a catalyst. Journal of Biomaterials Science: Polymer Edition, 2002, 13(1): 95–108

Fisher J P, Dean D, Mikos A G. Photocrosslinking characteristics and mechanical properties of diethyl fumarate/poly(propylene fumarate) biomaterials. Biomaterials, 2002, 23(22): 4333–4343

Suggs L J, Krishnan R S, Garcia C A, et al. In vitro and in vivo degradation of poly(propylene fumarate-co-ethylene glycol) hydrogels. Journal of Biomedical Materials Research, 1998, 42 (2): 312–320

Herold D A, Keil K, Bruns D E. Oxidation of polyethylene glycols by alcohol dehydrogenase. Biochemical Pharmacology, 1989, 38(1): 73–76

Gilding D K, Reed A M. Biodegradable polymers for use in surgery–poly(ethylene oxide) poly(ethylene terephthalate) (PEO/PET) copolymers: 1. Polymer, 1979, 20(12): 1454–1458

Mody P C, Wilkes G L, Wagener K B, et al. Structure–property relationships of a new series of segmented polyether–polyester copolymers. Journal of Applied Polymer Science, 1981, 26(9): 2853–2878

Pathak C P, Sawhney A S, Quinn C P, et al. Polyimidepolyethylene glycol block copolymers: synthesis, characterization, and initial evaluation as a biomaterial. Journal of Biomaterials Science: Polymer Edition, 1994, 6(4): 313–323

Zhu K J, Lin X, Yang S. Preparation and properties of D, Llactide and ethylene oxide copolymer: A modifying biodegradable polymeric material. Journal of Polymer Science Part C: Polymer Letters, 1986, 24(7): 331–337

Sawhney A S, Pathak C P, Hubbell J A. Bioerodible hydrogels based on photopolymerized poly(ethylene glycol)-co-poly(a- hydroxy acid) diacrylate macromers. Macromolecules, 1993, 26 (4): 581–587

Hill-West J L, Chowdhury S M, Slepian M J, et al. Inhibition of thrombosis and intimal thickening by in situ photopolymerization of thin hydrogel barriers. Proceedings of the National Academy of Sciences of the United States of America, 1994, 91 (13): 5967–5971

Suggs L J, Shive M S, Garcia C A, et al. In vitro cytotoxicity and in vivo biocompatibility of poly(propylene fumarate-co-ethylene glycol) hydrogels. Journal of Biomedical Materials Research, 1999, 46(1): 22–32

Kohn J, Langer R. Polymerization reactions involving the side chains of a-L-amino acids. Journal of the American Chemical Society, 1987, 109(3): 817–820

Ertel S I, Kohn J. Evaluation of a series of tyrosine-derived polycarbonates as degradable biomaterials. Journal of Biomedical Materials Research, 1994, 28(8): 919–930

Tangpasuthadol V, Pendharkar S M, Kohn J. Hydrolytic degradation of tyrosine-derived polycarbonates, a class of new biomaterials. Part I: study of model compounds. Biomaterials, 2000, 21(23): 2371–2378

Tangpasuthadol V, Pendharkar S M, Peterson R C, et al. Hydrolytic degradation of tyrosine-derived polycarbonates, a class of new biomaterials. Part II: 3-yr study of polymeric devices. Biomaterials, 2000, 21(23): 2379–2387

Pulapura S, Kohn J. Tyrosine-derived polycarbonates: backbonemodified “pseudo”-poly (amino acids) designed for biomedical applications. Biopolymers, 1992, 32(4): 411–417

Bourke S L, Kohn J, Dunn M G. Preliminary development of a novel resorbable synthetic polymer fiber scaffold for anterior cruciate ligament reconstruction. Tissue Engineering, 2004, 10 (1–2): 43–52

Bailey L O, Becker M L, Stephens J S, et al. Cellular response to phase-separated blends of tyrosine-derived polycarbonates. Journal of Biomedical Materials Research Part A, 2006, 76(3): 491–502

Strandberg E, Zeltinger J, Schulz D G, et al. Late positive remodeling and late lumen gain contribute to vascular restoration by a non-drug eluting bioresorbable scaffold: a four-year intravascular ultrasound study in normal porcine coronary arteries. Circulation: Cardiovascular Interventions, 2012, 5(1): 39–46

Grube E. The REVA Tyrosine-derived polycarbonate bioabsorbable stent: final results from the RESORB First-in-man clinical trial and next generation designs. Transcatheter Cardiovascular Therapeutics, 2008

Witte F. Reprint of: The history of biodegradable magnesium implants: A review. Acta Biomaterialia, 2015, 23(Supp l): S28–S40

Song G, Song S Z. A possible biodegradable magnesium implant material. Advanced Engineering Materials, 2007, 9(4): 298–302

Vormann J. Magnesium: nutrition and metabolism. Molecular Aspects of Medicine, 2003, 24(1–3): 27–37

Mult E, Haferkamp H, Niemeyer M, et al. Laser and electron beam welding of magnesium materials. Welding and Cutting, 2000, 52(8): 178–180

Marya M, Edwards G. The laser welding of magnesium alloy AZ91. Welding in the World, 2000, 44(2): 31–37

Mordike B, Ebert T. Magnesium: properties–applications–potential. Materials Science and Engineering A, 2001, 302(1): 37–45

Aghion E, Bronfin B. Magnesium alloys development towards the 21st century. Materials Science Forum, 2000, 350–351: 19–30

Pastor M, Zhao H, Debroy T. Continuous wave-Nd: yttrium–aluminum–garnet laser welding of AM60B magnesium alloy. Journal of Laser Applications, 2000, 12(3): 91–100

Marya M, Edwards G, Marya S, et al. Fundamentals in the fusion welding of magnesium and its alloys. Proceedings of the Seventh JWS International Symposium, Kobe, 2001, 597–602

Waksman R, Pakala R, Kuchulakanti P K, et al. Safety and efficacy of bioabsorbable magnesium alloy stents in porcine coronary arteries. Catheterization and Cardiovascular Interventions, 2006, 68(4): 607–617, discussion 618–619

Waksman R, Pakala R, Hellinga D, et al. Effect of bioabsorbable magnesium alloy stent on neointimal formation in a porcine coronary model. European Heart Journal, 2005, 26: 417

Waksman R, Pakala R, Okabe T, et al. Efficacy and safety of absorbable metallic stents with adjunct intracoronary beta radiation in porcine coronary arteries. Journal of Interventional Cardiology, 2007, 20(5): 367–372

Friedrich H E, Mordike B L. Magnesium Technology. Berlin: Springer, 2006, 788

Erbel R, Di Mario C, Bartunek J, et al. Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: a prospective, non-randomised multicentre trial. Lancet, 2007, 369(9576): 1869–1875

Peeters P, Bosiers M, Verbist J, et al. Preliminary results after application of absorbable metal stents in patients with critical limb ischemia. Journal of Endovascular Therapy, 2005, 12(1): 1–5

Schranz D, Zartner P, Michel-Behnke I, et al. Bioabsorbable metal stents for percutaneous treatment of critical recoarctation of the aorta in a newborn. Catheterization and Cardiovascular Interventions, 2006, 67(5): 671–673

Bach F W, Schaper M, Jaschik C. Influence of lithium on hcp magnesium alloys. Materials Science Forum, 2003, 419–422: 1037–1042

Kaese V, Niemeyer M, Tai P T, et al. Korrosionsschützendes Legieren von Magnesiumbasiswerkstoffen. Teil 1: Dynamische Alkalisierung der Grenzschicht-Tertiäre Legierungssysteme. Materials & Corrosion, 1999, 50(4): 191–198

Magnesium Elektron Datasheet. WE43. Magnesium Elektron, 2005

Günter N, Kohei K, Kenji H, et al. Magnesium-Based Alloys. Wiley-VCH Verlag GmbH & Co. KGaA, 2006

Nagels J, Stokdijk M, Rozing P M. Stress shielding and bone resorption in shoulder arthroplasty. Journal of Shoulder and Elbow Surgery, 2003, 12(1): 35–39

Park J B, Bronzino J D. Biomaterials: Principles and Applications. CRC Press, 2003

Clark G C, Williams D F. The effects of proteins on metallic corrosion. Journal of Biomedical Materials Research, 1982, 16 (2): 125–134

Waksman R, Pakala R, Kuchulakanti P K, et al. Safety and efficacy of bioabsorbable magnesium alloy stents in porcine coronary arteries. Catheterization and Cardiovascular Interventions, 2006, 68(4): 607–617, discussion 618–619

Waksman R, Pakala R, Okabe T, et al. Efficacy and safety of absorbable metallic stents with adjunct intracoronary beta radiation in porcine coronary arteries. Journal of Interventional Cardiology, 2007, 20(5): 367–372

Kitabata H, Waksman R, Warnack B. Bioresorbable metal scaffold for cardiovascular application: current knowledge and future perspectives. Cardiovascular Revascularization Medicine, 2014, 15(2): 109–116

Zartner P, Cesnjevar R, Singer H, et al. First successful implantation of a biodegradable metal stent into the left pulmonary artery of a preterm baby. Catheterization and Cardiovascular Interventions, 2005, 66(4): 590–594

Schranz D, Zartner P, Michel-Behnke I, et al. Bioabsorbable metal stents for percutaneous treatment of critical recoarctation of the aorta in a newborn. Catheterization and Cardiovascular Interventions, 2006, 67(5): 671–673

Zartner P, Buettner M, Singer H, et al. First biodegradable metal stent in a child with congenital heart disease: evaluation of macro and histopathology. Catheterization and Cardiovascular Interventions, 2007, 69(3): 443–446

McMahon C J, Oslizlok P, Walsh K P. Early restenosis following biodegradable stent implantation in an aortopulmonary collateral of a patient with pulmonary atresia and hypoplastic pulmonary arteries. Catheterization and Cardiovascular Interventions, 2007, 69(5): 735–738

Morice M C, Serruys P W, Sousa E J. A randomized comparison of a sirolimus-eluting stent with a standard stent for coronary revascularization. The New England Journal of Medicine, 2002, 346(23): 1773–1780

Se&Co B. CORRECTING & REPLACING BIOTRONIK announces positive 6-month results for dreams, the pioneering drug-eluting absorbable metal scaffold. Biomedical Market Newsletter, 5/17/2011, 257

Hentze M W, Muckenthaler M U, Andrews N C. Balancing acts: molecular control of mammalian iron metabolism. Cell, 2004, 117(3): 285–297

May T, Mueller P P, Weich H, et al. Establishment of murine cell lines by constitutive and conditional immortalization. Journal of Biotechnology, 2005, 120(1): 99–110

Hermawan H, Alamdari H, Mantovani D, et al. Iron–manganese: new class of metallic degradable biomaterials prepared by powder metallurgy. Powder Metallurgy, 2008, 51(1): 38–45

Peuster M, Hesse C, Schloo T, et al. Long-term biocompatibility of a corrodible peripheral iron stent in the porcine descending aorta. Biomaterials, 2006, 27(28): 4955–4962

Moravej M, Prima F, Fiset M, et al. Electroformed iron as new biomaterial for degradable stents: development process and structure–properties relationship. Acta Biomaterialia, 2010, 6(5): 1726–1735

Zhu S, Huang N, Xu L, et al. Biocompatibility of Fe–O films synthesized by plasma immersion ion implantation and deposition. Surface and Coatings Technology, 2009, 203(10–11): 1523–1529

Liu B, Zheng Y F, Ruan L. In vitro investigation of Fe30Mn6Si shape memory alloy as potential biodegradable metallic material. Materials Letters, 2011, 65(3): 540–543

Nie F L, Zheng Y F, Wei S C, et al. In vitro corrosion, cytotoxicity and hemocompatibility of bulk nanocrystalline pure iron. Biomedical Materials, 2010, 5(6): 065015

Mueller P P, May T, Perz A, et al. Control of smooth muscle cell proliferation by ferrous iron. Biomaterials, 2006, 27(10): 2193–2200

Francis A, Yang Y, Virtanen S, et al. Iron and iron-based alloys for temporary cardiovascular applications. Journal of Materials Science: Materials in Medicine, 2015, 26(3): 138

Peuster M, Wohlsein P, Brügmann M, et al. A novel approach to temporary stenting: degradable cardiovascular stents produced from corrodible metal-results 6–18 months after implantation into New Zealand white rabbits. Heart, 2001, 86(5): 563–569

Schinhammer M, Hänzi A C, Löffler J F, et al. Design strategy for biodegradable Fe-based alloys for medical applications. Acta Biomaterialia, 2010, 6(5): 1705–1713

Hermawan H, Purnama A, Dube D, et al. Fe–Mn alloys for metallic biodegradable stents: degradation and cell viability studies. Acta Biomaterialia, 2010, 6(5): 1852–1860

Moravej M, Purnama A, Fiset M, et al. Electroformed pure iron as a new biomaterial for degradable stents: in vitro degradation and preliminary cell viability studies. Acta Biomaterialia, 2010, 6 (5): 1843–1851

Liu B, Zheng Y F. Effects of alloying elements (Mn, Co, Al, W, Sn, B, C and S) on biodegradability and in vitro biocompatibility of pure iron. Acta Biomaterialia, 2011, 7(3): 1407–1420

Lin WJ, Zhang D Y, Zhang G, et al. Design and characterization of a novel biocorrodible iron-based drug-eluting coronary scaffold. Materials & Design, 2015, 91: 72–79

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, LD., Li, Z., Pan, Y. et al. A review on biodegradable materials for cardiovascular stent application. Front. Mater. Sci. 10, 238–259 (2016). https://doi.org/10.1007/s11706-016-0344-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-016-0344-x