Abstract

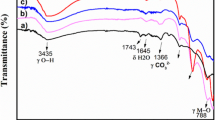

The Ru/C catalyst prepared by impregnation method was used for hydrogenation of 3,5-dimethylpyridine in a trickle bed reactor. Under the same reduction conditions (300 °C in H2), the catalytic activity of the non-in-situ reduced Ru/C-n catalyst was higher than that of the in-situ reduced Ru/C-y catalyst. Therefore, an in-situ H2 reduction and moderate oxidation method was developed to increase the catalyst activity. Moreover, the influence of oxidation temperature on the developed method was investigated. The catalysts were characterized by Brunauer—Emmett—Teller method, hydrogen temperature programmed reduction H2-TPR, hydrogen temperature-programmed dispersion (H2-TPD), X-ray diffraction, energy dispersive spectroscopy, X-ray photoelectron spectroscopy, Raman spectroscopy, O2 chemisorption and oxygen temperature-programmed dispersion (O2-TPD) analyses. The results showed that there existed an optimal Ru/RuOx ratio for the catalyst, and the highest 3,5-dimethylpyridine conversion was obtained for the Ru/C-i1 catalyst prepared by in-situ H2 reduction and moderate oxidation (oxidized at 100 °C). Excessive oxidation (200 °C) resulted in a significant decrease in the Ru/RuOx ratio of the in-situ H2 reduction and moderate oxidized Ru/C-i2 catalyst, the interaction between RuOx species and the support changed, and the hard-to-reduce RuOx species was formed, leading to a significant decrease in catalyst activity. The developed in-situ H2 reduction and moderate oxidation method eliminated the step of the non-in-situ reduction of catalyst outside the trickle bed reactor.

Similar content being viewed by others

References

Sridharan V, Suryavanshi P A, Menéndez J C. Advances in the chemistry of tetrahydroquinolines. Chemical Reviews, 2011, 111(11): 7157–7259

Scott J D, Williams R M. Chemistry and biology of the tetrahydroisoquinoline antitumor antibiotics. Chemical Reviews, 2002, 102(5): 1669–1730

Creemer L C, Kirst H A, Shryock T R, Campbell J B, Webb A G. Synthesis, antimicrobial activity and in vivo fluorine NMR of a hex fluorinated derivative of tilmicosin. Journal of Antibiotics, 1995, 48(7): 671–675

Wan K R, Lin T, Chen J, Li L, Zeng Y K, Zeng L H, Zhang Z X. The preparation method and application of the catalyst used for continuous preparation of 3,5-dimethyl piperidine. Chinese Patent, 201611126557.5, 2016-12-09

Beier R C, Creemer L C, Ziprin R L, Nisbet D J. Production and characterization of monoclonal antibodies against the antibiotic tilmicosin. Journal of Agricultural and Food Chemistry, 2005, 53(25): 9679–9688

Zones S I, Nakagawa Y, Evans S T, Lee G S. Zeolite SSZ-39. US Patent, 5958370A, 1999-09-28

Xu H, Zhang J, Wu Q M, Chen W, Lei C, Zhu Q Y, Han S C, Fei J H, Zheng A M, Zhu L F, Meng X, Maurer S, Dai D, Parvulescu A N, Müller U, Xiao F S. Direct synthesis of aluminosilicate SSZ-39 aeolite using colloidal ailica as a starting source. ACS Applied Materials & Interfaces, 2019, 11(26): 23112–23117

Lin T, Ma X X. Development of a new continuous process for the production of 3,5-dimethylpiperidine. Chinese Journal of Chemical Engineering, 2021, 41: 374–383

Ranade V V. Trickle bed reactors: reactor engineering & applications. Chemical Industry Press, 2003: 205–215

Takasaki M, Motoyama Y, Higashi K, Yoon S H, Mochida I, Nagashima H. Ruthenium nanoparticles on nano-level-controlled carbon supports as highly effective catalysts for arene hydrogenation. ChemInform, 2007, 39(12): 1524–1533

Zhao H, Song H, Zhao J, Yang J, Yan L, Chou L. The reactivity and deactivation mechanism of Ru@C catalyst over hydrogenation of aromatics to cyclohexane derivatives. ChemistrySelect, 2020, 5(14): 4316–4327

Wang Y, Rong Z M, Wang Y, Qu J P. Ruthenium nanoparticles loaded on functionalized graphene for liquid-phase hydrogenation of fine chemicals: comparison with carbon nanotube. Journal of Catalysis, 2016, 333: 8–16

Wang Y, Rong Z M, Wang Y, Zhang P, Wang Y, Qu J P. Ruthenium nanoparticles loaded on multiwalled carbon nanotubes for liquid-phase hydrogenation of fine chemicals: an exploration of confinement effect. Journal of Catalysis, 2015, 329: 95–106

Ban C, Yang S, Kim H, Kim D H. Effect of Cu addition to carbon-supported Ru catalysts on hydrogenation of alginic acid into sugar alcohols. Applied Catalysis A: General, 2019, 578(25): 98–104

Ban C, Yang S, Kim H, Kim D H. Catalytic hydrogenation of alginic acid into sugar alcohols over ruthenium supported on nitrogen-doped mesoporous carbons. Catalysis Today, 2020, 352(1): 66–72

Liang C H, Wei Z B, Xin Q, Li C. Ammonia synthesis over Ru/C catalysts with different carbon supports promoted by barium and potassium compounds. Applied Catalysis A: General, 2000, 208(1–2): 193–201

Upare P P, Lee J M, Hwang D W, Halligudi S B, Hwang Y K, Chang J S. Selective hydrogenation of levulinic acid to γ-valerolactone over carbon-supported noble metal catalysts. Journal of Industrial and Engineering Chemistry, 2011, 17(2): 287–292

Song W, Chen Z, Lai W, Rodríguez-Ramos I, Yi X, Weng W, Fang W. Effect of lanthanum promoter on the catalytic performance of levulinic acid hydrogenation over Ru/carbon fiber catalyst. Applied Catalysis A: General, 2017, 540(25): 21–30

Ma Y C, Lan G J, Fu W Z, Lai Y, Han W F, Tang H D, Liu H Z, Li Y. Role of surface defects of carbon nanotubes on catalytic performance of barium promoted ruthenium catalyst for ammonia synthesis. Journal of Energy Chemistry, 2020, 29(2): 79–86

Guerrero-Ruiz A, Bachiller-Baeza B, Rodríguez-Ramos I. RodríGuez-Ramos I. Catalytic properties of carbon-supported ruthenium catalysts for n-hexane conversion. Applied Catalysis A: General, 1998, 173(2): 231–238

Ma Y, Cheng S Q, Wu X D, Ma T X, Liu L P, Jin B F, Liu M H, Liu J B, Ran R, Si Z, Weng D. Improved hydrothermal durability of Cu-SSZ-13 NH3-SCR catalyst by surface Al modification: affinity and passivation. Journal of Catalysis, 2022, 405: 199–211

Tong Q, Cai T, Chen X T, Xu P, Ma Y L, Zhao K, He D. In-situ reduction-passivation synthesis of magnetic octahedron accumulated by Fe@Fe3O4-C core@complex-shell for the activation of persulfate. Journal of Environmental Chemical Engineering, 2022, 10(4): 108116

Birke P, Geyer R, Hoheisel K, Keck M, Pachulski A R, Schödel R. Stability of Ni/SiO2 catalysts. Chemieingenieurtechnik (Weinheim), 2012, 84(1–2): 165–168

Franz R, Tichelaar F D, Uslamin E A, Pidko E A. Dry reforming of methane to test passivation stability of Ni/Al2O3 catalysts. Applied Catalysis A, General, 2021, 612(25): 117987

Wolf M, Fischer N, Claeys M. Effectiveness of catalyst passivation techniques studied in situ with a magnetometer. Catalysis Today, 2016, 275(15): 135–140

Fratalocchi L, Groppi G, Visconti C G, Lietti L, Tronconi E. On the passivation of platinum promoted cobalt-based Fischer—Tropsch catalyst. Catalysis Today, 2020, 342(15): 79–87

Wyvratt B M, Gaudet J R, Thompson L T. Effects of passivation on synthesis, structure and composition of molybdenum carbide supported platinum water—gas shift catalysts. Journal of Catalysis, 2015, 330: 280–287

Hammache S, Goodwin J GJr, Oukaci R. Passivation of a Co-Ru/γ-Al2O3 Fichhrr—Tropsch catalyst. Catalysis Today, 2002, 71(3): 361–367

Moreno-Castilla C, López-Ramón M V, Carrasco-Marín F. Changes in surface chemistry of activated carbons by wet oxidation. Carbon, 2000, 38(14): 1995–2001

Collins J, Ngo T, Qu D, Foster M. Spectroscopic investigations of sequential nitric acid treatments on granulated activated carbon: effects of surface oxygen groups on π density. Carbon, 2013, 57: 174–183

Lin T, Wan K R, Chen J, Zhang Z X, Zeng Y K, Zeng L H, Gao W. An online device used for evaluating the fixed bed catalyst performance. Chinese patent, 201520609359.9, 2015-08-13

Gao P, Wang A, Wang X, Zhang T. Synthesis and catalytic performance of highly ordered Ru-containing mesoporous carbons for hydrogenation of cinnamaldehyde. Catalysis Letters, 2008, 125(3–4): 289–295

Su F, Lv L, Lee F Y, Liu T, Cooper A I, Zhao X S. Thermally reduced ruthenium nanoparticles as a highly active heterogeneous catalyst for hydrogenation of monoaromatics. Journal of the American Chemical Society, 2007, 129(46): 14213–14223

Lozano-Castelló D, Calo J M, Cazorla-Amorós D, Linares-Solano A. Carbon activation with KOH as explored by temperature programmed techniques, and the effects of hydrogen. Carbon, 2007, 45(13): 2529–2536

Veerakumar P, Dhenadhayalan N, Lin K C, Liu S B. Highly stable ruthenium nanoparticles on 3D mesoporous carbon: an excellent opportunity for reduction reactions. Journal of Materials Chemistry A: Materials for Energy and Sustainability, 2015, 3(46): 23448–23457

Li Y, Pan C, Han W, Chai H, Liu H. An efficient route for the preparation of activated carbon supported ruthenium catalysts with high performance for ammonia synthesis. Catalysis Today, 2011, 174(1): 97–105

Panagiotopoulou P, Vlachos D G. Liquid phase catalytic transfer hydrogenation of furfural over a Ru/C catalyst. ChemSusChem, 2014, 480: 17–24

Jae J, Zheng W, Karim A M, Guo W, Lobo R F, Vlachos D G. The role of Ru and RuO2 in the catalytic transfer hydrogenation of 5-hydroxymethylfurfural for the production of 2,5-dimethylfuran. ChemCatChem, 2014, 6(3): 848–856

Li C, Shao Z, Pang M, Williams C, Zhang X F, Liang C H. Carbon nanotubes supported mono- and bimetallic Pt and Ru catalysts for selective hydrogenation of phenylacetylene. Industrial & Engineering Chemistry Research, 2012, 51(13): 4934–4941

Martínez-Prieto L M, Puche M, Cerezo-Navarrete C, Chaudret B. Uniform Ru nanoparticles on N-doped graphene for selective hydrogenation of fatty acids to alcohols. Journal of Catalysis, 2019, 377: 429–437

Hossain M A, Phung T K Rahaman M S, Tulaphol S, Jasinski J B, Sathitsuksanoh N. Catalytic cleavage of the β-O-4 aryl ether bonds of lignin model compounds by Ru/C catalyst. Applied Catalysis A: General, 2019, 582(25): 117100

Li Z Q, Lu C J, Xia Z P Zhou Y, Luo Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon, 2007, 45(8): 1686–1695

Kerdi F, Rass H A, Pinel C Besson M, Peru G, Leger B, Rio S, Monflier E, Ponchel A. Evaluation of surface properties and pore structure of carbon on the activity of supported Ru catalysts in the aqueous-phase aerobic oxidation of HMF to FDCA. Applied Catalysis A: General, 2015, 506(5): 206–219

Zanutelo C Landers R Carvalho W A, Cobo A J G. Carbon support treatment effect on Ru/C catalyst performance for benzene partial hydrogenation. Applied Catalysis A: General, 2011, 409–410(15): 174–180

Taboada C D, Batista J, Pintar A, Levec J. Preparation, characterization and catalytic properties of carbon nanofiber-supported Pt, Pd, Ru monometallic particles in aqueous-phase reactions. Applied Catalysis B: Environmental, 2009, 89(3–4): 375–382

Lin B, Guo Y, Lin J, Ni J, Lin J, Jiang L, Wang Y. Deactivation study of carbon-supported ruthenium catalyst with potassium promoter. Applied Catalysis A: General, 2017, 541(5): 1–7

Huang H, Dai Q, Wang X Y. Morphology effect of Ru/CeO2 catalysts for the catalytic combustion of chlorobenzene. Applied Catalysis B: Environmental, 2014, 158–159: 96–105

Rossetti I, Pernicone N, Forni L. Characterisation of Ru/C catalysts for ammonia synthesis by oxygen chemisorption. Applied Catalysis A: General, 2003, 248(1–2): 97–103

Michel C, Gallezot P. Why is ruthenium an efficient catalyst for the aqueous-phase hydrogenation of bio-sourced carbonyl compounds? ACS Catalysis, 2015, 5(7): 4130–4132

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, T., Ma, X. Development of an in-situ H2 reduction and moderate oxidation method for 3,5-dimethylpyridine hydrogenation in trickle bed reactor. Front. Chem. Sci. Eng. 16, 1807–1817 (2022). https://doi.org/10.1007/s11705-022-2243-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-022-2243-2