Abstract

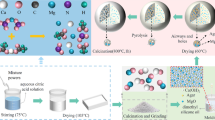

For decades, distiller waste and CO2 were not the first choice for production of high valued products. Here, CaCO3 hollow microspheres, a high-value product was synthesized from such a reaction system. The synthetic methods, the formation mechanism and operational cost were discussed. When 2.5 L·min−1·L−1 CO2 was flowed into distiller waste (pH = 11.4), spheres with 4–13 diameters and about 2 shell thickness were obtained. It is found that there is a transformation of CaCO3 particles from solid-cubic nuclei to hollow spheres. Firstly, the Ca(OH)2 in the distiller waste stimulated the nucleation of calcite with a non-template effect and further maintained the calcite form and prevented the formation of vaterite. Therefore, in absence of auxiliaries, the formation of hollow structures mainly depended on the growth and aging of CaCO3. Studies on the crystal morphology and its changes during the growth process point to the inside-out Ostwald effect in the formation of hollow spheres. Change in chemical properties of the bulk solution caused changes in interfacial tension and interfacial energy, which promoted the morphological transformation of CaCO3 particles from cubic calcite to spherical clusters. Finally, the flow process for absorption of CO2 by distiller waste was designed and found profitable.

Similar content being viewed by others

Abbreviations

- X V :

-

the molar fractions of vaterite

- X C :

-

the molar fractions of calcite

- I c 104 :

-

crystal plane peak intensities of calcite

- I v 110 :

-

110 crystal plane peak intensities of vaterite

- \({V_{{\rm{C}}{{\rm{O}}_2}}}\) :

-

the total amount of CO2 consumed during the carbonation reaction for 1 h, L

- V :

-

the volume of solution, L

- V m :

-

the standard molar volume of a gas, L·mol−1

- \({n_{{\rm{Ca}}{{\left( {{\rm{OH}}} \right)}_2}}}\) :

-

the amount of insoluble Ca(OH)2 reacted part at time t (negligible), mol

- M:

-

molecular weight of Ca(OH)2, g·mol−1

- n :

-

the amount of undissolved Ca(OH)2, mol

- \({c_{{\rm{Ca}}_0^{2 + }}}\) :

-

the initial concentration of Ca2+ in the solution, mol·L−1

- \({c_{{\rm{Ca}}_t^{2 + }}}\) :

-

the concentration of Ca2+ in the solution at time t, mol·L−1

- \({c_{{\rm{C}}{{\rm{a}}^{2 + }}}}\) :

-

the concentration of Ca2+, mol·L−1

- \({c_{{\rm{O}}{{\rm{H}}^ - }}}\) :

-

the concentration of OH−, mol·L−1

- J :

-

the activity products

- K :

-

solubility product constant of Ca(OH)2, K = 5.6 × 10−6 (25 °C)

- \({\gamma _{{\rm{C}}{{\rm{a}}^{2 + }}}}\) :

-

the activity coefficients of Ca2+

- \({\gamma _{{\rm{O}}{{\rm{H}}^ - }}}\) :

-

the activity coefficients of OH−

- \({\alpha _{{\rm{C}}{{\rm{a}}^{2 + }}}}\) :

-

activity of Ca2+ in solution, mol·L−1

- \({\alpha _{{\rm{O}}{{\rm{H}}^ - }}}\) :

-

activity of OH− in solution, mol·L−1

- θ :

-

contact angle between calcite and liquid, (°)

- γ ls :

-

solid-liquid interfacial tension, mN·m−1

- γ lg :

-

liquid-vapor interfacial tension, mN·m−1

- γ sg :

-

solid-vapor interfacial tension, mN·m−1, γsg= 43.5 mN·m−1

- \({c_{{\rm{Ca}}_{20\min }^{2 + }}}\) :

-

the concentration of Ca2+ in the system reacted for 20 min, mol·L−1

- Y :

-

the output of CaCO3 hollow microspheres, kg T cycle times of carbonation of distiller waste

- V′ :

-

the volume of distiller waste, L

- M′ :

-

the molecular weight of CaCO3, g·mol−1

References

Trypuc M, Bialowicz K. CaCO3 production using liquid waste from Solvay method. Journal of Cleaner Production, 2011, 19(6–7): 751–756

Calban T, Kavci E. Removal of calcium from soda liquid waste containing calcium chloride. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2010, 32(5): 407–418

Sun B C, Wang X M, Chen J M, Chu G W, Chen J F, Shao L. Synthesis of nano-CaCO3 by simultaneous absorption of CO2 and NH3 into CaCl2 solution in a rotating packed bed. Chemical Engineering Journal, 2011, 168(2): 731–736

Gao C Z, Dong Y, Zhang H J, Zhang J M. Utilization of distiller waste and residual mother liquor to prepare precipitated calcium carbonate. Journal of Cleaner Production, 2007, 15(15): 1419–1425

Zhang X, Asselin E, Li Z. CaCO3 precipitation kinetics in the system CaCl2−CO2−Mg(OH)2−H2O for comprehensive utilization of soda production wastes. ACS Sustainable Chemistry & Engineering, 2020, 9(1): 398–410

Luo X P, Song X W, Cao Y W, Song L, Bu X Z. Investigation of calcium carbonate synthesized by steamed ammonia liquid waste without use of additives. RSC Advances, 2020, 10(13): 7976–7986

Dong C, Song X, Li Y, Liu C, Chen H, Yu J. Impurity ions effect on CO2 mineralization via coupled reaction-extraction-crystallization process of CaCl2 waste liquids. Journal of CO2 Utilization, 2018, 27: 115–128

Song X W, Liu H, Wang J F, Cao Y W, Luo X P. A study of the effects of NH4+ on the fast precipitation of vaterite CaCO3 formed from steamed ammonia liquid waste and K2CO3/Na2CO3. CrystEngComm, 2021, 23(24): 4284–4300

Yan Z, Wang Y, Yue H, Liu C, Zhong S, Ma K, Liao W, Tang S, Liang B. Integrated process of monoethanolamine-based CO2 absorption and CO2 mineralization with SFGD slag: process simulation and life-cycle assessment of CO2 emission. ACS Sustainable Chemistry & Engineering, 2021, 9(24): 8238–8248

Alamdari A, Alamdari A, Mowla D. Kinetics of calcium carbonate precipitation through CO2 absorption from flue gas into distiller waste of soda ash plant. Journal of Industrial and Engineering Chemistry, 2014, 20(5): 3480–3486

Li Y, Song X, Chen G, Sun Z, Xu Y, Yu J. Preparation of calcium carbonate and hydrogen chloride from distiller waste based on reactive extraction-crystallization process. Chemical Engineering Journal, 2015, 278: 55–61

Sha F, Zhu N, Bai Y J, Li Q, Guo B, Zhao T X, Zhang F, Zhang J B. Controllable synthesis of various CaCO3 morphologies based on a CCUS idea. ACS Sustainable Chemistry & Engineering, 2016, 4(6): 3032–3044

Ma Y, Feng Q, Bourrat X. A novel growth process of calcium carbonate crystals in silk fibroin hydrogel system. Materials Science and Engineering C, 2013, 33(4): 2413–2420

Zheng T W, Zhang X, Yi H H. Spherical vaterite microspheres of calcium carbonate synthesized with poly(acrylic acid) and sodium dodecyl benzene sulfonate. Journal of Crystal Growth, 2019, 528(15): 125275

Chen H G, Leng S L. Rapid synthesis of hollow nano-structured hydroxyapatite rnicrospheres via microwave transformation method using hollow CaCO3 precursor microspheres. Ceramics International, 2015, 41(2): 2209–2213

Zheng T W, Yi H H, Zhang S Y, Wang C G. Preparation and formation mechanism of calcium carbonate hollow microspheres. Journal of Crystal Growth, 2020, 549: 125870

Wang J, Chen J S, Zong J Y, Zhao D, Li F, Zhuo R X, Cheng S X. Calcium carbonate/carboxymethyl chitosan hybrid microspheres and nanospheres for drug delivery. Journal of Physical Chemistry C, 2010, 114(44): 18940–18945

Park R J, Meldrum F C. Synthesis of single crystals of calcite with complex morphologies. Advanced Materials, 2002, 14(16): 1167–1169

Kim S, Ko J W, Park C B. Bio-inspired mineralization of CO2 gas to hollow CaCO3 microspheres and bone hydroxyapatite/polymer composites. Journal of Materials Chemistry, 2011, 21(30): 11070–11073

Yan G W, Huang J H, Zhang J F, Qian C J. Aggregation of hollow CaCO3 spheres by calcite nanoflakes. Materials Research Bulletin, 2008, 43(8–9): 2069–2077

Hadiko G, Han Y S, Fuji M, Takahashi M. Synthesis of hollow calcium carbonate particles by the bubble templating method. Materials Letters, 2005, 59(19–20): 2519–2522

Tomioka T, Fuji M, Takahashi M, Takai C, Utsuno M. Hollow structure formation mechanism of calcium carbonate particles synthesized by the CO2 bubbling method. Crystal Growth & Design, 2012, 12(2): 771–776

Yan P, Guo Y P, Xu Z, Wang Z C. Influence of surfactant-polymer complexes on crystallization and aggregation of CaCO3. Chemical Research in Chinese Universities, 2012, 28(4): 737–742

Watanabe H, Mizuno Y, Endo T, Wang X W, Fuji M, Takahashi M. Effect of initial pH on formation of hollow calcium carbonate particles by continuous CO2 gas bubbling into CaCl2 aqueous solution. Advanced Powder Technology, 2009, 20(1): 89–93

Chen J, Xiang L. Controllable synthesis of calcium carbonate polymorphs at different temperatures. Powder Technology, 2009, 189(1): 64–69

Wang B, Pan Z H, Du Z P, Cheng H G, Cheng F Q. Effect of impure components in flue gas desulfurization (FGD) gypsum on the generation of polymorph CaCO3 during carbonation reaction. Journal of Hazardous Materials, 2019, 369: 236–243

Li E Z, Lu Y, Cheng F Q, Wang X M, Miller J D. Effect of oxidation on the wetting of coal surfaces by water: experimental and molecular dynamics simulation studies. Physicochemical Problems of Mineral Processing, 2018, 54(4): 1039–1051

Marcolli C. Technical note: fundamental aspects of ice nucleation via pore condensation and freezing including Laplace pressure and growth into macroscopic ice. Atmospheric Chemistry and Physics, 2020, 20(5): 3209–3230

Cheng H G, Wang X, Wang B, Zhao J, Liu Y, Cheng F Q. Effect of ultrasound on the morphology of the CaCO3 precipitated from CaSO4−NH3−CO2−H2O system. Journal of Crystal Growth, 2017, 469: 97–105

Chen Q J, Ding W J, Sun H J, Peng T J, Ma G H. Utilization of phosphogypsum to prepare high-purity CaCO3 in the NH4Cl−NH4OH−CO2 system. ACS Sustainable Chemistry & Engineering, 2020, 8(31): 11649–11657

Cheng H G, Zhang X X, Song H P. Morphological investigation of calcium carbonate during ammonification-carbonization process of low concentration calcium solution. Journal of Nanomaterials, 2014, 2014: 1–7

Nesbitt H W. Activity coefficients of ions in alkali and alkalineearth chloride dominated waters including seawater. Chemical Geology, 1984, 43(1–2): 127–142

Fanghänel T, Neck V, Kim J I. The ion product of H2O, dissociation constants of H2CO3 and Pitzer parameters in the system Na+/H+/OH/HCO3−/CO32−/ClO4−/H2O at 25 °C. Journal of Solution Chemistry, 1996, 25(4): 327–343

Dean J A. Lang’s Handbook of Chemistry. New York: The Kingsport Press, 1985: 5–8

Li B, Zeng H C. Architecture and preparation of hollow catalytic devices. Advanced Materials, 2019, 31(38): 1801104

Yang X, Fu J, Jin C, Chen J, Liang C, Wu M, Zhou W. Formation mechanism of CaTiO3 hollow crystals with different microstructures. Journal of the American Chemical Society, 2010, 132(40): 14279–14287

Ding W, Hu L, Sheng Z, Dai J, Zhu X, Tang X, Hui Z, Sun Y. Magneto-acceleration of Ostwald ripening in hollow Fe3O4 nanospheres. CrystEngComm, 2016, 18(33): 6134–6137

Weng W, Lin J, Du Y, Ge X, Zhou X, Bao J. Template-free synthesis of metal oxide hollow micro-/nanospheres via Ostwald ripening for lithium-ion batteries. Journal of Materials Chemistry A: Materials for Energy and Sustainability, 2018, 6(22): 10168–10175

Zhao W, Zhang C, Geng F, Zhuo S, Zhang B. Nanoporous hollow transition metal chalcogenide nanosheets synthesized via the anion-exchange reaction of metal hydroxides with chalcogenide ions. ACS Nano, 2014, 8(10): 10909–10919

Yin Y D, Rioux R M, Erdonmez C K, Hughes S, Somorjai G A, Alivisatos A P. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science, 2004, 304(5671): 711–714

Fan H J, Gösele U, Zacharias M. Formation of nanotubes and hollow nanoparticles based on Kirkendall and diffusion processes: a review. Small, 2007, 3(10): 1660–1671

Fan H J, Knez M, Scholz R, Nielsch K, Pippel E, Hesse D, Zacharias M, Gösele U. Monocrystalline spinel nanotube fabrication based on the Kirkendall effect. Nature Materials, 2006, 5(8): 627–631

Gao J N, Li Q S, Zhao H B, Li L S, Liu C L, Gong Q H, Qi L M. One-pot synthesis of uniform Cu2O and CuS hollow spheres and their optical limiting properties. Chemistry of Materials, 2008, 20(19): 6263–6269

Gayevskii V R, Kochmarskii V Z, Gayevska S G. Nucleation and crystal growth of calcium sulfate dihydrate from aqueous solutions: speciation of solution components, kinetics of growth, and interfacial tension. Journal of Crystal Growth, 2020, 548: 125844

Keller K S, Olsson M H, Yang M, Stipp S L. Adsorption of ethanol and water on calcite: dependence on surface geometry and effect on surface behavior. Langmuir, 2015, 31(13): 3847–3853

Gao Z, Li C, Sun W, Hu Y. Anisotropic surface properties of calcite: a consideration of surface broken bonds. Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 2017, 520: 53–61

Tabar M A, Shafiei Y, Shayesteh M, Monfared A D, Ghazanfari M H. Wettability alteration of calcite rock from gas-repellent to gas-wet using a fluorinated nanofluid: a surface analysis study. Journal of Natural Gas Science and Engineering, 2020, 83: 103613

Ulusoy U, Hiçyılmaz C, Yekeler M. Role of shape properties of calcite and barite particles on apparent hydrophobicity. Chemical Engineering and Processing, 2004, 43(8): 1047–1053

Chen Z Q. Colloid and Interface Chemistry. Peking: Higher Education Press, 2001, 95–104 (In Chinese)

Tyson W R, Miller W A. Surface free energies of solid metals: estimation from liquid surface tension measurements. Surface Science, 1977, 62(1): 267–276

Pan S Y, Chang E E, Chiang P C, Chiang P C. CO2 capture by accelerated carbonation of alkaline wastes: a review on its principles and applications. Aerosol and Air Quality Research, 2012, 12(5): 770–791

Ruan J J, Huang J X, Dong L P, Huang Z. Environmentally friendly technology of recovering nickel resources and producing nano-Al2O3 from waste metal film resistors. ACS Sustainable Chemistry & Engineering, 2017, 5(9): 8234–8240

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant Nos. U20A20149, 21878180 and 21908137) and the Graduate Education Project of Shanxi Province (NO. 2021Y139).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Xu, W., Cheng, H., Li, E. et al. Formation of CaCO3 hollow microspheres in carbonated distiller waste from Solvay soda ash plants. Front. Chem. Sci. Eng. 16, 1659–1671 (2022). https://doi.org/10.1007/s11705-022-2173-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-022-2173-z