Abstract

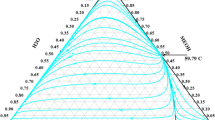

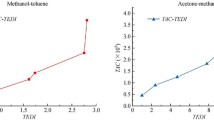

An energy-efficient triple-column extractive distillation process is developed for recovering tetrahydrofuran and ethyl acetate from industrial effluent. The process development follows a rigorous hierarchical design procedure that involves entrainer design, thermodynamic analysis, process design and optimization, and heat integration. The computer-aided molecular design method is firstly used to find promising entrainer candidates and the best one is determined via rigorous thermodynamic analysis. Subsequently, the direct and indirect triple-column extractive distillation processes are proposed in the conceptual design step. These two extractive distillation processes are then optimized by employing an improved genetic algorithm. Finally, heat integration is performed to further reduce the process energy consumption. The results indicate that the indirect extractive distillation process with heat integration shows the highest performance in terms of the process economics.

Similar content being viewed by others

References

Santaella M A, Orjuela A, Narváez P C. Comparison of different reactive distillation schemes for ethyl acetate production using sustainability indicators. Chemical Engineering and Processing, 2015, 96: 1–13

Tran L S, Verdicchio M, Monge F, Martin R C, Bounaceeur R, Sirjean B, Glaude P A, Alzueta M U, Battin Leclerc F. An experimental and modeling study of the combustion of tetrahydrofuran. Combustion and Flame, 2015, 162(5): 1899–1918

He Z, Lin S, Gong C, Xi Y. Study on separating tetrahydrofuran from the mixture made up tetrahydrofuran, ethyl acetate and water. Journal of Shenyang Institute of Chemical Technology, 1996, 10(2): 143–147

Deorukhkar O A, Deogharkar B S, Mahajan Y S. Purification of tetrahydrofuran from its aqueous azeotrope by extractive distillation: pilot plant studies. Chemical Engineering and Processing, 2016, 105: 79–91

Yin Y, Yang Y, De Lourdes Mendoza M, Zhai S, Feng W, Wang Y, Gu M, Cai L, Zhang L. Progressive freezing and suspension crystallization methods for tetrahydrofuran recovery from Grignard reagent wastewater. Journal of Cleaner Production, 2017, 144: 180–186

Zhang X, He J, Cui C, Sun J. A systematic process synthesis method towards sustainable extractive distillation processes with preconcentration for separating the binary minimum azeotropes. Chemical Engineering Science, 2020, 227: 115932

Graczová E, Šulgan B, Barabas S, Steltenpohl P. Methyl acetatemethanol mixture separation by extractive distillation: economic aspects. Frontiers of Chemical Science and Engineering, 2018, 12(4): 670–682

Wang C, Zhang Z, Zhang X, Guang C, Gao J. Comparison of pressure-swing distillation with or without crossing curved-boundary for separating a multiazeotropic ternary mixture. Separation and Purification Technology, 2019, 220: 114–125

Liang S, Cao Y, Liu X, Li X, Zhao Y, Wang Y, Wang Y. Insight into pressure-swing distillation from azeotropic phenomenon to dynamic control. Chemical Engineering Research & Design, 2017, 117: 318–335

Han Z, Ren Y, Li H, Li X, Gao X. Simultaneous extractive and azeotropic distillation separation process for production of PODEn from formaldehyde and methylal. Industrial & Engineering Chemistry Research, 2019, 58(13): 5252–5260

Haaz E, Szilagyi B, Fozer D, Toth A J. Combining extractive heterogeneous-azeotropic distillation and hydrophilic pervaporation for enhanced separation of non-ideal ternary mixtures. Frontiers of Chemical Science and Engineering, 2020, 14(5): 913–927

Yang A, Shen W, Wei S, Dong L, Li J, Gerbaud V. Design and control of pressure-swing distillation for separating ternary systems with three binary minimum azeotropes. AIChE Journal. American Institute of Chemical Engineers, 2019, 65(4): 1281–1293

Li W, Zhong L, He Y, Meng J, Yao F, Guo Y, Xu C. Multiple steady-states analysis and unstable operating point stabilization in homogeneous azeotropic distillation with intermediate entrainer. Industrial & Engineering Chemistry Research, 2015, 54(31): 7668–7686

Gerbaud V, Rodriguez Donis I, Hegely L, Lang P, Denes F, You X. Review of extractive distillation. Process design, operation, optimization and control. Chemical Engineering Research & Design, 2019, 141: 229–271

Li H, Wu Y, Li X, Gao X. State-of-the-art of advanced distillation technologies in China. Chemical Engineering & Technology, 2016, 39(5): 815–833

Yang A, Sun S, Shi T, Xu D, Ren J, Shen W. Energy-efficient extractive pressure-swing distillation for separating binary minimum azeotropic mixture dimethyl carbonate and ethanol. Separation and Purification Technology, 2019, 229: 115817

Shi T, Yang A, Jin S, Shen W, Wei S, Ren J. Comparative optimal design and control of two alternative approaches for separating heterogeneous mixtures isopropyl alcohol-isopropyl acetate-water with four azeotropes. Separation and Purification Technology, 2019, 225: 1–17

Pan Q, Shang X, Li J, Ma S, Li L, Sun L. Energy-efficient separation process and control scheme for extractive distillation of ethanolwater using deep eutectic solvent. Separation and Purification Technology, 2019, 219: 113–126

Shi X, Zhu X, Zhao X, Zhang Z. Performance evaluation of different extractive distillation processes for separating ethanol/tert-butanol/water mixture. Process Safety and Environmental Protection, 2020, 137: 246–260

Yang A, Zou H, Chien I L, Wang D, Wei S, Ren J, Shen W. Optimal design and effective control of triple-column extractive distillation for separating ethyl acetate/ethanol/water with multiazeotrope. Industrial & Engineering Chemistry Research, 2019, 58(17): 7265–7283

Cignitti S, Rodriguez-Donis I, Abildskov J, You X, Shcherbakova N, Gerbaud V. CAMD for entrainer screening of extractive distillation process based on new thermodynamic criteria. Chemical Engineering Research & Design, 2019, 147: 721–733

Woo H C, Kim Y H. Solvent selection for extractive distillation using molecular simulation. AIChE Journal. American Institute of Chemical Engineers, 2019, 65(9): e16665

Cui Y, Zhang Z, Shi X, Guang C, Gao J. Triple-column side-stream extractive distillation optimization via simulated annealing for the benzene/isopropanol/water separation. Separation and Purification Technology, 2020, 236: 116303

Zhu Z, Li G, Dai Y, Cui P, Xu D, Wang Y. Determination of a suitable index for a solvent via two-column extractive distillation using a heuristic method. Frontiers of Chemical Science and Engineering, 2020, 14(5): 824–833

Shen W, Dong L, Wei S, Li J, Benyounes H, You X, Gerbaud V. Systematic design of an extractive distillation for maximum-boiling azeotropes with heavy entrainers. AIChE Journal. American Institute of Chemical Engineers, 2015, 61(11): 3898–3910

Blahušiak M, Kiss A A, Babic K, Kersten S R A, Bargeman G, Schuur B. Insights into the selection and design of fluid separation processes. Separation and Purification Technology, 2018, 194: 301–318

Gani R, Brignole E. Molecular design of solvents for liquid extraction based on UNIFAC. Fluid Phase Equilibria, 1983, 13: 331–340

Gertig C, Kröger L, Fleitmann L, Scheffczyk J, Bardow A, Leonhard K. Rx-COSMO-CAMD: computer-aided molecular design of reaction solvents based on predictive kinetics from quantum chemistry. Industrial & Engineering Chemistry Research, 2019, 58(51): 22835–22846

Liu Q, Zhang L, Liu L, Du J, Meng Q, Gani R. Computer-aided reaction solvent design based on transition state theory and COSMO-SAC. Chemical Engineering Science, 2019, 202: 300–317

Zhou T, Wang J, McBride K, Sundmacher K. Optimal design of solvents for extractive reaction processes. AIChE Journal. American Institute of Chemical Engineers, 2016, 62(9): 3238–3249

Zhang L, Pang J, Zhuang Y, Liu L, Du J, Yuan Z. Integrated solvent-process design methodology based on COSMO-SAC and quantum mechanics for TMQ (2,2,4-trimethyl-1,2-H-dihydroquinoline) production. Chemical Engineering Science, 2020, 226: 115894

Song Z, Zhang C, Qi Z, Zhou T, Sundmacher K. Computer-aided design of ionic liquids as solvents for extractive desulfurization. AIChE Journal. American Institute of Chemical Engineers, 2018, 64(3): 1013–1025

Chao H, Song Z, Cheng H, Chen L, Qi Z. Computer-aided design and process evaluation of ionic liquids for n-hexane-methylcyclopentane extractive distillation. Separation and Purification Technology, 2018, 196: 157–165

Zhou T, Song Z, Zhang X, Gani R, Sundmacher K. Optimal solvent design for extractive distillation processes: a multiobjective optimization-based hierarchical framework. Industrial & Engineering Chemistry Research, 2019, 58(15): 5777–5786

Silva R O, Torres C M, Bonfim Rocha L, Lima O C M, Coutu A, Jiménez L, Jorge L M M. Multi-objective optimization of an industrial ethanol distillation system for vinasse reduction—a case study. Journal of Cleaner Production, 2018, 183: 956–963

Waltermann T, Grueters T, Muenchrath D, Skiborowski M. Efficient optimization-based design of energy-integrated azeotropic distillation processes. Computers & Chemical Engineering, 2020, 133: 106676

Krone D, Esche E, Asprion N, Skiborowski M, Repke J U. Conceptual design based on superstructure optimization in GAMS with accurate thermodynamic models. Computer-Aided Chemical Engineering, 2020, 48: 15–20

Li X, Cui C, Li H, Gao X. Process synthesis and simulation-based optimization of ethylbenzene/styrene separation using double-effect heat integration and self-heat recuperation technology: a technoeconomic analysis. Separation and Purification Technology, 2019, 228: 115760

Su Y, Jin S, Zhang X, Shen W, Eden M R, Ren J. Stakeholder-oriented multi-objective process optimization based on an improved genetic algorithm. Computers & Chemical Engineering, 2020, 132: 106618

Kruber K F, Grueters T, Skiborowski M. Efficient design of intensified extractive distillation processes based on a hybrid optimization approach. Computer-Aided Chemical Engineering, 2019, 46: 859–864

Yang A, Su Y, Chien I L, Jin S, Yan C, Wei S, Shen W. Investigation of an energy-saving double-thermally coupled extractive distillation for separating ternary system benzene/toluene/cyclohexane. Energy, 2019, 186: 115756

You X, Gu J, Gerbaud V, Peng C, Liu H. Optimization of preconcentration, entrainer recycle and pressure selection for the extractive distillation of acetonitrile-water with ethylene glycol. Chemical Engineering Science, 2018, 177: 354–368

Momoh S O. Assessing the accuracy of selectivity as a basis for solvent screening in extractive distillation processes. Separation Science and Technology, 1991, 26(5): 729–742

Marrero J, Gani R. Group-contribution based estimation of pure component properties. Fluid Phase Equilibria, 2001, 183: 183–208

Rodriguez Donis I, Gerbaud V, Joulia X. Thermodynamic insights on the feasibility of homogeneous batch extractive distillation, 1. azeotropic mixtures with a heavy entrainer. Industrial & Engineering Chemistry Research, 2009, 48(7): 3544–3559

Douglas J M. Conceptual Design of Chemical Processes. 1st ed. New York: McGraw-Hill, 1988, 461–462

Luyben W L. Distillation Design and Control Using Aspen Simulation. 1st ed. New Jersey: John Wiley & Sons, 2013, 87–89

Zhang Q, Liu M, Li C, Zeng A. Heat-integrated pressure-swing distillation process for separation of the maximum-boiling azeotrope diethylamine and methanol. Journal of the Taiwan Institute of Chemical Engineers, 2018, 93: 644–659

Yang J, Pan X, Yu M, Cui P, Ma Y, Wang Y, Gao J. Vaporliquid equilibrium for binary and ternary systems of tetrahydrofuran, ethyl acetate and N-methyl pyrrolidone at pressure 101.3 kPa. Journal of Molecular Liquids, 2018, 268: 19–25

Xia M, Shi H, Niu C, Ma Z, Lu H, Xiao Y, Hou B, Jia L, Li D. The importance of pressure-sensitive pinch/azeotrope feature on economic distillation design. Separation and Purification Technology, 2020, 250: 116753

Acknowledgements

This work is financially supported by the National Key Research and Development Project (Grant No. 2019YFC0214403), the Joint Supervision Scheme with the Chinese mainland, Taiwan region and Macao Universities—Other Chinese mainland, Taiwan region and Macao Universities (Grant No. SB2S to Yang A).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

11705_2021_2044_MOESM1_ESM.pdf

Energy-efficient recovery of tetrahydrofuran and ethyl acetate by triple-column extractive distillation: entrainer design and process optimization

Rights and permissions

About this article

Cite this article

Yang, A., Su, Y., Shi, T. et al. Energy-efficient recovery of tetrahydrofuran and ethyl acetate by triple-column extractive distillation: entrainer design and process optimization. Front. Chem. Sci. Eng. 16, 303–315 (2022). https://doi.org/10.1007/s11705-021-2044-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-021-2044-z