Abstract

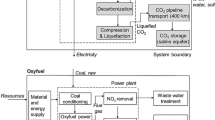

This paper compares the techno-economic performances of three technologies for CO2 capture from a lignite-based IGCC power plant located in the Czech Republic: (1) Physical absorption with a Rectisol-based process; (2) Polymeric CO2-selective membrane-based capture; (3) Low-temperature capture. The evaluations show that the IGCC plant with CO2 capture leads to costs of electricity between 91 and 120 € · MWh−1, depending on the capture technology employed, compared to 65 € · MWh−1 for the power plant without capture. This results in CO2 avoidance costs ranging from 42 to 84 € · \({\text{t}_{{\text{CO}_2},\text{avoided}}}^{ - 1}\), mainly linked to the losses in net power output. From both energy and cost points of view, the low-temperature and Rectisol based CO2 capture processes are the most efficient capture technologies. Furthermore, partial CO2 capture appears as a good mean to ensure early implementation due to the limited increase in CO2 avoidance cost when considering partial capture. To go beyond the two specific CO2-selective membranes considered, a cost/membrane property map for CO2-selective membranes was developed. This map emphasise the need to develop high performance membrane to compete with solvent technology. Finally, the cost of the whole CCS chain was estimated at 54 € · \({\text{t}_{{\text{CO}_2},\text{avoided}}}^{ - 1}\) once pipeline transport and storage are taken into consideration.

Similar content being viewed by others

References

International Energy Agency. IEA Statistics: Coal Information, 2015

Bauerova L. Europe’s Coal Curtain Is Complicating the Climate Fight. Bloomberg Business, 2015-01-12

Berstad D, Roussanaly S, Skaugen G, Anantharaman R, Neksa P, Jordal K. Energy and cost evaluation of a low-temperature CO2 capture unit for IGCC plants. Energy Procedia, 2014, 63: 2031–2036

IEAGHG. Assessment of Emerging CO2 Capture Technologies and Their Potential to Reduce Costs, 2014/TR4, 2014

Storset S, Tangen G, Berstad D, Eliasson P, Hoff K A, Langorgen O, Munkejord S T, Roussanaly S, Torsaster M. Profiting from CCS innovations: A study to measure potential value creation from CCS research and development. International Journal of Greenhouse Gas Control, 2019, 83: 208–215

Chen C, Rubin E. CO2 control technology effects on IGCC plant performance and cost. Energy Policy, 2009, 37(3): 915–924

Klara J, Plunkett J. The potential of advanced technologies to reduce carbon capture costs in future IGCC power plants. International Journal of Greenhouse Gas Control, 2010, 4(2): 112–118

Lin H, He Z, Sun Z, Kniep J, Ng A, Baker R, Merkel T. CO2-selective membranes for hydrogen production and CO2 capture-Part II: Techno-economic analysis. Journal of Membrane Science, 2015, 493: 794–806

Urech J, Tock L, Harkin T, Hoadley A, Marechal F. An assessment of different solvent-based capture technologies within an IGCC-CCS power plant. Energy, 2014, 64: 268–276

Anantharaman R, Bolland O, Booth N, Dorst E V, Ekstrom C, Franco F, Macchi E, Manzolini G, Nikolic D, Pfeffer A, et al. DI.4.3 European best practice guidelines for assessment of CO2 capture technologies (DECARBit Project), 2011

Zhai H, Rubin E. Systems analysis of physical absorption of CO2 in ionic liquids for pre-combustion carbon capture. Environmental Science & Technology, 2018, 52(8): 4996–5004

Gazzani M, Turi D, Ghoniem A, Macchi E, Manzolini G. Techno-economic assessment of two novel feeding systems for a dry-feed gasifier in an IGCC plant with Pd-membranes for CO2 capture. International Journal of Greenhouse Gas Control, 2014, 25: 62–78

Grainger D, Hagg M B. Techno-economic evaluation of a PVAm CO2-selective membrane in an IGCC power plant with CO2 capture. Fuel, 2008, 87(1): 14–24

Riboldi L, Bolland O. Comprehensive analysis on the performance of an IGCC plant with a PSA process integrated for CO2 capture. International Journal of Greenhouse Gas Control, 2015, 43: 57–69

Grabner M, Morstein O, Rappold D, Giinster W, Beysel G, Meyer B. Constructability study on a German reference IGCC power plant with and without CO2-capture for hard coal and lignite. Energy Conversion and Management, 2010, 51(11): 2179–2187

Rubin E, Booras G, Davison J, Ekstrom C, Matuszewski M, McCoy S T, Short C. Toward a common method of the cost estimation for CO2 capture and storage at fossil fuel power plants. Global CCS Institute, 2013

Falk-Pedersen O, Gundersen M H, Selfors A, Svendsen P T. Carbon capture and storage at Karsto. Oslo: Norges Vassdrags-og Energidirektorat, 2007 (in Norwegian)

Gararsdottir S, Normann F, Skagestad R, Johnsson F. Investment costs and CO2 reduction potential of carbon capture from industrial plants-A Swedish case study. International Journal of Greenhouse Gas Control, 2018, 76: 111–124

Roussanaly S, Aasen A, Anantharaman R, Danielsen B, Jakobsen J, Heme-De-Lacotte L, Neji G, Sodal A, Wahl P E, Vrana T K, Dreux R. Offshore power generation with carbon capture and storage to decarbonise mainland electricity and offshore oil and gas installations: A techno-economic analysis. Applied Energy, 2019, 233–234: 478–494

European Technology Platform for Zero Emission Fossil Fuel Power Plants (ZEP). The Costs of CO2 Transport, Post-Demonstration CCS in the EU, 2011

Roussanaly S, Jakobsen J P, Hognes E H, Brunsvold A L. Benchmarking of CO2 transport technologies: Part I-Onshore pipeline and shipping between two onshore areas. International Journal of Greenhouse Gas Control, 2013, 19: 584

Kunze C, Spliethoff H. Modelling, comparison and operation experiences of entrained flow gasifier. Energy Conversion and Management, 2011, 52(5): 2135–2141

Meerman J C, Knoope M M J, Ramirez A, Turkenburg W C, Faaij A P C. Technical and economic prospects of coal- and biomass-fired integrated gasification facilities equipped with CCS over time. International Journal of Greenhouse Gas Control, 2013, 16: 311–323

Kapetaki Z, Ahn H, Brandani S. Detailed process simulation of pre-combustion IGCC plants using coal-slurry and dry coal gasifiers. Energy Procedia, 2013, 37: 2196–2203

Padurean A, Cormos C C, Agachi P S. Pre-combustion carbon dioxide capture by gas-liquid absorption for integrated gasification combined cycle power plants. International Journal of Greenhouse Gas Control, 2012, 7: 1–11

Park S, Lee S, Lee J, Chun S, Lee J. The quantitative evaluation of two-stage pre-combustion CO2 capture processes using the physical solvents with various design parameters. Energy, 2015, 81: 47–55

Sun L, Smith R. Rectisol wash process simulation and analysis. Journal of Cleaner Production, 2013, 39: 321–328

Li P, Wang Z, Qiao Z, Liu Y, Cao X, Li W, Wang J, Wang S. Recent developments in membranes for efficient hydrogen purification. Journal of Membrane Science, 2015, 495: 130–168

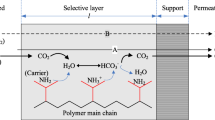

Qiao Z, Wang Z, Yuan S, Wang J, Wang S. Preparation and characterization of small molecular amine modified PVAm membranes for CO2/H2 separation. Journal of Membrane Science, 2015, 475: 290–302

Roussanaly S, Anantharaman R, Lindqvist K, Zhai H, Rubin E. Membrane properties required for post-combustion CO2 capture at coal-fired power plants. Journal of Membrane Science, 2016, 511: 250–264

Roussanaly S, Anantharaman R. Cost-optimal CO2 capture ratio for membrane-based capture from different CO2 sources. Chemical Engineering Journal, 2017, 327: 618–628

Roussanaly S, Anantharaman R, Lindqvist K, Hagen B. A new approach to the identification of high-potential materials for cost-efficient membrane-based post-combustion CO2 capture. Sustainable Energy & Fuels, 2018, 2(6): 1225–1243

Saltonstall C. Calculation of the membrane area required for gas separations. Journal of Membrane Science, 1987, 32(2–3): 185–193

Zhai H, Rubin E. Techno-economic assessment of polymer membrane systems for post-combustion carbon capture at coal-fired power plants. Environmental Science & Technology, 2013, 47(6): 3006–3014

Merkel T, Lin H, Wei X, Baker R. Power plant post-combustion carbon dioxide capture: An opportunity for membranes. Journal of Membrane Science, 2010, 359(1-2): 126–139

He X, Fu C, Hagg M B. Membrane system design and process feasibility analysis for CO2 capture from flue gas with a fixed-site-carrier membrane. Chemical Engineering Journal, 2015, 268: 1–9

Vakharia V, Ramasubramanian K, Winston H. An experimental and modeling study of CO2-selective membranes for IGCC syngas purification. Journal of Membrane Science, 2015, 488: 56–66

Lin H, Freeman B. Materials selection guidelines for membranes that remove CO2 from gas mixtures. Journal of Molecular Structure, 2005, 739(1–3): 57–74

Lin H, He Z, Sun Z, Vu J, Ng A, Mohammed M, Kniep J, Merkel T, Wu T, Lambrecht R. CO2-selective membranes for hydrogen production and CO2 capture. Part I: Membrane development. Journal of Membrane Science, 2014, 457: 149–161

Berstad D, Anantharaman R, Neksa P. Low-temperature CO2 capture technologies: Applications and potential. International Journal of Refrigeration, 2013, 36(5): 1403–1416

Anantharaman R, Berstad D, Roussanaly S. Techno-economic performance of a hybrid membrane-liquefaction process for post-combustion CO2 capture. Energy Procedia, 2014, 61: 1244–1247

Voldsund M, Gardarsdottir S, De Lena E, Perez-Calvo J F, Jamali A, Berstad D, Fu C, Romano M, Roussanaly S, Anantharaman R, et al. Comparison of technologies for CO2 capture from cement production. Part 1: Technical evaluation. Energies, 2019, 12(3): 559

Gardarsdottir S, De Lena E, Romano M, Roussanaly S, Voldsund M, Perez-Calvo J F, Berstad D, Fu C, Anantharaman R, Sutter D, et al. Comparison of technologies for CO2 capture from cement production. Part 2: Cost analysis. Energies, 2019, 12(3): 542

European Technology Platform for Zero Emission Fossil Fuel Power Plants (ZEP). The Costs of CO2 Capture, Transport and Storage, Post-Demonstration CCS in the EU, 2011

Ho M, Allinson G, Wiley D. Comparison of MEA capture cost for low CO2 emissions sources in Australia. International Journal of Greenhouse Gas Control, 2011, 5(1): 49–60

NETL. Quality Guidelines for Energy System Studies: Cost Estimation Methodology for Netl Assessments of Power Plant Performance. DOE/NETL-2011/1455, 2011

NETL. Quality Guidelines for Energy System Studies: Technology Learning Curve (FOAK to NOAK). DOE/NETL-341/042211, 2012

HIS. The IHS CERA European Power Capital Costs Index (EPCCI), 2013

Trading Economics. Trading Economics Database on Euro Area Inflation Rate, 2011

Richardson Engineering. Cost Factor Location Manual, 2007

IEAGHG. CO2 Capture in Natural Gas Production by Adsorption Processes for CO2 Storage, EOR and EGR, 2016

Grande C A, Roussanaly S, Anantharaman R, Lindqvist K, Singh P, Kemper J. CO2 capture in natural gas production by adsorption processes. Energy Procedia, 2017, 114: 2259–2264

Booz & Company. Understanding Lignite Generation Costs in Europe, 2014

Zhai H. Advanced membranes and learning scale required for cost-effective post-combustion carbon capture. iScience, 2019, 13: 440–451

Anantharaman R, Roussanaly S, Westman S F, Husebye J. Selection of optimal CO2 capture plant capacity for better investment decisions. Energy Procedia, 2013, 37: 7039–7045

Al-Mufachi N, Rees N, Steinberger-Wilkens R. Hydrogen selective membranes: A review of palladium-based dense metal membranes. Renewable & Sustainable Energy Reviews, 2015, 47: 540–551

Di Marcoberardino G, Binotti M, Manzolini G, Viviente J, Arratibel A, Roses L, Gallucci F. Achievements of European projects on membrane reactor for hydrogen production. Journal of Cleaner Production, 2017, 161: 1442–1450

Roussanaly S, Skaugen G, Aasen A, Jakobsen J, Vesely L. Techno-economic evaluation of CO2 transport from a lignite-fired IGCC plant in the Czech Republic. International Journal of Greenhouse Gas Control, 2017, 65(Suppl C): 235–250

Henriksen D, Ombudstvedt I. Cross-border transportation—A key to unlock full-scale CCS. Energy Procedia, 2017, 114: 7443–7458

European Technology Platform for Zero Emission Fossil Fuel Power Plants (ZEP). The Costs of CO2 Storage, Post-Demonstration CCS in the EU, 2011

Jakobsen J, Roussanaly S, Anantharaman R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. Journal of Cleaner Production, 2017, 144: 523–539

Acknowledgements

This work was supported by the Norway grants, as part of the project NF-CZ08-OV-1-003-2015.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Roussanaly, S., Vitvarova, M., Anantharaman, R. et al. Techno-economic comparison of three technologies for pre-combustion CO2 capture from a lignite-fired IGCC. Front. Chem. Sci. Eng. 14, 436–452 (2020). https://doi.org/10.1007/s11705-019-1870-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-019-1870-8