Abstract

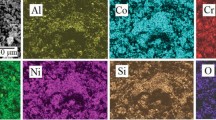

Stainless steels are considered to be corrosion resistant; however, the performance of the material is affected under long-term or extreme conditions. The development of high-entropy alloys (HEAs) has opened avenues to enhance a useful life even under extreme environmental conditions. However, the fabrication of HEAs involves multiple-stage (milling, compaction, sintering, and inert environment) manufacturing processes. The present study explores the single-stage process development of a TiNbMoMnFe high-entropy alloy (HEA) coating on 304L stainless steel substrate using a high-velocity oxy-fuel (HVOF) thermal spray technique. Prior to HVOF coating, the feedstock powders were milled for 5, 10, and 15 h, respectively. The coated surfaces were analyzed for morphology, wettability, microstructure, corrosion resistance, presence of different phases and their distribution. Scanning electron microscopy (SEM), microhardness tester, 3D optical profilometry, and x-ray diffraction (XRD) were used to get different metallurgical and mechanical characteristics. The results indicated that 15-h milled powder-coated substrate exhibited higher corrosion resistance than the other coatings as well as the 304L stainless steel substrate. Chemically stable BCC phase was observed in 15-h milled powder-coated substrates. Moreover, the microhardness, surface roughness, and hydrophobicity of the coated surface were also improved with an increased milling rate. Thus, corrosion resistance of HEA coating can be optimized by a good selection of milling time of powder feedstock.

Similar content being viewed by others

Change history

07 February 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11666-024-01725-3

References

R.M. Davison, T.R. Laurin, J.D. Redmond, H. Watanabe, and M. Semchyshen, A Review of Worldwide Developments in Stainless Steels, Mater. Des., 1986, 7(3), p 111-119.

K.H. Lo, C.H. Shek, and J.K.L. Lai, Recent Developments in Stainless Steels, Mater. Sci. Eng. R Rep., 2009, 65(4), p 39-104.

M. Saravanan, A. Devaraju, N. Venkateshwaran, A. Krishnakumari, and J. Saarvesh, A Review on Recent Progress in Coatings on AISI Austenitic Stainless Steel, Mater. Today Proc., 2018, 5(6), p 14392-14396.

E.H. Phelps, R.T. Jones, and H.P. Leckie, Review of the Application of Stainless Steels in Desalination Equipment, Electrochem. Soc. J., 1969, 116(6), p 213-217.

K.S. Prasad, C.S. Rao, and D.N. Rao, A Review on Welding of AISI 304L Austenitic Stainless Steel, J. Manuf. Sci. Prod., 2014, 14(1), p 1-11.

S. Papavinasam, The Main Environmental Factors Influencing Corrosion, Corrosion Control in the Oil and Gas Industry, 1st ed., S. Papavinasam Ed., Gulf Professional Publishing, Houston, 2014, p 179-247

Z. Wang, E.M. Paschalidou, A. Seyeux, S. Zanna, V. Maurice, and P. Marcus, Mechanisms of Cr and Mo Enrichments in the Passive Oxide Film on 316L Austenitic Stainless Steel, Front. Mater., 2019, 6(232), p 1-12.

A. Bahrami and P. Taheri, A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit, Metals, 2019, 9(9), p 969.

X.L. Yang, Y. Gong, Q. Tong, and Z.G. Yang, Failure Analysis on Abnormal Bursting of Heat Transfer Tubes in Spiral-Wound Heat Exchanger for Nuclear Power Plant, Eng. Fail. Anal., 2020, 108, p 104298.

Z.Y. Li, Z.B. Cai, T. Zhou, X.Y. Shen, and G.H. Xue, Characteristics and Formation Mechanism of Oxide Film on 304 Stainless Steel in High Temperature Water, Mater. Chem. Phys., 2019, 222, p 267-274.

J.W. Yeh, S.J. Lin, T.S. Chin, J.Y. Gan, S.K. Chen, T.T. Shun, C.H. Tsau, and S.Y. Chou, Formation of Simple Crystal Structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V Alloys with Multiprincipal Metallic Elements, Metall. Mater. Trans. A, 2004, 35, p 2533-2536.

J.W. Ye, J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299-274.

T.M. Hung and J.W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2(3), p 107-123.

B. Fotovvati, N. Namdari, and A. Dehghanghadikolaei, On Coating Techniques for Surface Protection: A Review, J. Manuf. Mater. Process., 2019, 3, p 28.

X. Wang, W. Guo, and Y. Fu, High-Entropy Alloys: Emerging Materials for Advanced Functional Applications, J. Mater. Chem. A, 2021, 9(2), p 663-701.

C. Shang, E. Axinte, W. Ge, Z. Zhang, and Y. Wang, High-Entropy Alloy Coatings with Excellent Mechanical, Corrosion Resistance and Magnetic Properties Prepared by Mechanical Alloying and Hot Pressing Sintering, Surf. Interfaces, 2017, 9(6), p 36-43.

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada, and A.S.M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, J. Therm. Spray Technol., 2020, 29(5), p 857-893.

J. Li, Y. Huang, X. Meng, and Y. Xie, A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment, Adv. Eng. Mater., 2019, 19(92), p 1-27.

H. Liang, H. Yao, D. Qiao, S. Nie, Y. Lu, D. Deng, Z. Cao, and T. Wang, Microstructures and Wear Resistance of AlCrFeNi2W0.2Nbx High-Entropy Alloy Coatings Prepared by Laser Cladding, J. Therm. Spray Technol., 2019, 28(6), p 1318-1329.

F. Ghadami and A.S.R. Aghdam, Improvement of High Velocity Oxy-Fuel Spray Coatings by Thermal Post-treatments: A Critical Review, Thin Solid Films, 2019, 678, p 42-52.

A.M. Panindre, Y. Khalifa, C.D. Taylor, and G.S. Frankel, Corrosion of Ni-Fe-Cr-Mo-W-X Multi-principal Element Alloys, J. Electrochem. Soc., 2021, 168(3), p 031513.

M. Löbel, T. Lindner, T. Mehner, and T. Lampke, Microstructure and Wear Resistance of AlCoCrFeNiTi High-Entropy Alloy Coatings Produced by HVOF, Coatings, 2017, 7(9), p 144.

Q. Fang, Y. Chen, J. Li, Y. Liu, and Y. Liu, Microstructure and Mechanical Properties of FeCoCrNiNbX High-Entropy Alloy Coatings, Phys. B Condens. Matter, 2018, 550, p 112-116.

Z. Wei et al., Ultrasonic Cavitation Erosion Behaviors of High-Velocity Oxygen-Fuel (HVOF) Sprayed AlCoCrFeNi High-Entropy Alloy Coating in Different Solutions, Surf. Coat. Technol., 2021, 409, p 126899.

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, and P.K. Liaw, Mechanical Behavior of High-Entropy Alloys, Prog. Mater. Sci., 2021, 118, p 100777.

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.P. Couzinie, Development and Exploration of Refractory High Entropy Alloys—A Review, J. Mater. Res., 2018, 33(19), p 3092-3128.

Y. Huang, Z. Wang, Z. Xu, X. Zang, and X. Chen, Microstructure and Properties of TiNbZrMo High Entropy Alloy Coating, Mater. Lett., 2021, 285, p 129004.

P.K. Sarswat, S. Sarkar, A. Murali, W. Huang, W. Tan, and M.L. Free, Additive Manufactured New Hybrid High Entropy Alloys Derived from the AlCoFeNiSmTiVZr System, Appl. Surf. Sci., 2019, 476, p 242-258.

S.W. McAlpine, J.V. Logan, and M.P. Short, Predicting Single Phase Stability and Segregation in the NbMoTaTi-(W, V) High Entropy Alloy System with the Vacancy Exchange Potential, Scr. Mater., 2021, 191, p 29-33.

M.J.R. Haché, C. Cheng, and Y. Zou, Nanostructured High-Entropy Materials, J. Mater. Res., 2020, 35(8), p 1051-1075.

N. Ma, S. Liu, W. Liu, L. Xie, D. Wei, L. Wang, L. Li, B. Zhao, and Y. Wang, Research Progress of Titanium-Based High Entropy Alloy: Methods, Properties, and Applications, Front. Bioeng. Biotechnol., 2020, 8, p 1303.

S.P. Wang and J. Xu, TiZrNbTaMo High-Entropy Alloy Designed for Orthopedic Implants: As-Cast Microstructure and Mechanical Properties, Mater. Sci. Eng. C, 2017, 73, p 80-89.

C.C. Juan, M.H. Tsai, C.W. Tsai, C.M. Lin, W.R. Wang, C.C. Yang, S.K. Chen, S.J. Lin, and J.W. Yeh, Enhanced Mechanical Properties of HfMoTaTiZr and HfMoNbTaTiZr Refractory High-Entropy Alloys, Intermetallics, 2015, 62, p 76-83.

Y. Guo and Q. Liu, MoFeCrTiWAlNb Refractory High-Entropy Alloy Coating Fabricated by Rectangular-Spot Laser Cladding, Intermetallics, 2018, 102, p 78-87.

X.H. Yan, J.S. Li, W.R. Zhang, and Y. Zhang, A Brief Review of High Entropy Films, Mater. Chem. Phys., 2018, 210, p 12-19.

L.R. Shaginyan, V.F. Gorban’, N.A. Krapivka, S.A. Firstov, and I.F. Kopylov, Properties of Coatings of the Al-Cr-Fe-Co-Ni-Cu-V High Entropy Alloy Produced by the Magnetron Sputtering, J. Superhard Mater., 2016, 38, p 25-33.

D.C. Tsai, Z.C. Chang, B.H. Kuo, M.H. Shiao, S.Y. Chang, and F.S. Shieu, Structural Morphology and Characterization of (AlCrMoTaTi)N Coating Deposited via Magnetron Sputtering, Appl. Surf. Sci., 2013, 282, p 789-797.

C.C. Yang, J.L. Hang Chau, C.J. Weng, C.S. Chen, and Y.H. Chou, Preparation of High-Entropy AlCoCrCuFeNiSi Alloy Powders by Gas Atomization Process, Mater. Chem. Phys., 2017, 202, p 151-158.

O.T. Onawale, P.V. Cobbinah, R.A. Nzeukou, and W.R. Matizamhuka, Synthesis Route, Microstructural Evolution, and Mechanical Property Relationship of High-Entropy Alloys (HEAs): A Review, Materials, 2021, 14, p 3065.

J.M. Torralba, P. Alvaredo, and A. García-Junceda, High-Entropy Alloys Fabricated via Powder Metallurgy. A Critical Review, Powder Metall., 2019, 62(2), p 84-114.

M. Vaidya, G.M. Muralikrishna, and B.S. Murty, High-Entropy Alloys by Mechanical Alloying: A Review, J. Mater. Res., 2019, 34(5), p 664-686.

A. Arab, Y. Guo, Q. Zhou, and P. Chen, Fabrication of Nanocrystalline AlCoCrFeNi High Entropy Alloy Through Shock Consolidation and Mechanical Alloying, Entropy, 2019, 21(9), p 880.

P.F. Yu, L.J. Zhang, H. Cheng, H. Zhang, M.Z. Ma, Y.C. Li, G. Li, P.K. Liaw, and R.P. Liu, The High-Entropy Alloys with High Hardness and Soft Magnetic Property Prepared by Mechanical Alloying and High-Pressure Sintering, Intermetallics, 2016, 70, p 82-87.

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, and H.R. Ammar, Manufacturing Methods, Microstructural and Mechanical Properties Evolutions of High-Entropy Alloys: A Review, Met. Mater. Int., 2020, 26(8), p 1099-1133.

S. Kamnis and S. Gu, Numerical Modelling of Propane Combustion in a High Velocity Oxygen-Fuel Thermal Spray Gun, Chem. Eng. Process., 2006, 45(4), p 246-253.

S. Zhu, Z. Zhang, B. Zhang, Y. Yu, Z. Wang, X. Zhang, and B. Lu, Microstructure and Properties of Al2O3-13 wt.%TiO2-Reinforced CoCrFeMnNi High-Entropy Alloy Composite Coatings Prepared by Plasma Spraying, J. Therm. Spray Technol., 2021, 30(3), p 772-786.

W. Li, P. Liu, and P.K. Liaw, Microstructures and Properties of High-Entropy Alloy Films and Coatings: A Review, Mater. Res. Lett., 2018, 6, p 199-229.

A. Gupta and D. Kumar, Development of Al2O3 Based Hybrid Ceramic Matrix Composite Coating to Mitigate the Erosive Wear of Advanced Steel, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2021, 235(4), p 752-762.

J. Pulsford, S. Kamnis, J. Murray, M. Bai, and T. Hussain, Effect of Particle and Carbide Grain Sizes on a HVOAF WC-Co-Cr Coating for the Future Application on Internal Surfaces: Microstructure and Wear, J. Therm. Spray Technol., 2018, 27, p 207-219.

Q. Liu, G. Wang, X. Sui, Y. Xu, Y. Liu, and J. Yang, Ultra-Fine Grain TixVNbMoTa Refractory High-Entropy Alloys with Superior Mechanical Properties Fabricated by Powder Metallurgy, J. Alloys Compd., 2021, 865, p 158592.

Z. Gu, P. Mao, Y. Gou, Y. Chao, and S. Xi, Microstructure and Properties of MgMoNbFeTi2Yx High Entropy Alloy Coatings by Laser Cladding, Surf. Coat. Technol., 2020, 402, p 126303.

C. Li, J. Zhang, J. Han, and B. Yao, A Numerical Solution to the Effects of Surface Roughness on Water-Coal Contact Angle, Sci. Rep., 2021, 11, p 459.

M.H. Zhao, X.P. Chen, and Q. Wang, Wetting Failure of Hydrophilic Surfaces Promoted by Surface Roughness, Sci. Rep., 2014, 4(6), p 6-10.

Y.Q. Jiang, J. Li, Y.F. Juan, Z.J. Lu, and W.L. Jia, Evolution in Microstructure and Corrosion Behavior of AlCoCrxFeNi High-Entropy Alloy Coatings Fabricated by Laser Cladding, J. Alloys Compd., 2019, 854, p 157140.

A. Mazzarolo, M. Curioni, A. Vicenzo, P. Skeldon, and G.E. Thompson, Anodic Growth of Titanium Oxide: Electrochemical Behaviour and Morphological Evolution, Electrochim. Acta, 2012, 75, p 288-295.

Y.W. Marsumi and A.W. Pramono, Influence of Niobium or Molybdenum in Titanium Alloy for Permanent Implant Application, Adv. Mater. Res., 2014, 900, p 53-63.

S.Y. Yu, J.R. Scully, and C.M. Vitus, Influence of Niobium and Zirconium Alloying Additions on the Anodic Dissolution Behavior of Activated Titanium in HCl Solutions, J. Electrochem. Soc., 2001, 148(2), p B68.

Y. Okazaki, A. Ito, T. Tateishi, and Y. Ito, Effect of Alloying Elements on Anodic Polarization Properties of Titanium Alloys in Acid Solutions, Mater. Trans., 1994, 35(1), p 58-66.

A. Kania, M.M. Szindler, and M. Szindler, Structure and Corrosion Behavior of TiO2 Thin Films Deposited by ALD on a Biomedical Magnesium Alloy, Coatings, 2021, 11(1), p 70.

S. Husain, M. Irfansyah, A. Riyanto, and S. Arjo, Synthesis and Characterization of Electrochemical Properties of Manganese Ferrite Nanoparticles ({MnFe2O4}) from Iron, Omega J. Fis. dan Pendidik. Fis., 2019, 5(1), p 15.

L. Agusu, Alimin, L.O. Ahmad, M.Z. Firihu, S. Mitsudo, and H. Kikuchi, Crystal and Microstructure of MnFe2O4 Synthesized by Ceramic Method Using Manganese Ore and Iron Sand as Raw Materials, J. Phys. Conf. Ser., 2019, 1153(1), p 2-9.

J. Lv, W. Guo, T. Liang, and M. Yang, The Effects of Ball Milling Time and Surface Enriched Chromium on Microstructures and Corrosion Resistance of AISI 304 Stainless Steel, Mater. Chem. Phys., 2017, 197, p 79-86.

Acknowledgments

The authors are grateful to BRNS, India (Project no. 34/14/01/2018-BRNS) for giving financial assistance for the HVOF coating unit and SERB, DST (CRG/2021/000754) for other financial support. The authors are also thankful to the Central Research Facility (CRF) and Nanoscale Research Facility (NRF) provided by the IIT Delhi, New Delhi, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

The original online version of this article was revised: This article was originally published without the following Acknowledgments.

The authors are grateful to BRNS, India (Project no. 34/14/01/2018-BRNS) for giving financial assistance for the HVOF coating unit and SERB, DST (CRG/2021/000754) for other financial support. The authors are also thankful to the Central Research Facility (CRF) and Nanoscale Research Facility (NRF) provided by the IIT Delhi, New Delhi, India.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abhijith, N.V., Kumar, D. & Kalyansundaram, D. Development of Single-Stage TiNbMoMnFe High-Entropy Alloy Coating on 304L Stainless Steel Using HVOF Thermal Spray. J Therm Spray Tech 31, 1032–1044 (2022). https://doi.org/10.1007/s11666-021-01294-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01294-9