Abstract

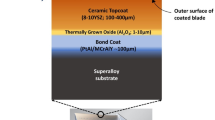

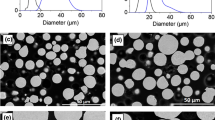

Different types of thermal spray systems, including HVOF (JP5000 and DJ2600-hybrid), APS (F4-MB and Axial III), and LPPS (Oerlikon Metco system) were employed to spray CoNiCrAlY bond coats (BCs) onto Inconel 625 substrates. The chemical composition of the BC powder was the same in all cases; however, the particle size distribution of the powder employed with each torch was that specifically recommended for the torch. For optimization purposes, these BCs were screened based on initial evaluations of roughness, porosity, residual stress, relative oxidation, and isothermal TGO growth. A single type of standard YSZ top coat was deposited via APS (F4MB) on all the optimized BCs. The TBCs were thermally cycled by employing a furnace cycle test (FCT) (1080 °C-1 h—followed by forced air cooling). Samples were submitted to 10, 100, 400, and 1400 cycles as well as being cycled to failure. The behavior of the microstructures, bond strength values (ASTM 633), and the TGO evolution of these TBCs, were investigated for the as-sprayed and thermally cycled samples. During FCT, the TBCs found to be both the best and poorest performing and had their BCs deposited via HVOF. The results showed that engineering low-oxidized BCs does not necessarily lead to an optimal TBC performance. Moreover, the bond strength values decrease significantly only when the TBC is about to fail (top coat spall off) and the as-sprayed bond strength values cannot be used as an indicator of TBC performance.

Similar content being viewed by others

References

D.J. Wortman, B.A. Nagaraj, and E.C. Duderstadt, Thermal Barrier Coatings for Gas Turbine Use, Mater. Sci. Eng. A, 1989, 121, p 433-440

C.U. Hardwicke and Y.-C. Lau, Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review, J. Thermal Spray Technol., 2013, 22(5), p 564-576

A.R. Nicoll and G. Wahl, The Effect of Alloying Additions on M-Cr-Al-Y Systems—An Experimental Study, Thin Solid Films, 1982, 95, p 21-34

M. Di Ferdinando, A. Fossati, A. Lavacchi, U. Bardi, F. Borgioli, C. Borri, C. Giolli, and A. Scrivani, Surf. Coat. Technol., 2010, 204, p 2499-2503

M. Shibata, S. Kuroda, H. Murakami, M. Ode, M. Watanabe, and Y. Sakamoto, Mater. Trans., 2006, 47(7), p 1638-1642

A. Fossati, M. Di Fernando, A. Lavacchi, A. Scrivani, C. Giolli, and U. Bardi, Improvement of the Oxidation Resistance of CoNiCrAlY Bond Coats Sprayed by High Velocity Oxygen-Fuel onto Nickel Superalloy Substrate, Coatings, 2011, 1, p 3-16. doi:10.3390/coatings1010003

W.R. Chen, X. Wu, B.R. Marple, D. Nagy, and P.C. Patnaik, TGO Growth Behaviour in TBCs with APS and HVOF Bond Coats, Surf. Coat. Technol., 2008, 202, p 2677-2683

A. Rabiei and A.G. Evans, Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48, p 3963-3976

P.K. Wright and A.G. Evans, Mechanisms Governing the Performance of Thermal Barrier Coatings, Curr. Opin. Solid State Mater. Sci., 1999, 4, p 255-265

J.A. Haynes, M.K. Ferber, and W.D. Porter, Thermal Cycling Behavior of Plasma-Sprayed Thermal Barrier Coatings with Various MCrAlX Bond Coats, J. Thermal Spray Technol., 2000, 9(1), p 38-48

T. Patterson, A. Leon, B. Jayaraj, J. Liu, and Y.H. Sohn, Thermal Cyclic Lifetime and Oxidation Behavior of Air Plasma Sprayed CoNiCrAlY Bond Coats for Thermal Barrier Coatings, Surf. Coat. Technol., 2008, 203, p 437-441

S. Saeidi, K.T. Voisey, and D.G. McCartney, Mechanical Properties and Microstructure of VPS and HVOF CoNiCrAlY Coatings, J. Thermal Spray Technol., 2011, 20(6), p 1231-1243

A. Schmidt, H. Aleksanoglu, T. Mao, A. Scholz, and C. Berger, Influence of Bond Coat Roughness on Life Time of APS Thermal Barrier Coating Systems under Thermo-Mechanical Load, J. Solid Mech. Mater. Eng., 2010, 4(2), p 208-220

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2014 International Thermal Spray Conference, held on May 21-23, 2014, in Barcelona, Spain, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Lima, R.S., Nagy, D. & Marple, B.R. Bond Coat Engineering Influence on the Evolution of the Microstructure, Bond Strength, and Failure of TBCs Subjected to Thermal Cycling. J Therm Spray Tech 24, 152–159 (2015). https://doi.org/10.1007/s11666-014-0181-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0181-3