Abstract

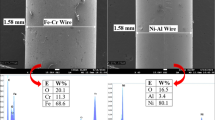

In this paper, slurry erosion performance of high velocity flame-sprayed Ni-Al2O3 based coatings was evaluated. The coatings were deposited on a hydroturbine steel (CA6NM) by varying the content of Al2O3 in Ni. Using jet-type test rig, erosion behavior of coatings and bare steel was evaluated at different impingement angles. Detailed investigation of the surface morphology of the eroded specimens was undertaken using SEM/EDS to identify potential erosion mechanism. A parameter named “erosion mechanism identifier” (ξ) was used to predict the mode of erosion. It was observed that the coating prepared using 40 wt.% of Al2O3 showed a highest resistance to erosion. This coating enhanced the erosion resistance of the steel by 2 to 4 times. Spalling in the form of splats and chunks of material (formed by interlinking of cracks) along with fracture of Al2O3 splats were identified as primary mechanisms responsible for the loss of coating material. The erosion mechanism of coatings and bare steel predicted by ξ was in good agreement with that observed experimentally. Among different parameters,\( \left( {K_{\text{IC}}^{2} H} \right)^{1/3} \), a function of fracture toughness (K IC) and hardness (H) showed excellent correlation with erosion resistance of coatings at both the impingement angles.

Similar content being viewed by others

References

T.R. Bajracharya, B. Acharya, C.B. Joshi, R.P. Saini, and O.G. Dahlhaug, Sand Erosion of Pelton Turbine Nozzles and Buckets: A Case Study of Chilime Hydropower Plant, Wear, 2008, 264(3-4), p 177-184

S.Y. Bergeron, T.C. Vu, and A.P. Vincent, Silt Erosion in Hydraulic Turbines: The Need for Real-Time Numerical Simulations, Simulation, 2000, 74(2), p 71-74

R. Chattopadhyay, High Silt Wear of Hydroturbine Runners, Wear, 1993, 162-164, p 1040-1044

H.S. Grewal, S. Bhandari, and H. Singh, Parametric Study of Slurry-Erosion of Hydroturbine Steels With and Without Detonation Gun Spray Coatings Using Taguchi Technique, Metall. Mater. Trans. A, 2012, 43(9), p 3387-3401

B. Mann, V. Arya, A. Maiti, M. Rao, and P. Joshi, Corrosion and Erosion Performance of HVOF/TiAlN PVD Coatings and Candidate Materials for High Pressure Gate Valve Application, Wear, 2006, 260(1-2), p 75-82

B.S. Mann, High-Energy Particle Impact Wear Resistance of Hard Coatings and Their Application in Hydroturbines, Wear, 2000, 237, p 140-146

J. Santa, J. Baena, and A. Toro, Slurry Erosion of Thermal Spray Coatings and Stainless Steels for Hydraulic Machinery, Wear, 2007, 263(1-6), p 258-264

J.F. Santa, L.A. Espitia, J.A. Blanco, S.A. Romo, and A. Toro, Slurry and Cavitation Erosion Resistance of Thermal Spray Coatings, Wear, 2009, 267(1-4), p 160-167

S.A. Romo, J.F. Santa, J.E. Giraldo, and A. Toro, Cavitation and High-Velocity Slurry Erosion Resistance of Welded Stellite 6 Alloy, Tribol. Int., 2012, 47, p 16-24

L.A. Espitia and A. Toro, Cavitation Resistance, Microstructure and Surface Topography of Materials Used for Hydraulic Components, Tribol. Int., 2010, 43(11), p 2037-2045

C. Duan and V.I.A. Karelin, Abrasive Erosion & Corrosion of Hydraulic Machinery, Imperial College Press, London, 2002

H.M. Clark, H.M. Hawthorne, and Y. Xie, Wear Rates and Specific Energies of Some Ceramic, Cermet and Metallic Coatings Determined in the Coriolis Erosion Tester, Wear, 1999, 233-235, p 319-327

B.S. Mann and V. Arya, Abrasive and Erosive Wear Characteristics of Plasma Nitriding and HVOF Coatings: Their Application in Hydro Turbines, Wear, 2001, 249(5-6), p 354-360

H.S. Grewal, H. Singh, and A. Agrawal, Microstructural and Mechanical Characterization of Thermal Sprayed Nickel-Alumina Composite Coatings, Surf. Coat. Technol., 2013, 216, p 78-92

H.S. Grewal, A. Agrawal, and H. Singh, Design and Development of High-Velocity Slurry Erosion Test Rig Using CFD, J. Mater. Eng. Perform., 2013, 22, p 152-161

I. Finnie, Some Reflections on the Past and Future of Erosion, Wear, 1995, 186-187, p 1-10

I. Finnie, Erosion of Surfaces by Solid Particles, Wear, 1960, 3(2), p 87-103

G. Sundararajan, M. Roy, and B. Venkataraman, Erosion Efficiency—A New Parameter to Characterize the Dominant Erosion Micromechanism, Wear, 1990, 140(2), p 369-381

H.S. Grewal, A. Agrawal, and H. Singh, Identifying Erosion Mechanism—A Novel Approach, Tribol. Lett., 2013, 51(1), p 1-7

G.-R. Yang, W.-M. Song, J.-J. Lu, Y. Hao, and Y. Ma, Three-point bending behavior of surface composite Al2O3/Ni on bronze substrate produced by vacuum infiltration casting, J. Mater. Process. Technol., 2008, 202(1-3), p 195-200

Acknowledgments

Authors thankfully acknowledge the financial assistance provided by Council of Scientific and Industrial Research (CSIR), India, under project title “Development of Slurry Erosion Resistant Coatings for Hydroturbines”, File No. 22(0604)/12/EMR-II.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grewal, H.S., Agrawal, A., Singh, H. et al. Slurry Erosion Performance of Ni-Al2O3 Based Thermal-Sprayed Coatings: Effect of Angle of Impingement. J Therm Spray Tech 23, 389–401 (2014). https://doi.org/10.1007/s11666-013-0013-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-0013-x