Abstract

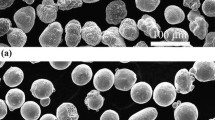

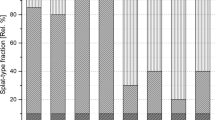

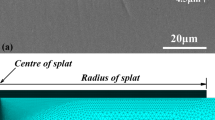

The plasma spraying process is still poorly understood in term of the processes by which the coating is built up, especially coating interactions with the substrate. This present study enhances this understanding by studying, through a range of electron microscopy techniques, single NiCr splats plasma sprayed onto stainless steel substrates, which were first exposed to different heat treatments. The microstructure of the splats, particularly the splat-substrate interface, was characterized, and the formation of the observed features is discussed. Evidence of localized substrate melting and inter-mixing with the splat material was found, showing metallurgical bonding. The structures observed were also correlated to the treatment of the substrate, demonstrating how such treatments can influence the properties of the fully deposited coating by modifying the splat formation process. Most notably, heating the substrate during spraying was found to significantly modify splat formation by reducing splashing and increasing the extent of substrate melting.

Similar content being viewed by others

References

R.F. Bunshah, Handbook of Hard Coatings. Deposition Technologies, Properties and Applications, William Andrew Publishing/Noyes, Norwich, NY, 2001

M. Dorfman, Thermal Spray Basics, Adv. Mater. Process., 2002, 160, p 47-50

M. Fukumoto, M. Shiiba, H. Kaji, and T. Yasui, Three-Dimensional Transition Map of Flattening Behavior in the Thermal Spray Process, Pure Appl. Chem., 2005, 77(2), p 429-442

F. Otsubo, H. Era, and K. Kishitake, Interface Reaction Between Nickel-Base Self-Fluxing Alloy Coating and Steel Substrate, J. Therm. Spray Technol., 2000, 9(2), p 259-263

H. Du, J.H. Shin, and S.W. Lee, Study on Porosity of Plasma-Sprayed Coatings by Digital Image Analysis Method, J. Therm. Spray Technol., 2005, 14(4), p 453-461

J.M. Guilemany, J. Nutting, and M.J. Dougan, A Transmission Electron Microscopy Study of the Microstructures Present in Alumina Coatings Produced by Plasma Spraying, J. Therm. Spray Technol., 1997, 6(4), p 425-429

J. Cedelle, M. Vardelle, and P. Fauchais, Influence of Stainless Steel Substrate Preheating on Surface Topography and on Millimeter- and Micrometer-Sized Splat Formation, Surf. Coat. Technol., 2006, 201, p 1373-1382

J. Cedelle, M. Vardelle, B. Pateyron, and P. Fauchais, Investigation of Plasma Sprayed Coatings Formation by Visualization of Droplet Impact and Splashing on a Smooth Substrate, Trans. Plasm. Sci., 2005, 33(2), p 414-415

R. Dhiman, A.G. McDonald, and S. Chandra, Predicting Splat Morphology in a Thermal Spray Process, Surf. Coat. Technol., 2007, 201, p 7789-7801

R. Ghafouri-Azar, S. Shakeri, S. Chandra, and J. Mostaghimi, Interactions Between Molten Metal Droplets Impinging on a Solid Surface, Int. J. Heat Mass Transf., 2003, 46, p 1395-1407

S. Goutier, M. Vardelle, J.C. Labbe, and P. Fauchais, Alumina Splat Investigation: Visualization of Impact and Splat/Substrate Interface for Millimetre Sized Drops, J. Therm. Spray Technol., 2010, 19(1-2), p 49-55

L. Bianchi, A. Denoirjean, F. Blein, and P. Fauchais, Microstructural Investigation of Plasma-Sprayed Ceramic Splats, Thin Solid Films, 1997, 299, p 125-135

S. Sampath and X. Jiang, Splat Formation and Microstructure Development During Plasma Spraying: Deposition Temperature Effect, Mater. Sci. Eng. A, 2001, 304-306, p 144-150

H. Zhang, X.Y. Wang, L.L. Zheng, and X.Y. Jiang, Studies of Splat Morphology and Rapid Solidification During Thermal Spraying, Int. J. Heat Mass Transf., 2001, 44, p 4579-4592

C.-L. Li and J.-L. Li, Evaporated-Gas-induced Splashing Model for Splat Formation During Plasma Spraying, Surf. Coat. Technol., 2004, 184, p 13-23

H. Li, S. Costil, H.-L. Liao, C.-J. Li, M. Planche, and C. Coddet, Effects of Surface Conditions on the Flattening Behavior of Plasma Sprayed Cu Splats, Surf. Coat. Technol., 2006, 200, p 5435-5446

M. Fukumoto, E. Nishioka, and T. Matsubara, Flattening Solidification Behavior of a Metal Droplet on a Flat Substrate Surface Held at Various Temperatures, Surf. Coat. Technol., 1999, 120-121, p 131-137

A. McDonald, C. Moreau, and S. Chandra, Thermal Contact Resistance Between Plasma-Sprayed Particles and Flat Surfaces, Int. J. Heat Mass Transf., 2007, 50, p 1737-1749

M. Fukumoto, H. Nagai, and T. Yasui, Influence of Surface Character Change of Substrate due to Heating on Flattening Behavior of Thermal Sprayed Particles, J. Therm. Spray Technol., 2006, 15(4), p 759-764

L. Bianchi, A.C. Leger, M. Vardelle, A. Vardelle, and P. Fauchais, Splat Formation and Cooling of Plasma-Sprayed Zirconia, Thin Solid Films, 1997, 305, p 35-47

T. Chraska and A.H. King, Effect of Different Substrate Conditions upon Interface with Plasma Sprayed Zirconia—A TEM Study, Surf. Coat. Technol., 2002, 157, p 238-246

Z.G. Feng, M. Domaszewski, G. Montavon, and C. Coddet, Finite Element Analysis of Effect of Substrate Surface Roughness on Liquid Droplet Impact and Flattening Process, J. Therm. Spray Technol., 2002, 11(1), p 62-68

A.A. Syed, A. Denoirjean, B. Hannoyer, P. Fauchais, P. Denoirjean, A.A. Khan, and J.C. Labbe, Influence of Substrate Surface Conditions on the Plasma Sprayed Ceramic and Metallic Particles Flattening, Surf. Coat. Technol., 2005, 200, p 2317-2331

S. Kitahara and A. Hasui, A Study of the Bonding Mechanism of Sprayed Coatings, J. Vac. Sci. Technol., 1974, 11(4), p 747-753

L. Li, X.Y. Wang, G. Wei, A. Vaidya, H. Zhang, and S. Sampath, Substrate Melting During Thermal Splat Quenching, Thin Solid Films, 2004, 468, p 113-119

H.-D. Steffens, B. Wielage, and J. Drozak, Interface Phenomena and Bonding Mechanism of Thermally-Sprayed Metal and Ceramic Composites, Surf. Coat. Technol., 1991, 45, p 299-308

C.-J. Li and J.-L. Li, Transient Contact Pressure During Flattening of Thermal Spray Droplet and its Effect on Splat Formation, J. Therm. Spray Technol., 2004, 13(2), p 229-238

L. Li, A. Vaidya, S. Sampath, H. Xiong, and L. Zheng, Particle Characterization and Splat Formation of Plasma Sprayed Zirconia, J. Therm. Spray Technol., 2006, 15(1), p 97-105

J. Mostaghimi and S. Chandra, Splat Formation in Plasma-Spray Coating Process, Pure Appl. Chem., 2002, 74(3), p 441-445

M. Pasandideh-Fard, S. Chandra, and J. Mostaghimi, A Three-Dimensional Model of Droplet Impact and Solidification, Int. J. Heat Mass Transf., 2002, 45, p 2229-2242

M.E. Aalamialeagha, S.J. Harris, and M. Emamighomi, Influence of the HVOF Spraying Process on the Microstructure and Corrosion Behaviours of Ni-20%Cr Coatings, J. Mater. Sci., 2003, 38, p 4587-4596

S. Brossard, P.R. Munroe, A.T.T. Tran, and M.M. Hyland, Study of the Effects of Surface Chemistry on Splat Formation for Plasma Sprayed NiCr onto Stainless Steel Substrates, Surf. Coat. Technol., 2009, 204(9-10), p 1599-1607

A.T.T. Tran, M.M. Hyland, T. Qiu, B. Withy, and B.J. James, Effect of Surface Chemistry on Splat Formation During Plasma Spraying, J. Therm. Spray Technol., 2008, 17(5-6), p 637-645

S. Brossard, P.R. Munroe, A.T.T. Tran, and M.M. Hyland, Study of the Microstructure of NiCr Splats Plasma Sprayed on Stainless Steel by TEM, Surf. Coat. Technol., 2009, 204(9-10), p 1608-1615

P.R. Munroe, The Application of Focused Ion Beam Microscopy in the Material Sciences, Mater. Charact., 2009, 60, p 2-13

A.T.T. Tran and M.M. Hyland, The Role of Substrate Surface Chemistry on Splat Formation During Plasma Spray Deposition by Experiments and Simulations, J. Therm. Spray Technol., 2010, 19(1-2), p 11-23

MatWeb, Material Property Data, 2008 11/11/2008; Available from: http://www.matweb.com/

S. B. Newcomb, “A Microstructural Study of the Oxidation of Ni-Cr Steels in Air and in CO-CO2”, PhD Thesis, University of Cambridge, 1982

G.C. Allen, J.M. Dyke, S.J. Harris, and A. Morries, A Surface Study of the Oxidation of Type 304L Stainless Steel at 600 K in Air, Oxid. Met., 1987, 29(5/6), p 1988

N.S. McIntyre, T.C. Chan, and C. Chen, Characterization of Oxide Structures Formed on Nickel-Chromium Alloy During Low Pressure Oxidation at 500-600 °C, Oxid. Met., 1990, 33(5/6), p 457-479

J. Stringer, B.A. Wilcox, and R.I. Jaffee, The High-Temperature Oxidation of Nickel-20 wt% Chromium Alloys Containing Dispersed Oxide Phases, Oxid. Met., 1972, 5(1), p 11-47

X.Y. Jiang, Y. Wan, H. Herman, and S. Sampath, Role of Condensate and Adsorbates on Substrate Surface on Fragmentation of Impinging Molten Droplets During Thermal Spray, Thin Solid Films, 2001, 385, p 132-141

C. Escure, M. Vardelle, and P. Fauchais, Experimental and Theoretical Study of the Impact of Alumina Droplets on Cold and Hot Substrates, Plasma. Chem. Plasma Process., 2003, 23(2), p 185-221

M. Xue, S. Chandra, and J. Mostaghimi, Investigation of Splat Curling up in Thermal Spray Coatings, J. Therm. Spray Technol., 2006, 15(4), p 531-536

Acknowledgments

The authors acknowledge the Australian Research Council for provision of funding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brossard, S., Munroe, P.R., Tran, A.T. et al. Study of the Splat Microstructure and the Effects of Substrate Heating on the Splat Formation for Ni-Cr Particles Plasma Sprayed onto Stainless Steel Substrates. J Therm Spray Tech 19, 1100–1114 (2010). https://doi.org/10.1007/s11666-010-9513-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9513-0