Abstract

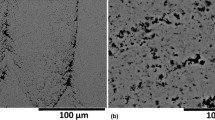

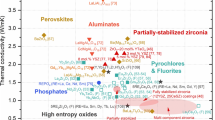

A review is presented of how heat transfer takes place in plasma-sprayed (zirconia-based) thermal barrier coatings (TBCs) during operation of gas turbines. These characteristics of TBCs are naturally of central importance to their function. Current state-of-the-art TBCs have relatively high levels of porosity (~15%) and the pore architecture (i.e., its morphology, connectivity, and scale) has a strong influence on the heat flow. Contributions from convective, conductive and radiative heat transfer are considered, under a range of operating conditions, and the characteristics are illustrated with experimental data and modeling predictions. In fact, convective heat flow within TBCs usually makes a negligible contribution to the overall heat transfer through the coating, although what might be described as convection can be important if there are gross through-thickness defects such as segmentation cracks. Radiative heat transfer, on the other hand, can be significant within TBCs, depending on temperature and radiation scattering lengths, which in turn are sensitive to the grain structure and the pore architecture. Under most conditions of current interest, conductive heat transfer is largely predominant. However, it is not only conduction through solid ceramic that is important. Depending on the pore architecture, conduction through gas in the pores can play a significant role, particularly at the high gas pressures typically acting in gas turbines (although rarely applied in laboratory measurements of conductivity). The durability of the pore structure under service conditions is also of importance, and this review covers some recent work on how the pore architecture, and hence the conductivity, is affected by sintering phenomena. Some information is presented concerning the areas in which research and development work needs to be focussed if improvements in coating performance are to be achieved.

Similar content being viewed by others

References

T.W. Clyne, Thermal and Electrical Conduction in MMCs, in Comprehensive Composite Materials, Vol. 3 : Metal Matrix Composites, T.W. Clyne, Ed., Elsevier: Amsterdam, 2000, p. 447-468.

T.W. Clyne, I.O. Golosnoy, J.C. Tan, and A.E. Markaki, Porous Materials for Thermal Management under Extreme Conditions, Phil. Trans. A: Math. Phys. Eng. Sci., 2006, 364(1838), p. 125-146.

T.W. Clyne and P.J. Withers, An Introduction to Metal Matrix Composites, Cambridge Solid State Science Series, E. Davis and I. Ward, Eds., Cambridge: Cambridge University Press, 1993.

I. Sevostianov and M. Kachanov, Anisotropic Thermal Conductivities of Plasma-Sprayed Thermal Barrier Coatings in Relation to the Microstructure, J. Therm. Spray Technol., 2000, 9(4), pp. 478-482.

B. Shafiro and M. Kachanov, Anisotropic effective conductivity of materials with nonrandomly oriented inclusions of diverse ellipsoidal shapes, J. Appl. Phys., 2000, 87(12), pp. 8561-8569.

F. Cernuschi, P. Bianchi, M. Leoni, and P. Scardi, Thermal diffusivity/microstructure relationship in Y-PSZ thermal barrier coatings, J. Therm. Spray Technol., 1999, 8(1), pp. 102-109.

R. McPherson, A Model for the Thermal Conductivity of Plasma-Sprayed Ceramic Coatings, Thin Solid Films, 1984, 112, pp. 89-95.

C.J. Li and A. Ohmori, Relationships between the microstructure and properties of thermally sprayed deposits, J. Therm. Spray Technol., 2002, 11(3), pp. 365-374.

S. Boire-Lavigne, C. Moreau, and R.G. Saint-Jacques, The Relationship between the Microstructure and Thermal- Diffusivity of Plasma-Sprayed Tungsten Coatings, J. Therm. Spray Technol., 1995, 4(3), pp. 261-267.

T.J. Lu, C.G. Levi, H.N.G. Wadley, and A.G. Evans, Distributed Porosity as a Control Parameter for Oxide Thermal Barriers Made by Physical Vapor Deposition, J. Am. Ceram. Soc., 2001, 84(12), pp. 2937-2946.

T.J. Lu and J.W. Hutchinson, Thermal-Conductivity and Expansion of Cross-Ply Composites with Matrix Cracks, J. Mech. Phys. Solid, 1995, 43(8), pp. 1175-1198.

D.Y. Tzou, The Effect of Internal Heat-Transfer in Cavities on the Overall Thermal-Conductivity, Int. J. Heat Mass Transf., 1991, 34(7), pp. 1839-1846.

Z. Hashin, The Differential Scheme and its Application to Cracked Materials, J. Mech. Phys. Solids, 1988, 36(6), pp. 719-734.

T.H. Bauer, A General Analytical Approach toward the Thermal Conductivity of Porous Media, Int. J. Heat Mass Transf., 1993, 36(17), pp. 4181-4191.

I.O. Golosnoy, S.A. Tsipas, and T.W. Clyne, An Analytical Model for Simulation of Heat Flow in Plasma Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2005, 14(2), pp. 205-214.

D.M. Zhu and R.A. Miller, Thermal Conductivity and Elastic Modulus Evolution of Thermal Barrier Coatings under High Heat Flux Conditions, J. Therm. Spray Technol., 2000, 9, pp. 175-180.

A.F. Renteria and B. Saruhan, Effect of ageing on microstructure changes in EB-PVD manufactured standard PYSZ top coat of thermal barrier coatings, J. Eur. Ceram. Soc., 2006, 26, pp. 2249-2255.

M.N. Rahaman, J.R. Gross, R.E. Dutton, and H. Wang, Phase Stability, Sintering, and Thermal Conductivity of Plasma-Sprayed ZrO2-Gd2O3 Compositions for Potential Thermal Barrier Coating Applications, Acta Mater., 2006, 54(6), pp. 1615-1621.

J.A. Thompson and T.W. Clyne, The Effect of Heat Treatment on the Stiffness of Zirconia Top Coats in Plasma-Sprayed TBCs, Acta Mater., 2001, 49(9), pp. 1565-1575.

M. Ahrens, S. Lampenscherf, R. Vassen, and D. Stover, Sintering and creep processes in plasma-sprayed thermal barrier coatings, J. Therm. Spray Technol., 2004, 13(3), pp. 432-442.

S.R. Choi, D.M. Zhu, and R.A. Miller, Effect of sintering on mechanical properties of plasma-sprayed zirconia-based thermal barrier coatings, J. Am. Ceram. Soc., 2005, 88(10), pp. 2859-2867.

L. Singheiser, R. Steinbrech, W.J. Quadakkers, and R. Herzog, Failure aspects of thermal barrier coatings, Mater. High Temp., 2001, 18(4), pp. 249-259.

R. Vassen, N. Czech, W. Mallener, W. Stamm, and D. Stoever, Influence of Impurity Content and Porosity of Plasma-Sprayed Yttria-Stabilized Zirconia Layers on the Sintering Behaviour, Surf. Coat. Technol., 2001, 141, pp. 135-140.

N.M. Yanar, M.J. Stiger, M. Maris-Sida, F.S. Pettit, and G.H. Meier, “The effects of high temperature exposure on the durability of thermal barrier coatings, Key Eng. Mater., 2001, 197, pp. 145-163.

V. Lughi, V.K. Tolpygo, and D.R. Clarke, Microstructural aspects of the sintering of thermal barrier coatings, Mater. Sci. Eng. A, 2004, 272, pp. 215-221.

S.A. Tsipas, I.O. Golosnoy, R. Damani, and T.W. Clyne, The Effect of a High Thermal Gradient on Sintering and Stiffening in the Top Coat of a Thermal Barrier Coating (TBC) System, J. Therm. Spray Technol., 2004, 13(3), pp. 370-376.

S. Kramer, J. Yang, C.G. Levi, and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89, pp. 3167-3175.

X. Chen, Calcium-magnesium-alumina-silicate (CMAS) delamination mechanisms in EB-PVD thermal barrier coatings, Surf. Coat. Technol., 2006, 200, pp. 3418-3427.

T. Strangman, D. Raybould, A. Jameel, and W. Baker, Damage mechanisms, life prediction, and development of EB-PVD thermal barrier coatings for turbine airfoils, Surf. Coat. Technol., 2007, 202, pp. 658-664.

K.M. Grant, S. Kramer, J.P.A. Lofvander, and C.G. Levi, CMAS degradation of environmental barrier coatings, Surf. Coat. Technol., 2007, 202, pp. 653-657.

S. Paul, A. Cipitria, I.O. Golosnoy, and T.W. Clyne, Effects of Impurity Content on the Sintering Characteristics of Plasma Sprayed Zirconia, J. Therm. Spray Technol., 2007, 16(5-6), pp. 798-803.

[32] R. Siegel and J.R. Howell, Thermal Radiation Heat Transfer, 1st ed. New York: McGraw-Hill, 1972.

R. Berman, Thermal Conduction in Solids, Oxford: Clarendon, 1976.

P.G. Klemens and R.K. Williams, Thermal Conductivity of Metals and Alloys, Int. Met. Rev., 1986, 31, pp. 197-215.

L.B. Loeb, The Kinetic Theory of Gases, New York: McGraw-Hill, 1934.

T.J. Lu, H.A. Stone, and M.F. Ashby, Heat Transfer in Open-Cell Metal Foams, Acta Mater., 1998, 46(10), pp. 3619-3635.

T.J. Lu, Heat Transfer Efficiency of Metal Honeycombs, Int. J. Heat Mass Transf., 1999, 42, pp. 2031-2040.

C.Y. Zhao, T. Kim, T.J. Lu, and H.P. Hodson, Thermal Transport in High Porosity Cellular Metal Foams, J. Thermophys. Heat Transf., 2004, 18(3), pp. 309-317.

S. Ahmaniemi, P. Vuoristo, T. Mantyla, F. Cernuschi, and L. Lorenzoni, Modified Thick Thermal Barrier Coatings: Thermophysical Characterization, J. Eur. Ceram. Soc., 2004, 24, pp. 2669-2679.

H. Guo, H. Murakami, and S. Kuroda, Thermal cycling behavior of plasma sprayed segmented thermal barrier coatings, Mater. Trans., 2006, 4, pp. 306-309.

H. Hatta and M. Taya, Thermal Conductivity of Coated Filler Composites, J. Appl. Phys., 1986, 59, pp. 1851-1860.

Y. Benveniste and T. Miloh, On the Effective Thermal Conductivity of Coated Short-Fiber Composites, J. Appl. Phys., 1991, 69(3), pp. 1337-1344.

I. Sevostianov, M. Kachanov, J. Ruud, P. Lorraine, and M. Dubois, Quantitative characterization of microstructures of plasma-sprayed coatings and their conductive and elastic properties, Mater. Sci. Eng. A, 2004, 386, pp. 164-174.

I. Sevostianov, L. Gorbatikh, and M. Kachanov, Recovery of information on the microstructure of porous/microcracked materials from the effective elastic/conductive properties, Mater. Sci. Eng. A, 2001, 318(1-2), pp. 1-14.

D. Zhu, N.P. Bansal, K.N. Lee, and R.A. Miller, Thermal Conductivity of Ceramic Thermal Barrier and Environmental Barrier Coating Materials, NASA TM-2001-211122, NASA Lewis Research Center, Cleveland, OH, 2001

S. Raghavan, H. Wang, R.B. Dinwiddie, W.D. Porter, and M.J. Mayo, The Effect of Grain Size, Porosity and Yttria Content on the Thermal Conductivity of Nanocrystalline Zirconia, Scr. Mater., 1998, 39(8), pp. 1119-1125.

R. Mevrel, J.-C. Laizet, A. Azzopardi, B. Leclercq, M. Poulain, O. Lavigne, and D. Demange, Thermal Diffusivity and Conductivity of Zr1−xYxO2−x/2 (x = 0, 0.084 and 0.179) Single Crystals, J. Eur. Ceram. Soc., 2004, 24, pp. 3081-3089.

R. McPherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramics Coatings, Surf. Coat. Technol., 1989, 39/40, pp. 173-181.

P. Bengtsson and T. Johannesson, Characterization of Microstructural Defects in Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 1995, 4(3), pp. 245-251.

J. Ilavsky, A.J. Allen, G.G. Long, S. Krueger, C.C. Berndt, and H. Herman, Influence of Spray Angle on the Pore and Crack Microstructure of Plasma Sprayed Deposits, J. Am. Ceram. Soc., 1997, 80(3), pp. 733-742.

A.J. Allen, J. Ilavsky, G.G. Long, J.S. Wallace, C.C. Berndt, and H. Herman, Microstructural Characterisation of Yttria-stabilised Zirconia Plasma-sprayed Deposits using Multiple Small-Angle Neutron Scattering, Acta Mater., 2001, 49, pp. 1661-1675.

A. Kulkarni, Z. Wang, T. Nakamura, S. Sampath, A. Goland, H. Herman, J. Allen, J. Ilavsky, G. Long, J. Frahm, and R.W. Steinbrech, Comprehensive microstructural characterization and predictive property modeling of plasma-sprayed zirconia coatings, Acta Mater., 2003, 51(9), pp. 2457-2475.

H. Boukari, A.J. Allen, G.G. Long, J. Ilavsky, J.S. Wallace, C.C. Berndt, and H. Herman, Small-angle neutron scattering study of the role of feedstock particle size on the microstructural behavior of plasma-sprayed yttria-stabilized zirconia deposits, J. Mater. Res., 2003, 18(3), pp. 624-634.

S. Paul, I.O. Golosnoy, A. Cipitria, T.W. Clyne, L. Xie, and M.R. Dorfman, Effect of Heat Treatment on Pore Architecture and Associated Property Changes in Plasma Sprayed TBCs, International Thermal Spray Conference CD (Beijing, China), ASM International, Materials Park, OH, USA, 2007.

D.M. Zhu and R.A. Miller, Sintering and Creep Behaviour of Plasma-Sprayed Zirconia- and Hafnia-Based Thermal Barrier Coatings, Surf. Coat. Technol., 1998, 109(1-3), pp. 114-120.

R.W. Trice, Y.J. Su, J.R. Mawdsley, K.T. Faber, A.R. De Arellano-Lopez, H. Wang, and W.D. Porter, Effect of Heat Treatment on Phase Stability, Microstructure, and Thermal Conductivity of Plasma-sprayed YSZ, J. Mater. Sci., 2002, 37(11), pp. 2359-2365.

R. Siegel and C.M. Spuckler, Analysis of Thermal Radiation Effects on Temperatures in Turbine Engine Thermal Barrier Coatings, Mater. Sci. Eng. A, 1998, 245(2), pp. 150-159.

V.A. Petrov and A.P. Chernyshev, Thermal-radiation Properties of Zirconia when heated by Laser Radiation up to the Temperature of High-rate Vaporization, High Temperature, 1999, 37(1), pp. 58-66.

J.I. Eldridge, C.M. Spuckler, K.W. Street, and J.R. Markham, Infrared Radiative Properties of Yttria-Stabilized Zirconia Thermal Barrier Coatings, Ceram. Eng. Sci. Proc., 2002, 23(4), pp. 417-430.

E. Litovsky, M. Shapiro, and A. Shavit, Gas pressure and temperature dependences of thermal conductivity of porous ceramic materials. 2. Refractories and ceramics with porosity exceeding 30%, J. Am. Ceram. Soc., 1996, 79(5), pp. 1366-1376.

CRC, Handbook of Chemistry and Physics: a Ready-Reference Book of Chemical and Physical Data, 57th ed., R.C. Weast, Ed., CRC Press, Cleveland, OH, 1976. ISBN: 0878194568

T.J. Lu, C.G. Levi, H.N.G. Wadley, and A.G. Evans, Distributed Porosity as a Control Parameter for Oxide Thermal Barriers made by Physical Vapor Deposition, J. Am. Ceram. Soc., 2001, 84, pp. 2937-2946.

G. Kaye and T. Laby, Tables of Physical and Chemical Constants. 14th ed., London: Longman, 1973.

F.P. Incropera and D.P. Dewitt, Introduction to Heat Transfer, 3rd ed., NY, USA: John Wiley & Sons, Inc., 1996.

A.C. Fox and T.W. Clyne, The Gas Permeability of Plasma Sprayed Ceramic Coatings, in Thermal Spray: A United Forum for Scientific and Technological Advances, Proceedings of the 1st United Thermal Spray Conference, C.C. Berndt, Ed., ASM, Indianapolis, USA, 1998, p 483-490.

A.C. Fox and T.W. Clyne, Oxygen Transport through the Zirconia Layer in Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2004, 184, pp. 311-321.

M. Öziçik, Heat Conduction, New York: John Wiley & Sons, 1979.

T. Makino, T. Kunitomo, I. Sakai, and H. Kinoshita, Thermal Radiation Properties of Ceramic Materials, Heat Transfer. Japanese Research, 1984, 13(4), pp. 33-50.

F.A. Akopov, G.E. Val’yano, A.Y. Vorob’ev, V.N. Mineev, V.A. Petrov, A.P. Chernyshev, and G.P. Chernyshev, Thermal radiative properties of ceramic of cubic ZrO2 stabilized with Y2O3 at high temperatures, High Temperature, 2001, 39(2), pp. 244-254.

F. Cabannes and D. Billard, Measurement of Infrared-Absorption of Some Oxides in Connection with the Radiative-Transfer in Porous and Fibrous Materials, Int. J. Thermophys., 1987, 8(1), pp. 97-118.

A. Ferriere, L. Lestrade, and J.F. Robert, Optical properties of plasma-sprayed ZrO2-Y2O3 at high temperature for solar applications, J. Sol. Energy Eng. (Trans. ASME), 2000, 122(1), pp. 9-13.

D.R. Clarke, Materials Selection Guidelines for Low Thermal Conductivity Barrier Coatings, Surf. Coat. Technol., 2003, 163-164, pp. 67-74.

H.J. Ratzer-Scheibe, U. Schulz, and T. Krell, The effect of coating thickness on the thermal conductivity of EB-PVD PYSZ thermal barrier coatings, Surf. Coat. Technol., 2006, 200(18-19), pp. 5636-5644.

H.J. Ratzer-Scheibe and U. Schulz, The effects of heat treatment and gas atmosphere on the thermal conductivity of APS and EB-PVD PYSZ thermal barrier coatings, Surf. Coat. Technol., 2007, 201, pp. 7880-7888.

L. Xie, M.R. Dorfman, A. Cipitria, S. Paul, I.O. Golosnoy, and T.W. Clyne, Properties and Performance of High Purity Thermal Barrier Coatings, J. Therm. Spray Technol, 2007, 16(5-6), pp. 804-808.

A. Cipitria, I.O. Golosnoy, and T.W. Clyne, Sintering Kinetics of Plasma-Sprayed Zirconia TBCs, J. Therm. Spray Technol., 2007, 16(5-6), pp. 809-815.

A. Cipitria, I.O. Golosnoy, and T.W. Clyne, A Sintering Model for Plasma-Sprayed Zirconia TBCs. Part I: Free-Standing Coatings, Acta Mater., 2009, 57, pp. 980-992.

S. Paul, A. Cipitria, S.A. Tsipas, and T.W. Clyne, Sintering Characteristics of Plasma Sprayed Zirconia Coatings containing different Stabilisers, Surf. Coat. Technol., 2009, 203, pp. 1069-1074.

H.E. Eaton and R.C. Novak, Sintering Studies of Plasma Sprayed Zirconia, Surf. Coat. Technol., 1987, 32, pp. 227-236.

S. Siebert, C. Funke, R. Vassen, and D. Stover, Changes in Porosity and Young’s Modulus due to Sintering of Plasma-Sprayed Thermal Barrier Coatings, J. Mater. Process. Technol., 1999, 93, pp. 217-223.

J. Pan, A.C.F. Cocks, and S. Kucherenko, Finite Element Formulation of Coupled Grain-Boundary and Surface Diffusion with Grain-Boundary Migration, Proc. Roy. Soc. Lond. A: Math. Phys. Sci., 1997, 453, pp. 2161-2184.

A.C.F. Cocks, S.P.A. Gill, and J. Pan, Modeling Microstructure Evolution in Engineering Materials, Advances in Applied Mechanics, 1999, 36, pp. 81-162.

J. Pan, Modelling Sintering at Different Length Scales, Int. Mater. Rev., 2003, 48(2), pp. 69-85.

R.G. Hutchinson, N.A. Fleck, and A.C.F. Cocks, A Sintering Model for Thermal Barrier Coatings, Acta Mater., 2006, 54(5), pp. 1297-1306.

A. Cipitria, I.O. Golosnoy, and T.W. Clyne, A Sintering Model for Plasma-Sprayed Zirconia TBCs. Part II: Coatings bonded to a Rigid Substrate, Acta Mater., 2009, 57, pp. 993-1003.

J.C. Tan, S.A. Tsipas, I.O. Golosnoy, S. Paul, J.A. Curran, and T.W. Clyne, A Steady-State Bi-Substrate Technique for Measurement of the Thermal Conductivity of Ceramic Coatings, Surf. Coat. Technol., 2006, 201(3-4), pp. 1414-1420.

S.E. Gustafsson, Transient Plane Source Techniques for Thermal Conductivity and Thermal Diffusivity Measurements of Solid Materials, Review of Scientific Instruments, 1990, 62(3), pp. 797-804.

S. Paul, “Pore Architecture in Ceramic Thermal Barrier Coatings, in Materials Science & Metallurgy,” Ph.D. Thesis, University of Cambridge, Cambridge, 2007.

R. Vassen, R. Traeger, and D. Stover, Correlation Between Spraying Conditions and Microcrack Density and their Influence on Thermal Cycling Life of Thermal Barrier Coatings, J. Therm. Spray Technol., 2004,13(3), pp. 396-404.

A. Kulkarni, J. Gutleber, S. Sampath, A. Goland, W.B. Lindquist, H. Herman, A.J. Allen, and B. Dowd, Studies of the microstructure and properties of dense ceramic coatings produced by high-velocity oxygen-fuel combustion spraying, Mater. Sci. Eng. A, 2004, 369(1-2), pp. 124-137.

Acknowledgments

Financial support has come from a Basque Government scholarship (for AC), from EPSRC via a Platform Grant (for IOG) and from Sulzer Metco (US) Inc. There has been extensive technical collaboration with Sulzer Metco, particularly Mitch Dorfman, Clive Britton, and Steve Bomford.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golosnoy, I.O., Cipitria, A. & Clyne, T.W. Heat Transfer Through Plasma-Sprayed Thermal Barrier Coatings in Gas Turbines: A Review of Recent Work. J Therm Spray Tech 18, 809–821 (2009). https://doi.org/10.1007/s11666-009-9337-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9337-y