Abstract

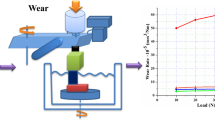

316L stainless steel (SS) is a widely used biomaterial with low cost, but the long-term safety of releasing metal ions and poor corrosion resistance have received sustained attention. In this paper, Ta protective coatings with increased thicknesses were deposited onto the 316L SS by plasma surface alloying with extended deposition time. The microstructure, wear and corrosion resistance in simulated body fluid, and the biocompatibility and osteogenic activities of the Ta coated 316L SS samples were investigated. The results showed that the Ta coating deposited for 10 min was composed of loose and brittle β-Ta phase, while those deposited over 30 min were mainly made up of dense and tough α-Ta phase. Due to the formation of a thick diffusion layer at the coating/substrate interface, well-adhered Ta coatings with high adhesion values of 109.8 N and 105.7 were obtained at 30 and 60 min, respectively. Moreover, Ta coatings deposited at these two parameters possessed better wear and corrosion resistance than 316L SS and those for 10 and 120 min. The best wear and corrosion resistance were about 4 and 66 times higher than the 316L SS. The good performance could be attributed to the suitable thickness and good compactness of Ta coatings, as well as the thick diffusion layer. These factors not only endowed the Ta coatings with good adhesion to resist peeling off during the friction but also protected 316L SS against corrosion of the phosphate-buffered saline (PBS) solution. The Ta coatings deposited for 30 and 60 min showed better capacity for osteoblast adhesion, spreading, and proliferation than 316L SS, where the Ta coating deposited for 60 min was the best.

Similar content being viewed by others

References

G. Manivasagam, D. Dhinasekaran and A. Rajamanickam, Biomedical Implants: Corrosion and its Prevention -A Review, Rec. Pat. Corros. Sci., 2010, 2(1), p 40–54.

H. Ghorbani, A. Abdollah-Zadeh, F. Bagheri et al., Improving the Bio-corrosion Behavior of AISI316L Stainless Steel Through Deposition of Ta-based thin Films Using PACVD, Appl. Surf. Sci., 2018, 456, p 398–402.

H. Lee, C.K. Yao, J.D. Liao et al., Annealed Thin-film Zirconia Coating Adhered on 316L Stainless Steel as a Bio-inert Indwelling Needle, Mater. Design, 2015, 88, p 651–658.

M. Kheirkhah, M. Fathi, H.R. Salimijazi et al., Surface Modification of Stainless Steel Implants Using Nanostructured Forsterite (Mg2SiO4) Coating for Biomaterial Applications, Surf. Coat. Technol., 2015, 276, p 580–586.

Y. Liu, D. Zhu, D. Pierre et al., Fretting Initiated Crevice Corrosion of 316LVM Stainless Steel in Physiological Phosphate Buffered Saline: Potential and Cycles to Initiation, Acta Biomater., 2019, 97, p 565–577.

M.A. Garcia-Lobato, A.I. Mtz-Enriquez, C.R. Garcia et al., Corrosion Resistance and in Vitro Bioactivity of Dense and Porous Titania Coatings Deposited on 316L SS by Spraying Method, Appl. Surf. Sci., 2019, 484, p 975–980.

Y.S. Hedberg and I.O. Wallinder, Metal Release from Stainless Steel in Biological Environments: A Review, Biointerphases, 2015, 11(1), 018901.

M. Shabani-Nooshabadi, S.M. Ghoreishi, Y. Jafari et al., Electrodeposition of Polyaniline-Montmorrilonite Nanocomposite Coatings on 316L Stainless Steel for Corrosion Prevention, J. Polym. Res., 2014, 21(416), p 1–10.

S. Mahathanabodee, T. Palathai, S. Raadnui et al., Dry Sliding wear Behavior of SS316L Composites Containing h-BN and MoS2 Solid Lubricants, Wear, 2014, 316(1–2), p 37–48.

V.K. Balla, S. Bose, N.M. Davies et al., Tantalum–A Bioactive Metal for Implants, JOM, 2010, 62(7), p 61–64.

Z. Miao, P. Liu, Y. Wang et al., PEGylated Tantalum Nanoparticles: A Metallic Photoacoustic Contrast Agent for Multiwavelength Imaging of Tumors, Small, 2019, 15(41), p 1903596.

S. Lei, S. Lei, W. Ling et al., The Improved Biological Performance of a Novel Low Elastic Modulus Implant, PLoS ONE, 2013, 8(2), e55015.

Z.A. Lei, S.A. Bo, B. Skc et al., A Topology Strategy to Reduce Stress Shielding of Additively Manufactured Porous Metallic Biomaterials, Int. J. Mech. Sci., 2021, 197, 106331.

S.H. Lin, C.S. Chien, T.Y. Kuo et al., Biomedical Evaluation of Vacuum Plasma Sprayed Tantalum Coatings Processed by Alkali Treatment and Alkali-heat Treatment with Different NaOH Concentrations, Surf, Coat. Tech., 2020, 403, 126400.

A.P. Manso, F.F. Marzo, X. Garicanoa et al., Corrosion Behavior of Tantalum Coatings on AISI 316L Stainless Steel Substrate for Bipolar Plates of PEM Fuel Cells, Int. J. Hydrogen. Energ., 2020, 45(40), p 20679–20691.

V.K. Balla, S. Banerjee, S. Bose et al., Direct Laser Processing of a Tantalum Coating on Titanium for Bone Replacement Structures, Acta Biomater., 2010, 6(6), p 2329–2334.

H. Yu, L. Yang, Z. Lei et al., Anticorrosion Properties of Ta-coated 316L Stainless Steel as Bipolar Plate Material in Proton Exchange Membrane Fuel Cells, J. Power Sources, 2010, 191(2), p 495–500.

S. Yuan, N. Lin, Q. Zeng et al., Recent Developments in Research of Double glow Plasma Surface Alloying technology: A Brief Review, J. Mater. Res. Technol., 2020, 9(3), p 6859–6882.

H. Zhao, Q. Miao, W. Liang et al., A Study on Pre-treatment with Rotation Accelerated Shot Peening in Multi-NbN Films by Double glow Plasma Surface Metallurgy, Surf. Coat. Technol., 2020, 405, p 126671.

D. Ma, Y. Xue, J. Gao et al., Effect of Ta Diffusion Layer on the Adhesion Properties of Diamond Coating on WC-Co Substrate, Appl. Surf. Sci., 2020, 527, p 146727.

L. Liu, J. Xu, X. Lu et al., Electrochemical Corrosion Behavior of Nanocrystalline β-Ta Coating for Biomedical Applications, ACS Biomater. Sci. Eng., 2016, 2, p 579–594.

M. Zhang, Y. Ma, J. Gao et al., Mechanical, Electrochemical and Osteoblastic Properties of Gradient Tantalum Coatings on Ti6Al4V by Prepared Plasma Alloying Technique, Coatings, 2021, 11(6), p 631.

S. Yuan, N. Lin, J. Zou et al., Effect of Laser Surface Texturing (LST) on Tribological Behavior of Double glow Plasma Surface Zirconizing Coating on Ti6Al4V Alloy, Surf. Coat. Technol., 2019, 368, p 97–109.

S. Maeng, L. Axe, T.A. Tyson et al., Corrosion Behaviour of Magnetron Sputtered α- and β-Ta Coatings on AISI 4340 Steel as a Function of Coating Thickness, Corros. Sci., 2006, 48(8), p 2154–2171.

G.C. Coelho, J. Neto, S. Gama et al., Experimental Study of the Iron-tantalum Equilibrium Diagram, J. Phase Equilib., 1995, 16(2), p 121–128.

L. Yang, X. Jiang, H. Sun et al., Interfacial Reaction and Microstructure Investigation of CoCrFeNiMo Medium-Entropy Alloys Diffusion-Bonded Joints, Mater. Lett., 2019, 261, 127140.

W. Wang, M. Dahl and Y. Yin, Hollow Nanocrystals through the Nanoscale Kirkendall Effect, Chem. Mater., 2013, 25(8), p 1179–1189.

A. Anders, A Structure Zone Diagram Including Plasma-based Deposition and ion Etching, Thin Solid Films, 2010, 518, p 4087–4090.

C.G.J. Prakash and R. Prasanth, Approaches to Design a Surface with Tunable Wettability: A Review on Surface Properties, J. Mater. Sci., 2021, 56(1), p 1–28.

R.N. Wenzel, Resistance of Solid Surfaces to Wetting by Water, Ind. Eng. Chem., 1936, 28, p 988–994.

H. Herrmann and H. Bucksch, Adhesion Strength, Springer, Berlin, Heidelberg, 2014.

C.H. Chien, T.H. Su, C.T. Wang et al., The Effects of Film Thickness Variations on the Residual Stress Distributions in Coated Cr Thin Films, Strain, 2017, 53(2), p e12222.

M.S. Zoei, T. Farizeh, M.H. Sadeghi et al., Residual Stress Distribution Through the Thickness of WC-10Co-4Cr Coating Deposited by HVOF: Experimental and Simulation Study, J. Therm. Spray Techn., 2020, 29(6), p 1351–1364.

K. Zheng, J. Gao, H. Hei et al., Design and Fabrication of HfC, SiC/HfC and HfC-SiC/HfC Interlayers for Improving the Adhesion Between Diamond Coatings and Cemented Carbides, J. Alloys Compd., 2020, 815, 152405.

W. Zhang, S. Yamashita, T. Kumazawa et al., Influence of surface Roughness Parameters and Surface Morphology on Friction Performance of Ceramics, J. Ceram. Soc. Jpn., 2019, 127(11), p 837–842.

K. Narita, K. Nakai et al., Differences in Wear Behaviors at Sliding Contacts for beta-Type and (alpha plus beta)-Type Titanium Alloys in Ringer’s Solution and Air, Mater Transact, 2015, 56(13), p 317–326.

H. Jun, Diffusion Impedance of Electroactive Materials, Electrolytic Solutions and Porous Electrodes: Warburg Impedance and Beyond, Electrochim. Acta, 2018, 281, p 170–188.

M. Zhang, B. Zhou, J. Gao et al., A Scalelike Micro/Nano-textured Structure on Ti-Based Implants with Enhanced Cytocompatibility and Osteogenic Activities, Surf. Coat. Technol., 2021, 3, 127497.

Y. Koumya, Y. Ait Salam, M.E. Khadiri et al., Pitting Corrosion Behavior of SS-316L in Simulated Body Fluid and Electrochemically Assisted Deposition of Hydroxyapatite Coating, Chem. Pap., 2021, 75(6), p 2667–2682.

M.C. Tanzi, S. Farè and G. Candiani, Interactions Between Biomaterials and the Physiological Environment, Foundations of Biomaterials Engineering. Academic Press, Cambridge, 2019, p 321–391

Z. Xu and F.F. Xiong, Plasma Surface Metallurgy, Double Glow Plasma Surface Alloying/Metallurgy Technology, 33–62, Springer, Singapore, 2017.

H. Wu, X. Zhao, J. Li et al., Effect of Processing Factors on the Microstructure and Gradual Diffusion of Tungstenized Layers, Appl. Surf. Sci., 2019, 477, p 232–240.

L.G. Feinstein and R.D. Huttemann, Factors Controlling the Structure of Sputtered Ta films, Thin Solid Films, 1973, 16(2), p 129–145.

L. Gladczuk, A. Patel, C. Paur et al., Tantalum films for Protective Coatings of Steel, Thin Solid Films, 2004, 467(1), p 150–157.

R. Wood, Tribo-Corrosion of Coatings: A Review, J. Phys. D, 2007, 40(18), p 5502.

N.V. Motlagh, F.C. Birjandi, J. Sargolzaei et al., Durable, Superhydrophobic, Superoleophobic and Corrosion Resistant Coating on the Stainless Steel Surface Using a Scalable Method, Appl. Surf. Sci., 2013, 283, p 636–647.

J. Zhang, J. Liu, C. Wang et al., A Comparative Study of the Osteogenic Performance Between the hierarchical Micro/submicro-Textured 3D-Printed Ti6Al4V Surface and the SLA Surface, Bioact. Mater., 2020, 5(1), p 9–16.

Q. Huang, T.A. Elkhooly, X. Liu et al., Effects of Hierarchical Micro/Nano-topographies on the Morphology, Proliferation and Differentiation of Osteoblast-like Cells, Colloids Surf. B, 2016, 145, p 37–45.

Z. Schwartz, C.H. Lohmann, J. Oefinger et al., Implant Surface Characteristics Modulate Differentiation Behavior of Cells in the Osteoblastic Lineage, Adv. Dent. Res., 1999, 13(1), p 38–48.

Acknowledgments

This work is supported by the National Natural Science Foundation of China [Grant No. 51901154], the Natural Science Foundation of Shanxi Province [Grant No. 201901D211092], the Science and Technology Major Project of Shanxi [Grant No. 20181102013].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, J., Cao, Y., Ma, Y. et al. Wear, Corrosion, and Biocompatibility of 316L Stainless Steel Modified by Well-Adhered Ta Coatings. J. of Materi Eng and Perform 31, 8784–8798 (2022). https://doi.org/10.1007/s11665-022-06928-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06928-9