Abstract

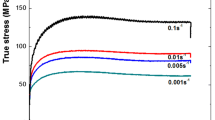

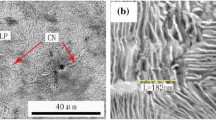

The SnSbCu alloy is widely used as the material for the main bearing in low-speed marine engines, and an accurate constitutive model is the foundation for studying the frictional behaviors of bearings. In this work, the compressive flow behaviors of the SnSbCu alloy were considered under the different strain rates (1000-5000 s−1) and temperatures (20-110 °C) by quasi-static and split-Hopkinson pressure bar dynamic compression tests. First, the original Johnson–Cook model was used to describe the constitutive relation of the SnSbCu alloy at high strain rates, and the results predicted by the original model showed relatively large errors compared with the experimental results since the coupled effect of temperature and strain rate was omitted. Then, a modified Johnson–Cook constitutive model was developed to describe the compressive flow behaviors of the SnSbCu alloy, and the results predicted by this modified model agreed well with the experimental data. Moreover, a finite element analysis was also conducted to verify the accuracy of the modified Johnson–Cook model.

Similar content being viewed by others

References

L. Gambirasio and E. Rizzi, An Enhanced Johnson–Cook Strength Model for Splitting Strain Rate and Temperature Effects on Lower Yield Stress and Plastic Flow, Comput. Mater. Sci., 2016, 113, p 231–265

R. Bobbili, and V. Madhu. A Modified Johnson–Cook Model for FeCoNiCr High Entropy Alloy Over a Wide Range of Strain Rates. Mater. Lett., 2018: S0167577X18301812.

W.D. Song, J.G. Ning, X.N. Mao, and H.P. Tang, A Modified Johnson–Cook Model for Titanium Matrix Composites Reinforced with Titanium Carbide Particles at Elevated Temperatures, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2013, 576, p 280–289

D.N. Zhang, Q.Q. Shangguan, C.J. Xie, and F. Liu, A Modified Johnson–Cook Model of Dynamic Tensile Behaviors for 7075-T6 Aluminum Alloy, J. Alloys Compd., 2015, 619, p 186–194

G.J. Chen, L. Chen, G.Q. Zhao, C.S. Zhang, and W.C. Cui, Microstructure Analysis of an Al-Zn-Mg Alloy During Porthole Die Extrusion Based on Modeling of Constitutive Equation and Dynamic Recrystallization, J. Alloys Compd., 2017, 710, p 80–91

G.R. Johnson, and W.H. Cook. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates, and High Temperatures. In: Proceedings of the Seventh International Symposium on Ballistics, International Ballistics Committee, The Hague, Netherlands, 1983, p 541–7.

D.J. Bammann, M.L. Chiesa, and G.C. Johnson, Modeling Large Deformation and Failure in Manufacturing Processes, Theor. Appl. Mech., 1996, 9, p 359–376

P.S. Follansbee and U.F. Kocks, A Constitutive Description of the Deformation of Copper Based on the Use of the Mechanical Threshold Stress as an Internal State Variable, Acta Metall., 1988, 36, p 81–93

F.J. Zerilli and R.W. Armstrong, Dislocation-Mechanics-Based Constitutive Relations for Material Dynamics Calculations, J. Appl. Phys., 1987, 61, p 1816–1825

S.N. Nasser and Y.L. Li, Flow Stress of fcc Polycrystals with Application to OFHC Cu, Acta Mater., 1998, 46, p 565–577

H.R.R. Ashtiani, M.H. Parsa, and H. Bisadi, Constitutive Equations for Elevated Temperature Flow Behavior of Commercial Purity Aluminum, Mater. Sci. Eng. A, 2012, 545, p 61–67

G.F. Xu, X.Y. Peng, X.P. Liang, X. Li, and Z.M. Yin. Constitutive Relationship for High Temperature Deformation of Al-3Cu-0.5Sc Alloy. Trans. Nonferrous Met. Soc. China, 2013, 23: 1549–55.

G.Z. Quan, Y. Shi, C.T. Yu, and J. Zhou, The Improved Arrhenius Model with Variable Parameters of Flow Behavior Characterizing for the as-Cast AZ80 Magnesium Alloy, Mater. Res., 2013, 16, p 785–791

D.N. Zou, K. Wu, Y. Han, W. Zhang, B. Cheng, and G.J. Qiao, Deformation Characteristic and Prediction of Flow Stress for as-Cast 21Cr Economical Duplex Stainless Steel Under Hot Compression, Mater. Des., 2013, 51, p 975–982

G.T. Gray, S.R. Chen, and K.S. Vecchio, Influence of Grain Size on the Constitutive Response and Substructure Evolution of MONEL 400, Metall. Mater. Trans. A, 1999, 30, p 1235–1247

S.T. Chiou, W.C. Cheng, and W.S. Lee, Strain Rate Effects on the Mechanical Properties of a Fe-Mn-Al Alloy Under Dynamic Impact Deformations, Mater. Sci. Eng., A, 2005, 392, p 156–162

J. Choung, W. Nam, and J.Y. Lee, Dynamic Hardening Behaviors of Various Marine Structural Steels Considering Dependencies on Strain Rate and Temperature, Marine Struct., 2013, 32, p 49–67

G.R. Johnson and W.H. Cook, Fracture Characteristics Of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21, p 31–48

Y. Prawoto, M. Fanone, S. Shahedi, M.S. Ismail, and W.B. Wan Nik, Computational Approach Using Johnson-Cook Model on Dual Phase Steel, Comput. Mater. Sci., 2012, 54, p 48–55

K. Vedantam, D. Bajaj, N.S. Brar, and S. Hill, Johnson–Cook Strength Models for Mild and DP 590 Steels//AIP Conference Proceedings, AIP, 2006, 845, p 775–778

L. Chen, G.Q. Zhao, and J.Q. Yu, Hot Deformation Behavior and Constitutive Modeling of Homogenized 6026 Aluminum Alloy, Mater. Des., 2015, 74, p 25–35

A. Shrot and M. Bäker, Determination of Johnson–Cook Parameters from Machining Simulations, Comput. Mater. Sci., 2012, 52, p 298–304

X.G. Deng, S.X. Hui, W.J. Ye, and X.Y. Song, Construction of Johnson–Cook Model for Gr2 Titanium Through Adiabatic Heating Calculation, Appl. Mech. Mater., 2014, 487, p 7–14

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr–1Mo Steel, Comput. Mater. Sci., 2009, 47, p 568–576

A. He, G.L. Xie, H.L. Zhang, and X.T. Wang. A Comparative Study on Johnson–Cook, Modified Johnson–Cook and Arrhenius-Type Constitutive Models to Predict the High Temperature Flow Stress in 20CrMo Alloy Steel. Mater. Des. (1980–2015), 2013, 52: 677–85.

H.Y. Li, X.F. Wang, J.Y. Duan, and J.J. Liu, A Modified Johnson Cook Model for Elevated Temperature Flow Behavior of T24 Steel, Mater. Sci. Eng. A, 2013, 577, p 138–146

X.Y. Wang, C.Z. Huang, B. Zou, H.L. Liu, H.T. Zhu, and J. Wang, Dynamic Behavior and a Modified Johnson-Cook Constitutive Model of Inconel 718 at High Strain Rate and Elevated Temperature, Mater. Sci. Eng. A, 2013, 580, p 385–390

Y.C. Lin and X.M. Chen, A Combined Johnson-Cook and Zerilli-Armstrong Model for hot Compressed Typical High-Strength Alloy Steel, Comput. Mater. Sci., 2010, 49, p 628–633

S. Gangireddy and S.P. Mates, High Temperature Dynamic Response of a Ti-6Al-4V Alloy: A Modified Constitutive Model for gradual Phase Transformation, J. Dyn. Behav. Mater., 2017, 3, p 557–574

H.Y. Li, Y.H. Li, X.F. Wang, J.J. Liu, and Y. Wu, A Comparative Study on Modified Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict the Hot Deformation Behavior in 28CrMnMoV Steel, Mater. Des., 2013, 49, p 493–501

J. Cai, K.S. Wang, P. Zhai, F.G. Li, and J. Yang, A Modified Johnson–Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2015, 24, p 32–44

A. Shokry, A Modified Johnson–Cook Model for Flow Behavior of Alloy 800H at Intermediate Strain Rates and High Temperatures, J. Mater. Eng. Perform., 2017, 26, p 5723–5730

L. Chen, G.Q. Zhao, J. Gong, X.X. Chen, and M.M. Chen, Hot Deformation Behaviors and Processing Maps of 2024 Aluminum Alloy in as-Cast and Homogenized States, J. Mater. Eng. Perform., 2015, 24, p 5002–5012

C.A. Ross and J.W. Tedesco, Split-Hopkinson Pressure-Bar Tests on Concrete and Mortar in Tension and Compression, Mater. J., 1989, 86, p 475–481

Z.G. Gao, X.M. Zhang, M.A. Chen, Y.S. Zhao, H.J. Li, and B. Liu, Effect of Temperature on Dynamic Yield Stress and Microstructure of 2519A Aluminum Alloy at High Strain Rate, Rare Metal Mater. Eng., 2009, 35, p 881–886

M.R. Rokni, A. Zarei-Hanzaki, A.A. Roostaei, and A. Abolhasani, Constitutive Base Analysis of a 7075 Aluminum Alloy During Hot Compression Testing, Mater. Des., 2011, 32, p 4955–4960

S. Srinivasulu and A. Jain, A Comparative Analysis of Training Methods for Artificial Neural Network Rainfall–Runoff Models, Appl. Soft Comput., 2006, 6, p 295–306

Y.H. Zhao, J. Sun, J.F. Li, Y.Q. Yan, and P. Wang, A Comparative Study on Johnson–Cook and Modified Johnson–Cook Constitutive Material Model to Predict the Dynamic Behavior Laser Additive Manufacturing FeCr Alloy, J. Alloys Compd., 2017, 723, p 179–187

M.J. Kim, H.J. Jeong, J.W. Park, S.T. Hong, and H.N. Han, Modified Johnson–Cook Model Incorporated with Electroplasticity for Uniaxial Tension Under a Pulsed Electric Current, Met. Mater. Int., 2018, 24, p 42–50

J.Q. Tan, M. Zhan, S. Liu, T. Huang, J. Guo, and H. Yang, A Modified Johnson–Cook Model for Tensile Flow Behaviors of 7050-T7451 Aluminum Alloy at High Strain Rates, Mater. Sci. Eng., A, 2015, 631, p 214–219

G. Warnecke and J.D. Oh, A New Thermo-Viscoplastic Material Model for Finite-Element-Analysis of the Chip Formation Process, CIRP Ann. Manuf. Technol., 2002, 51, p 79–82

B. Gladman. LS-Dyna Keyword Users’ Manual. Livermore Software Corporation California, 2007.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51809057) and the Marine Low-Speed Engine Project—Phase I (Grant No. CDGC01-KT11).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, H., Zhao, B., Lu, X. et al. A Modified Johnson–Cook Constitutive Model for the Compressive Flow Behaviors of the SnSbCu Alloy at High Strain Rates. J. of Materi Eng and Perform 28, 6958–6968 (2019). https://doi.org/10.1007/s11665-019-04407-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04407-2