Abstract

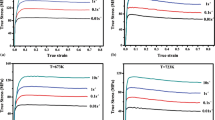

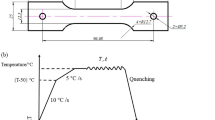

In the design of hot forming processes for aluminum alloys, hot processing maps are usually used as a powerful tool for processing parameters optimizations. Although the stability of deformation is considered in conventional hot processing (CHP) maps, the difficulty of deformation, i.e., whether deformation is easy to occur, is not taken into account. Therefore, it is difficult for CHP maps to efficiently and accurately obtain the optimal processing parameters and achieve satisfying hot workability. Hence, in this study, thermal compression tests were performed to investigate the hot forming behavior of 5052 aluminum alloy in the deformation temperature range of 553-733 K and strain rate range of 0.001-1 s−1. We proposed an activation energy-processing (AEP) map by coupling the CHP map and the activation energy value, and thereby applied it to evaluate the hot workability of 5052 aluminum alloy. In CHP maps, the region with the highest power dissipation efficiency is generally considered to be the best processing region. However, the AEP map shows that materials with satisfying hot workability not only depends on high power dissipation efficiency, but also on low activation energy values. At the strain of 0.7, the optimal hot processing region predicted by the CHP map lies in the temperature range of 583-673 K and strain rate range of 0.001-0.1 s−1, but that predicted by AEP map locates in the temperature range of 643-733 K and strain rate range of 0.001-0.1 s−1. Microstructure characterization implies that the optimal processing region predicted by the CHP map presents necklace-like structures, which are non-uniform and unbeneficial for deformation, while that predicted by the AEP map consists of fine, uniform and equiaxed grains. Thus, it is implied that the processing regions predicted by the AEP map are more suitable for forming, i.e., the reasonability of the AEP map is verified.

Similar content being viewed by others

References

Y.K. Lin, S.H. Wang, R.Y. Chen, T.S. Hsieh, L. Tsai, and C.C. Chiang, The Effect of Heat Treatment on the Sensitized Corrosion of the 5383-H116 Al-Mg Alloy, Materials, 2017, 10, p 275

F.J. Zhu, H.Y. Wu, M.C. Lin, S. Lee, and W.R. Wang, Hot Workability Analysis and Development of a Processing Map for Homogenized 6069 Al Alloy Cast Ingot, J. Mater. Eng. Perform., 2015, 24, p 2051–2059

C.R. Anoop, A. Prakash, S.K. Giri, S.V.S. Narayana Murty, and I. Samajdar, Optimization of Hot Workability and Microstructure Control in a 12Cr-10Ni Precipitation Hardenable Stainless Steel: An Approach Using Processing Maps, Mater. Charact., 2018, 141, p 97–107

Z. Su, L. Wan, C. Sun, Y. Cai, and D. Yang, Hot Deformation Behavior of AZ80 Magnesium Alloy Towards Optimization of Its Hot Workability, Mater. Charact., 2016, 122, p 90–97

C. Sun, Y. Xiang, Q. Zhou, D. Politis, Z. Sun, and M. Wang, Dynamic Recrystallization and Hot Workability of 316LN Stainless Steel, Metals, 2016, 6, p 152

S. Luo, D. Zhu, L. Hua, D. Qian, S. Yan, and F. Yu, Effects of Process Parameters on Deformation and Temperature Uniformity of Forged Ti-6Al-4V Turbine Blade, J. Mater. Eng. Perform., 2016, 25, p 4824–4836

B.J. Lv, F. Guo, Q.L. Che, Y. Xu, N. Cui, and Y.L. Guan, A New Method for Optimizing Hot Processing Parameters of Mg-6.0Zn-0.5Mn-0.5Er Alloy Based on Kinetic Model of Dynamic Recrystallization and Processing Map, J. Mater. Eng. Perform., 2018, 27, p 3773–3782

X. Zhou, R.R. Liu, H.T. Zhou, and W.X. Jiang, A Revisited Study of the Processing Map and Optimized Workability of AZ61 Magnesium Alloy, J. Mater. Eng. Perform., 2017, 26, p 2423–2429

H.E. Hu and X.Y. Wang, Superplastic Deformation Behavior and Hot-Processing Map of the TiNp/2014 Al Composite, Met. Mater. Int., 2016, 22, p 41–49

J.S. Jin, X.Y. Wang, H.E. Hu, and J.C. Xia, High-Temperature Deformation Behavior and Processing Map of 7050 Aluminum Alloy, Met. Mater. Int., 2012, 18, p 69–75

H. Sun, Y. Zhang, A.A. Volinsky, B. Wang, B. Tian, K. Song, Z. Chai, and Y. Liu, Effects of Ag Addition on Hot Deformation Behavior of Cu-Ni-Si Alloys, Adv. Eng. Mater., 2017, 19, p 1600607

Q. Zhang, Y. Lin, H. Chi, J. Chang, and G. Wu, Quasi-static and Dynamic Compression Behavior of Glass Cenospheres/5A03 Syntactic Foam and its Sandwich Structure, Compos. Struct., 2018, 183, p 499–509

J. Luo, M. Li, H. Li, and W. Yu, Effect of the Strain on the Deformation Behavior of Isothermally Compressed Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2009, 505, p 88–95

Y. Sun, Z. Cao, Z. Wan, L. Hu, W. Ye, N. Li, and C. Fan, 3D Processing Map and Hot Deformation Behavior of 6A02 Aluminum Alloy, J. Alloys Compd., 2018, 742, p 356–368

A.C. Kaya, P. Zaslansky, M. Ipekoglu, and C. Fleck, Strain Hardening Reduces Energy Absorption Efficiency of Austenitic Stainless Steel Foams While Porosity Does Not, Mater. Des., 2018, 143, p 297–308

J. Luo, L. Li, and M.Q. Li, The Flow Behavior and Processing Maps During the Isothermal Compression of Ti17 Alloy, Mater. Sci. Eng. A, 2014, 606, p 165–174

N. Srinivasan and Y.V.R.K. Prasad, Hot Working Characteristics of Nimommic 75, 80A and 90 Superalloys A Comparison Using Processing Maps, J. Mater. Process. Technol., 1995, 51, p 171–192

S.V.S.N. Murty and B.N. Rao, On the Development of Instability Criteria During Hotworking with Reference to IN718, Mater. Sci. Eng. A, 1998, 254, p 76–82

L. Xu, L. Chen, G.J. Chen, and M.Q. Wang, Hot Deformation Behavior and Microstructure Analysis of 25Cr3Mo3NiNb Steel During Hot Compression Tests, Vacuum, 2018, 147, p 8–17

S. Wang, L.G. Hou, J.R. Luo, J.S. Zhang, and L.Z. Zhuang, Characterization of Hot Workability in AA 7050 Aluminum Alloy Using Activation Energy and 3-D Processing Map, J. Mater. Process. Technol., 2015, 225, p 110–121

Z. Mingjie, L. Fuguo, W. Shuyun, and L. Chenyi, Characterization of Hot Deformation Behavior of a P/M Nickel-Base Superalloy Using Processing Map and Activation Energy, Mater. Sci. Eng. A, 2010, 527, p 6771–6779

S. Wang, J.R. Luo, L.G. Hou, J.S. Zhang, and L.Z. Zhuang, Identification of the Threshold Stress and True Activation Energy for Characterizing the Deformation Mechanisms During Hot Working, Mater. Des., 2017, 113, p 27–36

Z. Yang, Y. Li, Y. Li, F. Zhang, and M. Zhang, Constitutive Modeling for Flow Behavior of Medium-Carbon Bainitic Steel and Its Processing Maps, J. Mater. Eng. Perform., 2016, 25, p 5030–5039

J.Q. Zhang, H.S. Di, H.T. Wang, K. Mao, T.J. Ma, and Y. Cao, Hot Deformation Behavior of Ti-15-3 Titanium Alloy a Study Using Processing Maps, Activation Energy Map, and Zener-Hollomon Parameter Map, J. Mater. Sci., 2012, 47, p 4000–4011

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

F.J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomena, 2nd ed., Elsevier, Oxford, 2004

X. Wang, Z. Liu, and H. Luo, Hot Deformation Characterization of Ultrahigh Strength Stainless Steel Through Processing Maps Generated Using Different Instability Criteria, Mater. Charact., 2017, 131, p 480–491

Y. Zhang, H. Sun, A.A. Volinsky, B. Wang, B. Tian, Z. Chai, Y. Liu, and K. Song, Small Y Addition Effects on Hot Deformation Behavior of Copper-Matrix Alloys, Adv. Eng. Mater., 2017, 19, p 1700197

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad, Hot Working of Commercial Ti-6Al-4V with an Equiaxed Microstructure Materials Modeling Considerations, Mater. Sci. Eng. A, 2000, 284, p 184–194

Z.B. Xiao, Y.C. Huang, and Y. Liu, Plastic Deformation Behavior and Processing Maps of 35CrMo Steel, J. Mater. Eng. Perform., 2016, 25, p 1219–1227

R. Łyszkowski and J. Bystrzycki, Hot Deformation and Processing Maps of a Fe–Al Intermetallic Alloy, Mater. Charact., 2014, 96, p 196–205

K.P. Rao, Y.V.R.K. Prasad, and K. Suresh, Hot Working Behavior and Processing Map of a γ-TiAl Alloy Synthesized by Powder Metallurgy, Mater. Des., 2011, 32, p 4874–4881

S. Chen, D. Fu, H. Luo, Y. Wang, J. Teng, and H. Zhang, Hot Workability of PM 8009Al/Al2O3 Particle-Reinforced Composite Characterized Using Processing Maps, Vacuum, 2018, 149, p 297–305

J. Luo, M.Q. Li, and B. Wu, The Correlation Between Flow Behavior and Microstructural Evolution of 7050 Aluminum Alloy, Mater. Sci. Eng. A, 2011, 530, p 559–564

L. Wang, F. Liu, J.J. Cheng, Q. Zuo, and C.F. Chen, Hot Deformation Characteristics and Processing Map Analysis for Nickel-Based Corrosion Resistant Alloy, J. Alloys Compd., 2015, 623, p 69–78

B. Shen, L. Deng, and X. Wang, A New Dynamic Recrystallisation Model of an Extruded Al-Cu-Li Alloy During High-Temperature Deformation, Mater. Sci. Eng. A, 2015, 625, p 288–295

T. Sakai, H. Miura, A. Goloborodko, and O. Sitdikov, Continuous Dynamic Recrystallization During the Transient Severe Deformation of Aluminum Alloy 7475, Acta Mater., 2009, 57, p 153–162

Z.C. Sun, L.S. Zheng, and H. Yang, Softening Mechanism and Microstructure Evolution of As-Extruded 7075 Aluminum Alloy During Hot Deformation, Mater. Charact., 2014, 90, p 71–80

Acknowledgments

This work was financially supported by National Natural Science Found for Distinguished Young Scholars of China (Grant No.: 51725504) and the Key Program of National Natural Science Foundation of China (Grant No. 51435007). The authors are also grateful for the technical assistance from the Analytical and Testing Center of Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Contributions

XW and PZ conceived and designed the experiments; LD performed the experiments; PG contributed reagents/materials/analysis tools; PZ wrote the paper and analyzed the data; MZ and XW reviewed and revised the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, P., Deng, L., Zhang, M. et al. Characterization of Hot Workability of 5052 Aluminum Alloy Based on Activation Energy-Processing Map. J. of Materi Eng and Perform 28, 6209–6218 (2019). https://doi.org/10.1007/s11665-019-04367-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04367-7