Abstract

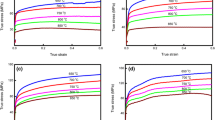

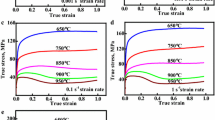

Based on the hot compressive tests in the temperature range of 700-900 °C and strain rate range of 0.01-10 s−1, the hot deformation behavior of a Cu-Cr-In alloy was investigated. The true stress–strain curves of the alloy were obtained, and a constitutive equation for the alloy was established by the method of equivalent stress. The processing maps were constructed based on the constitutive equation, and the microstructural evolutions were analyzed and correlated with the processing maps. The results show that the true stress of the alloy increased with decreasing strain rate and decreased with increasing temperature. The microstructures of the alloy deformed under different conditions were in good accordance with the processing maps results. According to the processing maps and the microstructures of the alloy with true strains of 0.4 and 0.8, the optimal hot deformation conditions lie in the range of 850-900 °C and strain rate range of 0.01-0.1 s−1.

Similar content being viewed by others

References

Q. Liu, X. Zhang, Y. Ge, J. Wang, and J.Z. Cui, Effect of Processing and Heat Treatment on Behavior of Cu-Cr-Zr Alloys to Railway Contact Wire, Metall. Mater. Trans. A, 2006, 37(11), p 3233–3238

C.D. Xia, Y.L. Jia, W. Zhang, K. Zhang, Q.Y. Dong, G.Y. Xu, and M.P. Wang, Study of Deformation and Aging Behaviors of a Hot Rolled-Quenched Cu-Cr-Zr-Mg-Si Alloy during Thermo Mechanical Treatments, Mater. Des., 2012, 39, p 404–409

K. Wang, K.F. Liu, and J.B. Zhang, Microstructure and Properties of Aging Cu-Cr-Zr Alloy, Rare Metals, 2014, 33(2), p 134–138

Y. Pang, C.D. Xia, M.P. Wang, Z. Li, Z. Xiao, H.G. Wei, X.F. Sheng, Y.L. Jia, and C. Chen, Effects of Zr and (Ni, Si) Additions on Properties and Microstructure of Cu-Cr alloy, J. Alloys Comp., 2014, 582, p 786–792

M. Hatakeyama, T. Toyama, Y. Nagai, M. Hasegawa, M. Eldrup, and B.N. Singh, Nanostructural Evolution of Cr-Rich Precipitates in a Cu-Cr-Zr Alloy During Heat Treatment Studied by 3 Dimensional Atom Probe, Mater. Trans., 2008, 49(3), p 518–521

Z.Q. Wang, Y.B. Zhong, G.H. Cao, C. Wang, J. Wang, W.L. Ren, Z.S. Lei, and Z.M. Ren, Influence of DC Electric Current on the Hardness of Thermally Aged Cu-Cr-Zr Alloy, J. Alloys Comp., 2009, 479(1-2), p 303–306

J.Y. Cheng, B. Shen, and F.X. Yu, Precipitation in a Cu-Cr-Zr-Mg Alloy During Aging, Mater. Charact., 2013, 81, p 68–75

J.Y. Cheng, F.X. Yu, and B. Shen, Solute Clusters and Chemistry in a Cu-Cr-Zr-Mg Alloy During the Early Stage of Aging, Mater. Lett., 2014, 115, p 201–204

J.H. Su, F.Z. Ren, B.H. Tian, P. Liu, and Q.M. Dong, Aging Strengthening in Rapidly Solidified Cu-Cr-Sn-Zn Alloy, J. Mater. Sci. Technol., 2009, 25(2), p 230–232

D.W. Yuan, B. Yang, J.S. Chen, H.M. Chen, J.B. Zhang, and H. Wang, Upward Continuous Casting in the Manufacture of Cu-Cr-Ag Alloy: Potential for Enhancing Strength Whilst Maintaining Ductility, Metall. Mater. Trans. A, 2017, 48(12), p 6083–6090

Y. Liu, Z. Li, Y.X. Jiang, Y. Zhang, Z.Y. Zhou, and Q. Lei, The Microstructure Evolution and Properties of a Cu-Cr-Ag Alloy During Thermal-Mechanical Treatment, J. Mater. Res., 2017, 32(7), p 1324–1332

M.M. Li, X.P. Zhang, H.M. Chen, H. Wang, and B. Yang, Microstructural Evolution and Mechanical Property of Cu-Cr-In Alloy During Thermo-Mechanical Treatment, Chin. J. Rare Metals, 2017, 41, p 1311–1317

L. Zhang, Z. Li, Q. Lei, W.T. Qiu, and H.T. Luo, Hot Deformation Behavior of Cu-8.0Ni-1.8Si-0.15Mg Alloy, Mater. Sci. Eng. A, 2011, 528(3), p 1641–1647

H. Zhang, H.G. Zhang, and L.X. Li, Hot Deformation Behavior of Cu-Fe-P Alloys During Compression at Elevated Temperatures, J. Mater. Process. Technol., 2009, 209(6), p 2892–2896

P. Lin, A.H. Feng, S.J. Yuan, G.P. Li, and J. Shen, Microstructure and Texture Evolution of a Near-α Titanium Alloy During Hot Deformation, Mater. Sci. Eng. A, 2013, 563, p 16–20

Z.Y. Ding, S.G. Jia, R.F. Zhao, M. Deng, and K.S. Song, Hot Deformation Behavior of Cu-0.6Cr-0.03Zr Alloy During Compression, Mater. Sci. Eng. A, 2013, 570, p 87–91

K.P. Rao, Y.V.R.K. Presad, and K. Suresh, Hot Working Behavior and Processing Map of a γ-TiAl Alloy Synthesized by Powder Metallurgy, Mater. Des., 2011, 32(10), p 4874–4881

Z. Gronostajski, Deformation Processing Map for Control of CuSi3.9 Silicon Bronze Microstructure, J. Mater. Process. Technol., 2005, 159(3), p 377–382

Y. Zhang, Z. Chai, A.A. Volinsky, B.H. Tian, H.L. Sun, and P. Liu, Processing Maps for the Cu-Cr-Zr-Y Alloy Hot Deformation Behavior, Mater. Sci. Eng. A, 2016, 662, p 320–329

Y. Zhang, A.A. Volinsky, H.L. Sun, B.H. Tian, P. Liu, and Y. Liu, Hot Deformation Characteristics and Processing Maps of the Cu-Cr-Zr-Ag Alloy, J. Mater. Eng. Perform., 2016, 25, p 1191–1198

Y. Zhang, H.L. Sun, A.A. Volinsky, B.H. Tian, Z. Chai, P. Liu, and Y. Liu, Characterization of the Hot Deformation Behavior of Cu-Cr-Zr Alloy by Processing Maps, Acta Metall. Sin. Engl., 2016, 29(5), p 422–430

C.M. Sellars and W.J. Mctegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138

C. Zener and J.H. Hollomon, Effect of Strain Rate upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22–32

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive Modeling for Elevate Temperature Flow Behavior of 42CrMo Steel, Comp. Mater. Sci., 2008, 42, p 470–477

Y.V.R.K. Prasad and K.P. Rao, Processing Maps for Hot Deformation of Rolled AZ31 Magnesium Alloy Plate: Anisotropy of Hot Workability, Mater. Sci. Eng. A, 2012, 487(1-2), p 316–327

Y.V.R.K. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243(1-2), p 82–88

S.V.S.N. Murty and B.R. Nageswara, On the Flow Localization Concepts in the Process Maps of Titanium Alloy Ti-24Al-20Nb, J. Mater. Process. Technol., 2000, 104(1-2), p 103–109

H. Mirzadeh, Constitutive Description of 7075 Aluminum Alloy During Hot Deformation by Apparent and Physically-Based Approaches, J. Mater. Eng. Perform., 2015, 24(3), p 1095–1099

A. Momeni, S.M. Abbasi, M. Morakabati, H. Badri, and X. Wang, Dynamic Recrystallization Behavior and Constitutive Analysis of Incoloy 901 Under Hot Working Condition, Mater. Sci. Eng. A, 2014, 615, p 51–60

Acknowledgments

This work is financially supported by the National Key Research and Development Program of China (Grant No. 2016YFB0301400). Thanks are also given to Dr. Liang Qi and Dr. Wenjing Wang for their help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, H., Gao, P., Peng, H. et al. Study on the Hot Deformation Behavior and Microstructure Evolution of Cu-Cr-In Alloy. J. of Materi Eng and Perform 28, 2128–2136 (2019). https://doi.org/10.1007/s11665-019-03961-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03961-z