Abstract

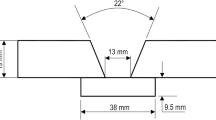

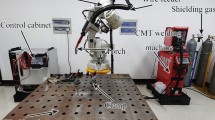

Creep-resistant 9Cr steels are extremely important in thermal power generation industry due to their marked resistance to creep and corrosion. The weldability of these alloys is critical since they are used in welded construction equipment. The required mechanical properties are achieved after post-weld heat treatment. This study examined the effect of different post-weld heat treatments on microstructure and mechanical properties of creep strength-enhanced 9Cr steel welding deposits. It was obtained with an experimental flux-cored arc welding wire used under protective gas (Ar-20% CO2). The heat treatments used were: (1) tempering (760 °C × 2 h), (2) solubilizing (1050 °C × 1 h) + tempering (760 °C × 2 h) and (3) solubilizing (1150 °C × 1 h) + first tempering (660 °C × 3 h) + second tempering (660 °C × 3 h). All-weld metal chemical composition was analyzed, and hot tensile tests were carried out at different temperatures. Charpy-V impact tests and Vickers microhardness measurements were also performed. Microstructures were studied using x-ray diffraction and optical and scanning electron microscopy. In all cases, a martensitic matrix with intergranular and intra-granular precipitates was detected. In the as-welded condition, δ-ferrite was also found. Microhardness dropped, and the impact energy increased with post-weld heat treatments. The highest hot tensile strength result was achieved with samples submitted to austenization at 1150 °C and double tempering at 660 °C.

Similar content being viewed by others

References

R. Viswanathan, J.F. Henry, J. Tanzosh, G. Stanko, J. Shingledecker, B. Vitalis, and R. Purgert, U.S. Program on Materials Technology for Ultra-Supercritical Coal Power Plants, J. Mater. Eng. Perform., 2005, 14, p 281–292

J. Oñoro, Weld Metal Microstructure Analysis of 9–12% Cr Steels, Int. J. Press. Vessels Pip., 2006, 83, p 540–545

E. Oakey, L.W. Pinder, R. Vanstone, M. Henderson, and S. Osgerby, Review of Status of Advanced Materials for Power Generation Part 4, COAL R224 02/1509, DTI/Pub URN, 2003

G. Posch, S. Baumgartner, and M. Fiedler, GMA-Welding of Creep Resistant Steels with Flux Cored Wires (FCAW): Perspectives and Limitations, Weld. World, 2009, 53, p 619–624

W. Marshall, Z. Zhang, and G.B. Holloway, Welding Consumables for P92 and T23 Creep Resisting Steels A, in Fifth International EPRI RRAC Conference, June 27th, 2002, p. 1–17

Z. Zhang, J.C.M. Farrar, and A.M. Barnes, Weld Metals for P91—Tough Enough, Metrode Products Limited, U.K. TWI, Ltd., Chertsey, 2002

B. Arivazhagan, S. Sundaresan, and M. Kamaraj, A Study on Influence of Shielding Gas Composition on Toughness of Flux-Cored Arc Weld of Modified 9Cr-1Mo (P91) Steel, J. Mater. Process. Technol., 2009, 209(12–13), p 5245–5253

C. Chovet, E. Galand, and B. Leduey, Effect of Various Factors on Toughness in P92 Saw Weld Metal, Weld. World, 2013, 52(7–8), p 18–26

Z. Zhang, G. Holloway, and A. Marshall, Properties of T/P92 Steel Weld Metals for Ultra Super Crtitical (USC) Power Plant, Weld. World, 2008, 6(1), p 1–13

H. Wang, H. Zhang, and J. Li, Microstructural Evolution of 9Cr-1Mo Deposited Metal Subjected to Weld Heating, J. Mater. Process. Technol., 2009, 209(6), p 2803–2811

A.C. Chovet, E. Bauné, G. Ehrhart, E. Galand, and G. Liberati, Development of Filler Materials for New 9–12% Cr Martensitic Creep Resistant Steels, in New Developments on Metallurgy and Applications of High Strength Steels Brazil, 2008, p. 1–7

ISO, Welding Consumables—Covered Electrodes for Manual Metal Arc Welding of Creep-Resisting Steels—Classification, ISO 3580:2017, International Organization for Standardization, Geneva, 2017

K. Maruyama, K. Sawada, and J. Koike, Strengthening Mechanisms of Creep Resistant Tempered Martensitic Steel, ISIJ Int., 2001, 41(6), p 641–653

P.J. Ennis, The Creep Rupture Behaviour and Steam Oxidation Resistance of P92 Weldments, Mater. High Temp., 2006, 23(3), p 187–193

L.I. Yajiang, W. Juan, Z. Bing, and F. Tao, XRD and TEM Analysis of Microstructure in the Welding Zone of 9Cr-1Mo-V-Nb Heat-Resisting Steel, Bull. Mater. Sci., 2002, 25(3), p 213–217

Y. Yin, R. Faulkner, P. Morris, and P. Clarke, Modelling and Experimental Studies of Alternative Heat Treatments in Steel 92 to Optimise Long Term Stress Rupture Properties, Energy Mater., 2008, 3(4), p 232–242

L.O. Bueno and J.F.R. Sobrinho, Correlation between Creep and Hot Tensile Behaviour for 2.25Cr-1Mo Steel from 500 °C to 700 °C Part 1: An Assessment According to Usual Relations Involving Stress, Temperature, Strain Rate and Rupture Time, Rev. Mater., 2012, 17(3), p 1098–1108

J.A. Moreto, D.B.V. De Castro, L.D.O. Bueno, and H.D.A. Ponte, Correlação de Dados de Tração a Quente e Fluência Para a Liga Kanthal A1, Rev. Esc. Minas, 2011, 64(2), p 181–186

P.R. Sreenivasan, Hot-Tensile Data and Creep p Properties Derived there-from for 316L (N) Stainless Steel with Various Nitrogen Contents, Procedia Eng., 2013, 55, p 82–87

American Welding Society, Specification for Low-Alloy Steel Electrodes for Flux Cored Arc Welding, ANSI/AWS A5.29/A5.29M:2010, American Welding Society, Miami, 2010

ASTM International, Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes, ASTM A213/A213 M-17, ASTM International, West Conshohocken, 2017

ASTM International, Standard specification for seamless ferritic alloy-steel pipe for high-temperature service, ASTM A335/A335 M-15a, ASTM International, West Conshohocken, 2015

ASTM International, Standard test methods for notched bar impact testing of metallic materials, ASTM E23-16b, ASTM International, West Conshohocken, 2016

R.G. Faulkner, J.A. Williams, E.G. Sanchez, and A.W. Marshall, Influence of Co, Cu and W on Microstructure of 9%Cr Steel Weld Metals, Mater. Sci. Technol., 2003, 19(3), p 347–354

V.T. Paul, S. Saroja, P. Hariharan, A. Rajadurai, and M. Vijayalakshmi, Identification of Microstructural Zones and Thermal Cycles in a Weldment of Modified 9Cr-1Mo Steel, J. Mater. Sci., 2007, 42(14), p 5700–5713

P. Mayr, T.A. Palmer, J.W. Elmer, E.D. Specht, and S.M. Allen, Formation of Delta Ferrite in 9 wt Pct Cr Steel Investigated by In-Situ X-ray Diffraction Using Synchrotron Radiation, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, 41(10), p 2462–2465

F. Abe and M. Tabuchi, Microstructure and Creep Strength of Welds in Advanced Ferritic Power Plant Steels, Sci. Technol. Weld. Join., 2004, 9(1), p 22–30

K. Kaneko, S. Matsumura, A. Sadakata, K. Fujita, W.J. Moon, S. Ozaki, N. Nishimura, and Y. Tomokiyo, Characterization of Carbides at Different Boundaries of 9Cr-Steel, Mater. Sci. Eng., A, 2004, 374(1–2), p 82–89

M. Taneike, F. Abe, and K. Sawada, Creep-Strengthening of Steel at High Temperatures Using Nano-Sized Carbonitride Dispersions, Nature, 2003, 424(6946), p 294–296

M.A. Yescas and P.F. Morris, Improved Creep Resistance of Steel 92 by the Use of Modified Heat Treatments, in ECCC Creep Conference, 2005

K. Tokumo, K. Hanada, R. Uemori, T. Takeda, and K. Itoh, A Complex Carbonitride of Niobium Ans Vanadium in 9% Cr Ferritic Steel, Scr. Mater., 1991, 25(4), p 871–876

K. Hamada, K. Tokuno, Y. Tomita, H. Mabuchi, and K. Okamoto, Effects of Precipitate Shape on High Temperature Strength of Modified 9Cr-1 Mo Steels, ISIJ Int., 1995, 35(1), p 86–91

M. Hättestrand and H.-O. Andrén, Boron Distribution in 9–12% Chromium Steels, Mater. Sci. Eng., A, 1999, 270(1), p 33–37

T. Horiuchi, M. Igarashi, and F. Abe, Improved Utilization of Added B in 9Cr Heat-Resistant Steel Containing W, ISIJ Int., 2002, 42(Supplement), p S67–S71

K. Coleman and W. Newell, P91 and Beyond, Weld. J. N. Y., 2007, 86, p 29–33

G. Sainath, B.K. Choudhary, J. Christopher, E. Isaac Samuel, and M.D. Mathew, Effects of Temperature and Strain Rate on Tensile Stress-Strain and Workhardening Behaviour of P92 Ferritic Steel, Mater. Sci. Technol., 2014, 30(8), p 911–920

D.J. Michel, J. Moteff, and A.J. Lovell, Substructure of Type 316 Stainless Deformed in Slow Tension at Temperatures between 21° and 816 °C, Acta Metall., 1973, 21, p 1269–1277

B.P. Kashyap, K. McTaggart, and K. Tangri, Study on the Substructure Evolution and Flow Behaviour in Type 316L Stainless Steel over the Temperature Range 21–900 °C, Philos. Mag. A, 1988, 57(1), p 97–114

J.W. Edingtont and R.E. Smallman, The Relationship Between Flow Stress and Dislocation in Deformed Vanadium, Acta Metall., 1964, 12, p 1313–1328

D.J. Dingley and D. McLean, Components of Iron, Acta Metall., 1967, 15, p 885–901

A.M. Garde, A.T. Santhanam, and R.E. Reed-Hill, The Significance of Dynamic Strain Aging in Titanium, Acta Metall., 1972, 20(2), p 215–220

J.G. Morris, Dynamic Strain Aging in Aluminum Alloys, Mater. Sci. Eng., 1974, 13(2), p 101–108

S. Okamoto, D.K. Matlock, and G. Krauss, The Transition from Serrated to Non-Serrated Flow in Low-Carbon Martensite at 150 °C, Scr. Metall. Mater., 1991, 25(1), p 39–44

G.B. Holloway, Z. Zhang, and A. Marshall, Properties of T/P92 CrMo Weld Metals for Ultra Super Critical (USC) Power Plant, Int. J. Microstruct. Mater. Prop., 2011, 6(1/2), p 20–39

Acknowledgments

The authors wish to express their gratitude to METRODE PRODUCTS LTD—UK for the design, fabrication and donation of the consumable used, to CONARCO-ESAB Argentina for performing the chemical analysis, to AIR LIQUIDE Argentina for donating gases for welding and to the SCANNING ELECTRON MICROSCOPY LABORATORY OF INTI-Mechanics, Argentina, for facilities for both SEM analysis and Charpy-V tests. They also recognize CONICET, ANPCyT and APUEMFI (National University of Lomas de Zamora), Argentina, for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Burgos, A., Svoboda, H., Zhang, Z. et al. Alternative PWHT to Improve High-Temperature Mechanical Properties of Advanced 9Cr Steel Welds. J. of Materi Eng and Perform 27, 6328–6338 (2018). https://doi.org/10.1007/s11665-018-3736-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3736-5