Abstract

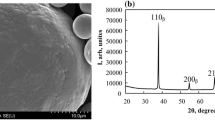

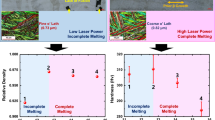

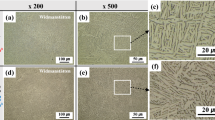

In this study, Ti6Al4V alloy was produced via laser powder deposition (LPD). To obtain Ti6Al4V alloy with maximum density, LPD parameters for preparing Ti6Al4V samples were optimized using the Taguchi method. Results were analyzed on the basis of the signal-to-noise (S/N) ratios and analyses of variance. A high energy density should be used to achieve higher levels of densification. The optimal combination of parameters for density was a scanning speed of 550 mm/min, laser power of 160 W, powder feeding rate of 0.99 g/min, and shield gas flow of 8 L/min. An almost fully dense Ti6Al4V sample was prepared using the optimized LPD process, and the relative density was greater than 99%. In addition, the microstructure and properties of Ti6Al4V samples prepared by optimized LPD process were investigated. The microstructure investigation revealed that the LPD-prepared Ti6Al4V sample was predominantly composed of fine acicular α phase and lath-type α phase. Tensile and microhardness tests indicated that the LPD sample had higher mechanical properties than the traditional cast Ti6Al4V alloy because of the acicular martensitic phase and smaller grain size.

Similar content being viewed by others

References

H.S. Tran, J.T. Tchuindjang, H. Paydas, A. Mertens, R.T. Jardin, L. Duchêne, R. Carrus, J. Lecomte-Beckers, and A.M. Habraken, 3D Thermal Finite Element Analysis of Laser Cladding Processed Ti-6Al-4V Part with Microstructural Correlations, Mater. Des., 2017, 128, p 130–142. https://doi.org/10.1016/j.matdes.2017.04.092

J. Sun, Y. Yang, and D. Wang, Parametric Optimization of Selective Laser Melting for Forming Ti6Al4V Samples by Taguchi Method, Opt. Laser Technol., 2013, 49, p 118–124. https://doi.org/10.1016/j.optlastec.2012.12.002

J. Liu, X.L. Gao, L.J. Zhang, and J.X. Zhang, Effects of the Heterogeneity in the Electron Beam Welded Joint on Mechanical Properties of Ti6Al4V Alloy, J. Mater. Eng. Perform., 2015, 24(1), p 319–328

J. Lu, L. Chang, J. Wang, L. Sang, S. Wu, and Y. Zhang, In-Situ Investigation of the Anisotropic Mechanical Properties of Laser Direct Metal Deposition Ti6Al4V Alloy, Mater. Sci. Eng. A, 2018, 712, p 199–205. https://doi.org/10.1016/j.msea.2017.11.106

C. Pirozzi, S. Franchitti, R. Borrelli, F. Caiazzo, V. Alfieri, and P. Argenio, Study on the Factors Affecting the Mechanical Behavior of Electron Beam Melted Ti6Al4V, J. Mater. Eng. Perform., 2017, 26(9), p 4491–4499

A.J. Sterling, B. Torries, N. Shamsaei, S.M. Thompson, and D.W. Seely, Fatigue Behavior and Failure Mechanisms of Direct Laser Deposited Ti-6Al-4V, Mater. Sci. Eng. A, 2016, 655, p 100–112. https://doi.org/10.1016/j.msea.2015.12.026

X. Tan, Y. Kok, Y.J. Tan, M. Descoins, D. Mangelinck, S.B. Tor, K.F. Leong, and C.K. Chua, Graded Microstructure and Mechanical Properties of Additive Manufactured Ti-6Al-4V via Electron Beam Melting, Acta Mater., 2015, 97, p 1–16. https://doi.org/10.1016/j.actamat.2015.06.036

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, and B.E. Stucker, Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting, J. Mater. Eng. Perform., 2013, 22(12), p 3872–3883. https://doi.org/10.1007/s11665-013-0658-0

A. Crespo and R. Vilar, Finite Element Analysis of the Rapid Manufacturing of Ti-6Al-4V Parts by Laser Powder Deposition, Scr. Mater., 2010, 63(1), p 140–143

Y.J. Liang, D. Liu, and H.M. Wang, Microstructure and Mechanical Behavior of Commercial Purity Ti/Ti-6Al-2Zr-1Mo-1V Structurally Graded Material Fabricated by Laser Additive Manufacturing, Scr. Mater., 2014, 74, p 80–83. https://doi.org/10.1016/j.scriptamat.2013.11.002

M. Iebba, A. Astarita, D. Mistretta, I. Colonna, M. Liberini, F. Scherillo, C. Pirozzi, R. Borrelli, S. Franchitti, and A. Squillace, Influence of Powder Characteristics on Formation of Porosity in Additive Manufacturing of Ti-6Al-4V Components, J. Mater. Eng. Perform., 2017, 26(8), p 4138–4147

Y. Liu, C. Liu, W. Liu, Y. Ma, C. Zhang, Q. Cai, and B. Liu, Microstructure and Properties of Ti/Al Lightweight Graded Material by Direct Laser Deposition, Mater. Sci. Technol., 2017, https://doi.org/10.1080/02670836.2017.1412042

Y.Z. Zhang, C. Meacock, and R. Vilar, Laser Powder Micro-Deposition of Compositional Gradient Ti-Cr Alloy, Mater. Des., 2010, 31(8), p 3891–3895. https://doi.org/10.1016/j.matdes.2010.02.052

X. Wang, D. Deng, H. Yi, H. Xu, S. Yang, and H. Zhang, Influences of Pulse Laser Parameters on Properties of AISI316L Stainless Steel Thin-Walled Part by Laser Material Deposition, Opt. Laser Technol., 2017, 92, p 5–14. https://doi.org/10.1016/j.optlastec.2016.12.021

M.S. Sawant and N.K. Jain, Characteristics of Single-Track and Multi-Track Depositions of Stellite by Micro-Plasma Transferred Arc Powder Deposition Process, J. Mater. Eng. Perform., 2017, 26(8), p 4029–4039

U.S. Bertoli, A.J. Wolfer, M.J. Matthews, J.P.R. Delplanque, and J.M. Schoenung, On the Limitations of Volumetric Energy Density as a Design Parameter for Selective Laser Melting, Mater. Des., 2017, 113, p 331–340. https://doi.org/10.1016/j.matdes.2016.10.037

R.M. Mahamood and E.T. Akinlabi, Scanning Speed Influence on the Microstructure and Micro Hardness Properties of Titanium Alloy Produced by Laser Metal Deposition Process, Mater. Today Proc., 2017, 4(4), p 5206–5214. https://doi.org/10.1016/j.matpr.2017.05.028

H. Ali, H. Ghadbeigi, and K. Mumtaz, Effect of Scanning Strategies on Residual Stress and Mechanical Properties of Selective Laser Melted Ti6Al4V, Mater. Sci. Eng. A, 2017, 712, p 175–187. https://doi.org/10.1016/j.msea.2017.11.103

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck, and J.P. Kruth, A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V, Acta Mater., 2010, 58(9), p 3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

B.A.E. Ben-Arfa, I.M.M. Salvado, J.R. Frade, and R.C. Pullar, Fast Route for Synthesis of Stoichiometric Hydroxyapatite by Employing the Taguchi Method, Mater. Des., 2016, 109, p 547–555. https://doi.org/10.1016/j.matdes.2016.07.083

M. Tutar, H. Aydin, C. Yuce, N. Yavuz, and A. Bayram, The Optimisation of Process Parameters for Friction Stir Spot-Welded AA3003-H12 Aluminium Alloy Using a Taguchi Orthogonal Array, Mater. Des., 2014, 63, p 789–797. https://doi.org/10.1016/j.matdes.2014.07.003

N. Read, W. Wang, K. Essa, and M.M. Attallah, Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development, Mater. Des., 2015, 65, p 417–424. https://doi.org/10.1016/j.matdes.2014.09.044

S. Hong, Y. Wu, B. Wang, Y. Zheng, W. Gao, and G. Li, High-Velocity Oxygen-Fuel Spray Parameter Optimization of Nanostructured WC-10Co-4Cr Coatings and Sliding Wear Behavior of the Optimized Coating, Mater. Des., 2014, 55, p 286–291. https://doi.org/10.1016/j.matdes.2013.10.002

Siddhartha, A. Patnaik, and A.D. Bhatt, Mechanical and Dry Sliding Wear Characterization of Epoxy-TiO2 Particulate Filled Functionally Graded Composites Materials Using Taguchi Design of Experiment, Mater. Des., 2011, 32(2), p 615–627. https://doi.org/10.1016/j.matdes.2010.08.011

Y. Qin, Y. Wu, J. Zhang, S. Hong, W. Guo, L. Chen, and H. Liu, Optimization of the HOVF Spray Parameters by Taguchi Method for High Corrosion-Resistant Fe-Based Coatings, J. Mater. Eng. Perform., 2015, 24(7), p 2637–2644

X. Lin, T.M. Yue, H.O. Yang, and W.D. Huang, Microstructure and Phase Evolution in Laser Rapid Forming of a Functionally Graded Ti-Rene88DT Alloy, Acta Mater., 2006, 54(7), p 1901–1915

Y. Li, H. Yang, X. Lin, W. Huang, J. Li, and Y. Zhou, The Influences of Processing Parameters on Forming Characterizations during Laser Rapid Forming, Mater. Sci. Eng. A, 2003, 360(1–2), p 18–25

Y. Li, Y. Hu, W. Cong, L. Zhi, and Z. Guo, Additive Manufacturing of Alumina Using Laser Engineered Net Shaping: Effects of Deposition Variables, Ceram. Int., 2017, 43(10), p 7768–7775

H. Attar, S. Ehtemam-Haghighi, D. Kent, X. Wu, and M.S. Dargusch, Comparative Study of Commercially Pure Titanium Produced by Laser Engineered Net Shaping, Selective Laser Melting and Casting Processes, Mater. Sci. Eng. A, 2017, 705, p 385–393. https://doi.org/10.1016/j.msea.2017.08.103

K. Nandagopal and C. Kailasanathan, Analysis of Mechanical Properties and Optimization of Gas Tungsten Arc Welding (GTAW) Parameters on Dissimilar Metal Titanium (6Al-4V) and Aluminium 7075 by Taguchi and ANOVA Techniques, J. Alloys Compd., 2016, 682, p 503–516. https://doi.org/10.1016/j.jallcom.2016.05.006

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, and A.M. Rubenchik, Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing, J. Mater. Process. Technol., 2014, 214(12), p 2915–2925. https://doi.org/10.1016/j.jmatprotec.2014.06.005

H. Albetran, Y. Dong, and I.M. Low, Characterization and Optimization of Electrospun TiO2/PVP Nanofibers Using Taguchi Design of Experiment Method, J. Asian Ceram. Soc., 2015, 3(3), p 292–300. https://doi.org/10.1016/j.jascer.2015.05.001

S.N. Li, H.P. Xiong, N. Li, B.Q. Chen, C. Gao, W.J. Zou, and H.S. Ren, Mechanical Properties and Formation Mechanism of Ti/SiC System Gradient Materials Fabricated by In-Situ Reaction Laser Cladding, Ceram. Int., 2017, 43(1), p 961–967

Acknowledgments

Financial support from the State Key Basic Research Program of China (Grant No. 61XXXX02) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Liu, C., Liu, W. et al. Laser Powder Deposition Parametric Optimization and Property Development for Ti-6Al-4V Alloy. J. of Materi Eng and Perform 27, 5613–5621 (2018). https://doi.org/10.1007/s11665-018-3708-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3708-9