Abstract

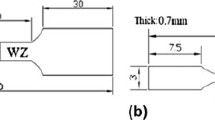

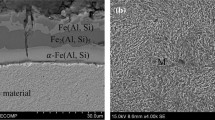

Laser welding–brazing of 6061-T6 aluminum alloy to DP590 dual-phase steel with Al-Si12 flux-cored filler wire was performed. The microstructure at the brazing interface was characterized. Fracture behavior was observed and analyzed by in situ scanning electron microscope. The microstructure of the brazing interface showed that inhomogeneous intermetallic compounds formed along the thickness direction, which had a great influence on the crack initiation and propagation. In the top region, the reaction layer at the interface consisted of scattered needle-like Fe(Al,Si)3 and serration-shaped Fe1.8Al7.2Si. In the middle region, the compound at the interface was only serration-shaped Fe1.8Al7.2Si. In the bottom region, the interface was composed of lamellar-shaped Fe1.8Al7.2Si. The cracks were first detected in the bottom region and propagated from bottom to top along the interface. At the bottom region, the crack initiated and propagated along the Fe1.8Al7.2Si/weld seam interface during the in situ tensile test. When the crack propagated into the middle region, a deflection of crack propagation appeared. The crack first propagated along the steel/Fe1.8Al7.2Si interface and then moved along the weld seam until the failure of the joint. The tensile strength of the joint was 146.5 MPa. Some micro-cracks were detected at Fe(Al,Si)3 and the interface between the steel substrate and Fe(Al,Si)3 in the top region while the interface was still connected.

Similar content being viewed by others

References

Y. Zheng, J.H. Huang, W. Gao et al., Combined Effects of MIG and TIG Arcs on Weld Appearance and Interface Properties in Al/Steel Double-Sided Butt Welding-Brazing, J. Mater. Process. Technol., 2017, 250, p 25–34

M. Masoud, N. Yazdian, H.P. Wang et al., Effect of Filler Wire Composition on Performance of Al/Galvanized Steel Joints by Twin Spot Laser Welding-Brazing Method, J. Manuf. Process., 2018, 31, p 20–34

Y. Yu, H.H. Ma, K. Zhao et al., Study on Underwater Explosive Welding of Al-Steel Coaxial Pipes, Cent. Eur. J. Energ. Mater., 2017, 14(1), p 251–265

P. Joaquin, M. Svoboda, G. Hernan et al., Tool Geometry Optimization in Friction Stir Spot Welding of Al-Steel Joints, J. Manuf. Process., 2017, 26, p 142–154

J.L. Yang, S.B. Xue, P. Xue et al., Development of Zn-15Al-xZr Filler Metals for Brazing 6061 Aluminum Alloy to Stainless Steel, Mater. Sci. Eng., A, 2016, 651, p 425–434

J. Yang, Y. Li, H. Zhang et al., Microstructure and Mechanical Properties of Pulsed Laser Welded Al/Steel Dissimilar Joint, Trans. Nonferrous Met. Soc. China, 2016, 26, p 994–1002

M. Masoud, Y. Nima, Y. Guang et al., Effect of Dual Laser Beam on Dissimilar Welding-Brazing of Aluminum to Galvanized Steel, Opt. Laser Technol., 2018, 98, p 214–228

J.H. Sun, J. Huang, Q. Yan et al., Fiber Laser Butt Joining of Aluminum to Steel Using Welding-Brazing Method, Int. J. Adv. Manuf. Technol., 2016, 85, p 9–12

B. Sushovan, D. Hrishikesh, P.T. Kumar et al., Characterization of Intermetallics in Aluminum to Zinc Coated Interstitial Free Steel Joining by Pulsed MIG Brazing for Automotive Application, Mater. Charact., 2016, 112, p 229–237

M.J. Zhang, G.Y. Chen, Y. Zhang et al., Research on Microstructure and Mechanical Properties of Laser Keyhole Welding-Brazing of Automotive Galvanized to Aluminum Alloy, Mater. Des., 2013, 45(6), p 24–30

H. Ozaki and M. Kutsuna, Dissimilar Metal Joining of Zinc Coated Steel and Aluminum Alloy Laser Roll Welding, Weld. Process., 2012, https://doi.org/10.5772/48242

M.J. Torkamany, S. Tahamtan, and J. Sabbaghzadeh, Dissimilar Welding of Carbon Steel to 5754 Aluminum Alloy by Nd:YAG Pulsed Laser, Mater. Des., 2010, 31(1), p 458–465

V. Soundararajan, E. Yarrapareddy, and R. Kovacevic, Investigation of the Friction Stir Lap Welding of Aluminum Alloys AA 5182 and AA 6022, J. Mater. Eng. Perform., 2007, 16(4), p 477–484

S. Meco, S.G. Stewart, W. Norman et al., Effect of Laser Processing Parameters on the Formation of Intermetallic Compounds in Fe-Al Dissimilar Welding, J. Mater. Eng. Perform., 2014, 23(9), p 3361–3370

Y.B. Chen, S.H. Chen, L.Q. Li et al., Influence of Interfacial Reaction Layer Morphologies on Crack Initiation And Propagation in Ti/Al Joint by Laser Welding-Brazing, Mater. Des., 2010, 31(1), p 227–233

R. Qiu, S. Satonaka, C. Iwamoto et al., Effect of Interfacial Reaction Layer Continuity on the Tensile Strength of Resistance Spot Welded Joints Between Aluminum Alloy and Steels, Mater. Des., 2009, 30(9), p 3686–3689

H. Springer, A. Kostka, E.J. Payton et al., On the Formation and Growth of Intermetallic Phases During Inter Diffusion Between Low-Carbon Steel and Aluminum Alloys, Acta Mater., 2010, 59(4), p 1586–1600

X.M. Meng, G.L. Qin, Y.H. Su et al., Numerical Simulation of Large Spot Laser Plus MIG Arc Brazing-Fusion Welding of Al Alloy to Galvanized Steel, J. Mater. Process. Technol., 2017, 222, p 307–314

J.L. Song, S.B. Lin, C.L. Yang et al., Effects of Si Additions on Intermetallic Compound Layer of Aluminum-Steel TIG Welding-Brazing Joint, J. Alloys Compd., 2009, 488(1), p 217–222

L.Q. Li, D.J. Liu, Y.B. Chen et al., Electron Microscope Study of Reaction Layers Between Single-Crystal WC Particles and Ti-6Al-4 V After Laser Melt Injection, Acta Mater., 2009, 57(12), p 3606–3614

D. Akbari, M. Farahani, N. Soltani et al., Effect of the Weld Groove Shape and Geometry on Residual Stresses in Dissimilar Butt-Welded Pipes, J. Strain Anal., 2011, 47(2), p 73–82

J.L. Song, S.B. Lin, C.L. Yang et al., Analysis of Intermetallic Layer in Dissimilar TIG Welding-Brazing Butt Joint of Aluminium Alloy to Stainless Steel, Sci. Technol. Weld. Join., 2010, 15(3), p 213–218

A. Mathieu, R. Shabadi, A. Deschamps et al., Dissimilar Material Joining Using Laser (Aluminum to Steel Using Zinc-Based Filler Wire), Opt. Laser Technol., 2007, 39(3), p 652–661

Acknowledgment

The research was financially supported by National Natural Science Foundation of China (Grant No. 51504074), Key Research and Development Program in Shandong Province (Grant Nos. 2017GGX30147 and 2017CXGC0811), and China Postdoctoral Science Special Foundation (2016T90280).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xia, H., Tan, C., Li, L. et al. In Situ SEM Observations of Fracture Behavior of Laser Welded–Brazed Al/Steel Dissimilar Joint. J. of Materi Eng and Perform 27, 1047–1057 (2018). https://doi.org/10.1007/s11665-018-3227-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3227-8