Abstract

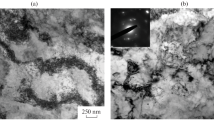

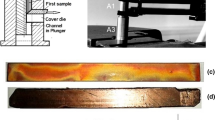

The uniaxial ratcheting behavior of ultrafine-grained pure Cu processed by equal-channel angular pressing (ECAP) was investigated through uniaxial asymmetric cyclic stress-controlled experiments at room temperature. The effects of the mean stress and stress amplitude on the uniaxial ratcheting response and ratcheting life of the ECAP Cu were analyzed. With increasing mean stress or stress amplitude, the ratcheting strain and its rate increased, but the ratcheting life decreased. An approach based on Basquin’s method was used to describe the fatigue lifetime of the ECAP pure Cu. Additionally, a power law relationship was adopted to describe the cyclic steady creep rate. Finally, the microscopic and macroscopic fracture features were examined. It was found that at high peak stresses, cyclic creep governs the overall failure process; otherwise, cyclic creep-fatigue interaction is the dominant failure mode.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater Sci., 2000, 45, p 103–189

W. Blum, Y.J. Li, Y. Zhang, and J.T. Wang, Deformation Resistance in the Transition from Coarse-Grained to Ultrafine-Grained Cu by Severe Plastic Deformation up to 24 Passes of ECAP, Mater. Sci. Eng. A, 2011, 528, p 8621–8627

C. Xu, Z. Horita, and T.G. Langdon, Microstructural Evolution in an Aluminum Alloy Processed by ECAP, Mater. Sci. Eng. A, 2011, 528, p 6059–6065

H.W. Hoppel, M. Kautz, C. Xu, M. Murashkin, T.G. Langdon, R.Z. Valiev, and H. Mughrabi, An Overview: Fatigue Behavior of Ultrafine-Grained Metals and Alloys, Int. J. Fatigue, 2006, 28, p 1001–1010

S.K. Paul, S. Sivaprasad, S. Dhar, and S. Tarafder, Cyclic Plastic Deformation and Damage in 304LN Stainless Steel, Mater. Sci. Eng. A, 2011, 528, p 4873–4882

A. Satyadevi, S.M. Sivakunar, and S.S. Bhattacharya, A New Failure Criterion for Materials Exhibiting Ratcheting During Very Low Cycle Fatigue, Mater. Sci. Eng. A, 2007, 452-453, p 380–385

S.R. Agnew, A.Y. Vinofradov, S. Hashimoto, and J.R. Weertman, Overview of Fatigue Performance of Cu Processed by Severe Plastic Deformation, J. Electronic Mater., 1999, 28, p 1038–1044

G. Kang, Y. Liu, Y. Dong, and Q. Gao, Uniaxial Ratcheting Behaviors of Metals with Different Crystal Structures or Values of Fault Energy: Macroscopic Experiments, J. Mater. Sci. Technol., 2011, 27, p 453–459

S.K. Paul, S. Sivaprasad, S. Dhar, and S. Tarafder, Ratcheting and Low Cycle Fatigue Behavior of SA333 Steel and Their Life Prediction, J. Nuclear Nater., 2010, 401, p 17–24

L. Kunz, Mechanical Properties of Copper Processed by Severe Plastic Deformation, Copper Alloy-Early Applications and Current Performance-Enhancing Processes, L. Collini, Ed., In Tech, Croatia, 2012, p 93–126

Q.S. Pan, Q.H. Lu, and K. Lu, Fatigue Behavior of Columnar-Grained Cu with Preferentially Orientated Nanoscale Twins, Acta Mater., 2013, 61, p 1383–1393

S.R. Agnew and J.R. Weertman, Cyclic Softening of Ultrafine Grain Copper, Mater. Sci. Eng. A, 1998, 244, p 145–153

Y. Jiang and J. Zhang, Benchmark Experiments and Characteristic Cyclic Plasticity Deformation, Int. J. Plasticity, 2008, 24, p 1481–1515

Y.C. Lin, X.M. Chen, Z.H. Liu, and J. Chen, Investigation of Uniaxial Low-Cycle Fatigue Failure Behavior of Hot-Rolled AZ91 Magnesium Alloy, Int. J. Fatigue, 2013, 18, p 122–132

Y.C. Lin, Z.H. Liu, X.M. Chen, and J. Chen, Uniaxial Ratcheting and Fatigue Failure Behaviors of Hot-Rolled AZ31B Magnesium Alloy Under Asymmetrical Cyclic Stress-Controlled Loadings, Mater. Sci. Eng. A, 2013, 573, p 234–244

C. Li, G. Chen, X. Chen, and W. Zhang, Ratcheting Strain and Simulation of 16MnR Steel Under Uniaxial Cyclic Loading, Comput. Mater. Sci., 2012, 57, p 43–47

Y.C. Lin, Z.H. Liu, X.M. Chen, and J. Chen, Stress-Based Fatigue Life Prediction Models for AZ31B Magnesium Alloy Under Single-Step and Multi-Step Asymmetric Stress-Controlled Cyclic Loadings, Comput. Mater. Sci., 2013, 73, p 128–138

J.D. Morrow, Cyclic Plastic Strain Energy and Fatigue of Metals, ASTM STP, 1964, 378, p 45–87

S. Kwofie, An Exponential Stress Function for Predicting Fatigue Strength and Life Due to Mean Stresses, Int. J. Fatigue, 2001, 23, p 829–836

S. Suresh, Fatigue of Materials, Cambridge University Press, Cambridge, 1998

S. Kwofie and H.D. Chandler, Fatigue Life Prediction Under Conditions Where Cyclic Creep-Fatigue Interaction Occurs, Int. J. Fatigue, 2007, 29, p 2117–2124

S. Kwofie, Cyclic Creep of Copper Due to Axial Cyclic and Tensile Mean Stresses, Mater. Sci. Eng. A, 2006, 427, p 263–267

R.Z. Valiev, E.V. Kozlov, Y.F. Ivalov, J. Lian, and A. Nazarov, Deformation Behavior of Ultra-Fine-Grained Copper, Acta Metall. Mater., 1994, 42, p 2467–2475

M. Martin, A. Mishra, M.A. Meyers, and N.N. Thadhani, Instrumented Anvil-on-Rod Tests for Constitutive Model Validation and Determination of Strain-Rate Sensitivity of Ultrafine-Grained Copper, Mater. Sci. Eng. A, 2007, 464, p 202–209

I. Savirov, M.R. Barnett, Y. Estrin, and P.D. Hodgson, The Effect of Strain Rate on the Deformation Mechanisms and the Strain Rate Sensitivity of an Ultra-Fine-Grained Al Alloy, Scr. Mater., 2009, 61, p 181–184

K.S. Han and H. Margolin, Void Formation, Void Growth and Tensile Fracture of Plain Carbon Steel and a Dual-Phase Steel, Mater. Sci. Eng., A, 1989, 112, p 133–141

Acknowledgments

This work was financially supported by Natural Science Foundation of Jiangsu Province (No. BK20161582), Jiangsu Overseas Research & Training Program for University Prominent Young & Middle-aged Teachers and Presidents, and Scientific Research Foundation of the Nanjing Communications Institute of Technology, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Y., Yang, J., Shen, X. et al. Cyclic Creep of Ultrafine-Grained Pure Cu Under Cyclic Tension Deformation. J. of Materi Eng and Perform 26, 837–842 (2017). https://doi.org/10.1007/s11665-017-2500-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2500-6