Abstract

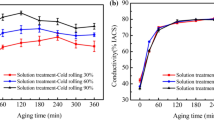

A combination of high strength and good ductility was achieved in a precipitation hardenable Cu-3Ag-0.5Zr alloy through cryo-rolling (80% reduction in thickness) and aging in the temperature range (200-500 °C). The high-strength sheets produced by cryo-rolling showed a threefold increase in yield strength compared to that of the solution-treated and aged (220 MPa) sample, while retaining good ductility. An optimum combination of high strength (614 MPa) and ductility (8%) was achieved by 80% cryo-rolling and aging at 320 °C for 1 h. The high strength and good ductility obtained was attributed to various microstructural factors such as deformation twins, ultra-fine grains, high dislocation density and fine nano-sized silver precipitates.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45, p 103–189. doi:10.1016/S0079-6425(99)00007-9

D.J. Alexander, New Methods for Severe Plastic Deformation Processing, J. Mater. Eng. Perform., 2007, 16, p 360–374. doi:10.1007/s11665-007-9054-y

S.K. Panigrahi, R. Jayaganthan, and V. Chawla, Effect of Cryorolling on Microstructure of Al-Mg-Si Alloy, Mater. Lett., 2008, 62, p 2626–2629. doi:10.1016/j.matlet.2008.01.003

V.S. Sarma, J. Wang, W.W. Jian, A. Kauffmann, H. Conrad, J. Freudenberger et al., Role of Stacking Fault Energy in Strengthening due to Cryo-Deformation of FCC Metals, Mater. Sci. Eng. A, 2010, 527, p 7624–7630. doi:10.1016/j.msea.2010.08.015

T. Shanmugasundaram, B.S. Murty, and Sarma V. Subramanya, Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling, Scr. Mater., 2006, 54, p 2013–2017. doi:10.1016/j.scriptamat.2006.03.012

J.K. Kim, H.G. Jeong, S.I. Hong, Y.S. Kim, and W.J. Kim, Effect of Aging Treatment on Heavily Deformed Microstructure of a 6061 Aluminum Alloy After Equal Channel Angular Pressing, Scr. Mater., 2001, 45, p 901–907. doi:10.1016/S1359-6462(01)01109-5

S. Nagarjuna, U. Chinta Babu, and P. Ghosal, Effect of Cryo-Rolling on Age Hardening of Cu-1.5Ti Alloy, Mater. Sci. Eng. A, 2008, 491, p 331–337. doi:10.1016/j.msea.2008.02.014

S. Cheng, Y.H. Zhao, Y.T. Zhu, and E. Ma, Optimizing the Strength and Ductility of Fine Structured 2024 Al Alloy by Nano-precipitation, Acta Mater., 2007, 55, p 5822–5832. doi:10.1016/j.actamat.2007.06.043

C. Zhu, A. Ma, J. Jiang, X. Li, D. Song, D. Yang et al., Effect of ECAP Combined Cold Working on Mechanical Properties and Electrical Conductivity of Conform-Produced Cu-Mg Alloys, J. Alloys Compd., 2014, 582, p 135–140. doi:10.1016/j.jallcom.2013.08.007

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Strength and Ductility of Ultrafine Grained Aluminum and Iron Produced by ARB and Annealing, Scr. Mater., 2002, 47, p 893–899. doi:10.1016/S1359-6462(02)00282-8

Y.M. Wang, E. Ma, and M.W. Chen, Enhanced Tensile Ductility and Toughness in Nanostructured Cu, Appl. Phys. Lett., 2002, 80, p 2395. doi:10.1063/1.1465528

C.J. Luis, R. Luri, J. León, I. Puertas, D. Salcedo, and I. Pérez. Development of Nanostructured AA3103 by Equal Channel Angular Pressing and Thermal Treatments 2014, 2014

B. Gopi and N.N. Krishna, Influence of Rolling Temperature on Microstructure and Mechanical Properties of Cryorolled Al-Mg-Si Alloy. World Acad. Sci. Eng. Technol., 2012, 61, p. 731–735

S. Farè, N. Lecis, and M. Vedani, Aging Behaviour of Al-Mg-Si Alloys Subjected to Severe Plastic Deformation by ECAP and Cold Asymmetric Rolling, J. Metall., 2011, 2011, p 1–8. doi:10.1155/2011/959643

H. Miura, T. Sakai, S. Maruoka, and J.J. Jonas, Production of Recrystallized Nano-grains in a Fine-grained Cu-Zn Alloy, Philos. Mag. Lett., 2010, 90, p 93–101. doi:10.1080/09500830903459648

K. Neishi, T. Uchida, A. Yamauchi, K. Nakamura, Z. Horita, and T.G. Langdon, Low-Temperature Superplasticity in a Cu-Zn-Sn Alloy Processed by Severe Plastic Deformation, Mater. Sci. Eng. A, 2001, 307, p 23–28

A. Gaganov, J. Freudenberger, E. Botcharova, and L. Schultz, Effect of Zr Additions on the Microstructure, and the Mechanical and Electrical Properties of Cu-7 wt%Ag Alloys, Mater. Sci. Eng. A, 2006, 437, p 313–322. doi:10.1016/j.msea.2006.07.121

X.H. An, W.Z. Han, C.X. Huang, P. Zhang, G. Yang, S.D. Wu et al., High Strength and Utilizable Ductility of Bulk Ultrafine-Grained Cu-Al Alloys, Appl. Phys. Lett., 2008, 92, p 201915. doi:10.1063/1.2936306

H. Bahmanpour, A. Kauffmann, M.S. Khoshkhoo, K.M. Youssef, S. Mula, J. Freudenberger et al., Effect of Stacking Fault Energy on Deformation Behavior of Cryo-Rolled Copper and Copper Alloys, Mater. Sci. Eng. A, 2011, 529, p 230–236. doi:10.1016/j.msea.2011.09.022

V.S. Sarma, K. Sivaprasad, D. Sturm, and M. Heilmaier, Microstructure and Mechanical Properties of Ultra Fine Grained Cu-Zn and Cu-Al Alloys Produced by Cryorolling and Annealing, Mater. Sci. Eng. A, 2008, 489, p 253–258

D. Witkin, Z. Lee, R. Rodriguez, S. Nutt, and E. Lavernia, Al-Mg Alloy Engineered with Bimodal Grain Size for High Strength and Increased Ductility, Scr. Mater., 2003, 49, p 297–302. doi:10.1016/S1359-6462(03)00283-5

Y.M. Wang and E. Ma, Three Strategies to Achieve Uniform Tensile Deformation in a Nanostructured Metal, Acta Mater., 2004, 52, p 1699–1709. doi:10.1016/j.actamat.2003.12.022

Y. Zhao, T. Topping, J.F. Bingert, J.J. Thornton, A.M. Dangelewicz, Y. Li et al., High Tensile Ductility and Strength in Bulk Nanostructured Nickel, Adv. Mater., 2008, 20, p 3028–3033. doi:10.1002/adma.200800214

E. Ma, Eight Routes to Improve the Tensile Ductility of Bulk Nanostructured Metals and Alloys, JOM, 2006, 58, p 49–53. doi:10.1007/s11837-006-0215-5

Y.G. Ko, S. Namgung, B.U. Lee, and D.H. Shin, Mechanical and Electrical Responses of Nanostructured Cu-3wt%Ag Alloy Fabricated by ECAP and Cold Rolling, J. Alloys Compd., 2010, 504, p S448–S451. doi:10.1016/j.jallcom.2010.02.198

Z. Horita, K. Ohashi, T. Fujita, K. Kaneko, and T.G. Langdon, Achieving High Strength and High Ductility in Precipitation-Hardened Alloys, Adv. Mater., 2005, 17, p 1599–1602. doi:10.1002/adma.200500069

S. Nagarjuna, U. Chinta Babu, and P. Ghosal, Effect of Cryo-Rolling on Age Hardening of Cu-1.5Ti Alloy, Mater. Sci. Eng. A, 2008, 491, p 331–337. doi:10.1016/j.msea.2008.02.014

T. Akita, K. Kitagawa, K. Kita, M. Gotoh, Y. Hirose, and N. Tsuji, High Performance of Mechanical and Electrical Properties of Cu-Cr-Zr Alloy Sheets Produced by ARB Process and Additional Thermo-Mechanical Treatment, J. Phys. Conf. Ser., 2010, 240, p 012119. doi:10.1088/1742-6596/240/1/012119

K. Sitarama Raju, V. Subramanya Sarma, A. Kauffmann, Z. Hegedus, J. Gubicza, M. Peterlechner et al., High Strength and Ductile Ultrafine-Grained Cu-Ag Alloy Through Bimodal Grain Size, Dislocation Density and Solute Distribution, Acta Mater., 2013, 61, p 228–238. doi:10.1016/j.actamat.2012.09.053

X.-Z. Zhou and Y.-C. Su, A Novel Cu-Ni-Zn-Al Alloy with High Strength Through Precipitation Hardening, Mater. Sci. Eng. A, 2010, 527, p 5153–5156. doi:10.1016/j.msea.2010.04.089

N. Takata, Y. Ohtake, K. Kita, K. Kitagawa, and N. Tsuji, Increasing the Ductility of Ultrafine-Grained Copper Alloy by Introducing Fine Precipitates, Scr. Mater., 2009, 60, p 590–593. doi:10.1016/j.scriptamat.2008.12.018

S.C. Krishna, K. Thomas Tharian, B. Pant, and R.S. Kottada, Age-Hardening Characteristics of Cu-3Ag-0.5Zr Alloy, Mater. Sci. Forum, 2012, 710, p 563–568. doi:10.4028/www.scientific.net/MSF.710.563

H.C. Groh, D.L. Ellis, and W.S. Loewenthal, Comparison of GRCop-84 to other Cu Alloys with High Thermal Conductivities, J. Mater. Eng. Perform., 2007, 17, p 594–606. doi:10.1007/s11665-007-9175-3

S.C. Krishna, N.K. Gangwar, A.K. Jha, B. Pant, and K.M. George, Enhanced Strength in Cu-Ag-Zr Alloy by Combination of Cold Working and Aging, J. Mater. Eng. Perform., 2014, 23, p 1458–1464. doi:10.1007/s11665-014-0882-2

S.C. Krishna, K.T. Tharian, B. Pant, and R.S. Kottada, Microstructure and Mechanical Properties of Cu-Ag-Zr Alloy, J. Mater. Eng. Perform., 2013, 22, p 3884–3889. doi:10.1007/s11665-013-0659-z

S.C. Krishna, N.K. Gangwar, A.K. Jha, B. Pant, and K.M. George, Properties and Strengthening Mechanisms in Cold-Rolled and Aged Cu-3Ag-0.5Zr Alloy, Metallogr. Microstruct. Anal., 2014, 3, p 323–327. doi:10.1007/s13632-014-0147-3

J. Gubicza, N.Q. Chinh, G. Krállics, I. Schiller, and T. Ungár, Microstructure of Ultrafine-Grained FCC Metals Produced by Severe Plastic Deformation, Curr. Appl. Phys., 2006, 6, p 194–199. doi:10.1016/j.cap.2005.07.039

J. Gallego, T.S. Pinheiro, R.Z. Valiev, V. Polyakova, C. Bolfarini, C.S. Kiminami et al., Microstructural Characterization of Ti-6Al-7Nb Alloy After Severe Plastic Deformation, Mater. Res., 2012, 15, p 786–791. doi:10.1590/S1516-14392012005000100

L. Lu, Ultrahigh Strength and High Electrical Conductivity in Copper, Science, 2004, 304, p 422–426. doi:10.1126/science.1092905

J.B. Singh, R. Kapoor, A. Durga-Prasad, and J.K. Chakravartty, Comparison of Microstructures and Strengths of an Al-2.5Mg Alloy Subjected to Severe Plastic Deformation at Room and Liquid Nitrogen Temperatures, Mater Sci Eng A, 2013, 581, p 26–30. doi:10.1016/j.msea.2013.05.073

M. Furukawa, Z. Horita, and T.G. Langdon, Developing Ultrafine Grain Sizes Using Severe Plastic Deformation, 2001, doi:10.1002/1527-2648(200103)3:3<121::AID-ADEM121>3.0.CO;2-V

M. Furukawa, Z. Horita, M. Nemoto, and T. Langdon, The Use of Severe Plastic Deformation for Microstructural Control, Mater. Sci. Eng. A, 2002, 324, p 82–89. doi:10.1016/S0921-5093(01)01288-6

Y.H. Zhao, Y.T. Zhu, X.Z. Liao, Z. Horita, and T.G. Langdon, Tailoring Stacking Fault Energy for High Ductility and High Strength in Ultrafine grained Cu and Its Alloy, Appl. Phys. Lett., 2006, 89, p 121906. doi:10.1063/1.2356310

S.C. Krishna, G.S. Rao, A.K. Jha, B. Pant, and K.M. George, Analysis of Phases and Their Role in Strengthening of Cu-Cr-Zr-Ti Alloy. J. Mater. Eng. Perform., 2015, 24, p 2341–2345. doi:10.1007/s11665-015-1516-Z

S.C. Krishna, A.K. Jha, B. Pant, and K.M. George, Achieving Higher Strength in Cu–Ag–Zr Alloy by Warm/Hot Rolling. Rare Met., 2015. doi:10.1007/s12598-015-0502-9

Acknowledgment

The authors would like to thank Dr. K. Sivan Director, Vikram Sarabhai Space Centre, Trivandrum, India, for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishna, S.C., Chawake, N., Kottada, R.S. et al. High Strength and Good Ductility in Cu-3Ag-0.5Zr Alloy by Cryo-Rolling and Aging. J. of Materi Eng and Perform 26, 350–357 (2017). https://doi.org/10.1007/s11665-016-2419-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2419-3