Abstract

In the present study, the effect of cold deformation on the electrochemical and passive behaviors of pure copper in 0.01 M NaOH solution was investigated. The dislocation density in cold deformation was calculated using a recently developed JAVA-based software, materials analysis using diffraction, based on Rietveld’s whole x-ray pattern fitting methodology. At the thickness reduction of 70%, the microhardness measured as 125.30 HV, which is 1.56 times than that in the annealed pure copper (80.25 HV). Potentiodynamic polarization plots and electrochemical impedance spectroscopy measurements showed that increasing the cold deformation offers better conditions for forming the passive films. In the Mott-Schottky analysis, no evidence for n-type behavior was obtained which indicates that the oxygen vacancies and the copper interstitials did not have any significant population density in the passive films. Also, this analysis revealed that with increasing cold deformation, the acceptor density of the passive films decreased.

Similar content being viewed by others

References

H.R. Ashtiani, M.H. Parsa, and H. Bisadi, Effects of Initial Grain Size on hot Deformation Behavior of Commercial Pure Aluminum, Mater. Des., 2012, 42, p 478–485

R.B. Hmida, S. Thibaud, A. Gilbin, and F. Richard, Influence of the Initial Grain Size in Single Point Incremental Forming Process for Thin Sheets Metal and Microparts: Experimental Investigations, Mater. Des., 2013, 45, p 155–165

Y. Yang, Z. Zhang, X. Li, Q. Wang, and Y. Zhang, The Effects of Grain Size on the Hot Deformation and Processing Map for 7075 Aluminum Alloy, Mater. Des., 2013, 51, p 592–597

L. Karthikeyan and V.S. Kumar, Relationship Between Process Parameters and Mechanical Properties of Friction Stir Processed AA6063-T6 Aluminum Alloy, Mater. Des., 2011, 32, p 3085–3091

S.W. Xu, K. Oh-ishi, S. Kamado, H. Takahashi, and T. Homma, Effects of Different Cooling Rates During Two Casting Processes on the Microstructures and Mechanical Properties of Extruded Mg–Al–Ca–Mn Alloy, Mater. Sci. Eng. A, 2012, 542, p 71–78

S. Pang, G. Wu, W. Liu, M. Sun, Y. Zhang, Z. Liu, and W. Ding, Effect of Cooling Rate on the Microstructure and Mechanical Properties of Sand-Casting Mg–10Gd–3Y–0.5Zr Magnesium Alloy, Mater. Sci. Eng. A, 2013, 562, p 152–160

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45, p 103–189

N.R. Kumar, J.J. Blandin, C. Desrayaud, F. Montheillet, and M. Suéry, Grain Refinement in AZ91 Magnesium Alloy During Thermomechanical Processing, Mater. Sci. Eng. A, 2003, 359, p 150–157

J.A. Wert, N.E. Paton, C.H. Hamilton, and M.W. Mahoney, Grain Refinement in 7075 Aluminum by Thermomechanical Processing, Metall. Trans. A, 1981, 12, p 1267–1276

Y.F. Shen, C.H. Qiu, L. Wang, X. Sun, X.M. Zhao, and L. Zuo, Effects of Cold Rolling on Microstructure and Mechanical Properties of Fe–30Mn–3Si–4Al–0.093C TWIP Steel, Mater. Sci. Eng. A, 2013, 561, p 329–337

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51, p 881–981

A. Hassani and M. Zabihi, High Strain Rate Superplasticity in a Nano-Structured Al–Mg/SiCP Composite Severely Deformed by Equal Channel Angular Extrusion, Mater. Des., 2012, 39, p 140–150

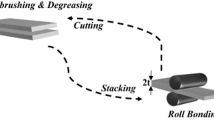

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Novel Ultra-High Straining Process for Bulk Materials Development of the Accumulative Roll-Bonding (ARB) Process, Acta Mater., 1999, 47(2), p 579–583

S. Kaneko, K. Fukuda, H. Utsunomiya, T. Sakai, Y. Saito, and N. Furushiro, Ultra Grain Refinement of Aluminium 1100 by ARB with Cross Rolling, Mater. Sci. Forum, 2003, 426–432, p 2649–2654

N.A. Smirnova, V.I. Levit, V.I. Pilyugin, R.I. Kuznetsov, L.S. Davydova, and V.A. Sazonova, Evolution of Structure of fcc Single Crystals During Strong Plastic Deformation, Phys. Met. Metallogr., 1989, 61(6), p 127–134

V. Varyukhin, Y. Beygelzimer, R. Kulagin, O. Prokof’eva, and A. Reshetov, Twist Extrusion: Fundamentals and Applications, Mater. Sci. Forum, 2011, 667–669, p 31–37

S. Amirkhanlou, M. Askarian, M. Ketabchi, N. Azimi, N. Parvin, and F. Carreño, Gradual Formation of Nano/Ultrafine Structure Under Accumulative Press Bonding (APB) Process, Mater. Charact., 2015, 109, p 57–65

Z.W. Wu, J. Chen, N. Piao, C. Sun, W. Hassan, X.H. Zhang, and Y.J. Xie, Electrochemical Corrosion Behavior of Bulk Ultra-Fine Grained Fe–Ni–Cr Alloy, Trans. Nonferrous Metal. Soc. China, 2014, 24, p 1989–1994

A. Di Schino and J. Kenny, Effect of Grain Size on the Corrosion Resistance of a High Nitrogen–Low Nickel Austenitic Stainless Steel, J. Mater. Sci. Lett., 2002, 21, p 1969–1971

S.V. Phadnis, A.K. Satpati, K.P. Muthe, J.C. Vyas, and R.I. Sundaresan, Comparison of Rolled and Heat Treated SS304 in Chloride Solution Using Electrochemical and XPS Techniques, Corros. Sci., 2003, 45, p 2467–2483

D. Nakhaie and M.H. Moayed, Pitting Corrosion of Cold Rolled Solution Treated 17-4PH Stainless Steel, Corros. Sci., 2014, 80, p 290–298

A. Fattah-Alhosseini and S. Vafaeian, Comparison of Electrochemical Behavior Between Coarse Grained and Fine-Grained AISI, 430 Ferritic Stainless Steel by Mott–Schottky Analysis and EIS Measurements, J. Alloy. Compd., 2015, 639, p 301–307

A. Fattah-Alhosseini and S. Vafaeian, Influence of Grain Refinement on the Electrochemical Behavior of AISI, 430 Ferritic Stainless Steel in an Alkaline Solution, Appl. Surf. Sci., 2016, 360, p 921–928

K. Ralston and N. Birbilis, Effect of Grain Size on Corrosion: A Review, Corrosion, 2010, 66, p 75005–75013

L. Liu, Y. Li, and F. Wang, Electrochemical Corrosion Behavior of Nanocrystalline Materials—A Review, J. Mater. Sci. Technol., 2010, 26, p 1–14

A. Fattah-alhosseini, F. Soltani, F. Shirsalimi, B. Ezadi, and N. Attarzadeh, The Semiconducting Properties of Passive Films Formed on AISI, 316 L and AISI, 321 Stainless Steels: A Test of the Point Defect Model (PDM), Corros. Sci., 2011, 53, p 3186–3192

A. Fattah-Alhosseini and S.O. Gashti, Passive Behavior of Ultra-Fine-Grained 1050 Aluminum Alloy Produced by Accumulative Roll Bonding in a Borate Buffer Solution, Acta Metall. Sin. (Engl. Lett.), 2015, 28, p 1222–1229

A. Fattah-alhosseini and S.O. Gashti, Corrosion Behavior of Ultra-Fine Grained 1050 Aluminum Alloy Fabricated by ARB Process in a Buffer Borate Solution, J. Mater. Eng. Perform., 2015, 24, p 3386–3393

A. Fattah-alhosseini and O. Imantalab, Passivation Behavior of Ultrafine-Grained Pure Copper Fabricated by Accumulative Roll Bonding (ARB) Process, Metall. Mater. Trans. A, 2016, 47, p 572–580

O. Imantalab and A. Fattah-alhosseini, Electrochemical and Passive Behaviors of Pure Copper Fabricated by Accumulative Roll-Bonding (ARB) Process, J. Mater. Eng. Perform., 2015, 24, p 2579–2585

A. Fattah-alhosseini and O. Imantalab, Effect of Accumulative Roll Bonding Process on the Electrochemical Behavior of Pure Copper, J. Alloy. Compd., 2015, 632, p 48–52

P. Sahu, M. De, and S. Kajiwara, Microstructural Characterization of Fe–Mn–C Martensites Athermally Transformed at Low Temperature by Rietveld Method, Mater. Sci. Eng. A, 2002, 333, p 10–23

P. Sahu, M. De, and S. Kajiwara, Microstructural Characterization of Stress-Induced Martensites Evolved at Low Temperature in Deformed Powders of Fe–Mn–C Alloys by the Rietveld Method, J. Alloy. Compd., 2002, 346, p 158–169

M. Naseri, A. Hassani, and M. Tajally, Fabrication and Characterization of Hybrid Composite Strips with Homogeneously Dispersed Ceramic Particles by Severe Plastic Deformation, Ceram. Int., 2015, 41, p 3952–3960

M. Naseri, A. Hassani, and M. Tajally, An Alternative Method for Manufacturing Al/B4C/SiC Hybrid Composite Strips by Cross Accumulative Roll Bonding (CARB) Process, Ceram. Int., 2015, 41, p 13461–13469

R. Jamaati, M. Naseri, and M.R. Toroghinejad, Wear Behavior of Nanostructured Al/Al2O3 Composite Fabricated Via Accumulative Roll Bonding (ARB) Process, Mater. Des., 2014, 59, p 540–549

M. Naseri, M. Reihanian, and E. Borhani, A New Strategy to Simultaneous Increase in the Strength and Ductility of AA2024 Alloy Via Accumulative Roll Bonding (ARB), Mater. Sci. Eng. A, 2016, 656, p 12–20

R. Jamaati, M.R. Toroghinejad, and H. Edris, Effect of Stacking Fault Energy on Nanostructure Formation Under Accumulative Roll Bonding (ARB) Process, Mater. Sci. Eng. A, 2013, 578, p 191–196

A. Kauffmann, J. Freudenberger, D. Geissler, S. Yin, W. Schillinger, V. Subramanya Sarma, H. Bahmanpour, R. Scattergood, M.S. Khoshkhoo, H. Wendrock, C.C. Koch, J. Eckert, and L. Schultz, Severe Deformation Twinning in Pure Copper by Cryogenic Wire Drawing, Acta Mater., 2011, 59, p 7816–7823

H. Maleki-Ghaleh, K. Hajizadeh, A. Hadjizadeh, M.S. Shakeri, S. Ghobadi Alamdari, S. Masoudfar, E. Aghaie, M. Javidi, J. Zdunek, and K.J. Kurzydlowski, Electrochemical and Cellular Behavior of Ultrafine-Grained Titanium In Vitro, Mater. Sci. Eng. C. Mater. Biol. Appl., 2014, 39, p 299–304

A. Fattah-alhosseini and S. Vafaeian, Passivation Behavior of a Ferritic Stainless Steel in Concentrated Alkaline Solutions, J. Mater. Res. Technol., 2015, 4, p 423–428

L. Jinlong and L. Hongyun, Effect of Temperature and Chloride Ion Concentration on Corrosion of Passive Films on Nano/Ultrafine Grained Stainless Steels, J. Mater. Eng. Perform., 2014, 23, p 4223–4229

H. Luo, S. Gao, C. Dong, and X. Li, Characterization of Electrochemical and Passive Behaviour of Alloy 59 in Acid Solution, Electrochim. Acta, 2014, 135, p 412–419

L. Hamadou, L. Aïnouche, A. Kadri, S.A.A. Yahia, and N. Benbrahim, Electrochemical Impedance Spectroscopy Study of Thermally Grown Oxides Exhibiting Constant Phase Element Behaviour, Electrochim. Acta, 2013, 113, p 99–108

H. Wu, Y. Wang, Q. Zhong, M. Sheng, H. Du, and Z. Li, The Semi-conductor Property and Corrosion Resistance of Passive Film on Electroplated Ni and Cu–Ni Alloys, J. Electroanal. Chem., 2011, 663, p 59–66

B. Zhang, Y. Li, and F. Wang, Electrochemical Corrosion Behaviour of Microcrystalline Aluminium in Acidic Solutions, Corros. Sci., 2007, 49, p 2071–2082

Q.J. Wang, M.S. Zheng, and J.W. Zhu, Semi-conductive Properties of Passive Films Formed on Copper in Chromate Solutions, Thin Solid Films, 2009, 517, p 1995–1999

C. Escrivà-Cerdán, E. Blasco-Tamarit, D.M. García-García, J. García-Antón, R. Akid, and J. Walton, Effect of Temperature on passive Film Formation of UNS N08031 Cr–Ni Alloy in Phosphoric Acid Contaminated with Different Aggressive Anions, Electrochim. Acta, 2013, 111, p 552–561

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fattah-Alhosseini, A., Naseri, M., Imantalab, O. et al. The Passive Film Characteristics of Cold Deformed Pure Copper. J. of Materi Eng and Perform 25, 4741–4749 (2016). https://doi.org/10.1007/s11665-016-2352-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2352-5