Abstract

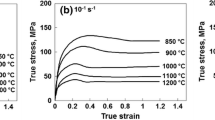

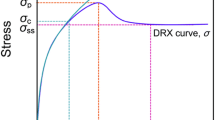

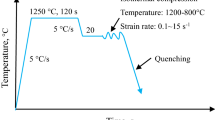

The hot deformation behavior of a medium-carbon bainitic steel was studied in a temperature range of 900–1100 °C and a strain rate range of 0.01–10 s−1. With increasing strain, the flow stress displays three tendencies: a continuous increase under most conditions and a peak stress with and without a steady-state region. Accurate constitutive modeling was proposed and exhibits a correlation coefficient of 0.984 and an average absolute relative error of 0.063 between the experimental and predicted stress values. The activation energy of the steel increased from 393 to 447 kJ/mol, when the strain increased from 0.1 to 0.4, followed by a slight fluctuation at higher strain. Finally, processing maps under different strains were constructed and exhibit a varied instability region with increasing strain. Microstructural observations show that a mischcrystal structure formed in the specimens that worked on the instability regions, which resulted from the occurrence of flow localization. Some deformation twins were also observed in certain specimens and were responsible for negative m-values. The optimum hot working processing parameters for the studied steel were 989–1012 °C, 0.01–0.02 s−1 and 1034–1066 °C, 0.07–0.22 s−1, and a full dynamic recrystallization structure with fine homogeneous grains could be obtained.

Similar content being viewed by others

References

J. Chakraborty, D. Bhattacharjee, and I. Manna, Austempering of bearing steel for improved mechanical properties, Scr. Mater., 2008, 59, p 247–250

E. Choi, T.H. Nam, J.T. Oh, and B.S. Cho, An isolation bearing for highway bridges using shape memory alloys, Mater. Sci. Eng. A, 2006, 438–440, p 1081–1084

F.C. Zhang, Z.N. Yang, and J. Kang, 铁路辙叉用贝氏体钢研究进展 (Research progress of bainitic steel used for railway crossing), J Yanshan Univ., 2013, 37, p 1–7 ((in Chinese))

F.G. Caballero and H.K.D.H. Bhadeshia, Very strong bainite, Curr. Opin. Solid State Mater. Sci., 2004, 8, p 251–257

C.M. Sellars and W.J. McTegart, On the mechanism of hot deformation, Acta Metall., 1966, 14, p 1136–1138

J.Q. Zhang, H.S. Di, X.Y. Wang, Y. Cao, J.C. Zhang, and T.J. Ma, Constitutive analysis of the hot deformation behavior of Fe–23Mn–2Al–0.2C twinning induced plasticity steel in consideration of strain, Mater. Des., 2013, 44, p 354–364

Y.C. Lin, M.S. Chen, and J. Zhong, Prediction of 42CrMo steel flow stress at high temperature and strain rate, Mech. Res. Commun., 2008, 35, p 142–150

A. Momeni and K. Dehghani, Characterization of hot deformation behavior of 410 martensitic stainless steel using constitutive equations and processing maps, Mater. Sci. Eng. A, 2010, 527, p 5467–5473

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of dynamic material behavior in hot deformation: forging of Ti-6242, Metall. Trans. A, 1984, 15, p 1883–1892

Z.N. Yang, F.C. Zhang, C.L. Zheng, M. Zhang, B. Lv, and L. Qu, Study on hot deformation behaviour and processing maps of low carbon bainitic steel, Mater. Des., 2015, 66, p 258–266

G.Z. Quan, L. Zhao, T. Chen, Y. Wang, Y.P. Mao, W.Q. Lv, and J. Zhou, Identification for the optimal working parameters of as-extruded 42CrMo high-strength steel from a large range of strain, strain rate and temperature, Mater. Sci. Eng., A, 2012, 538, p 364–373

X.Y. Long, J. Kang, B. Lv, and F.C. Zhang, Carbide-free bainite in medium carbon steel bainite in low-carbon steel, Mater. Des., 2014, 62, p 237–245

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, Amsterdam, 2004, p 427–441

C.M. Sellars and W.J. McG Tegart, Hot Workability, Int. Metall. Rev., 1972, 17, p 1–24

S. Gangolu, A.G. Rao, N. Prabhu, V.P. Deshmukh, and B.P. Kashyap, Hot workability and flow characteristics of Aluminum-5 wt.% B4C composite, J. Mater. Eng. Perform., 2014, 23, p 1366–1373

N. Radovi and D. Drobnjak, Effect of interpass time and cooling rate on apparent activation energy for hot working and critical recrystallization temperature of Nb-microalloyed steel, ISIJ Int., 1999, 39, p 575–582

Y.B. Tan, L.H. Yang, C. Tian, W.C. Liu, R.P. Liu, and X.Y. Zhang, Processing maps for hot working of 47Zr-45Ti-5Al-3 V alloy, Mater. Sci. Eng., A, 2014, 597, p 171–177

J. Cai, F.G. Li, T.Y. Liu, B. Chen, and M. He, Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain, Mater. Des., 2011, 32, p 1144–1151

T. Yan, E.L. Yu, and Y.Q. Zhao, Constitutive modeling for flow stress of 55SiMnMo bainite steel at hot working conditions, Mater. Des., 2013, 50, p 574–580

J.M. Cabrera, A. Al Omar, J.M. Prado, and J.J. Jonas, Modeling the flow behavior of a medium carbon microalloyed steel under hot working conditions, Metall. Mater. Trans. A, 1997, 28, p 233–244

R.W. Lund and W.D. Nix, On high creep activation energies for dispersion strengthened metals, Metall. Trans. A, 1975, 6, p 1329–1333

M. Malu and J.K. Tien, The elastic modulus correction term in creep activation energies: applied to oxide dispersion strengthened superalloy, Scr. Metall., 1975, 9, p 1117–1120

H.J. McQueen and N.D. Ryan, Constitutive analysis in hot working, Mater. Sci. Eng., A, 2002, 322, p 43–63

H. Mirzadeh, J.M. Cabrera, J.M. Prado, and A. Najafizadeh, Hot deformation behavior of a medium carbon microalloyed steel, Mater. Sci. Eng., A, 2011, 528, p 3876–3882

L.X. Li, L. Tang, J.L. Zhou, and L.Y. Wang, 碳含量及晶粒尺寸对微合金钢激活能的影响 (Influence of carbon content and grain size on activation energy of microalloy steel), Special Steel, 2003, 24, p 24–26 ((in Chinese))

S.V.S. Narayana Murty and B. Nageswara Rao, Ziegler’s criterion on the instability regions in processing maps, J. Mater. Sci. Lett., 1998, 17, p 1203–1205

H. Ziegler, Progress in solid mechanics, Wiley, New York, 1963, p 63–193

J. Luo, L. Li, and M.Q. Li, The flow behavior and processing maps during the isothermal compression of Ti17 alloy, Mater. Sci. Eng. A, 2014, 606, p 165–174

C. Wang, Y.B. Xu, and E.H. Han, Serrated flow and abnormal strain rate sensitivity of a magnesium–lithium alloy, Mater. Lett., 2006, 60, p 2941–2944

F. Kabirian, A.S. Khana, and A. Pandey, Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: experiment and constitutive modelling, Int. J. Plast, 2014, 55, p 232–246

Y.V.R.K. Prasad, Processing maps: a status report, J. Mater. Eng. Perform., 2003, 12, p 638–645

Y.B. Chun and C.H. Davies, Twinning-induced negative strain rate sensitivity in wrought Mg alloy AZ31, Mater. Sci. Eng., A, 2011, 528, p 5713–5722

E.X. Pu, W.J. Zheng, J.Z. Xiang, Z.G. Song, and J. Li, Hot deformation characteristic and processing map of superaustenitic stainless steel S32654, Mater. Sci. Eng., A, 2014, 598, p 174–182

Y. Wang, Q.L. Pan, Y.F. Song, C. Li, and Z.F. Li, Hot deformation and processing maps of X-750 nickel-based superalloy, Mater. Des., 2013, 51, p 154–160

Acknowledgments

The authors would like to thank the funding support to this work from the National High Technology Research and Development Program of China (863 Program) (No. 2012AA03A504), the National Natural Science Foundation of China (No. 51471146), and the Open Project Program of National Engineering Research Center for Equipment and Technology of Cold Strip Rolling (NECSR-201304).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Z., Li, Y., Li, Y. et al. Constitutive Modeling for Flow Behavior of Medium-Carbon Bainitic Steel and Its Processing Maps. J. of Materi Eng and Perform 25, 5030–5039 (2016). https://doi.org/10.1007/s11665-016-2301-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2301-3