Abstract

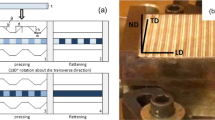

Severe plastic deformation (SPD) is routinely employed to modify microstructure to obtain improved mechanical properties, particularly strength. Constrained groove pressing (CGP) is one of the SPD techniques that has gained prominence recently. However, the efficacy of the method in terms of homogeneity of microstructure and properties has not been well explored. In this work, we examine the microstructure and mechanical properties of CGP processed Cu-Zn alloy sheet and also explore homogeneity in their characteristics. We found that CGP is very effective in improving the mechanical properties of the alloy. Although the reduction in grain size with the number of passes in CGP is not as huge (~38 µm in annealed sample to ~10.2 µm in 1 pass sample) as is expected from a SPD technique, but there is a drastic improvement in ultimate tensile strength (~230 to ~380 MPa) which shows the effectiveness of this process. However, when mechanical properties were examined at smaller length scale using micro-indentation technique, it was found that hardness values of CGP processed samples were non-uniform along transverse direction with a distinct sinusoidal variation. Uniaxial tensile test data also showed strong anisotropy along principal directions. The cause of this anisotropy and non-uniformity in mechanical properties was found to lie in microstructural inhomogeneity which was found to exist at the length scale of the grooves of the die.

Similar content being viewed by others

References

D.H. Shin, J.-J. Park, Y.-S. Kim, and K.-T. Park, Constrained Groove Pressing and Its Application to Grain Refinement of Aluminum, Mater. Sci. Eng. A, 2002, 328(1–2), p 98–103

F. Khodabakhshi and M. Kazeminezhad, The Effect of Constrained Groove Pressing on Grain Size, Dislocation Density and Electrical Resistivity of Low Carbon Steel, Mater. Des., 2011, 32(6), p 3280–3286

M. Shaarbaf and M.R. Toroghinejad, Nano-grained Copper Strip Produced by Accumulative Roll Bonding Process, Mater. Sci. Eng. A, 2008, 473(1–2), p 28–33

S.A. Hosseini and H.D. Manesh, High-Strength, High-Conductivity Ultra-Fine Grains Commercial Pure Copper Produced by ARB Process, Mater. Des., 2009, 30(8), p 2911–2918

X. Molodova, G. Gottstein, M. Winning, and R.J. Hellmig, Thermal Stability of ECAP Processed Pure Copper, Mater. Sci. Eng. A, 2007, 460–461, p 204–213

F. Al-Mufadi and F. Djavanroodi, Effect of Equal Channel Angular Pressing Process on Impact Property of Pure Copper, Int. J. Chem. Nucl. Mater. Metall. Eng., 2014, 8(1), p 30–34

Z. Horita and T.G. Langdon, Achieving Exceptional Superplasticity in a Bulk Aluminum Alloy Processed by High-Pressure Torsion, Scr. Mater., 2008, 58(11), p 1029–1032

G. Khatibi, J. Horky, B. Weiss, and M.J. Zehetbauer, High Cycle Fatigue Behaviour of Copper Deformed by High Pressure Torsion, Int. J. Fatigue, 2010, 32(2), p 269–278

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51(7), p 881–981

A. Babaei and M.M. Mashhadi, Tubular Pure Copper Grain Refining by Tube Cyclic Extrusion-Compression (TCEC) as a Severe Plastic Deformation Technique, Prog. Nat. Sci. Mater. Int., 2014, 24(6), p 623–630

Y. Beygelzimer, V. Varyukhin, S. Synkov, and D. Orlov, Useful Properties of Twist Extrusion, Mater. Sci. Eng. A, 2009, 503(1–2), p 14–17

M.I. Latypov, E.Y. Yoon, D.J. Lee, R. Kulagin, Y. Beygelzimer, and M. Seyed, Salehi, and H. S. Kim, Microstructure and Mechanical Properties of Copper Processed by Twist Extrusion with a Reduced Twist-Line Slope, Metall. Mater. Trans. A, 2014, 45(4), p 2232–2241

A. Krishnaiah, U. Chakkingal, and P. Venugopal, Applicability of the Groove Pressing Technique for Grain Refinement in Commercial Purity Copper, Mater. Sci. Eng. A, 2005, 410–411, p 337–340

G.G. Niranjan and U. Chakkingal, Deep Drawability of Commercial Purity Aluminum Sheets Processed by Groove Pressing, J. Mater. Process. Technol., 2010, 210(11), p 1511–1516

K. Edalati, T. Fujioka, and Z. Horita, Microstructure and Mechanical Properties of Pure Cu Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2008, 497(1–2), p 168–173

J. Wongsa-Ngam, M. Kawasaki, Y. Zhao, and T.G. Langdon, Microstructural Evolution and Mechanical Properties of a Cu–Zr alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2011, 528(25–26), p 7715–7722

S. Li, M.A.M. Bourke, I.J. Beyerlein, D.J. Alexander, and B. Clausen, Finite Element Analysis of the Plastic Deformation Zone and Working Load in Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2004, 382(1–2), p 217–236

V. Patil Basavaraj, U. Chakkingal, and T.S. Prasanna Kumar, Study of Channel Angle Influence on Material Flow and Strain Inhomogeneity in Equal Channel Angular Pressing Using 3D Finite Element Simulation, J. Mater. Process. Technol., 2009, 209(1), p 89–95

W. Wei, A.V. Nagasekhar, G. Chen, Y. Tick-Hon, and K.X. Wei, Origin of Inhomogenous Behavior During Equal Channel Angular Pressing, Scr. Mater., 2006, 54(11), p 1865–1869

G. Purcek, B.S. Altan, I. Miskioglu, and P.H. Ooi, Processing of Eutectic Zn-5% Al Alloy by Equal-Channel Angular Pressing, J. Mater. Process. Technol., 2004, 148(3), p 279–287

C.F. Zhu, F.P. Du, Q.Y. Jiao, X.M. Wang, A.Y. Chen, F. Liu, and D. Pan, Microstructure and Strength of Pure Cu with Large Grains Processed by Equal Channel Angular Pressing, Mater. Des., 2013, 52, p 23–29

Z.S. Wang, Y.J. Guan, L.B. Song, and P. Liang, Finite Element Analysis and Deformation Homogeneity Optimization of Constrained Groove Pressing. Applied Mechanics and Materials, Trans Tech Publications, Dürnten, 2013, p 505–513

K.S. Fong, D. Atsushi, T.M. Jen, and B.W. Chua, Effect of Deformation and Temperature Paths in Severe Plastic Deformation Using Groove Pressing on Microstructure, Texture, and Mechanical Properties of AZ31-O, J. Manuf. Sci. Eng., 2015, 137(5), p 051004

A. Shirdel, A. Khajeh, and M.M. Moshksar, Experimental and Finite Element Investigation of Semi-constrained Groove Pressing Process, Mater. Des., 2010, 31(2), p 946–950

A. Sajadi, M. Ebrahimi, and F. Djavanroodi, Experimental and Numerical Investigation of Al Properties Fabricated by CGP Process, Mater. Sci. Eng. A, 2012, 552, p 97–103

Z.-S. Wang, Y.-J. Guan, G.-C. Wang, and C.-K. Zhong, Influences of Die Structure on Constrained Groove Pressing of Commercially Pure Ni Sheets, J. Mater. Process. Technol., 2015, 215, p 205–218

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Constrained Groove Pressing of Low Carbon Steel: Nano-structure and Mechanical Properties, Mater. Sci. Eng. A, 2010, 527(16–17), p 4043–4049

F. Khodabakhshi, M. Abbaszadeh, H. Eskandari, and S.R. Mohebpour, Application of CGP-Cross Route Process for Microstructure Refinement and Mechanical Properties Improvement in Steel Sheets, J. Manuf. Process., 2013, 15(4), p 533–541

M.S. Ghazani and A. Vajd, Finite Element Analysis of the Groove Pressing of Aluminum Alloy, Model. Simul. Mater. Sci. Eng., 2014, 4(1), p 32–36

K. Peng, L. Su, L.L. Shaw, and K.W. Qian, Grain Refinement and Crack Prevention in Constrained Groove Pressing of Two-Phase Cu-Zn Alloys, Scr. Mater., 2007, 56(11), p 987–990

K. Peng, Y. Zhang, L.L. Shaw, and K.W. Qian, Microstructure Dependence of a Cu-38Zn Alloy on Processing Conditions of Constrained Groove Pressing, Acta Mater., 2009, 57(18), p 5543–5553

K. Peng, X. Mou, J. Zeng, L.L. Shaw, and K.W. Qian, Equivalent Strain, Microstructure and Hardness of H62 Brass Deformed by Constrained Groove Pressing, Comput. Mater. Sci., 2011, 50(4), p 1526–1532

X. Mou, K. Peng, J. Zeng, L.L. Shaw, and K.W. Qian, The Influence of the Equivalent Strain on the Microstructure and Hardness of H62 Brass Subjected to Multi-cycle Constrained Groove Pressing, J. Mater. Process. Technol., 2011, 211(4), p 590–596

J.W. Lee and J.J. Park, Numerical and Experimental Investigations of Constrained Groove Pressing and Rolling for Grain Refinement, J. Mater. Process. Technol., 2002, 130–131, p 208–213

F. Khakbaz and M. Kazeminezhad, Work Hardening and Mechanical Properties of Severely Deformed AA3003 by Constrained Groove Pressing, J. Manuf. Process., 2012, 14(1), p 20–25

F. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Pergamon Press, Oxford, 1995

M. Richert, Q. Liu, and N. Hansen, Microstructural Evolution Over a Large Strain Range in Aluminium Deformed by Cyclic-Extrusion-Compression, Mater. Sci. Eng. A, 1999, 260(1–2), p 275–283

B. Hadzima, M. Janeček, Y. Estrin, and H.S. Kim, Microstructure and Corrosion Properties of Ultrafine-Grained Interstitial Free Steel, Mater. Sci. Eng. A, 2007, 462(1–2), p 243–247

B. Tolaminejad and K. Dehghani, Microstructural Characterization and Mechanical Properties of Nanostructured AA1070 Aluminum After Equal Channel Angular Extrusion, Mater. Des., 2012, 34, p 285–292

A. Mishra, B.K. Kad, F. Gregori, and M.A. Meyers, Microstructural Evolution in Copper Subjected to Severe Plastic Deformation: Experiments and Analysis, Acta Mater., 2007, 55(1), p 13–28

A. Yamashita, Z. Horita, and T.G. Langdon, Improving the Mechanical Properties of Magnesium and a Magnesium Alloy Through Severe Plastic Deformation, Mater. Sci. Eng. A, 2001, 300(1–2), p 142–147

A. Krishnaiah, U. Chakkingal, and P. Venugopal, Production of Ultrafine Grain Sizes in Aluminium Sheets by Severe Plastic Deformation Using the Technique of Groove Pressing, Scr. Mater., 2005, 52(12), p 1229–1233

N.D. Stepanov, A.V. Kuznetsov, G.A. Salishchev, G.I. Raab, and R.Z. Valiev, Effect of Cold Rolling on Microstructure and Mechanical Properties of Copper Subjected to ECAP with Various Numbers of Passes, Mater. Sci. Eng. A, 2012, 554, p 105–115

M. Ebrahimi and F. Djavanroodi, Experimental and Numerical Analyses of Pure Copper During ECFE Process as a Novel Severe Plastic Deformation Method, Prog. Nat. Sci. Mater. Int., 2014, 24(1), p 68–74

V.Y. Gertsman and S.M. Bruemmer, Study of Grain Boundary Character Along Intergranular Stress Corrosion Crack Paths in Austenitic Alloys, Acta Mater., 2001, 49(9), p 1589–1598

M. Qian and J.C. Lippold, The Effect of Annealing Twin-Generated Special Grain Boundaries on HAZ Liquation Cracking of Nickel-Base Superalloys, Acta Mater., 2003, 51(12), p 3351–3361

A. Vaid, K. Mittal, S. Sahu, and S. Shekhar, Controlled Evolution of Coincidence Site Lattice Related Grain Boundaries, Trans. Indian Inst. Met., 2016. doi:10.1007/s12666-016-0834-7

J. Lubahn and G. Sachs, Bending of an Ideal Plastic Metal, Trans. ASME, 1950, 72, p 201–208

B.W. Shaffer and E.E. Ungar, Mechanics of the Sheet-Bending Process, J. Appl. Mech., 1960, 27(1), p 34–40

Acknowledgments

The authors acknowledge the funding support received from Quality Improvement Program (TEQIP) at Indian Institute of Technology (IIT) Kanpur, which ensured the completion of this work. We also acknowledge support from Electron Microscopy Facility and Mechanical Testing Facility of Advanced Center of Materials Science (ACMS) at IIT Kanpur for conducting various tests and characterization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, P.C., Sinhal, A., Sahu, S. et al. Microstructural Inhomogeneity in Constrained Groove Pressed Cu-Zn Alloy Sheet. J. of Materi Eng and Perform 25, 2604–2614 (2016). https://doi.org/10.1007/s11665-016-2142-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2142-0