Abstract

Recent interest has emerged in techniques that modify the surfaces of carbon fibers, such as carbon nanotube (CNT) grafting or polymer coating. Hybridization of these surface modifications has the potential to generate highly tunable, high-performance materials. In this study, the mechanical properties of surface-modified polyacrylonitrile (PAN)-based and pitch-based carbon fibers were investigated. Single-filament tensile tests were performed for fibers modified by CNT grafting, dipped polyimide coating, high-temperature vapor deposition polymerized polyimide coating, grafting-dipping hybridization, and grafting-vapor deposition hybridization. The Weibull statistical distributions of the tensile strengths of the surface-modified PAN- and pitch-based carbon fibers were examined. All surface modifications, especially hybrid modifications, improved the tensile strengths and Weibull moduli of the carbon fibers. The results exhibited a linear relationship between the Weibull modulus and average tensile strength on a log-log scale for all surface-modified PAN- and pitch-based carbon fibers.

Similar content being viewed by others

Notes

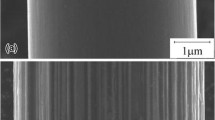

Several growth temperatures and times were examined for CNT deposition (e.g., 650, 700, 750, and 800 °C and 120, 300, 600, 900, 1200, and 1800 s). SEM micrographs showed that the quality of CNT deposition was similar for PAN- and pitch-based carbon fibers at the above growth conditions. Differences due to temperature were attributed to the differing thermal conductivities and surface morphologies of PAN- and pitch-based carbon fibers.

Similar results are also shown in Fig. 4(e).

This result is shown in Fig. 5(c).

Several data points for the as-received carbon fibers did not fall on the line (T1000GB in Fig. 7(a)) when the gage length was >100 mm because the Weibull modulus stabilized at a larger value of the gage length than that at which the average tensile strength stabilized. The results clearly show that when the gage length was <100 mm, the Weibull moduli and the average tensile strengths of both the PAN- and pitch-based carbon fibers increased with decreasing gage length, and linear relationships were observed between the Weibull moduli and the average tensile strengths of the as-received and CNT-grafted carbon fibers on a log-log scale.

References

S. Chand, Review-Carbon Fibers for Composites, J. Mater. Sci., 2000, 35(6), p 1303–1313

K. Naito, Y. Tanaka, J.M. Yang, and Y. Kagawa, Tensile Properties of Ultrahigh Strength PAN-Based, Ultrahigh Modulus Pitch-Based and High Ductility Pitch-Based Carbon Fibers, Carbon, 2008, 46(2), p 189–195

K. Naito, Y. Tanaka, J.M. Yang, and Y. Kagawa, Flexural Properties of PAN- and Pitch-Based Carbon Fibers, J. Am. Ceram. Soc., 2009, 92(1), p 186–192

T.D. Juska and P.M. Puckett, Matrix Resins and Fiber/Matrix Adhesion, Composites Engineering Handbook, P.K. Mallick, Ed., New York, Dekker, 1997, p 101–165

W.B. Downs and R.T.K. Baker, Novel Carbon Fiber-Carbon Filament Structures, Carbon, 1991, 29(8), p 1173–1179

S. Zhu, C.H. Su, S.L. Lehoczky, I. Muntele, and D. Ila, Carbon Nanotube Growth on Carbon Fibers, Diam. Relat. Mater., 2003, 12(10–11), p 1825–1828

J.O. Zhao, L. Liu, Q.G. Guo, J.L. Shi, G.T. Zhai, J.R. Song, and Z.J. Liu, Growth of Carbon Nanotubes on the Surface of Carbon Fibers, Carbon, 2008, 46(2), p 380–383

K. Naito, J.M. Yang, Y. Tanaka, and Y. Kagawa, Tensile Properties of Carbon Nanotubes Grown on Ultrahigh Strength Polyacrylonitrile-Based and Ultrahigh Modulus Pitch-Based Carbon Fibers, Appl. Phys. Lett., 2008, 92(23), p 231912-1-3

K. Naito, J.M. Yang, Y. Xu, and Y. Kagawa, Enhancing the Thermal Conductivity of Polyacrylonitrile- and Pitch-Based Carbon Fibers by Grafting Carbon Nanotubes on Them, Carbon, 2010, 48(6), p 1849–1857

J.K. Kim and Y.W. Mai, Effects of Interfacial Coating and Temperature on the Fracture Behaviors of Unidirectional Kevlar and Carbon-Fiber Reinforced Epoxy-Resin Composites, J. Mater. Sci., 1991, 26(17), p 4702–4720

P.C. Varelidis, R.L. McCullough, and C.D. Papaspyrides, The Effect on the Mechanical Properties of Carbon/Epoxy Composites of Polyamide Coatings on the Fibers, Compos. Sci. Technol., 1999, 59(12), p 1813–1823

S. Dujardin, R. Lazzaroni, L. Rigo, J. Riga, and J.J. Verbist, Electrochemically Polymer-Coated Carbon-Fibers—Characterization and Potential for Composite Applications, J. Mater. Sci., 1986, 21(12), p 4342–4346

B. Zinger, S. Shkolnik, and H. Höcke, Electrocoating of Carbon-Fibers with Polyaniline and Poly(hydroxyalkyl methacrylates), Polymer, 1989, 30(4), p 628–635

L.T. Drzal, Adhesion of Graphite Fibers to Epoxy Matrices 2. The Effect of Fiber Finish, J. Adhes., 1983, 16(2), p 133–152

R.J. Dauksys, Graphite Fiber Treatments Which Affect Fiber Surface Morphology and Epoxy Bonding Characteristics, J. Adhes., 1973, 5(3), p 211–244

T. Naganuma, K. Naito, and J.M. Yang, High-Temperature Vapor Deposition Polymerization Polyimide Coating for Elimination of Surface Nano-Flaws in High-Strength Carbon Fiber, Carbon, 2011, 49(12), p 3881–3890

K. Naito, The Effect of High-Temperature Vapor Deposition Polymerization of Polyimide Coating on Tensile Properties of Polyacrylonitrile- and Pitch-Based Carbon Fibers, J. Mater. Sci., 2013, 48(17), p 6056–6064

A.R. Bunsell and B. Harris, Hybrid Carbon and Glass Fibre Composites, Composites, 1974, 5(4), p 157–164

K.M. Hardaker and M.O.W. Richardson, Trends in Hybrid Composite Technology, Polym.-Plast. Technol., 1980, 15(2), p 169–182

K. Naito, J.M. Yang, and Y. Kagawa, Tensile Properties of High Strength Polyacrylonitrile (PAN)-Based and High Modulus Pitch-Based Hybrid Carbon Fibers-Reinforced Epoxy Matrix Composite, J. Mater. Sci., 2012, 47(6), p 2743–2751

K. Naito, Tensile Properties of Polyacrylonitrile- and Pitch-Based Hybrid Carbon Fiber/Polyimide Composites with Some Nanoparticles in the Matrix, J. Mater. Sci., 2013, 48(12), p 4163–4176

T. Naganuma, K. Naito, J.M. Yang, J. Kyono, D. Sasakura, and Y. Kagawa, The Effect of a Compliant Polyimide Nanocoating on the Tensile Properties of a High Strength PAN-Based Carbon Fiber, Compos. Sci. Technol., 2009, 69(7–8), p 1319–1322

A. Kubono, H. Higuchi, S. Umemoto, and N. Okui, Direct Formation of Polyimide Thin Films by Vapor Deposition Polymerization, Thin Solid Films, 1993, 232(2), p 256–260

H. Hatori, Y. Yamada, M. Shiraishi, and Y. Takahashi, Carbonization and Graphitization of Polyimide Coating on Carbon-Fiber, Carbon, 1991, 29(4–5), p 679–680

American Society for Testing and Materials, Standard Test Method for Tensile Strength and Young’s Modulus of Fibers, in ASTM C1557-03, ASTM Annual Book of Standards, Vol. 15.01. 2013, American Society for Testing and Materials, West Conshohocken, PA, 2013

M.G. Sung, K. Sassa, T. Tagawa, T. Miyata, H. Ogawa, M. Doyama, S. Yamada, and S. Asai, Application of a High Magnetic Field in the Carbonization Process to Increase the Strength of Carbon Fibers, Carbon, 2002, 40(11), p 2013–2020

W. Weibull, A Statistical Distribution Function of Wide Applicability, J. Appl. Mech., 1951, 18, p 293–297

W. Johnson, The Structure of PAN Based Carbon Fibres and Relationship to Physical Properties, Strong Fibers, W. Watt and B.V. Perov, Eds., vol 1, Amsterdam, Elsevier, 1985, p 389–443

K. Naito, J.M. Yang, Y. Tanaka, and Y. Kagawa, The Effect of Gauge Length on Tensile Strength and Weibull Modulus of Polyacrylonitrile (PAN)- and Pitch-Based Carbon Fibers, J. Mater. Sci., 2012, 47(2), p 632–642

K. Naito, J.M. Yang, Y. Inoue, and H. Fukuda, The Effect of Surface Modification with Carbon Nanotubes Upon the Tensile Strength and Weibull Modulus of Carbon Fibers, J. Mater. Sci., 2012, 47(23), p 8044–8051

Acknowledgment

This work was supported by JSPS (Japan Society for the Promotion of Science) KAKENHI 26420715 and JST (Japan Science and Technology Agency) through Advanced Low Carbon Technology Research and Development Program (ALCA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naito, K. Effect of Hybrid Surface Modifications on Tensile Properties of Polyacrylonitrile- and Pitch-Based Carbon Fibers. J. of Materi Eng and Perform 25, 2074–2083 (2016). https://doi.org/10.1007/s11665-016-2028-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2028-1