Abstract

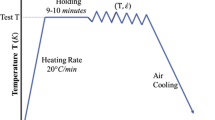

The present study comprises the determination of constitutive relationship for thermo-mechanical processing of INCONEL 718 through double multivariate nonlinear regression, a newly developed approach which not only considers the effect of strain, strain rate, and temperature on flow stress but also explains the interaction effect of these thermo-mechanical parameters on flow behavior of the alloy. Hot isothermal compression experiments were performed on Gleeble-3500 thermo-mechanical testing machine in the temperature range of 1153 to 1333 K within the strain rate range of 0.001 to 10 s−1. The deformation behavior of INCONEL 718 is analyzed and summarized by establishing the high temperature deformation constitutive equation. The calculated correlation coefficient (R) and average absolute relative error (AARE) underline the precision of proposed constitutive model.

Similar content being viewed by others

References

S.-H. Zhang, H.-Y. Zhang, and M. Cheng, Tensile Deformation and Fracture Characteristics of Delta-Processed Inconel 718 Alloy at Elevated Temperature, Mater. Sci. Eng. A, 2011, 528(19), p 6253–6258

Y. Lin, M.-S. Chen, and J. Zhong, Study of Metadynamic Recrystallization Behaviors in a Low Alloy Steel, J. Mater. Process. Technol., 2009, 209(5), p 2477–2482

Y. Lin, M.-S. Chen, and J. Zhong, Effects of Deformation Temperatures on Stress/Strain Distribution and Microstructural Evolution of Deformed 42CrMo Steel, Mater. Des., 2009, 30(3), p 908–913

Y. Lin and M.-S. Chen, Study of Microstructural Evolution During Static Recrystallization in a Low Alloy Steel, J Mater Sci, 2009, 44(3), p 835–842

T. Seshacharyulu et al., Hot Working of Commercial Ti–6Al–4V with an Equiaxed α–β Microstructure: Materials Modeling Considerations, Mater. Sci. Eng. A, 2000, 284(1), p 184–194

H. McQueen, Development of Dynamic Recrystallization Theory, Mater. Sci. Eng. A, 2004, 387, p 203–208

K. Ohwue, T. Yoshida, and M. Usuda, Influence of Material Properties and Work Process Factors in Sheet Metal Forming, Proceedings of the 4th International Conference on Numerical Methods in Industrial Forming Processes-Numisheet, 1992

R. Wagoner, Y. Kim, and Y. Keum, 3-D Sheet Forming Analysis Including the Effects of Strain Hardening, Rate Sensitivity, Anisotropy, Friction, Heat Generation, and Transfer. Advanced Technology of Plasticity, Jpn Soc Technol Plast, 1990, 4, p 1751–1756

G.R. Johnson, and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, Proceedings of the 7th International Symposium on Ballistics, 1983, The Netherlands.

F.J. Zerilli and R.W. Armstrong, Dislocation-Mechanics-Based Constitutive Relations for Material Dynamics Calculations, J. Appl. Phys., 1987, 61(5), p 1816–1825

D. Samantaray, S. Mandal, and A. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr–1Mo Steel, Comput. Mater. Sci., 2009, 47(2), p 568–576

S.-T. Chiou, W.-C. Cheng, and W.-S. Lee, Strain Rate Effects on the Mechanical Properties of a Fe–Mn–Al Alloy Under Dynamic Impact Deformations, Mater. Sci. Eng. A, 2005, 392(1), p 156–162

W.-S. Lee and C.-Y. Liu, Comparison of Dynamic Compressive Flow Behavior of Mild and Medium Steels over Wide Temperature Range, Metall Mater Trans A, 2005, 36(11), p 3175–3186

W.-S. Lee and C.-Y. Liu, The Effects of Temperature and Strain Rate on the Dynamic Flow Behaviour of Different Steels, Mater. Sci. Eng. A, 2006, 426(1), p 101–113

G.R. Johnson and T.J. Holmquist, Evaluation of Cylinder-Impact Test Data for Constitutive Model Constants, J. Appl. Phys., 1988, 64(8), p 3901–3910

G.Z. Voyiadjis and F.H. Abed, Microstructural Based Models for bcc and fcc Metals with Temperature and Strain Rate Dependency, Mech. Mater., 2005, 37(2), p 355–378

S. Dey et al., On the Influence of Constitutive Relation in Projectile Impact of Steel Plates, Int. J. Impact Eng, 2007, 34(3), p 464–486

A. Lennon and K. Ramesh, The Influence of Crystal Structure on the Dynamic Behavior of Materials at High Temperatures, Int. J. Plast, 2004, 20(2), p 269–290

O. Sabokpa et al., Artificial Neural Network Modeling to Predict the High Temperature Flow Behavior of an AZ81 Magnesium Alloy, Mater. Des., 2012, 39, p 390–396

D. Samantaray et al., Analysis and Mathematical Modelling of Elevated Temperature Flow Behaviour of Austenitic Stainless Steels, Mater. Sci. Eng. A, 2011, 528(4), p 1937–1943

M. Xiao et al., Constitutive Equation for Elevated Temperature Flow Behavior of TiNiNb Alloy Based on Orthogonal Analysis, Mater. Des., 2012, 35, p 184–193

Y. Yang et al., A Modified Constitutive Equation for Aluminum Alloy Reinforced by Silicon Carbide Particles at Elevated Temperature, J. Mater. Eng. Perform., 2013, 22(9), p 2641–2655

Z. Yuan et al., A Modified Constitutive Equation for Elevated Temperature Flow Behavior of Ti–6Al–4V Alloy Based on Double Multiple Nonlinear Regression, Mater. Sci. Eng. A, 2013, 578, p 260–270

B. Zhang, D.J. Mynors, A. Mugarra, and K. Ostolaza, Representing the Super Plasticity of Inconel 718, J. Mater. Process. Technol., 2004, 153–154, p 694–698

H.Y. Zhang, S.H. Zhang, Z.X. Li, and M. Cheng, Hot Die Forging Process Optimization of Superalloy IN718 Turbine Disc Using Processing Map and Finite Element Method, J. Eng. Manuf., 2010, 224, p 103–110

Y. Wang, W.Z. Shao, L. Zhen, L. Yang, and X.M. Zhang, Flow Behavior and Microstructures of Superalloy 718 During High Temperature Deformation, Mater. Sci. Eng. A, 2008, 497, p 479–486

A. Nowotnik, Effect of High Temperature Deformation on the Structure of Ni Based Superalloy, J. Achiev Mater Manuf Eng, 2008, 27(2), p 115–122

E.C. Aifantis, The Physics of Plastic Deformation, Int. J. Plast, 1987, 3(3), p 211–247

S. Bodner and Y. Partom, Constitutive Equations for Elastic-Viscoplastic Strain-Hardening Materials, J. Appl. Mech., 1975, 42(2), p 385–389

Perzyna, P., The Constitutive Equations for Rate Sensitive Plastic Materials, 1962, DTIC Document.

C. Sellars and W.M. Tegart, Hot Workability, Int. Metall. Rev., 1972, 17(1), p 1–24

A. Nowotnik, High Temperature Deformation of Superalloy Inconel 718, Solid State Phenom., 2012, 186, p 147–150

M. Tresa, Pollock and Sammy Tin, and Properties, J. Propul. Power, 2006, 22(2), p 361–374

A. Bunsch, J. Kowalska, and M. Witkowska, Influence of Die Forging Parameters on the Microstructure and Phase Composition of INCONEL 718, Arch. Metall. Mater., 2012, 57(4), p 929–935

Acknowledgment

The authors are very grateful for the support received from National Natural Science Foundation of China (No. 51275414), Aeronautical Science Foundation of China under Grant No. 2011ZE53059, and Graduate Starting Seed Fund of Northwestern Polytechnical University (Grant No. Z2014007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hussain, M.Z., Li, F., Wang, J. et al. Determination of Constitutive Equation for Thermo-mechanical Processing of INCONEL 718 Through Double Multivariate Nonlinear Regression Analysis. J. of Materi Eng and Perform 24, 2744–2756 (2015). https://doi.org/10.1007/s11665-015-1542-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1542-x